Gebr. Bräm AG

Contacts

Martin Bräm

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (4)

Technologies

Cutting dies / deep drawing dies

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / Cutting tools | - | 10 - 200 | 10 - 200 | 10 - 200 | - | max. 5 | - |

Follow-on composite tools | - | 10 - 200 | 10 - 200 | 10 - 200 | - | max. 5 | - |

Fineblanking tools | - | 10 - 200 | 10 - 200 | 10 - 200 | - | max. 5 | - |

Deep-drawing dies | - | 10 - 200 | 10 - 200 | 10 - 200 | - | max. 5 | - |

Die replacement / wearing part manufacturing | - | - | - | - | - | - | - |

Impact extrusion dies | - | 10 - 200 | 10 - 200 | 10 - 200 | - | max. 5 | - |

Embossing / swage dies | - | 10 - 200 | 10 - 200 | 10 - 200 | - | max. 5 | - |

Rod extrusion dies | - | 10 - 200 | 10 - 200 | 10 - 200 | - | max. 5 | - |

Company description

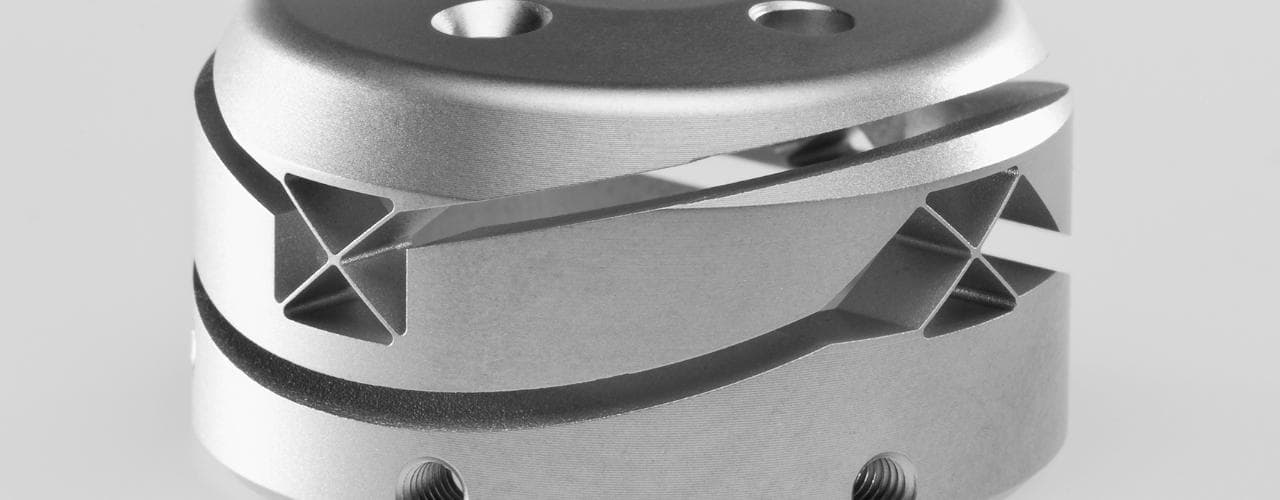

Core competences «We cannot be the best in every aspect. Therefore, we have positioned ourselves at the top where our core competences lie.» Electrical Discharge Machining (EDM): In 1969, we bought our first electrical discharge machine, which has been the foundation for our most important core capability. EDM very soon proved to be one of the promising new key technologies in metalworking. We have continually expanded our experience in die sinking and wire EDM and, these days, count ourselves amongst the leading contract manufacturers for precise metal machining. It is not the ten machines that we productively utilise every day that are getting us further, but the very high standards of our customers for surface quality and precision forming. The advantages of EDM are: no mechanical stress to the metal piece, no limitations through hard metal grade or shape, high degree of machine autonomy, greater design possibilities at engineering level. Only an EDM-compatible design will profit from all EDM benefits – a piece of advice our customers will gladly follow. Tungsten carbide working: «It is the combination of knowledge of materials and knowledge of methods that form a basis for the skilled working of hard metal.» We have managed to form a solid base to work tungsten carbide parts efficiently by liaising intensively with the outstanding tungsten carbide manufacturer Metzger Ltd, Lotzwil/Switzerland, and by meeting the very high standards of our customers. We support our customers when it comes to choosing the right hard metal and the most suitable methods such as grinding and abrasion, polishing and extrude-honing and also provide the handling during and after the production process. Only perfectly manufactured hard metal parts will convince the customer to pay a higher unit price. Laser Machining: As with EDM, we decided early (1986) to go with this new key technology. We have been using the Nd:YAG pulsed laser (LASAG) for laser welding, cutting, drilling, marking and laser cladding. The high power pulse and high beam quality melt or vaporise nearly all known materials. Lasering is used to produce microstructures and to connect highly challenging geometrical shapes by conduction welding. The same rules apply as for EDM: only a laser-compatible design will be able to take advantage of all the benefits laser technology has to offer.

Machines (32)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Carbide

Silicium

Plastics/synthetic materials

Thermoplastics

Glass fibre-reinforced plastic

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Cast metals

Cast steel

Cast iron

Sintered materials

Metal powder for formed parts

Metal powder for hard metal

Non-metal inorganic materials

Ceramics

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Industries

Packaging industry

Precision engineering, mechatronics and optics

Medical technology

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.