HBtec GmbH

Contacts

Jürgen Hartung

Production

Phone:

E-Mail:

Competencies

Parts (2)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 500 | 5 - 700 | - | - | 2 - 280 | - | - |

Company description

Company Description The company Knauß - metal machining is active in the areas of wire EDM, sinker EDM, turning, milling. The machinery in tool consists of 3 wire EDM, an EDM machine, 2 CNC milling machines, two lathes, a sand blasting cabinet and a surface grinder. Our CNC milling, we have a Chiron FZ12 W milling center the opportunity to very large numbers in a very short time coping (pivot table with 4 Vices and fast tool change times) and a Hermle 900E with the following travels: X 600mm, Y 400mm, Z 420mm We Customize falling in our tooling, stamping, embossing and composite tools, 1-gang and multiple. We manufacture in small and large series, hollow spindle stops, T-Nutensägen, circuit boards, stamps, cutting dies, pinions, gears of all types, gripper jaws, gill pins and all kinds of drilling and clamping devices on our CNC milling and EDM machines. If they need more information, they are welcome to contact us. Unfortunately, our web - page is still under construction. In our modern CAM Programming Course (PC FAPT-Cut i) we construct your Aspruchsvollen Erodierwünsche. Our customers are found in the following industries: * Auto, electric, plastic and toy industry * Plants, molds, machinery, model and tool Our strengths are: * Quality and precision * Short-term and timely execution * Balanced price / performance ratio * Customisable care Services Versions of any eroding * Electrically conductive materials and tools of any kind (steel, copper, carbide, aluminum, etc.) * Gearings * Erosion of copper electrodes * Rohplatinen * Mechanical engineering parts * Dies and plates for stamping, embossing and progressive dies * EDM and EDM Hole * Single and series production part Difficult workpieces and contours Some materials - especially the newer ones - can not always be processed with the standard technology because of its composition. Such difficult jobs are not rejected by us. They are seen by us as a challenge we gladly face with vigor and flexibility. Economically, although some trial use is not always feasible, however, our company is thus a certain level of knowledge of which is useful to us in other projects and in the future. We would be pleased to hear from them soon.

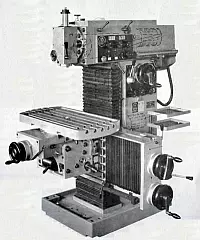

Machines (5)

Copmany images

Materials

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Carbide

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Cast metals

Cast steel

Cast iron

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Plastics/synthetic materials

Thermoplastics

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Sintered materials

Metal powder for hard metal

Non-metal inorganic materials

Graphite

Industries

Machine tool manufacturing

Aerospace and aviation industry

Boiler, container and tank construction

Building, agricultural and forestry machinery manufacturing

Construction and architectural supplies

Hydraulic and pneumatic industry

Apparatus engineering

Automotive and vehicle construction

Chemical industry

Medical technology

Military engineering

Furniture industry

Special purpose machinery manufacturing

Packaging industry

Paper and printing machinery industry

Electrical industry

Plant engineering and construction

Office machinery and supplies

Precision engineering, mechatronics and optics

Air conditioning, refrigeration and ventilation industry

Mechanical engineering

Power generation and transmission industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.