TECNOMEC di GIiudici s.r.l.

Contacts

Giovanni Giudici

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (11)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 50 - 100000 | 10 - 400 | - | - | 10 - 200 | - | - |

Full-range turning (including milling) | 20 - 10000 | 0.5 - 500 | - | - | 8 - 200 | - | - |

Company description

The comapny TECNOMEC of GIUDICI S.R.L. was born in 1996 from the experience gained by the owner, Giovanni Giudici, at an important workshop in the valley. The company carries out mechanical work with third parties, creating mechanical parts based on the customer's design. We specialize in the processing of die-castings, castings and printed materials of various materials such as: light alloys gray and spheroidal cast iron carbon steels stainless steels furthermore, the company has its own machinery capable of producing turned and milled parts of any other material (special steel, bronze, copper, brass and even plastic materials). The company covers an area of about 1400 square meters, is equipped with a metrology room with a three-dimensional measuring machine to ensure maximum accuracy and control of the work performed. In order to satisfy customers, a space of approximately 200 square meters was assigned to the assembly of mechanical units, the components are partly produced by the company and partly purchased on the market by certified suppliers. To date, the company has about fifteen employees.

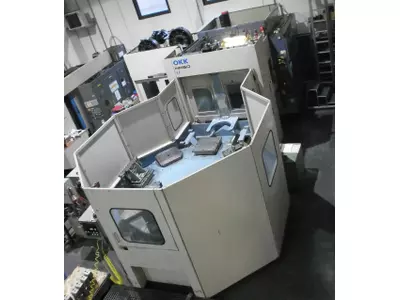

Machines (9)

Copmany images

Materials

Cast metals

Cast steel

Cast iron

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Plastics/synthetic materials

High performance plastic

Industries

Mechanical engineering

Precision engineering, mechatronics and optics

Apparatus engineering

Hydraulic and pneumatic industry

Automotive and vehicle construction

Packaging industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.