Kovinski izdelki HRAST d.o.o.<br>CNC Precision Turned Parts

Kontakte

Mitja Hrast

Technische Leitung

Telefon:

E-Mail:

In vier Schritten zur einzigartigen Markttransparenz

Kompetenzen

Teile (4)

Technologien

Drehen

| Technologien | Stückzahl | Länge | Breite | Höhe | Durch-messer | Gewicht | Material stärke |

|---|---|---|---|---|---|---|---|

Drehen | 10 - 5000000 | 0.5 - 250 | - | - | 3 - 65 | - | - |

Automatendrehen (Stange) | 10 - 1000000 | 0.5 - 250 | - | - | 1 - 65 | - | - |

Langdrehen | 10 - 1000000 | 0.5 - 600 | - | - | 1 - 30 | - | - |

Komplettbearbeitung Drehen (mit Fräsbearbeitung) | 10 - 1000000 | 0.5 - 250 | - | - | 3 - 65 | - | - |

Firmenbeschreibung

The company KOVINSKI IZDELKI Hrast s.p. was established in the year 1984 and was registered in Borjana, municipality of Kobarid. Production programme includes the whole range of machining of metal (CNC turning on the lathes, milling, drilling, grinding) on the classic and CNC automated lathes. In 2002 we established Soca valley cluster with 5 partner companies (www.pkg.si). We are producing different assembly parts and finishing semi-finished products (wrought-iron) used by the car industries on multi-spindle automated lathes and CNC turning lathes. Due to enhanced requirements of customers and for better penetration on the foreign markets, we succeeded in obtaining the quality certificate ISO9001-2000 and ISO14001:2004. With very high level of knowledge and experience, with up-to-date equipment and technological resources we are manufacturing: • machining on classic automated lathes up to the diameter of 28 mm, • machining on multi-spindle automated lathes up to the diameter of 30 mm, ��� machining on CNC automated lathes (turned milled parts) up to the diameter of 42 mm, • machining on CNC long turning lathes up to the diameter of 20 mm • swiss turning (micro turned parts) on CNC (Citizen) lathes from bar diameter 1 mm • all finishing operations (heat treatment, surface protection...), necessary for different specific products. Our basic products are: nuts - screws - pins - pivot pins - bolts - washers - bushes - ball ring housings - shafts Materials that we are using in our production: Steel - High-grade steel - Tempering steel - Brass - Aluminum (Al) - Copper (Cu) - Copper nickel - Bronze - Nickel silver - Titanium * This is a selection of the most frequently requested materials. If other materials are required, please contact us! Surface protection that is being used: inc-coated - nickel-coated - thick film passivating - Cr6-free - silver-plated - gold-plated - tin-coated - hot dip tin-coated - copper-coated - brass-coated - chromium-plated - phosphatise - lubricant coating - patch coating - polished - stainless - anodised - burr-free * This is a selection of the most frequently requested surface protections. If other protection is required, please contact us!

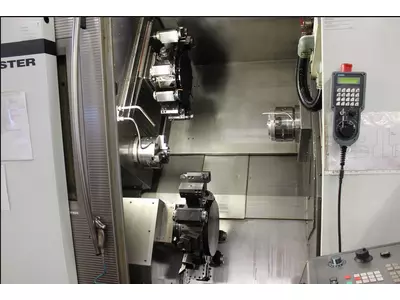

Maschinen (9)

Firmenbilder

Werkstoffe

Eisengusswerkstoffe

Stahlguss

Gusseisen

Kunststoffe

Thermoplaste

Leichtmetalle

Aluminium und Aluminiumlegierung

Magnesium und Magnesiumlegierung

Titan und Titanlegierung

Stahl

Baustahl

Einsatz-/Vergütungsstahl

Edelstahl (rostfrei V2A)

Edelstahl (rostfrei/säurebeständig V4A)

Automatenstahl

Werkzeugstahl

Federstahl

Kaltfließpressstahl

Schwermetalle

Kupfer-Zink-Legierung (Messing)

Kupfer und Kupferlegierung

Zink und Zinklegierung

Lote

Sinterwerkstoffe

Metallpulver für Formteile

Metallpulver für Hartmetall

Branchen

Telekommunikationstechnik

Armaturenbau

Feinmechanik, Mechatronik und Optik

Beleuchtungsmittelindustrie

Werkzeugmaschinenbau

Möbelindustrie

Antriebs- und Getriebetechnik

Bürotechnik und Zubehör

Luft- und Raumfahrtindustrie

Eisenbahnindustrie und Schienenfahrzeugbau

Elektroindustrie

Hydraulik- und Pneumatikindustrie

Militärtechnik

Kessel- und Behälterbau

Kälte-, Klima- und Lufttechnik

Automobilindustrie und Fahrzeugbau

Maschinenbau allgemein

Sie sind Zulieferer?

Finden Sie ideal passende Anfragen.

Sie sind Einkäufer?

Laden Sie Ihre Anfrage hoch.