Buerstätte GmbH Stanz- und Umformtechnik

Contacts

Andreas Müller

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

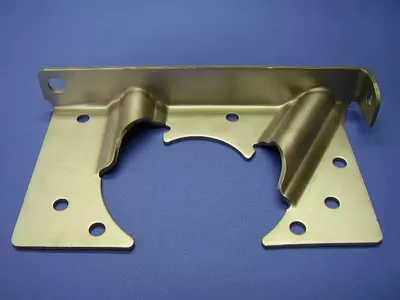

Parts (30)

Technologies

Sheet Metal Forming (Stamping, Deep-drawing)

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / pressing (Out-of-tool) | 100 - 1000000 | 10 - 400 | 10 - 400 | - | - | - | - |

Stamping and bending machine (Bihler) | 100 - 1000000 | 10 - 400 | 10 - 400 | - | - | - | 0.8 - 12 |

Deep-drawing | 100 - 200000 | - | - | - | - | - | - |

Company description

Buerstätte stamping and forming Your competent partner for stamping parts, bending parts and deep drawn parts • In-house tool with its own design • Own prototypes built • punching machines up to 300 tons press force and 8 mm thickness for stampings progressive dies • Deep drawing presses up to 600 tons press power and up to 20 mm sheet thickness for deep drawn parts, bending parts and stampings • Buerstätte specializes in stamping parts with small to average annual production amounts • Typical annual quantities of 500 pieces to 500,000 pieces • Buerstätte is extremely flexibly to your deadlines • Quality according to ISO 9001:2008 The two basic production lines be as follows: Production of medium and large series Stamping parts, bending parts and deep drawn parts Stamping parts in batches of 5000-500000 piece Production on composite tools Production via stamping presses up to 300t pressure Material thickness up to 8 mm Punching from slit strip (hot rolled, cold rolled and stainless steel) Bandwidth up to 350 mm Production of small and medium series, inlaid intricate parts Stamping parts, bending parts and deep drawn parts Stamping parts in lot sizes from 500 to approximately 5,000 Production of stamped parts and bent parts on eccentric presses between 35t and 180t printing performance Production of deep drawn parts and bent parts on hydraulic presses between 40t and 600t printing performance Material thicknesses up to 20 mm Punching sheet metal strip Strip widths from 15 mm to 500 mm Company Information • Founded in 1961 - almost 50 years of experience and innovation for your stamping parts, bending parts and deep drawn parts • 30 employees • family - famili

Copmany images

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Light metals

Aluminium and aluminium alloys

Industries

Plant engineering and construction

Furniture industry

Measurement and control technique, laboratory equipment

Medical technology

Air conditioning, refrigeration and ventilation industry

Paper and printing machinery industry

Boiler, container and tank construction

Building, agricultural and forestry machinery manufacturing

Fittings engineering

Special purpose machinery manufacturing

Precision engineering, mechatronics and optics

Machine tool manufacturing

Hydraulic and pneumatic industry

Electrical industry

Packaging industry

Chemical industry

Mechanical engineering

Military engineering

Railway and rail vehicles industry

Construction and architectural supplies

Power generation and transmission industry

Apparatus engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.