Deep drawing: receive an avg. of 7 offers per request

Discover specialized suppliers for deep drawing on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to create high-quality deep-drawn products. Use the e-sourcing process to find suitable suppliers in real time.

436 suppliers for Deep drawing

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

WKK Kaltbrunn AG - enormously in form The beginning of the WKK Brunn AG is founded in 1967. As a dedicated tooling the company had at that time only one purpose: the production of cutting, bending and forming tools. Shortly thereafter, the fabrication shop was put into operation and some ten years later, the company introduced her first own product. By continuity, innovation and perfection was out of the formerly peaceful Toolmaking a successful SME with about 45 employees.Today, the CHP is an international punching operation with most modern manufacturing methods in the supplier sector. enormously complete - from the first idea to the final series, we offer comprehensive services - Consulting: individual and professional, on-site or at our - Construction: in-house with 3D Autodesk Inventor - Prototyping: short to illustrate your ideas - Tool: for punching tool and teaching building, with modern machinery - Series production: stamping products of all types up to 250 tons of pressure and up to 300 mm width at 3 mm thickness (up to 5 mm after consultation) made of steel, stainless steel, non-ferrous and light metals - Component manufacture: Total manufacturer of your products, automated assembly - Post-Processing: Heat and surface treatments for partners near - Finish machining: by machining (milling, turning, drilling), eroding and vibratory finishing - Did you know? Also welding

Founded

1967

Employees

20 - 50

Certifications

Kaltbrunn

Switzerland - CH-8722

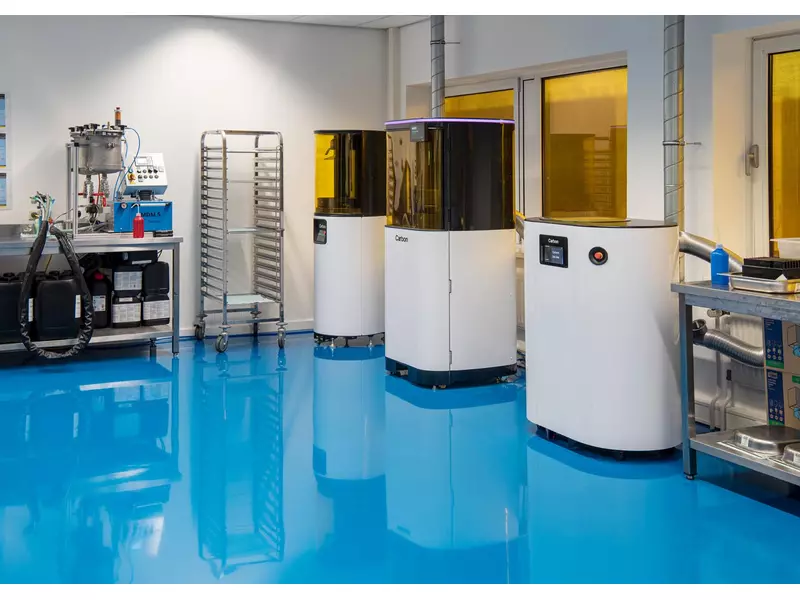

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

Short YOUTUBE Video: https://youtu.be/FzPtBnGDq2Q?si=E-E8EgaQiIz05Aov Our company is located in eastern Slovakia, in the industrial district of Široké village. Our over 7000 m2 of working area is divided among seven halls that are utilised for production, storage and offices. We are able to provide the best possible solutions for your needs, since we constantly invest in state of the art technologies and have extensive company expertise. In addition to Slovakia, we work with several businesses around Europe. We always strive to improve ourselves and to adjust technology to the newest trends. We are looking forward to cooperation!

Founded

2017

Employees

50 - 100

Certifications

Siroke

Slovakia - 08237

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

N&H Technology – Your Development Partner for Custom Components, HMI Solutions and Electromechanical Assemblies Since 2001, N&H Technology has been your certified system supplier for tailor-made electromechanical assemblies, technical components and HMI solutions. Our focus lies in the development and serial production of plastic, elastomer and metal parts – including multi-component solutions (e.g. 2K/3K technology, rubber-metal combinations). Our portfolio is complemented by customized input systems such as silicone and membrane keypads as well as cable assemblies and connectors. Whether precision-molded parts, elastomeric functional elements or complete input units – we realize your project reliably from concept to series production. ++++ Our Capabilities: ++++ Technical Components & Housings • Injection-molded parts made of thermoplastics, high-performance polymers and fiber-reinforced materials • Silicone and rubber components incl. seals, protective covers, keycaps • Die-cast, milled, stamped and turned parts made of metal • 2K/3K components and hybrid solutions (plastic/metal, rubber/metal) ---- HMI Components & Input Systems • Silicone rubber keypads, membrane keypads, capacitive keyboards • Stainless steel and hygiene keyboards • Touch display units & full HMI assemblies ---- Connectors & Cable Assemblies • Spring-loaded contacts, magnetic connectors, custom plug solutions • Cable assemblies: data, coaxial, ribbon and hybrid cables • Assemblies with integrated interconnect systems ++++ Our Services: ++++ Engineering & Development • CAD design, feasibility studies, DFM optimization • Prototyping using 3D printing, silicone casting or small series production • Tool design including mold-flow simulation ---- Project Support & Quality • Technical consulting from initial concept to series approval • In-house testing laboratories (mechanical, electrical, optical) • Certified & exclusive supplier network according to ISO 9001 and ISO 14001, optionally IATF 16949 and ISO 13485 ---- Procurement & Logistics • Procurement of third-party components & system integration • Final assembly, end-of-line testing and logistics including buffer warehouse in Germany ++++ Industries We Serve: Automotive · Medical Technology · Telecommunications · Building Automation · Industrial Electronics · Measurement & Control Technology ++++ N&H Technology stands for engineering expertise, flexibility and trusted partnership. We combine customer-specific product development with efficient manufacturing – delivering reliable and cost-effective solutions in series.

Founded

2001

Employees

50 - 100

Certifications

Willich

Germany - 47877

TMV Vago is a company located close to Milano, specialized in precision mechanical machining. Born as a mechanical turning shop, over the time it has developed a set of technologies and skills that now collaborate in the mass production of mechanical components for various sectors: Turning, milling, laser cutting and welding. Machining from solid of multiple metals, some plastic materials, and sheet metal and three-dimensional laser cutting is carried out. Additionl services such ad mechanical assembly, laser marking, finishing are provided.

Founded

1991

Employees

5 - 10

Certifications

Gerenzano (VA)

Italy - 21040

Our core competencies are: Tools - Hard Metal Processing - Sheet metal rounds - Punching / pressing (tool Falling) - Punching-bending (Bihler machine) - Stamping - Injection molding, extruding - injection molding - Encapsulation of inserts - To water - Die-casting - Ingot - Machine molding (sand casting) Translation by Google Translate

Founded

2003

Employees

5 - 10

Certifications

Offenburg

Germany - 77652

Customised production of housings and steel solutions based on intelligent metal processing. Our experienced specialists work together with you on the development of prototypes and support you in the implementation of your projects through to series production with a wide range of services such as planning, construction, manufacturing and logistics. At the same time, we meet even the highest quality requirements thanks to our strict controls. A modern production site in Poland is the basis for being able to respond flexibly, quickly and economically to your needs. A constantly growing machine park and a highly qualified team are the key to success and enable us to offer competitive prices using the latest technology.

Founded

2008

Employees

50 - 100

Certifications

Stammham

Germany - 85134

Consortium of companies active in the development of foreign markets. It acts as an export sales department for a number of SMEs located in Italy, all operating in sub-supply in the mechanical engineering industry. Our partners can offer, among others, the following main operations - Turning - Milling - Grinding - Sheet metal cutting and bending - Sheet metal forming - Assembling - Complete sub-assemblies - Sheet metal forming - Welded construction - Assembly of assemblies

Founded

2011

Employees

20 - 50

Certifications

Vicenza

Italy - 36100

Othni employs about 100 people and manufactures over 6000 square meters of production space parts made of steel, stainless steel and aluminum sheet. We see ourselves as an active partner system. Customer proximity is lived. From the development, the first prototype of complex assemblies, through to series production, we offer our services. A certified quality management completes our range of services.

Founded

1996

Employees

100 - 200

Certifications

Borchen

Germany - 33178

We are a medium-sized company based in Ganderkesee and have been producing sophisticated sheet metal and formed parts for our customers for over 65 years. Our customer base includes the automotive, mechanical engineering, electrical, marine and aircraft industries, where we are listed as an A-supplier and have already received several awards as a 0-ppm supplier. Our company is fundamentally different from other companies that can produce either only large or only small series at low cost. We are proficient in both technologies. Since we are convinced that only holistic quality and sustainability can lead to success today and in the future, we have a certified integrated management system in accordance with the requirements of IATF 16949, DIN EN ISO 9001 and DIN EN ISO 14001 established. (ext. TÜV Cert link). Our homepage is intended to give you a brief overview of our diverse production options. We would be delighted to work for you too. Give us a chance to do that.

Founded

1948

Employees

20 - 50

Certifications

Ganderkesee

Germany - 27777

Bauflaschnerei Winter GmbH is one of the leading companies in sheet metal technology and sheet metal processing. We have established ourselves in the fields of plumbing, roofing and façade construction. In addition, the brands Bleche-nach-mass.de and Magnetwandshop.de offer individual solutions according to customer requirements for B2B and B2C. Sheet metal technology at the highest level with the latest machinery.

Founded

1986

Employees

20 - 50

Certifications

Essingen

Germany - 73457

Our company was founded on 28.02.2005. It builds on the experiences that have been collected for years in the FIRE tool-und Maschinenbau GmbH in the field of stamping production. The acquisition of new hydraulic presses and the investment in a new Production facility enables us your client's wishes and not least Your product innovations enhanced implementation. We will advise you in the choice of materials and develop with you a tool concept. This can be thanks to the close cooperation with the FIRE tool and Maschinenbau GmbH are implemented quickly and effectively. Production of stamped parts Stampings band Stamping parts with thread Pressed, stamped and drawn parts connected tooling with 35 employees since 1992 CNC milling 3/5-Achs CAD CAM CNC turning CNC Wire EDM CNC sinker EDM List of machines We can customize your stampings on the following machines: Belt systems - 600mm width 8mm tape cross-section Eccentric EBU 1000 KN 80Hub/min Eccentric PME 2000 CN 80Hub/min Eccentric EBU 2000 CN 80Hub/min Eccentric PME 3150 CN 60Hub/min Insert presses: Eccentric Helmerding 850KN 60Hub/min Hydraulic press 250 kN 2x Hydraulic Press 400-630

Founded

2005/1992

Employees

10 - 20

Certifications

Oederan

Germany - 09569

SYS Pres company is metal fabrication company which spealizes in laser cutting, laser welding, welding, bending, and surface treatment operations. Surface treatments are automatic sand blasting, zinc plate, copper plate and etc. SYS Pres company's facility is 3000 sq. Our export countries are Austria, Germany, England, Netherlands, Belgium, Israel.

Founded

1992

Employees

50 - 100

Certifications

Manisa

Turkey - 45400

We are a company dedicated to ugarisches sheet metal processing and exciting machining by machining centers for small and medium series .. The focus of our work lies in the production of complex assemblies including assembly such as FTS, Heber and packaging machines. Our machinery, we continuously expand and modernize one of the most modern in Hungary. From single part production through installation to commissioning of the modules and machines, we can offer the full range of services you need. Give us a try. We put an offer below that will convince you.

Founded

1993

Employees

50 - 100

Certifications

Kiskörös

Hungary - 6200

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Manufacture of metal press members on a rotating basis, a variety of materials from CNS to copper to 3mm

Founded

1990

Employees

20 - 50

Certifications

Imst

Austria - 6460

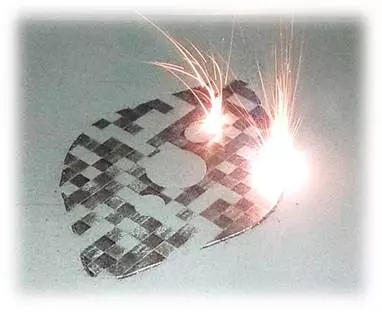

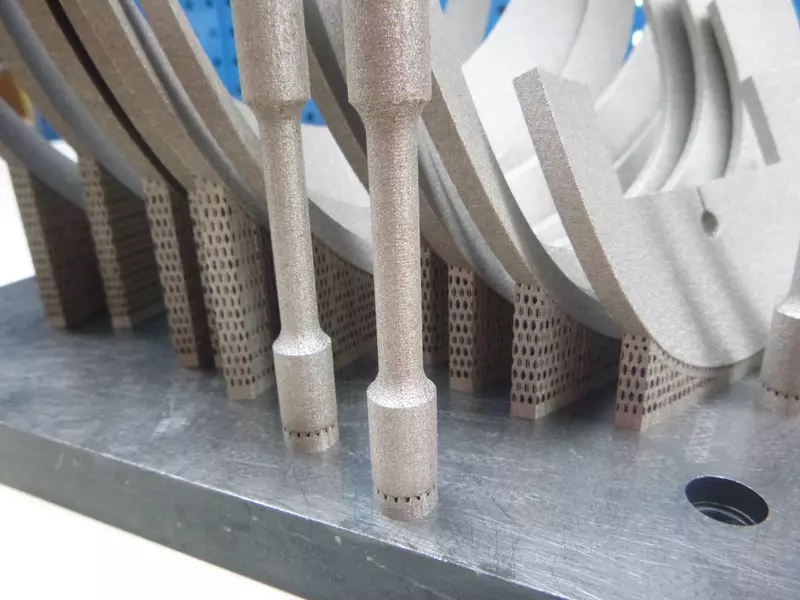

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Founded

Employees

5 - 10

Certifications

Amstetten

Austria - 3300

We serve as Automotive , HVAC applications , Sheet - Metal box Set. , Machining. and White goods sub-industry with Laser Cutting, Press Bending, Welding and Assembly processes. We process all quality stainless steel, aluminum, galvanized, titanium, lead and black materials in the most precise way within the desired dimensions and tolerances.

Founded

2015

Employees

20 - 50

Certifications

Yunusemre

Turkey - 45140

- Manufacture of stamping parts according to sample or drawing to 1250 kN - Manufacture of stamping parts made of copper, brass, aluminum, bronze, steel, stainless steel up to 3mm thickness from tape using electronic feed, up to 6mm from sheets or strip - Manufacture of stamping parts made of non-metallic materials - Point-and inert gas welding (MAG, TIG) - Drilling - Tapping - Thread rolling, knurling + - High gloss polishing by polishing rotary table (6 stations) or manually - Supplier `s and-drag to 80 mm in length (even more grooves per part possible) - Belt loops - Mounting (single and assembly) - Cleaning of stampings using cleaning machine - Special solutions In cooperation: Laser technology (also 3D) laser, laser welding, Bending, CNC punching nibbling, turning and milling parts, surface finishing, tool - Quantities of 100 units to 5 million units

Founded

1937

Employees

10 - 20

Certifications

Schwarzenberg/OT Pöhla

Germany - 08340

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge

Deep drawing

Deep-drawing is a part of Sheet metal processing and the most important forming method for the production of sheet metal parts. According to the definition of DIN 8584, it is tensile compressive forming and the processing is carried out by simultaneous tensile and compressive stress in different operating directions. The drawing method most commonly used is deep-drawing with rigid tools from tool making. The tools consist of a punch, a die and a sheet holder. The sheet metal blank is fixed by the sheet holder and during immersion the stamp spans the sheet in the board across the die radius, pressing it into the die (also called drawing ring). In doing so, the required punch force constantly increases until the dead-centre position is reached. The edges of the punch and the die are rounded, otherwise the sheet might tear. If the roundings are too large, the sheet at the end of the draw can no longer be fixed by the downholder, which may lead to wrinkling. If the draw depth is not reached in a single step, the draw is executed in several steps, especially in case of thick sheet metals.