Vacuum casting: Techpilot - free for buyers

Discover specialized suppliers for vacuum casting on Techpilot. Our platform connects buyers with suppliers who use advanced casting technologies to manufacture high-quality parts. Use the e-sourcing process to find suitable suppliers in real time.

169 suppliers for Vacuum casting

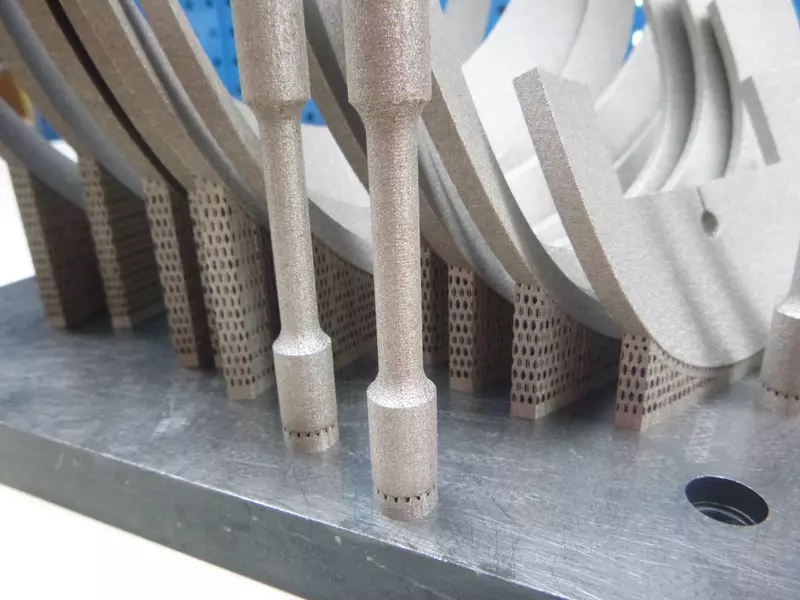

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Innovative plastic products since 1989 The BÖHL-plastic GmbH & Co. KG specializes in the production certified technical precision injection molded thermoplastics. We cooperate with raw material manufacturers, but also with colleges and universities. Because the plastic processing is a challenging topic. Individual solutions are our strength. Our activities span the injection molding production for the lighting and automotive supplier industry. We are also working for the industries fittings, electrical and electronics, medical, furniture, steel and textiles. The headquarters of our plastic processing company located in southern Westphalia. Here we present for you since 1989 plastic parts from all common thermoplastics ago. We are supported by our own mold.

Founded

1989

Employees

20 - 50

Certifications

Bad Berleburg-Aue

Germany - 57319

Founded

2001

Employees

20 - 50

Certifications

Dornhan

Germany - 72175

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

3D printing service for small series, functional parts and prototypes made of plastic.

Founded

2018

Employees

5 - 10

Certifications

Pfaffenhofen

Germany - 89284

As a Swiss company in the field of precision CNC milling and turning, we offer turned and milled parts of the highest quality, always on time and at competitive prices. You will never look for other CNC service providers again!

Founded

2022

Employees

5 - 10

Certifications

Fiesch

Switzerland - 3984

inotec GmbH, based in Manching in Upper Bavaria, is a medium-sized company in the plastics processing industry. We specialize in manufacturing optical and technical plastic parts. Our components are used in the automotive industry, medical technology, the construction machinery industry and the electrical and electronics sector, among others. At our site in Manching, we have a wide range of injection molding machines ranging from 25 tons to 1500 tons of clamping force. With these, we produce thermoplastic parts up to a part weight of 5200 grams using both standard and very special injection molding processes. Thanks to our experience in the field of plastics processing, we are your competent partner for the production of a wide variety of components

Founded

1997

Employees

50 - 100

Certifications

Manching

Germany - 85077

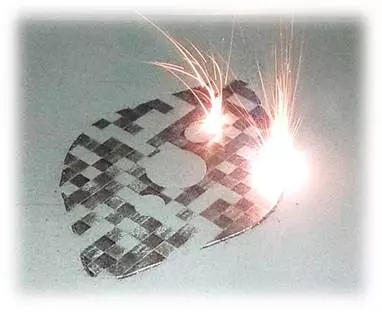

Since the 1960s, the Simaform company has mastered many manufacturing processes including 4 laser technologies: high-precision cutting, welding, engraving and marking, and metal 3D printing. But also wire erosion cutting (EDM), micro-milling, press shaping, heat treatment (quenching / tempering), deburring by tumbling, sanding and polishing. In addition, the Simaform design office supports and advises you at every stage of your project. Simaform is an expert in the manufacture of complex high-precision parts in fine sheet metal for all industry sectors as well as in 3D printing using metal powder. Simaform guarantees products perfectly suited to your needs with optimum quality and value to satisfy all domestic and International customers.

Founded

1960

Employees

20 - 50

Certifications

Eselborn

Luxembourg - 9779

Our customers are offered everything they need within our group of companies, all in one basket: from development and project management via the production of tools for plastic and metal fabrication, through to manufacturing the parts. In this way we closely co-operate with our customers in developing functional structural plastic and metal components on the basis of the design, thereby achieving an optimum combination between plan, design, manufacture, and cost structure. The integrated possibilities have enabled us substantially to shorten the project run up to the point of series production. The systems Pro-engineer and Catia, available to our staff, permit the creation of structural components and tools, "in one casting" as it were. Injection Moulds Our staff in the individual manufacturing areas have state-of-the-art technologies and most up-to-date machines (such as 12-wire and 15-wire cavity sinking EDM machines) at their disposal. In producing moulds with a guaranteed number of shots, especially for the automobile industry and consumer electronics, our dictum is precision and quality. This holds true for injection moulds, diecasting, duroplastic, two-component, rotating, transfer and insert/outsert moulds, just as much as it does for two-colour moulds, combinations of hard and soft plastics, automatic wire leads, in-mould decoration, and precision gear wheels. Rapid tooling with the aid of our EOS metal sintering machine M250 Extended makes it possible to produce mould inserts for injection moulds and prototype tools within a very short time. Eighty moulding machines in Vienna and Hungary, with a clamping force of between 25 and 1,100 tons, offer all the possibilities of manufacturing moulded, thermosetting and duroplast, gas-injection moulded, two-component moulded, insert and outsert moulded, as well as in-mould decoration parts. Our machines are equipped with automatic robot systems, and automatic packaging lines complement the production line. Vienna: 3-shift operation / technical products and precision parts with a mould clamping force of up to 500 tons, Hungary: 4-shift operation / technical products and design parts with a mould clamping force of up to 1,100 tons. Your plastic parts are coated in three fully automated painting lines on a water-soluble basis (single-component or two-component coating). Your metal parts are electrostatically painted, from the smallest parts up to housing coatings for consumer electronics.

Founded

1966

Employees

100 - 200

Certifications

Wien

Austria - 1230

We specialize in Additive Manufacturing - particularly DMLS and precision CNC processes. From design conceptualization to AM, modeling, prototyping, serial production, and post-processing, we offer comprehensive Engineering and Manufacturing solutions tailored to drive your success.

Founded

Employees

5 - 10

Certifications

Valencia

Spain - 46013

We, Metallbau Schmalenbach, specialize in manufacturing a wide variety of high-quality and tasteful stainless steel and corten steel accessories. Years of experience in working with metal products, experienced know-how and the gift for exceptional design give our products uniqueness. The focus is on narrowing down to the essentials. In a charmingly flooded world, peace and relaxation are important to us. Simplicity is the goal and with it the uniqueness of our products. In addition to our wide range of products, we also offer you the opportunity to have your ideas implemented. We offer you custom-made custom-made products. You are welcome to visit us at Linienstr.14 in 42289 Wuppertal.

Founded

2022

Employees

5 - 10

Certifications

Wuppertal

Germany - 42289

As a metal-processing industrial company, SBOT employs about 350 people at its Ternitz location. A 100 % subsidiary of Schoeller-Bleckmann Oilfied Equipment AG, we are listed on the Vienna Stock Exchange, we have around 1,200 employees worldwide and are part of an internationally active group. As global market leader, we process and distribute our own non-mag steels and manufacture high-precision parts for the oilfield industry, which we export to all oil-producing regions in the world. With our products, we supply the core components for MWD/LWD parts, which are used for measurement and determination of data during the drilling process on the oilfields. As a supplier for machining long parts from various materials (especially high-alloy steels), we can support customers in all sectors of industry with our many years of experience in metalworking. Certified in accordance with EN/AS 9100 in 2016, SBOT has also made its first successful step into the aviation industry.

Founded

1924

Employees

200 - 500

Certifications

Ternitz

Austria - 2630

We are your supplier for high-quality injection molding tools, plastic and metal components, from development to production. We develop and manufacture individual vehicles for you exactly according to your requirements. We offer you certified special protection vehicles and solutions that protect lives. Companies from the automotive sector, industry, medical technology and other sectors rely on our expertise. Our special vehicle construction meets every wish and requirement. Emergency personnel, NGOs and high-ranking personalities rely on our certified special protection solutions. With over 1,000 employees at seven locations across Europe and powerful machinery, we are ready for any task — and are sure to offer you the best solution.

Founded

Employees

500 - 1000

Certifications

Georgsmarienhütte

Germany - 49124

The world is fast moving! Product lifecycles are becoming ever shorter and development times ever faster. With conventional methods, many companies often reach their limits. Producing prototypes, functional models and series parts is often too complex and takes too long. And the lower quantities in the later series have become too expensive and uneconomical with the conventional processes. This is exactly where our 3D printing and rapid prototyping service can help you! While you may not be new to 3D printing, the industry and technology span is large and wide. Finding your way around here is certainly not easy. Use our expertise in 3D printing to find a suitable and cost-effective solution. Get in touch with us now and take advantage of the opportunities that our 3D printing service offers you! With our various processes and materials, PROTOTEC has the right technology and solution for almost every application.

Founded

1995

Employees

5 - 10

Certifications

Attendorn

Germany - 57439

We are a small company, founded in 2007 company based in the center of Cologne. We are specialized in the production of precision parts from all areas and materials. From a single prototype to series, we use the most modern equipment of the highest quality.

Founded

2007

Employees

10 - 20

Certifications

Reichshof

Germany - 51580

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

D3D Additive Manufacturing GmbH has specialized in the production of complex individual parts and small series using additive manufacturing and CNC processing. By using the latest technology, we are able to precisely manufacture products from various metals and thus cover different areas of application with different quality standards .

Founded

2017

Employees

5 - 10

Certifications

Baindt

Germany - 88255

RE.TT - Rehau Tool Technologie We are the toolmaking company of REHAU AG + Co. We have been active in the field of extrusion technology for many years and design and build extrusion tools for the areas of pipe, tube and profile extrusion. The products that are manufactured with our tools are used in medical technology, the furniture sector, in the automotive environment and in civil engineering and construction (pipes, window profiles). Based on decades of experience, we have excellent expertise in a wide range of applications and materials. In addition to the extrusion tools, we also build gauges for various applications. Small gauges are used to test the products made with our extrusion tools, large gauges are used in the field of injection molding. We are happy to support external partners and are open to all inquiries.

Founded

1948

Employees

20 - 50

Certifications

Rehau

Germany - 95111

JG AUTOMOTIVE: Developer and Supplier in the manufacture of metal parts JG Automotive was founded in 1982, dedicated to the manufacturing, development and supply of metal components for the automotive and industrial sector. Thanks to the mastery of the technologies of manufacturing of metal products specifications provided by clients, we have diversified the industrial sectors of performance and optimized our work processes. In 2002, together with 18 international partners, we created Global Alliance, a large group with 230 cooperative engineers, manufacturers in Brazil, Germany, China, India, Italy, Japan, Korea and USA, among others, managing a joint turnover of € 1,720 M. Dozens of companies in the automotive, energy, railway, agricultural, elevation, etc. sectors, are already among our customers and fortunately for us every year we continue to grow thanks to the trust of our customers and the incorporation of new ones. Our products are presented with their corresponding quality certificates (IATF / TS / ISO / CE / PPAP). In short Technology and high competitiveness in products to specifications provided by clients. TECHNOLOGIES: Forging, Casting, Machining, Stamping, Laser cut, Welding, Raw Material, Microforge, Microfusion, Fasteners, High Pressure Cylinders, Hydrogen cylinders for hydrogen filling stations, Toolings, Precision Bar Turning and Special Parts, Inserts and Profiles, Tubes SW and DW and Rod Formers, Springs, E-mobility, Precision Gears, Bearings, automotive plastic injection parts and Returnable packaging of metal parts.

Founded

1982

Employees

50 - 100

Certifications

Madrid

Spain - 28108

The Brinkmann mold GmbH offers its customers services started with the construction of prototypes, to the realization of complete process chains for injection molding components. Our range includes the development phase, the construction and tool to series deliveries in bulk or small series about our embedded partners. In addition, we support our customers in the procurement strategy to include best-cost country suppliers in the field of tool in order to increase competitiveness. In this section, we work with many years of professional partners and take over the complete technical and logistical management. In the field of injection molding, we process all common plastics in single and multi-component injection molding of products manufactured by A as ABS curtains decor holders to Z as the gear of PA 30% GF. Toolmaking: Construction CAD / CAM, wire EDM, sinker EDM, 3D HSC milling, grinding, assembly, sampling Injection molding partner companies: 60 injection molding machines (20-1000t clamping force), screen printing Sectors: agriculture, automotive, consumer goods industry, furniture industry Delivery program: injection molding and stamping tools, injection molded parts, screen printing, stamping parts

Founded

2001

Employees

20 - 50

Certifications

Mühlen

Germany - 49439

CNC contract manufacturing for tool, machine and plant construction. Do you build tools, machines or special machines? Do you need precision parts for your machines and systems? We take over the CNC manufacturing. Contract manufacturing for mechanical engineering, tool making or mold making. Take a look at our manufacturing examples! We manufacture highly efficiently on modern machining centers quickly with high quality and on time. Leading machine manufacturers have been relying on our production since 1989.

Founded

Employees

Certifications

Vrnjacka Banja

Serbia - 36210

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge