Thread grinding: use Techpilot - free for buyers

Discover specialized suppliers for thread grinding on Techpilot. Our platform connects buyers with suppliers who use advanced grinding technologies to create precise threads on components. Use the e-sourcing process to find the best suppliers.

98 suppliers for Thread grinding

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

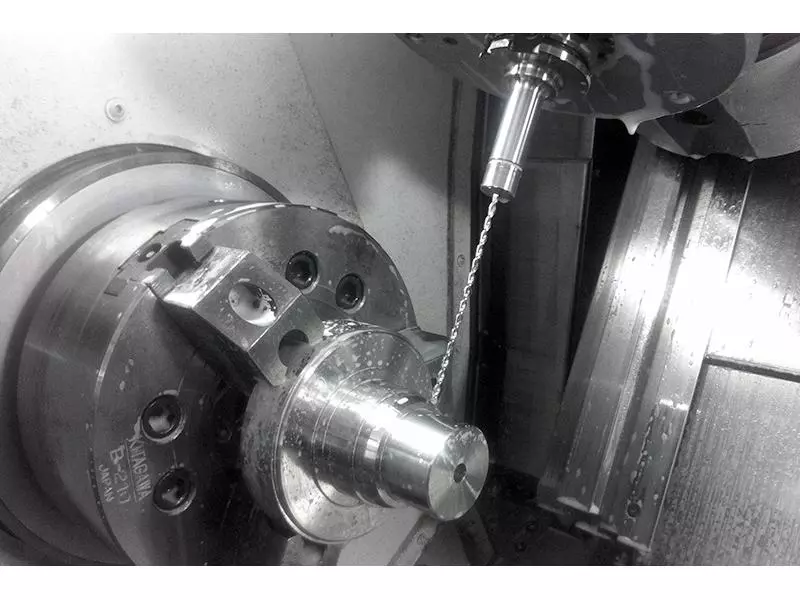

Your expert for complicated components and very critical applications • Beutter is a supplier of fine mechanical components with a high production depth in small batch series. • Beutter was founded in 1909, and is located in Baden-Württemberg, very close to the A81 motorway, 60km south of Stuttgart. • We have about 125 employees. Of our production staff, over 90 % are skilled workers. • We have the capability to perform, in-house, all machining processes (turning, milling, grinding, honing), while for special processes and surface and heat treatment processes we use competent third-party suppliers. • For us, the ideal is small- to medium-sized production runs with a lot size of between 20 and 1,000 pieces. • Beutter is particularly capable within the manufacturing of components with close production tolerances. • We process all machinable materials, and are particularly experienced in processing high-alloyed steels (stainless steel, V2A, V4A, 1.4441, 17-4PH), titanium and special materials (inconel, hasteloy, Ni-base alloy, chromium molybdenum steel, tantalum, platinum-iridium, PEEK). • Our main fields of activity are: Medical technology, aeronautics, hydraulics, military engineering, mechanical engineering and measuring equipment technology. • Our quality management system is certified according to DIN EN ISO 9001:2008, DIN EN 13485 (medical products) and DIN EN ISO 9100 (aeronautics). • We can process your data via our CAD system “SolidWorks“.

Founded

1909

Employees

100 - 200

Certifications

Rosenfeld

Germany - 72348

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

Founded

2011

Employees

10 - 20

Certifications

Láb

Slovakia - 900 67

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

metal cutting technology, Steel, stainless-, brass turning, milling, grinding, inductive hardening, assembling

Founded

1969

Employees

50 - 100

Certifications

Winden

Germany - 79297

Our goal is to convince our customers through our performance, which is always oriented towards our customers' high requirements regarding quality and on-time delivery. The most modern production equipment, quality assurance during production, and optimized processes make it possible for us to produce with speed, precision, and cost efficiency, all at the same time. Regardless of whether we mass-produce for you, deliver popular models on short-term notice, or manufacture individualized single components according to your specifications - we are consistently working on optimizing our customer-oriented service. Bevel gears Hobbing max. Ø 250 mm, up to module 6 Splines Hobbing Grinding upon request up tp 1200 mm in length max. distance between centers: 1250 mm Sprockets Hobbing Shaping max. Ø 400 mm, up to 1 inch up to 1 inch Worms Chasing Milling Whirling Grinding up to module 3 up to module 6 up to module 6 up to module 7 Worm wheels Hobbing upon request Helical gears Tooth flank grinding max. Ø 300 mm, module 6 Spur gears Hobbing Shaping max. Ø 600 mm, module 6 max. Ø 500 mm, module 6 Timing gears Milling available on short notice, in stock: from module 0,5 to 10 mm and from partition 2 - 10 mm; up to 3000 mm in length External grinding up tp max. 270 mm, max. distance between centers: 1000 mm CNC drilling upon request CNC and conventional turning up to Ø 400 mm, length 1200 mm Surface grinding max. length 2000 mm CNC and conventional milling upon request Thread grinding upon request Internal grinding max. grinding Ø 200 mm, max. grinding depth 250 mm Grooving: milling, cutting, reaming up to 28 mm Surface treatment such as hardening, nitriding, etc. Centerless cylindrical grinding max. Ø 70 mm Racks (High-Precision Racks) Type of Machining Machining Sizes Milling available on short notice, in stock: from module 0,5 to 10 and from partition 2-10 mm up to 3000 mm in length Delivery program: Gear wheels, spur wheels, racks, snails, worm gears, worm shafts, chain wheels, toothed belt wheels, helical gears, bevel gears, splined shafts, pump impellers, any waves, flange. Nearly everything with teeth. Materials: Steel, high-grade steels, non-ferrous metals is processed such as copper, brass, aluminum and plastics in complete and wage labours. Thermal treatment and surface coating: Additionally to our achievements we offer still any surface treatments. Case-harden, nitrating, Nitrocarburieren, carburizing, sandblast, TENNIFER QPQ, as well as galvanizing, burnishing and the like. Our customers expect to get low-priced precision products from us, with short delivery times, reliable service, and constant high quality. This is exactly our strength - which is based on state-of-the-art production equipment, quality assurance during production, and optimized processes!

Founded

1957

Employees

200 - 500

Certifications

Kohlberg

Germany - 72664

HKR GmbH & Co. KG The HKR GmbH & Co. KG is a subsidiary of Vaillant GmbH. This medium-sized companies went on 01 January 2006 from the previous profit center heating at the location Roding forth. The reliable service manager of the parent company also acts as a competent partner and supplier for external customers of the heating industry, automotive engineering, and for the sanitary sector. The 317 employees achieved a turnover of 52 million euros in fiscal 2007. Core competence is the development and production of components, gas and water leading assemblies and turning and forgings for the heating industry and the assembly of modules. The products are manufactured with an annual capacity of 8,000 tons per year, mainly made of brass but also made of steel and aluminum. WE PRODUCE SUCCESS! Experience the precision and the success with the products of HKR.Put your project with confidence in our hands. We support all around - from design, through production to installation. With over 40 years experience we can convince mainly in the following areas: · Production and development of components · Construction and installation of gas and water leading assemblies · Turning and forging production for heating · Assembly Your success is accurately measurable with us! WE QUALITY OF LIFE! We take responsibility! But we live in an integrated quality management system, which we constantly improve and control. In the production test systems integrated and systematic and methodological measures guarantee us to produce the highest standard. Quality means for us to deal responsibly with natural resources. Environmental protection and safeguarding the future are critical components of our quality management.As our customer you are in working with us, especially one who: Complete security, they have made us the right choice! Sustainable quality - piece by piece - sets us apart. For us, this also the appreciation and development of our employees. They turn us into what our customers expect from us, suppliers of living and quality of lived from production to assembly to delivery! WE MAKE THE POTENTIAL TO LIFE! Rigid routine is not us. We go off the front and living innovation through and through. Years of experience and the latest techniques to help us not to stop, but always think one step ahead for our customers. Sophisticated programs and structured processes enable a consistent production chain. Right from the start, we can rule out this way many sources of error. A direct access of the employees involved in each project can be short-term changes at any time, allowing the use of different concepts. We recognize your potential and develop together with you further. Experience completely new with HKR precision. We are your competent partner from the initial idea to the production stage!

Founded

1965

Employees

100 - 200

Certifications

Roding

Germany - 93426

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

QBER Srl, a consolidated company in the production of high quality mechanical parts. For over 50 years we have been working with important Italian and foreign companies that need reliable and serious partners, managing to guarantee them an excellent level of technological performance at low costs and fast delivery times. Our production is directed to the petrochemical, energy, automotive, pipe mills and wire technology sectors. The experience gained allows us to work different types of materials: steel, stainless steel, cast iron, non-ferrous materials and heat-resistant alloys. We also process materials for the production of tools such as hard metal and ceramics. A team that collaborates with commitment and a fleet of machines in continuous renewal and expansion are our response to the continuous challenges that the market offers us. From design to production, from outbound quality control to after-sales assistance. The entire production cycle takes place within our facility, which provides both single special mechanical processing and mass production.

Founded

Employees

5 - 10

Certifications

Mapello

Italy - 24030

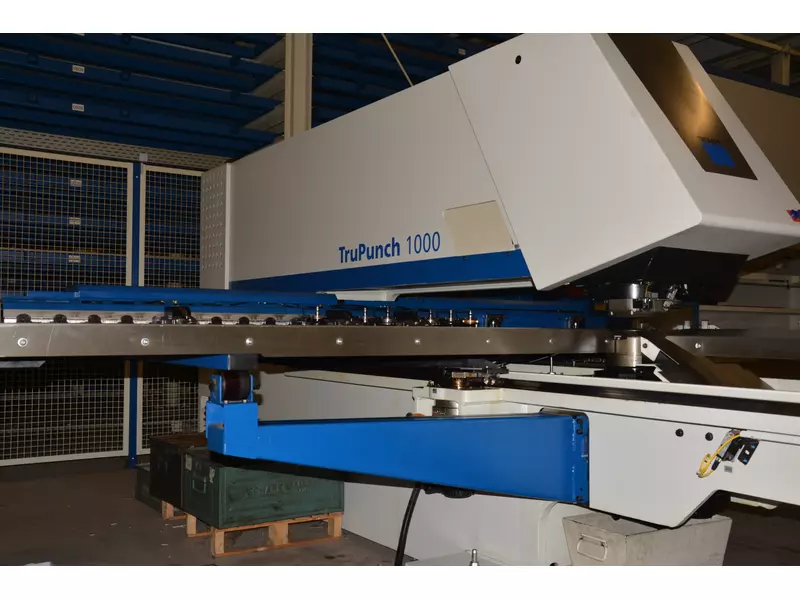

In 1877 the company was founded Uebele. Since then the company has grown steadily and today offers the complete program around the punching technique. We manufacture high sophisticated tools, high-precision fine blanked parts, stamping parts, bending parts, stamping and deep drawn parts and metal pressing parts. The assembly production and the production of small and large series are part of our extensive range of services. For our national and international customers, we manufacture complex parts on the following presses: - Deep drawing presses 400-4000 kN (table size up to: 2,000 x 1,300) - Automatic punching 400-6300 kN (table size up to: 3,000 x 1,500), - Fine blanking presses from 1,600 kN to 3,200 kN, - Pressing machine to Dm 900 x 5 mm - Press brakes up to 1,500 mm long Materials / Materials: Steel, stainless steel (1.4301 / 1.4571 / 4310, etc.) and non-ferrous metals such as aluminum, copper, bronze and brass, and substance capable plastics. Sheet thickness: 0.05 mm - 10.0 mm Coil: 300 mm x 10 mm and 1000 mm x 8 mm Product Line / products: Fastening systems for photovoltaic systems such as roof hooks, shielding, Cell connectors, mugs, fittings, spacers, flanges, housings, holders, sleeves, Contacts, discs, covers, clamps, braces, disc springs, angles and gears Toolmaking The following services offered by our professional expert toolmaking: - Project development to series production - Tool design - Prototype production - Construction of composite tools, drawing tools, stamping tools, bending tools, Fine-cut and cutting tools as well as devices Subsequent processing - Vibratory grinding, brush deburring, drums, tape loops with automatic feed - Heat treatment - all standard methods (inter-stage hardening, Nitriding, Hardening, and Nitrocarburizinga) Surface Finishing / Surface coating - Powder coating, KTL, painting - Electroplated coatings of Au to Zn / Ni (chrome plating, galvanizing, burnishing) Assembly production As a system supplier, we offer our customers from different industries all from a single source - from product development to the mounted assembly. - Inert gas welding (TIG / MIG / MAG) - Robot welding - Stud Welding - Spot and projection welding - Pressure joining (Clinching / clinching) - Riveting, caulking, gluing

Founded

1877

Employees

50 - 100

Certifications

Göppingen

Germany - 73037

The beginnings of the company reach back to 2015, when we started our operation as a part-time sole proprietorship – turning on a CVC lathe. In 2016, we moved from a part-time sole proprietorship to a limited liability company – GANTAR OBDELAVA KOVIN D.O.O. and with perseverance, we succeeded in buying our first machine at the beginning of 2017 and since then, due to sheer willpower, we have managed to grow our machine park to its current size. 5× CNC lathe 1× milling centre 1× bandsaw for serial cutting of individual pieces 1× bandsaw for cutting of unique pieces At GANTAR obdelava kovin d.o.o., we mainly perform turning on CNC lathes and processing on a CNC milling centre. We process individual pieces as well as larger series, depending on the customer requirements. We achieve customer satisfaction with the high quality of our products and punctual delivery dates.

Founded

2015

Employees

5 - 10

Certifications

Idrija

Slovenia - 5280

SPANPOWER CNC Precision Parts is the manufacturing specialist for high-quality CNC-manufactured components and assemblies. With our modern machinery, we produce prototypes and series. Our services include CNC turning and milling and wire EDM. Customer-specific surface treatments and module assembly round off our manufacturing options. Our customers come from the fields of plant engineering, mechanical engineering, optics, automotive and aerospace.

Founded

2024

Employees

10 - 20

Certifications

Rednitzhembach

Germany - 91126

We, Metallbau Schmalenbach, specialize in manufacturing a wide variety of high-quality and tasteful stainless steel and corten steel accessories. Years of experience in working with metal products, experienced know-how and the gift for exceptional design give our products uniqueness. The focus is on narrowing down to the essentials. In a charmingly flooded world, peace and relaxation are important to us. Simplicity is the goal and with it the uniqueness of our products. In addition to our wide range of products, we also offer you the opportunity to have your ideas implemented. We offer you custom-made custom-made products. You are welcome to visit us at Linienstr.14 in 42289 Wuppertal.

Founded

2022

Employees

5 - 10

Certifications

Wuppertal

Germany - 42289

Our domain is the field of laser cutting, punching, bending and welding. We own a wide range of modern technologies, thanks to which we process various types of materials (sheet metal, stainless steel, aluminum, brass, copper, plastic...), various types of materials (boards, pipes, profiles, moldings...) in various thicknesses. and dimensions.

Founded

1995

Employees

100 - 200

Certifications

Sazovice

Czech Republic - 76301

As a manufacturer of metal laboratory instruments, we manufacture most parts for our components in-house. We also accept external orders for our lathes. In addition, we can manufacture components on customer request and assist with development tasks.

Founded

1872

Employees

10 - 20

Certifications

Radevormwald

Germany - 42477

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

The Anant GmbH is a marketing subsidiary for own products & representation for few well-selected Indian manufacturing units. We have a good knowledge + experience for quality systems & supervised manufacturing outsourcing from India. Our German representation offers a potential to take up a responsibility to supply the article as door delivered & being your contact/contract partner. whereas our Indian technical team offers possibly of economical in-house manufacturing as well as local outsourcing under our supervision & our own quality control. At Patel Technomation - India, We have the experience and capability of sub-contract CNC machining including supply/procuring of foundry and forging products in small batches as well in large quantity. We follow the TÜV SÜD ISO 9001-2000 quality system and are dedicated to providing excellent customer service, and the timely delivery of quality products. Our Manufacturing unit is located at major Auto-parts manufacturing, Casting, Forging & engineering hub in India; which offers us a good development possibility for any specific/special part manufacturing possibility in a most economical manner.

Founded

2006

Employees

200 - 500

Certifications

Oberschleissheim

Germany - 85764

With over 50 years of experience, we are one of the most innovative and modern companies in the field of precision technology. We have achieved international series prices through automation and robotic assembly. Our ultra-modern machinery enables the production of custom-made products, prototypes as well as small, medium and large series. Well-known companies from the semiconductor, optics, medical and aviation industries already rely on our quality.

Founded

2024

Employees

20 - 50

Certifications

Kufstein

Austria - 6330

LINHARDT toolmaking, come to us - whether with data, a sketch, a technical drawing, a picture or a workpiece. We help you! Milling / turning / eroding / grinding / assembly

Founded

1943

Employees

50 - 100

Certifications

Geiersthal

Germany - 94244

Our main profile is the production of high quality (DIN Q3) gears of small quantity and high precision. Noise measuring gears, master gears, gearbox prototypes, non standard gears, marine industry gears (beveloid type), We grind gears up to 1000mm diameter and 14 modul, width 650mm with any modification in the profile and leed. Last year we have developed a method for internal theeth grinding with any modification. The size for this is max diameter 400mm, the quality is DIN Q4.

Founded

1983

Employees

10 - 20

Certifications

Budapest

Hungary - 1116

Welcome We see ourselves as an average modern operating company, based in Istanbul. Our company is working successfully in different industries (mechanical engineering, textile machinery, medical instrument industry, automotive industry, construction industry, graphic and optical industry, etc.) whose requirements are as varied as your products. In our mechanical production, we offer you virtually all machining manufacturing processes. Drilling, turning, milling and external cylindrical grinding in conventional production, milling and turning on modern CNC machines. That is our guarantee for your series production. With us you always get a completely finished product. Whether small series or prototype, whether raw or finished coating, whether or Kuststoff steel - all orders we finished quickly, reliably and accurately measured. Take advantage of our many years of experience and learn in the following pages to know our wide program. We are happy to await your inquiries and would be pleased if we could count you among our satisfied customers and your company. We support each other. The quality of our work ensured the success of our company. "Everyone is for each model, with production processes, each of the customer of the neighbor." About us The company Integral Makina sees itself with its long-standing and qualified staff as a traditional but modern positioned and competitive manufacturer of components for the Maschienenbau, Textilmaschienen, Medical Instrument Industry, Mechanical biomedical sector, automotive industry, construction industry, graphic and optical industry, etc. The technological requirements are determined by modern CNC machining centers. As the material in addition to steel and cast iron, aluminum, plastic and stainless steel, etc. is processed. Through close cooperation with companies from the region, we are able to manufacture complementary areas, suchEtc. to use as sheet metal processing (laser cutting), Hardening, Surface Finishing, external and internal cylindrical grinding, surface grinding, welding, assembly in a variety of ways and included in our manufacturing facilities. Customer-oriented quality assurance and on-time delivery are our determined measure of performance.

Founded

2010

Employees

10 - 20

Certifications

Maltepe - İstanbul

Turkey - 34843

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge