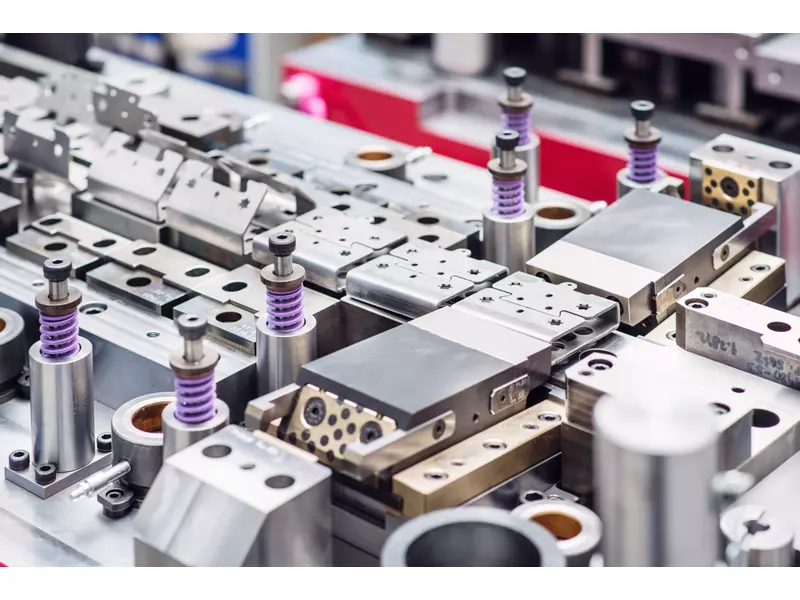

Mould construction: receive an avg. of 7 offers per request

Discover specialized suppliers for mold construction on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to manufacture precise and durable molds. Use the e-sourcing process to find suitable suppliers in real time.

984 suppliers for Mould construction

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

Inter Technic sro has developed in more than 5 years into a powerful company. If you are interested, we work for you as an extended workbench or can help reduce overcapacity, then ask us. In January 2015, our machinery was another new and powerful 5-axis simultaneous milling extended Hermle C42. We have currently in another, new DMG CNC milling machine invested. - Table load up to 2,000 kg - Table size 1700 x 750 mm - Travel X = 1450 mm, Y = 700 mm, Z = 550 mm This machine is our production in addition to available from the KW22 / 15th A robot welding system was installed. This brings us to weld able TIG and MAG. We are very well set up for you to produce tools and jigs. We are happy to customize items, zero series, production parts or assemble complete modules. With two new wire EDM machines we can in 2-shift operation for you. Our machinery has been almost entirely reinvested. For quality assurance, is from March 2016 new Zeiss measuring machine available! For programming we use two CAD CAM - Siemens NX Unigraphics, Version: 8.5 programming stations and enables us to offer services to the 3-D machining. Another added advantage of unsrem companies: All contacts at Inter Technic spoke German except Slovak, English.

Founded

2010

Employees

100 - 200

Certifications

Liptovsky Mikulas

Slovakia - 03101

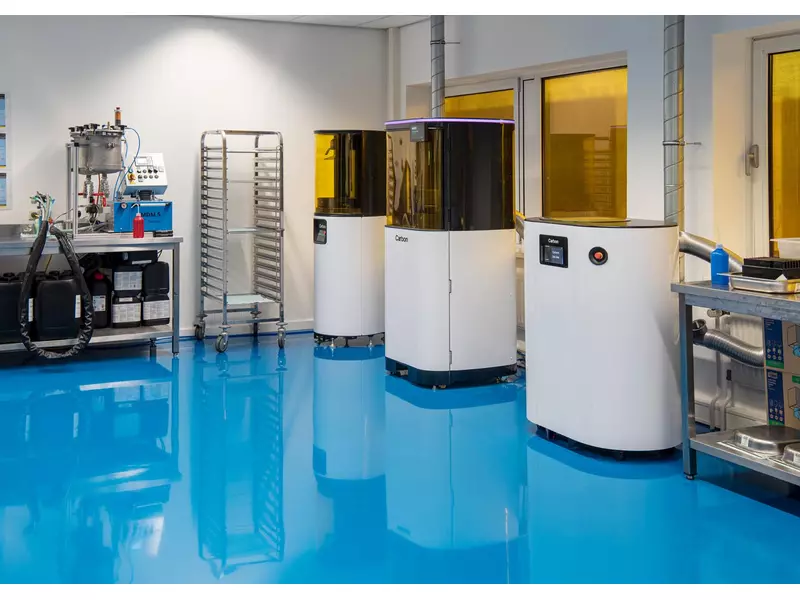

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

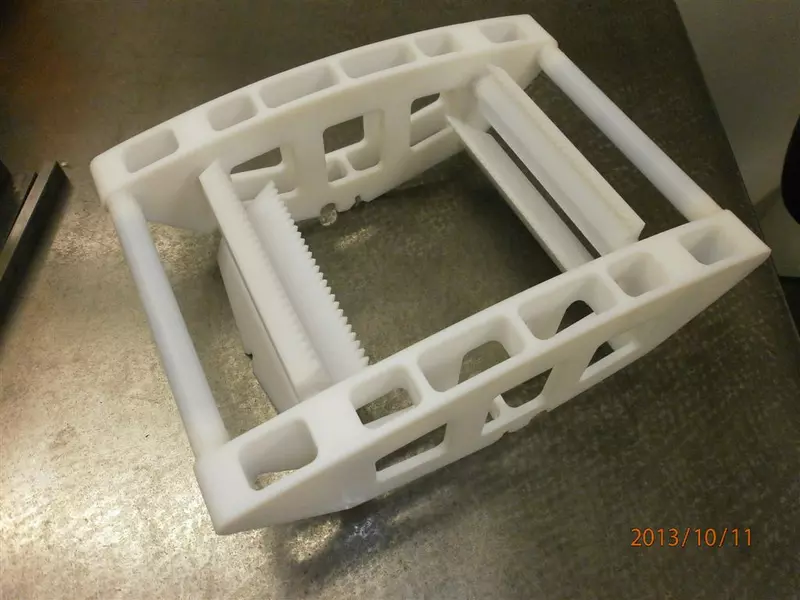

Company Profile Since 1991 Our family manufactures customized solutions made of plastic. In Gornau at Chemnitz today about 50 employees in the fields of semi-finished product processing, container and equipment construction, plant construction and cleanroom technology operate. Our solutions are used in industries such as machine and plant engineering, medical and environmental technology, the semiconductor industry and photovoltaics. The high quality of our products and services is evidenced by the certification of our company according to ISO 9001:2008. The internal design office as well as the technically and technologically advanced manufacturing guarantee our customers a comprehensive and high-quality advice and support. Involve us when planning your plastic just solution. Illustrate With our experience and the available CAD technology and we work out the best solution. We are happy to solve with our know-how your challenges. Products / Services Semi-finished processing Behälter-/Apparatebau Transparent Plastics Wasser-/Labortechnik Cleanroom technology Semiconductor engineering / photovoltaics Piping systems / special fittings Prototyping / Rapid Prototyping Machine technology With a well-equipped and very broad machinery, we can meet diverse customer needs. CNC lathe turning length up to 500 m 2 Milling Machine CNC 3-axis 1000 x 1300 x 160 Milling Machine CNC 3-axis 2300 x 1300 x 160 Milling Machine

Founded

2001

Employees

50 - 100

Certifications

Gornau

Germany - 09405

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Dear Ladies and Gentlemen, in this way we would like our service companies introducing we produce single pieces or small series, series, sub-assemblies, gauges, fixtures Tools, special machine parts for the Varied fields of application according to your Requirements, specifications, drawings. We can at reference customers from eg mechanical engineering, special engineering, medical, aircraft, automotive industry, tooling, etc. References. Our range of machines includes most modern technology currently available in these areas CNC milling, CNC turning, CNC surface grinding, CNC wire EDM, CNC sinker EDM CNC-Erodierbohren/Präzisionsbohrungen, CNC Ultra Sonic is offering. Thanks to this modern manufacturing equipment and years of experience and a team of employees profounded we are to be able almost all requirements in manufacturing technology needs. For more information about our machine park can be found on our website CNC milling, CNC turning, CNC surface grinding, CNC wire EDM, CNC sinker EDM CNC-Erodierbohren/Präzisionsbohrungen, CNC Ultrasonic www.KaPe-erodiertechnik.de

Founded

98

Employees

10 - 20

Certifications

Ostbevern

Germany - 48346

We enable you to focus on the essentials. The production of your parts and assemblies you provide to us, the Roeder GmbH & Co. KG is your competent partner for precision.

Founded

1999

Employees

10 - 20

Certifications

Biebergemünd

Germany - 63599

We are a medium-sized company in the field of metal processing. Our core competencies include the production of series parts and assemblies for industry and plant and mechanical engineering, in particular the food and beverage industry. For over 75 years, Lungmetall OHG has stood for efficiency, flexibility and competence in steel, stainless steel and aluminum. Whether individual or series production, with our modern machine park tailored to the requirements of our customers, we manufacture for you flexibly, inexpensively and quickly. We are lean enough to flexibly implement your ideas and wishes, but also large enough to provide you with the capacity you need, even for large series. Thanks to our high level of vertical integration, we appear on the market as a system supplier, as we are not dependent on other trades. This manifests itself in short delivery times and a high quality standard. With our currently 60 employees and our in-house design office, we offer you an extensive service portfolio and reliable processing of your orders! We would be happy to win you as a valued customer and assure you of a partnership and team-oriented cooperation.

Founded

1924

Employees

50 - 100

Certifications

Kottenheim

Germany - 56736

Machining, Milling, Turning, Mold Injection Design and Manufacturing, Engineer Designing, Precision Machining, SolidWorks design

Founded

2008

Employees

< 5

Certifications

Budapest

Hungary - 1045

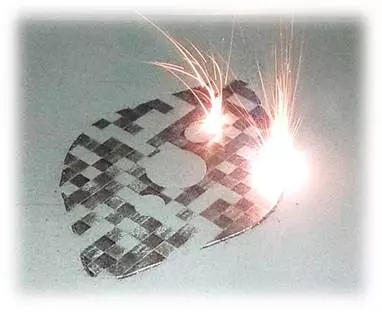

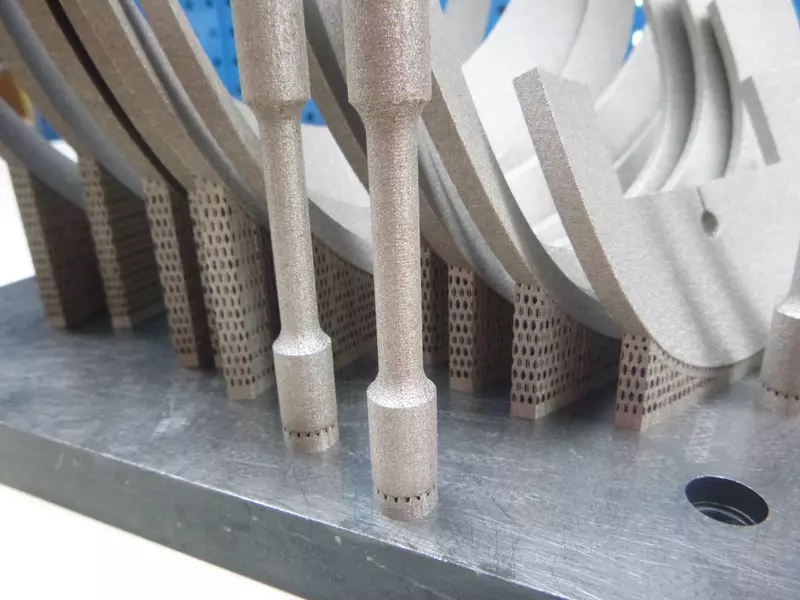

3D laser accompanies your ideas from prototypes to series if. In the design or production Project Management / Consulting - Consulting for the optimal manufacturing process of your components if sand casting, investment casting, metal laser melting, 3D plastic printing or from the full milling - Feasibility study for the respective process - Procurement of plastic parts in PA2200, PA3200GF, Alumide, DuraForm ® Flex - Procurement of castings (sand casting, investment casting) Construction - Component development of plastic, sand or die casting components - Prototype tools, special machine, fixture, equipment - FEM calculations - Deriving electrodes - Interpretation of contour-hugging cooling for mold - Optimize the components on the metal laser melting process Metall-Laserschmelzen/LaserCUSING ® / SLM - Production of functional prototypes - Production of mold inserts with conformal cooling

Founded

2011

Employees

5 - 10

Certifications

Kirchheim u. Teck

Germany - 73230

The company Fetec Engelhardt GmbH is a modern enterprise specializing in CNC milling and turning as well as the construction of complete functional units. For the 2D and 3D Complete machining of simple to extremely complex workpieces made of steel, stainless steel, aluminum, plastic, etc. we are the right partner for you. Even sophisticated operations such as the production of free-form surfaces, supported by a CAD-CAM programming system belong to our services. Business The company FETEC Engelhardt GmbH was established on 1 Founded in May 1997 in Ruhla / Thuringia as a civil law and on 1 July 2005 umformiert into a GmbH. Starting point of the company producing basic turning and milling parts, the one manufactured in order for suppliers to the automotive industry. With the move in January 2001 in a new building, the production of parts, prototypes, small batches in contract manufacturing as well as complete assemblies and devices has been made possible.The expansion of contract manufacturing required on 1 July 2006 another move to a larger and also its own production facility. The workforce of FETEC Engelhardt GmbH consists of seven employees and three apprentices. Managing directors are Gerald and Ursula Engelhardt. Products Because of our diverse experience in the field of metal machining, we are able to offer comprehensive services. These range from performing individual work steps bishin for assembly of complete functional units. Turn 1 Turning the conventional way ----- BRAND NEW ------- Lathe with bar feeder 3m to 32mm diameter x / y machining with driven tools * Between centers 1000mm x D 220mm * In feed D 300mm * From the rod D 47mm 2 CNC turning with counter-spindle, Y-axis and bar feeder * Maximum diameter D 100mm (45mmStange) * Maximum turning length D500mm Mill 1Milling in a conventional manner * X-, Y, - Z-direction 300 mm x 220 mm x 300 mm 2 CNC milling Maximum travel: * DMU 60T monoblock (five axes) / X 500 mm, 400 mm, Y-, Z-400mm * Hurco VMX 42t (3-axis) / X 1060mm Devices Production of complete functional units * Devices * Tools * Assembly workstations * Special Machines * Prototypes * Items * Small series * And much more

Founded

1997

Employees

10 - 20

Certifications

Ruhla

Germany - 99842

Our company was founded on 28.02.2005. It builds on the experiences that have been collected for years in the FIRE tool-und Maschinenbau GmbH in the field of stamping production. The acquisition of new hydraulic presses and the investment in a new Production facility enables us your client's wishes and not least Your product innovations enhanced implementation. We will advise you in the choice of materials and develop with you a tool concept. This can be thanks to the close cooperation with the FIRE tool and Maschinenbau GmbH are implemented quickly and effectively. Production of stamped parts Stampings band Stamping parts with thread Pressed, stamped and drawn parts connected tooling with 35 employees since 1992 CNC milling 3/5-Achs CAD CAM CNC turning CNC Wire EDM CNC sinker EDM List of machines We can customize your stampings on the following machines: Belt systems - 600mm width 8mm tape cross-section Eccentric EBU 1000 KN 80Hub/min Eccentric PME 2000 CN 80Hub/min Eccentric EBU 2000 CN 80Hub/min Eccentric PME 3150 CN 60Hub/min Insert presses: Eccentric Helmerding 850KN 60Hub/min Hydraulic press 250 kN 2x Hydraulic Press 400-630

Founded

2005/1992

Employees

10 - 20

Certifications

Oederan

Germany - 09569

Since 1986 we have been working as injection molding manufacturers serving a variety of local and international companies which operate in various fields and need molds either for big productions and limited edition products. What we do is easily explained. We design, manufacture and supply injection molds for the production of high-precision thermoplastic parts with exceptional aesthetic demands. We are specialized in the production of high-precision technical parts and multiple-impression molds for high production requirements, but we also supply prototypes and pilot molds for small and medium series that requires complex and intricate geometries – for instance, for limited editions. The headquarters are located in the Italian city of Rovereto, just 30 km from Trento, on the Brenner motorway link. This is the ideal crossroads between the major industrial districts in Northern Italy, such as the manufacturing (Lombardy, Vicenza) and optical (Belluno) ones, and important European countries such as Austria, Germany and Switzerland. However, there is more. We also work with factories based in the US and in the rest of the world. The know-how we developed over the years of experience in the field allows us to identify the most suitable kinds of injection molds on the base of your production types and aesthetic needs.

Founded

1986

Employees

20 - 50

Certifications

Rovereto

Italy - 38068

VS steel GmbH has been active in the domestic market since 2012. Our core competencies are in the field of metalworking and toolmaking. Since the founding of the company we are constantly developing and expanding. We are constantly working on improving our production processes, increasing the production area and investing in state-of-the-art production technologies. With us you get from prototypes to small series up to long-term serial deliveries. The company caters to all its customers, whether they are individuals, craft businesses or well-known clients in the automotive sector. Your satisfaction is our goal. Reliability, precision and high quality are our top priority. We have many years of experience in the automotive industry, which enables us to put our customers' orders into practice using state-of-the-art technologies. Thanks to our many years of experience, we are able to develop unique solutions for the customer according to their requirements. We accompany you from the primary idea to the final product. For reference, we refer to Skoda Auto AG. We are one of two companies that provides tooling services for the production of stamping tools for new models for Skoda Auto AG.

Founded

2012

Employees

20 - 50

Certifications

Prag

Czech Republic - 10000

msf-Reichert GmbH from Bissingen an der Teck is a family-run master company specializing in the CNC production of high-quality 5-axis milled parts. We have many years of experience when it comes to CNC milling and work for customers – demanding companies in the automotive, mechanical engineering, mold making, fixture construction and medical technology sectors – in the region and throughout Germany.

Founded

2010

Employees

5 - 10

Certifications

Bissingen Teck

Germany - 73266

Company ZUT "PROJEKT" offers services in: Processing of metal - milling, turning, Inen and outer grinding, Surface grinding, cutting, welding - steel, aluminum, stainless steel, Engineering, manufacturing spare parts and machine elements We offer: - Turning - Automatic turning (bar) - Hard roes - Milling - .... etc.

Founded

1991

Employees

10 - 20

Certifications

Konarzewo

Poland - 62-070

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

With our experience in various casting techniques and finishing processes of various casting, we have been active in the market for more than 40 years. We support and relieve our customers and offer the possibility to deliver a complete product, from processing to after-treatment. Our mission We focus on designing, manufacturing and delivering a total package of products. You can call on us for small and large work, but you can also use a certain processing or finishing process for your products. We are happy to be your adviser and partner for all your castings, whether it is a single piece of product or a larger series of products. We cast, melt, rotate milling, assemble and construct your product exactly as you wish. We place high demands on our quality. With us, a product does not leave the warehouse until it meets all the requirements regarding the mechanical properties and conditions. That way you can be sure that you will receive the highest quality at a competitive price.

Founded

2018

Employees

50 - 100

Certifications

Doetinchem

Netherlands - 7002CA

SINCE 2009 .... The company was founded in 2009 by Mrs. Bettina Landgraf-Kaiser, storage capacity today is about 3000 m² in three halls. As a leading warehouse distributors constantly about 100 cars and well-preserved machines of best brands offered. State of the art warehouses with crane capacity up to 10 tons and forklift capacities up to 7 and highly trained staff are the benefits for potential customers to find the "perfect machine". Complete "all-inclusive" packages (eg transport, introduction, installation Complete training) are developed and implemented according to your. MEMBER OF: Since 2009 FDM - Germany Since 2009 EAMTM - Brussels (International) SPECIALITY: Cutting metal-working machines Our specialty is the trade used machines from metal cutting. Whether conventional or CNC - controlled, we each offer the right machine for you.In CNC - area we act almost exclusively with the control type Fanuc & Heidenhain. Here we can give you the best - provide service, whether coverage with qualified staff, service staff or software solutions. OTHER: Furthermore, even spare parts - remakes produced directly in the house with us. Through years of experience of our employees in the cutting process on Fanuc & Heidenhain controls, we can therefore offer cost effective replacement parts alternatives you.

Founded

2009

Employees

5 - 10

Certifications

Bruchsal-Büchenau

Germany - 76646

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

we are a young and dynamic company. our company was founded and collaborates with a company with over 30 years of experience in the mechanical processing sector and in the construction of molds for the injection of plastic materials.

Founded

Employees

5 - 10

Certifications

Gradiska

Bosnia & Herzegovina - 78400

Company with over 60 years of history in hot forging. It currently has 5+1 forging lines. The production departments are mainly these: 1 - steel warehouse 2 - cutting department 3 - DIES construction and assembly tooling 4 - hot forging steel 5 - heat treatment 6 - warehouse and shipping Other important departments : - Quality department - Technical Office - Work shop - Maintenance department.

Founded

1960

Employees

100 - 200

Certifications

SUMIRAGO

Italy - 21040

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge