Find suppliers for fineblanking tools

Find specialized suppliers for fineblanking tools on Techpilot. Our platform offers access to suppliers who use advanced technologies to manufacture precise tools for fineblanking processes. Benefit from comprehensive market transparency and efficient supplier search.

208 suppliers for Fineblanking tools

About us Kreutz & Mock is a medium-sized company and the leading manufacturers of wire bending parts of all types. With over 3000 different articles we can offer our customers a wide and diverse range of different wire products. The necessary machines for the production are developed and built in-house by our own engineering department which gives us the possibility to always be flexible according to our customer's needs. You can find further details about us and our philosophy on our website. Products We manufacture wire bending parts in all sorts of variations and models. We supply many industries with our products like the automotive industry, construction industry, agriculture, blinds manufacturers and many more. We also have numerous technical bent parts in our repertoire. We are happy to try to achieve your specific needs and requirements, because quality, punctuality and being in step with actual practice are our basic principles to deliver high quality as well as best functionality products. It does not matter whether they are single quantities, small quantities or a large series. We are flexible and deliver quality at fair conditions. We offer + Qualitycertficate DIN ISO 9001:2008 + in-house specified tool construction + in-house machinery construction + quick production of samples + technical and experienced know how + skilled telephone service + large production spectrum Materials Every material processed in our factory has a dedicated inspection certificate that will be provided with your delivery on request. We manufacture bent wire components for you in all variants and materials. Here a selection of the materials used: + Stainless steel wire 1.4301, 1.4310, 1.4362, 1.4401, 1.4404, 1.4571 in different tensile strengths + Spring steel wire 0.9 mm to 6.0 mm. Qualities A, B, C, D + Steel wire C9D bare or copper-plated. C9D soft galvanised in 1.0 mm to 8.0 mm + Crapal wire + Becrosi valve spring wire + Silver and Palladium wire

Founded

1934

Employees

20 - 50

Certifications

Neuendorf

Germany - 97788

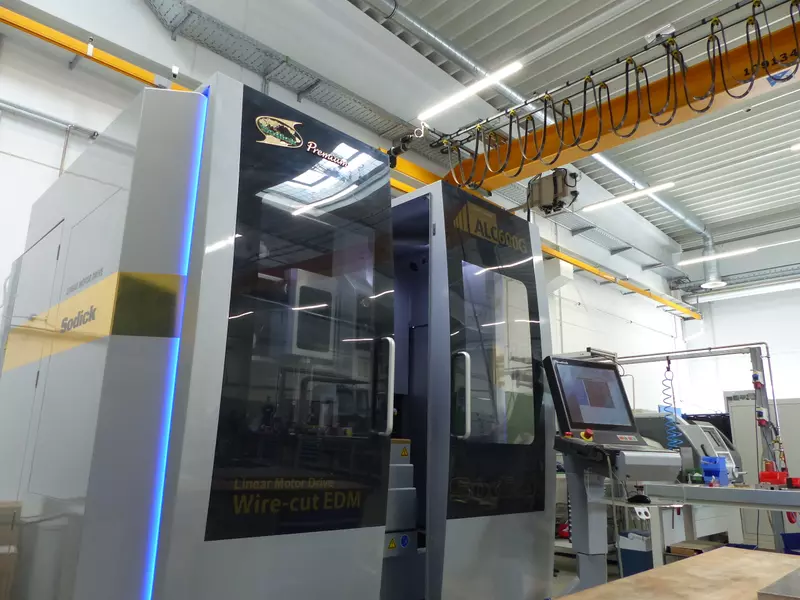

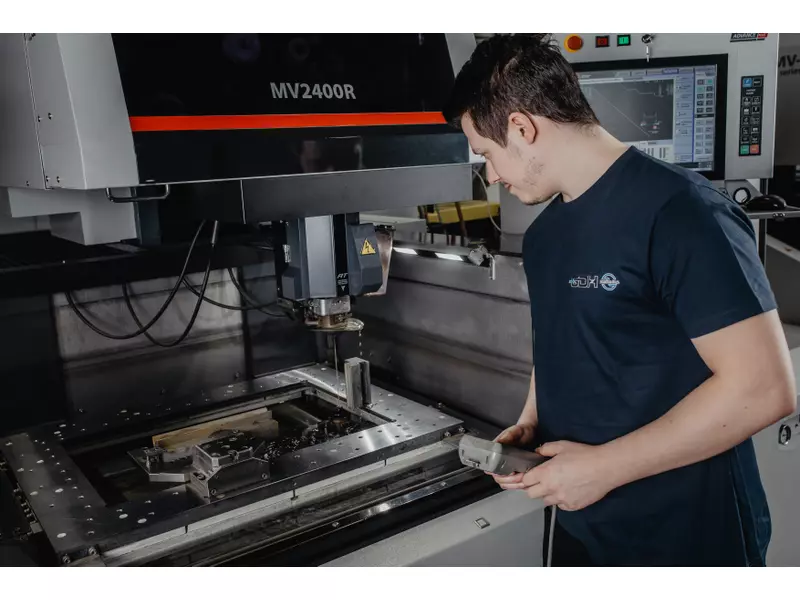

Our company was founded on 28.02.2005. It builds on the experiences that have been collected for years in the FIRE tool-und Maschinenbau GmbH in the field of stamping production. The acquisition of new hydraulic presses and the investment in a new Production facility enables us your client's wishes and not least Your product innovations enhanced implementation. We will advise you in the choice of materials and develop with you a tool concept. This can be thanks to the close cooperation with the FIRE tool and Maschinenbau GmbH are implemented quickly and effectively. Production of stamped parts Stampings band Stamping parts with thread Pressed, stamped and drawn parts connected tooling with 35 employees since 1992 CNC milling 3/5-Achs CAD CAM CNC turning CNC Wire EDM CNC sinker EDM List of machines We can customize your stampings on the following machines: Belt systems - 600mm width 8mm tape cross-section Eccentric EBU 1000 KN 80Hub/min Eccentric PME 2000 CN 80Hub/min Eccentric EBU 2000 CN 80Hub/min Eccentric PME 3150 CN 60Hub/min Insert presses: Eccentric Helmerding 850KN 60Hub/min Hydraulic press 250 kN 2x Hydraulic Press 400-630

Founded

2005/1992

Employees

10 - 20

Certifications

Oederan

Germany - 09569

Wirths & Werres GmbH is your partner for: Special machine construction, spindle lift gears, tool making, machine knives and series production

Founded

Employees

10 - 20

Certifications

Wuppertal

Germany - 42349

VS steel GmbH has been active in the domestic market since 2012. Our core competencies are in the field of metalworking and toolmaking. Since the founding of the company we are constantly developing and expanding. We are constantly working on improving our production processes, increasing the production area and investing in state-of-the-art production technologies. With us you get from prototypes to small series up to long-term serial deliveries. The company caters to all its customers, whether they are individuals, craft businesses or well-known clients in the automotive sector. Your satisfaction is our goal. Reliability, precision and high quality are our top priority. We have many years of experience in the automotive industry, which enables us to put our customers' orders into practice using state-of-the-art technologies. Thanks to our many years of experience, we are able to develop unique solutions for the customer according to their requirements. We accompany you from the primary idea to the final product. For reference, we refer to Skoda Auto AG. We are one of two companies that provides tooling services for the production of stamping tools for new models for Skoda Auto AG.

Founded

2012

Employees

20 - 50

Certifications

Prag

Czech Republic - 10000

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

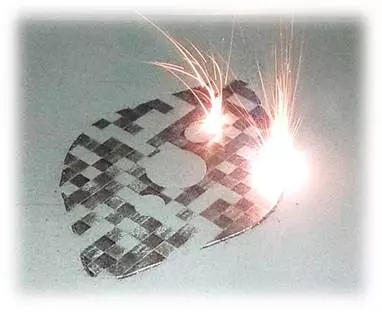

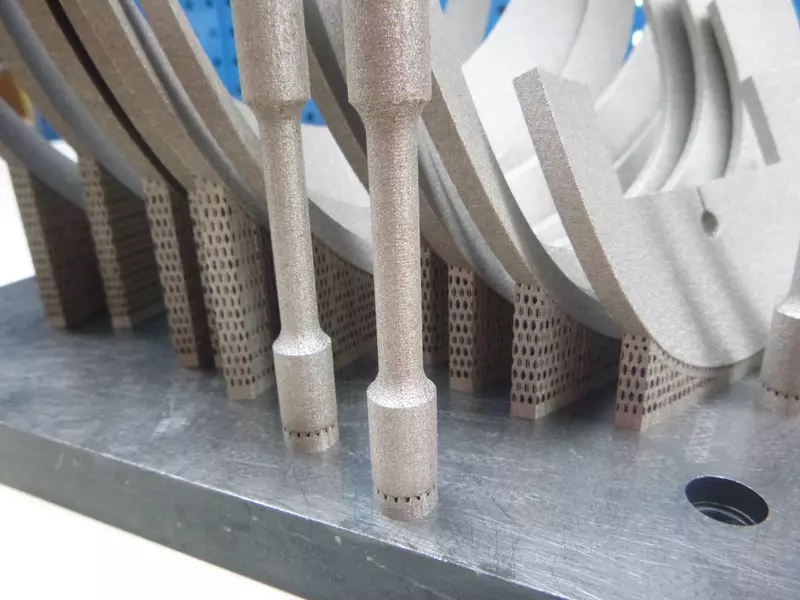

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

As a system supplier for electromechanical assemblies, we manufacture plastic and metal components using hybrid technology. This means that we concentrate on the production technologies of plastic injection moulding and punching and bending of metal components. The advantage for you is that you can obtain ready-assembled assemblies of the most diverse production processes from one source. By moving Friedrich Joerg GmbH in 2016 to newly built production and office premises, we were able to create a capacitive buffer. Thanks to a high degree of automation, we can offer you particularly competitive prices. We manufacture manually in small series up to large series fully automated and pre-assemble all components for you. In short, we adapt flexibly to your requirements. We provide support as early as the product development stage in order to take into account quality, cost and tool-specific aspects in the early phase. We manufacture the necessary tools or devices in our own tool shop. This also allows us to increase our flexibility, for example in case of short-term changes. Furthermore, we also offer finishing processes such as: printing on plastic parts (cliché/pad printing), hot foil stamping for a particularly noble appearance of the products, machining and ultrasonic welding. It goes without saying that we are certified according to ISO 9001:2015 and deliver a very high and consistent quality. We would be pleased if you contact us. categories: Electromechanical assemblies; Foil hot stamping; Customised plastic mouldings; Plastic optical fibres; Optical fibre components; Optical fibre systems; Optical fibre technology; Optical fibre transmission systems; Pre-assembly Assembly of small parts for industry; Assembly of plastic components; Assembly of mechanical components; Stamp-bending parts made of stainless steel, non-ferrous metal, steel; Stamp-bending tools; Connectors; Connectors for surface mounting; Complete plug connections; Pad printing; Thermoplastic precision mouldings; Thermoplastic overmoulding with plastic; ultrasonic welding of plastics; overmoulding tools for insert parts; 3-D MID components; connecting terminals for power cables low voltage & high voltage; component assembly; die casting; mould making; housings for the electrical industry; terminals for electrical cables; plastic injection moulded parts; plastic injection moulded parts with metal insert; electrotechnical plastic parts; technical plastic parts; plastic processing; multi-component injection-moulded parts; plastic-injected metal parts; product development; prototype construction; terminal blocks; technical injection-moulded parts; thermoplastic elastomer (TPE) moulded parts; jig and fixture construction; toolmaking; two-component injection-moulded parts; Imprint: https://www.friedrich-joerg.com/kontakt/impressum/ Privacy policy: https://www.friedrich-joerg.com/kontakt/datenschutzerklaerung/

Founded

1920

Employees

50 - 100

Certifications

Marktrodach

Germany - 96364

Founding of the company 2002 First commercial premises in Lovrenc na Dravskem polje Experiences mean the future We work with 15 years of experience and are constantly investing in new technologies. We manufacture high-quality and sophisticated machine parts and offer a complete service.

Founded

2002

Employees

5 - 10

Certifications

Kidričevo

Slovenia - 2325

TROB Tröstler & Oberbauer GmbH

PRECISION COMPONENTS FOR SONDERMASCHINENBAU Spectrum: wear and replacement tools, cutting, bending, crimping, anvil, embossing and drawing tools. Management and feed rails and all other parts that may be in the range of tolerance to UNDER 0.005 mm. SPECIAL TOOLS FOR PRECISION MASS PARTS MANUFACTURER Range: indoor and outdoor round mold steels, Flachformmeissel, shape inserts, Abstechklingen, flanging, roll forming, punch and matrices. MANUFACTURING SECTORS IN PRECISION MACHINING CNC Flat, round and Optical profile grinding, full-cut grinding, wire and sinker EDM, milling and turning machining centers. CNC 3D measuring and CNC Optical fairs. Materials: carbide, ceramic, HSS, titanium, PM and VA-steels, aluminum.

Founded

1984

Employees

20 - 50

Certifications

Rohrbach

Germany - 85296

Tools of GDH Need smart tool solutions or the realization of complicated processing problems? From planning and design through the development of the individual components to the construction of the finished tool: GDH is in the design and manufacture of tools for sheet metal processing since 1992 competent partner. Our strengths are our deep-drawing tools especially when multiple trains are required. Tools we manufacture as an insert, consequential, Progressive and transfer dies, both for prototypes, as well as for series production up to a maximum weight of 10 tons. Deep-drawn parts of GDH We manufacture drawn parts made of all metal forming materials to be processed. Materials such as steel, stainless steel and nonferrous metals are brought with us into the right shape. The processing at a material thickness of 0.3 mm - 10 mm thickness up to a pressure of 800 tons possible. We manufacture according to your drawings, CAD data, and according to your samples.Their tools are taken or produced in-house. In addition, we offer the possibility of deep drawing simulation with single trains in our house. Pressed parts of GDH With us you get spun parts from all metal forming materials to be processed. Materials such as copper, brass, steel, aluminum, stainless steel, tin, and zinc are staying with us in the right shape. Rotationally symmetrical workpieces are to oä to a round plate size of 800 mm in diameter with an initial sheet thickness of 6 mm in St, 4 mm in VA, 8 mm in CU / CnZu. and 10 mm in Al manufactured as pressed parts. We manufacture according to your drawings, CAD data, and according to your samples. Their tools are taken or produced in-house. Laser Technology at GDH Lasers: We laser in 2D technology in possible sizes 3000 x 1500 mm. maximum thickness * In VA to 12 mm * St to 20 mm * Al to 6 mm In 3D technology routes of sizes 3200 x 1525 x 600 mm are possible. Maximum thickness here * In VA to 4 mm * St to 8 mm * Al to 3 mm Punch Technology GDH Punching: Up to a print capacity of 120 tons from the tape. Up to 800 tonnes in the insertion process.

Founded

1992

Employees

100 - 200

Certifications

Bad Marienberg

Germany - 56470

Features Quality Management zertfiziert according to ISO / TS 16949:2002 including ISO 9001:2000 Measurement: Zeiss CNC 3D coordinate measuring machine, Mitutoyo 2D metrology Production range: Stamped, pressed and drawn parts, assembly, welding joints, joints Materials: Varieties: steel, stainless steel, aluminum, brass Dimensions: Coil: Bandwidth up to 800mm - strap thickness up to 6mm - Weight 5.000kg to Customers: Automotive, electrical, construction, camping and leisure industry, child safety Machine types: Stamping presses, eccentric presses, hydraulic presses, Orbital, MAG-welding robots, press welding machines, stud welding machines Dimensions: Punching machines: 40 - 400 tonnes Eccentric: 10 - 160t Hydraulic Presses: 40 - 160to Own tool: Wire EDM, sinker EDM, CNC milling, drilling, grinding Development and design: CAD - CAM System VISI-CAD Interfaces: DXF, IGES, VDA, CATIA V4, Parasolid Data exchange: E-mail, Odette

Founded

1956

Employees

20 - 50

Certifications

Lennestadt

Germany - 57368

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

HELLO WE ARE A COMPANY THAT HAS SET OUT TO SERVE OUR CUSTOMERS AROUND THE WORLD WITH OUR 15 YEARS OF EXPERIENCE IN OUR BUSINESS LIFE AND TRIES TO COMBINE THIS SERVICE WITH THE HIGHEST LEVEL OF QUALITY, TIMELY DELIVERY AND REASONABLE PRICE POLICY. OUR GOAL IS ALWAYS TO REACH BETTER QUALITY

Founded

2023

Employees

5 - 10

Certifications

İstanbul / Tuzla

Turkey - 34940

Precision rotary parts, - milling and ground parts (Ground parts) - Transmission shafts (drive shafts) to 1500 mm, hollow shafts, rotor shafts - Flanges (Intermediate), bolts, fittings, machine components - Cells wheels, worm shafts, knife shafts. - Guide rails, shaped pillars Machine Knives Knives industrial Press Brake - Perforating, squeezing knives, shear blades, packaging knives. Knives for plastics industry, mill knives, textile knives, sheeter knives, crush cutter, foil knife, knives, tungsten carbide blades, serrated blades, welded-on blades, slitter knives, Plotter and other machinery knives. Circular knife round knife Circle diameter (round blade) are rotating tools that can be (with counter-blade) was used with a knife cut or shear cut method. Circle diameter (round blade) can be produced for different applications from different materials (stainless steel, tool steel, HSS or stainless steel).The particular design can customized (eg ground on both sides, toothed, 2-wading, etc.). There arise because different names such as, crush cutter, top cutter, bottom cutter, pen-knife, plate diameter, perforating circular knives, rotor diameter, roller blades, etc. In addition, we also manufacture the knife holder and knife shafts and induviduelle cutting devices. The regrinding of circular knives is almost always worthwhile. Punching tools Punching diameter: Punching knife and cutting die are made from solid steel (eg tool steel 1.2379). The blades are hardened and ground. Punching blade made of solid material, are especially suitable for punching work with very precise contours as well as for long-term use, as they can be reground. Made of solid steel, we can also very small and precise punching knife and punching iron manufacture (eg samples dancing). Dies: We manufacture cutting knife and cutting dies from hardened steel strip and for a variety of punching tasks.Depending on the application, band knife made of spring steel, carbon steel, tool steel, stainless steel. Compared with the cutting knives made of solid steel, they are affordable and are suitable especially for disposable knives as well as large punch surfaces. We have stamping tools for individual tasks. - Cutting die, die cutting knife, cutting knife for test specimens, punches, punching, stamping dies, Steel rule dies, punches, - Cutting rollers, cutting mills, crushing blade - Punches and dies, punches, forming punches Flat - and cylindrical grinding - Surface grinding, surface grinding up to 3000 mm length - Cylindrical grinding up to 400 mm diameter - Fine grinding, lapping, polishing - Carbide Grinding Roll manufacturing roll grinding and - Rolls, roll cores, drive rollers, winding rollers, form rollers, fluted rollers Nippers, the cutting rollers, roll forming, turning rolls

Founded

Employees

Certifications

Schenefeld (bei Hamburg)

Germany - 22869

Our company since its founding in 1780 to the processing of metal and has successfully specialized in the course of the last century, among other things stamping and wire bending technology. Technical possibilities Stamping: punching machines from 40 to 400 tons of pressure all material qualities: bright, galvanized, aluminum, brass and stainless steel, from 0.5 mm to 5 mm plate widths from 20 mm to 450 mm component connections in the tool (metal and plastic) sequence editing and Follow-on composite tools finished catching products surface treatment Wire bending technology: different wire bending machines wire thicknesses of 2 mm to 10 mm processing of bare, galvanized, stainless steel and aluminum wires finishing operations: * Welding, chamfering, recesses, threads * Cutting, drilling, crushing, etc. component connections (metal and plastic) surface treatment FOX is already active internationally and seeks to improve its national and international presence and continues to edit about potential promising Neumärkte / Neubranchen intense.

Founded

1780

Employees

50 - 100

Certifications

Ybbsitz

Austria - 3341

We have been manufacturing high-quality precision parts, cable assemblies, stamping and pressing of plastic since 1990 Materials: steel, stainless steel, aluminum, brass, bronze, copper, plastics Flexibility and reliability form the basis of our actions.

Founded

1990

Employees

> 1000

Certifications

Náchod

Czech Republic - 547 01

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our customers are offered everything they need within our group of companies, all in one basket: from development and project management via the production of tools for plastic and metal fabrication, through to manufacturing the parts. In this way we closely co-operate with our customers in developing functional structural plastic and metal components on the basis of the design, thereby achieving an optimum combination between plan, design, manufacture, and cost structure. The integrated possibilities have enabled us substantially to shorten the project run up to the point of series production. The systems Pro-engineer and Catia, available to our staff, permit the creation of structural components and tools, "in one casting" as it were. Injection Moulds Our staff in the individual manufacturing areas have state-of-the-art technologies and most up-to-date machines (such as 12-wire and 15-wire cavity sinking EDM machines) at their disposal. In producing moulds with a guaranteed number of shots, especially for the automobile industry and consumer electronics, our dictum is precision and quality. This holds true for injection moulds, diecasting, duroplastic, two-component, rotating, transfer and insert/outsert moulds, just as much as it does for two-colour moulds, combinations of hard and soft plastics, automatic wire leads, in-mould decoration, and precision gear wheels. Rapid tooling with the aid of our EOS metal sintering machine M250 Extended makes it possible to produce mould inserts for injection moulds and prototype tools within a very short time. Eighty moulding machines in Vienna and Hungary, with a clamping force of between 25 and 1,100 tons, offer all the possibilities of manufacturing moulded, thermosetting and duroplast, gas-injection moulded, two-component moulded, insert and outsert moulded, as well as in-mould decoration parts. Our machines are equipped with automatic robot systems, and automatic packaging lines complement the production line. Vienna: 3-shift operation / technical products and precision parts with a mould clamping force of up to 500 tons, Hungary: 4-shift operation / technical products and design parts with a mould clamping force of up to 1,100 tons. Your plastic parts are coated in three fully automated painting lines on a water-soluble basis (single-component or two-component coating). Your metal parts are electrostatically painted, from the smallest parts up to housing coatings for consumer electronics.

Founded

1966

Employees

100 - 200

Certifications

Wien

Austria - 1230

In 1877 the company was founded Uebele. Since then the company has grown steadily and today offers the complete program around the punching technique. We manufacture high sophisticated tools, high-precision fine blanked parts, stamping parts, bending parts, stamping and deep drawn parts and metal pressing parts. The assembly production and the production of small and large series are part of our extensive range of services. For our national and international customers, we manufacture complex parts on the following presses: - Deep drawing presses 400-4000 kN (table size up to: 2,000 x 1,300) - Automatic punching 400-6300 kN (table size up to: 3,000 x 1,500), - Fine blanking presses from 1,600 kN to 3,200 kN, - Pressing machine to Dm 900 x 5 mm - Press brakes up to 1,500 mm long Materials / Materials: Steel, stainless steel (1.4301 / 1.4571 / 4310, etc.) and non-ferrous metals such as aluminum, copper, bronze and brass, and substance capable plastics. Sheet thickness: 0.05 mm - 10.0 mm Coil: 300 mm x 10 mm and 1000 mm x 8 mm Product Line / products: Fastening systems for photovoltaic systems such as roof hooks, shielding, Cell connectors, mugs, fittings, spacers, flanges, housings, holders, sleeves, Contacts, discs, covers, clamps, braces, disc springs, angles and gears Toolmaking The following services offered by our professional expert toolmaking: - Project development to series production - Tool design - Prototype production - Construction of composite tools, drawing tools, stamping tools, bending tools, Fine-cut and cutting tools as well as devices Subsequent processing - Vibratory grinding, brush deburring, drums, tape loops with automatic feed - Heat treatment - all standard methods (inter-stage hardening, Nitriding, Hardening, and Nitrocarburizinga) Surface Finishing / Surface coating - Powder coating, KTL, painting - Electroplated coatings of Au to Zn / Ni (chrome plating, galvanizing, burnishing) Assembly production As a system supplier, we offer our customers from different industries all from a single source - from product development to the mounted assembly. - Inert gas welding (TIG / MIG / MAG) - Robot welding - Stud Welding - Spot and projection welding - Pressure joining (Clinching / clinching) - Riveting, caulking, gluing

Founded

1877

Employees

50 - 100

Certifications

Göppingen

Germany - 73037

Stands for quality, precision and custom products and considers itself a service provider. From the initial contact through to the finished product We are your competent contact for: • Advice • Formulation of the concept • Design • Manufacture of the components ...sawing, turning, milling, hardening, heat treatment, surface and circular ...grinding, co-ordinate grinding, hard turning, 5-axis milling, HSC milling, ...eroding, laser cutting, water jet cutting, verified welding, surface treatment ...(bronzing, anodising, hard-coding, silver-plating, gold-plating, chemically ...nickel-plating) • Polishing, coating • Provision of outsourced parts: ...Electrical parts, standard parts, guide components, pneumatic parts and ...hydraulic parts • Installation work • Adjustment works • Test runs • Delivery with company vehicle or freight company and courier services.

Founded

2000

Employees

20 - 50

Certifications

Viereth-Trunstadt

Germany - 96191

We bring metal into shape! Your specialist for metalworking & production of complete assemblies About us: We face many different challenges every day. Our range of services ranges from classic sheet metal processing to the production of complex components and assemblies as well as the production of individual components. Custom-made products and individual solutions round off our capabilities. Whether you are a craftsman or a bulk buyer – thanks to our versatility, we are able to meet everything according to customer requirements.

Founded

1934

Employees

50 - 100

Certifications

Schopfloch

Germany - 91626

The Johann Kaifel tooling GmbH produces tools and stampings for all areas of industry and trade. Our customers include suppliers to the automotive industry, and manufacturers of lighting fixtures, electrical appliances, household appliances and cosmetics packaging. The company Johann Kaifel tooling GmbH currently employs 15 people, including 6 in parts production. Since October 2002 we produce in our newly built factory with over 1000 square meters of production area. Our strengths lie in the complete production of tools and standard parts with all related operations, such finished examine, refine and assemble. Overview of services 1 Toolmaking Manufacture of progressive dies, cutting, bending and stamping tools. It can be used the following manufacturing processes: wire EDM, sinker EDM, grinding, cylindrical grinding, CNC turning and CNC milling. 2 Stamping Production of stamped parts from all materials such as aluminum, brass, copper, stainless steel, PVC and much more, with all kinds of follow-up processing. (Thread cutting, surface finishes, spot welding up to a stamping pressure of 160 tons.)

Founded

1975

Employees

10 - 20

Certifications

Tittenkofen

Germany - 85447

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge