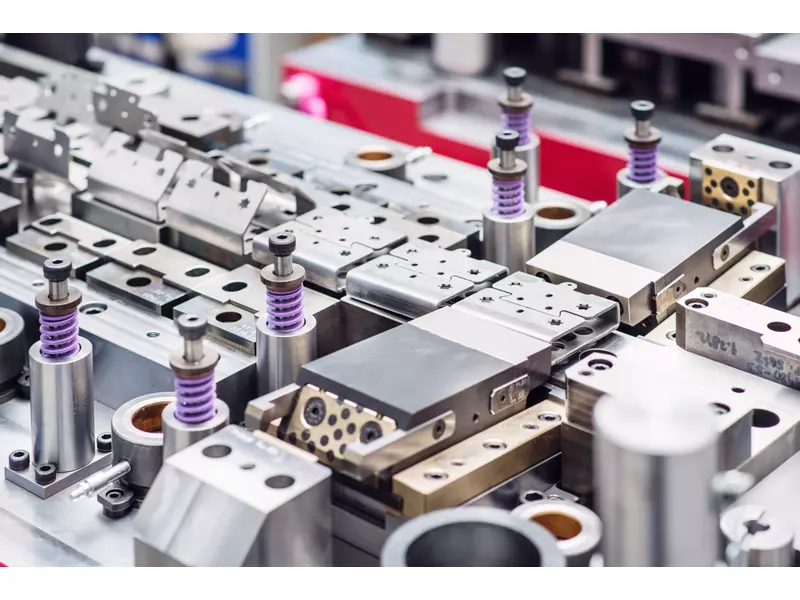

Tool making: find suitable suppliers nearby

Discover specialized suppliers for toolmaking on Techpilot. Our platform connects buyers with suppliers who manufacture high-quality tools for various industries. Use the e-sourcing process to find the best suppliers.

1376 suppliers for Tool making

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

WKK Kaltbrunn AG - enormously in form The beginning of the WKK Brunn AG is founded in 1967. As a dedicated tooling the company had at that time only one purpose: the production of cutting, bending and forming tools. Shortly thereafter, the fabrication shop was put into operation and some ten years later, the company introduced her first own product. By continuity, innovation and perfection was out of the formerly peaceful Toolmaking a successful SME with about 45 employees.Today, the CHP is an international punching operation with most modern manufacturing methods in the supplier sector. enormously complete - from the first idea to the final series, we offer comprehensive services - Consulting: individual and professional, on-site or at our - Construction: in-house with 3D Autodesk Inventor - Prototyping: short to illustrate your ideas - Tool: for punching tool and teaching building, with modern machinery - Series production: stamping products of all types up to 250 tons of pressure and up to 300 mm width at 3 mm thickness (up to 5 mm after consultation) made of steel, stainless steel, non-ferrous and light metals - Component manufacture: Total manufacturer of your products, automated assembly - Post-Processing: Heat and surface treatments for partners near - Finish machining: by machining (milling, turning, drilling), eroding and vibratory finishing - Did you know? Also welding

Founded

1967

Employees

20 - 50

Certifications

Kaltbrunn

Switzerland - CH-8722

Inter Technic sro has developed in more than 5 years into a powerful company. If you are interested, we work for you as an extended workbench or can help reduce overcapacity, then ask us. In January 2015, our machinery was another new and powerful 5-axis simultaneous milling extended Hermle C42. We have currently in another, new DMG CNC milling machine invested. - Table load up to 2,000 kg - Table size 1700 x 750 mm - Travel X = 1450 mm, Y = 700 mm, Z = 550 mm This machine is our production in addition to available from the KW22 / 15th A robot welding system was installed. This brings us to weld able TIG and MAG. We are very well set up for you to produce tools and jigs. We are happy to customize items, zero series, production parts or assemble complete modules. With two new wire EDM machines we can in 2-shift operation for you. Our machinery has been almost entirely reinvested. For quality assurance, is from March 2016 new Zeiss measuring machine available! For programming we use two CAD CAM - Siemens NX Unigraphics, Version: 8.5 programming stations and enables us to offer services to the 3-D machining. Another added advantage of unsrem companies: All contacts at Inter Technic spoke German except Slovak, English.

Founded

2010

Employees

100 - 200

Certifications

Liptovsky Mikulas

Slovakia - 03101

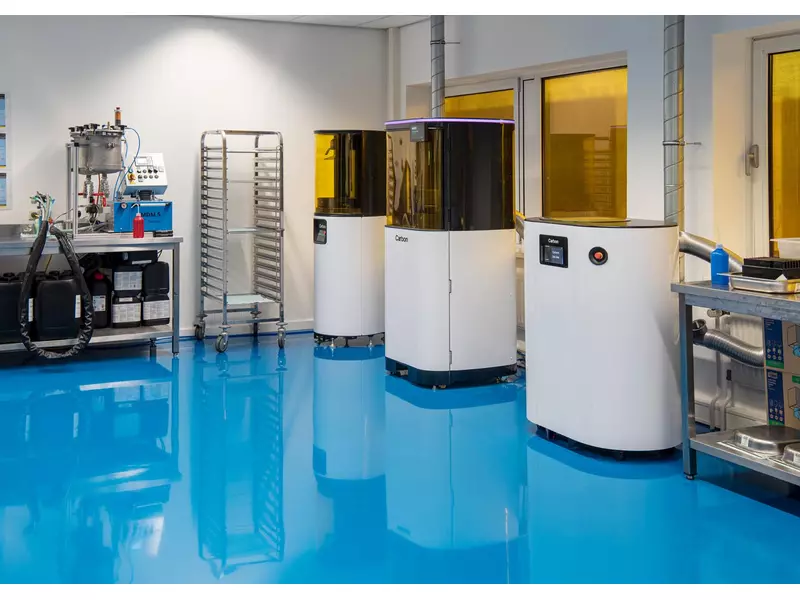

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

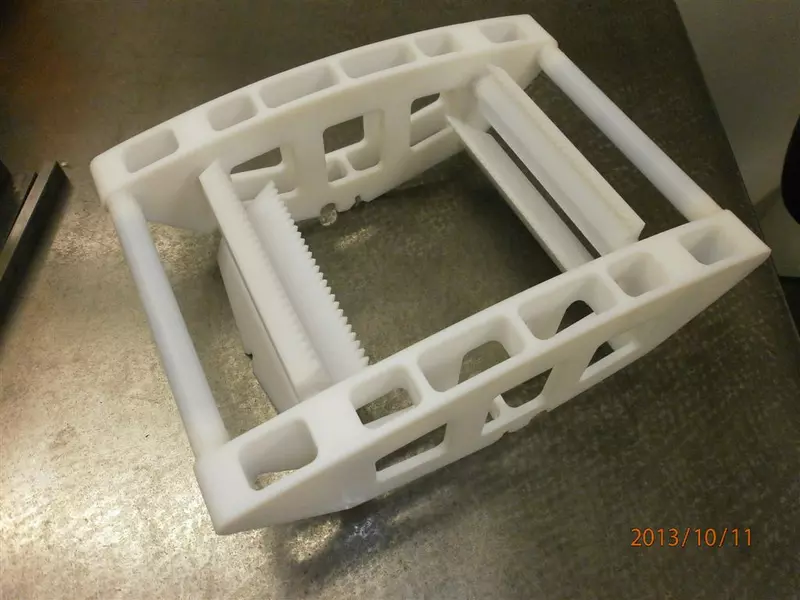

Company Profile Since 1991 Our family manufactures customized solutions made of plastic. In Gornau at Chemnitz today about 50 employees in the fields of semi-finished product processing, container and equipment construction, plant construction and cleanroom technology operate. Our solutions are used in industries such as machine and plant engineering, medical and environmental technology, the semiconductor industry and photovoltaics. The high quality of our products and services is evidenced by the certification of our company according to ISO 9001:2008. The internal design office as well as the technically and technologically advanced manufacturing guarantee our customers a comprehensive and high-quality advice and support. Involve us when planning your plastic just solution. Illustrate With our experience and the available CAD technology and we work out the best solution. We are happy to solve with our know-how your challenges. Products / Services Semi-finished processing Behälter-/Apparatebau Transparent Plastics Wasser-/Labortechnik Cleanroom technology Semiconductor engineering / photovoltaics Piping systems / special fittings Prototyping / Rapid Prototyping Machine technology With a well-equipped and very broad machinery, we can meet diverse customer needs. CNC lathe turning length up to 500 m 2 Milling Machine CNC 3-axis 1000 x 1300 x 160 Milling Machine CNC 3-axis 2300 x 1300 x 160 Milling Machine

Founded

2001

Employees

50 - 100

Certifications

Gornau

Germany - 09405

Our history dates back to 1990, when engineer Dimitar Karagyozov laid the foundations for our company. In 2006, the company was re-registered as EOOD, and since then we have continued to develop and expand our offering. We specialize in manufacturing high-quality injection molds and plastic products that are used in medical technology, electronics and many other industries. Our experience and expertise enable us to develop tailor-made solutions for the individual requirements of our customers. In doing so, we attach great importance to quality, precision and reliability. We are proud to be a company that continuously strives to exceed customer expectations and drive innovation. Our mission is to add value through our products and services and to build long-term partnerships.

Founded

1990

Employees

5 - 10

Certifications

Sofia

Bulgaria - 1510

About us Kreutz & Mock is a medium-sized company and the leading manufacturers of wire bending parts of all types. With over 3000 different articles we can offer our customers a wide and diverse range of different wire products. The necessary machines for the production are developed and built in-house by our own engineering department which gives us the possibility to always be flexible according to our customer's needs. You can find further details about us and our philosophy on our website. Products We manufacture wire bending parts in all sorts of variations and models. We supply many industries with our products like the automotive industry, construction industry, agriculture, blinds manufacturers and many more. We also have numerous technical bent parts in our repertoire. We are happy to try to achieve your specific needs and requirements, because quality, punctuality and being in step with actual practice are our basic principles to deliver high quality as well as best functionality products. It does not matter whether they are single quantities, small quantities or a large series. We are flexible and deliver quality at fair conditions. We offer + Qualitycertficate DIN ISO 9001:2008 + in-house specified tool construction + in-house machinery construction + quick production of samples + technical and experienced know how + skilled telephone service + large production spectrum Materials Every material processed in our factory has a dedicated inspection certificate that will be provided with your delivery on request. We manufacture bent wire components for you in all variants and materials. Here a selection of the materials used: + Stainless steel wire 1.4301, 1.4310, 1.4362, 1.4401, 1.4404, 1.4571 in different tensile strengths + Spring steel wire 0.9 mm to 6.0 mm. Qualities A, B, C, D + Steel wire C9D bare or copper-plated. C9D soft galvanised in 1.0 mm to 8.0 mm + Crapal wire + Becrosi valve spring wire + Silver and Palladium wire

Founded

1934

Employees

20 - 50

Certifications

Neuendorf

Germany - 97788

We are a company that has been the right partner for 14 years now when it comes to prototypes, tools and devices for the mobile sector. General contract manufacturing in the areas of HSC machining, mold making and model making complete our offering.

Founded

Employees

10 - 20

Certifications

Sarntal

Italy - 39058

Founded

2015

Employees

20 - 50

Certifications

Oravska Polhora

Slovakia - 02947

Dear Ladies and Gentlemen, in this way we would like our service companies introducing we produce single pieces or small series, series, sub-assemblies, gauges, fixtures Tools, special machine parts for the Varied fields of application according to your Requirements, specifications, drawings. We can at reference customers from eg mechanical engineering, special engineering, medical, aircraft, automotive industry, tooling, etc. References. Our range of machines includes most modern technology currently available in these areas CNC milling, CNC turning, CNC surface grinding, CNC wire EDM, CNC sinker EDM CNC-Erodierbohren/Präzisionsbohrungen, CNC Ultra Sonic is offering. Thanks to this modern manufacturing equipment and years of experience and a team of employees profounded we are to be able almost all requirements in manufacturing technology needs. For more information about our machine park can be found on our website CNC milling, CNC turning, CNC surface grinding, CNC wire EDM, CNC sinker EDM CNC-Erodierbohren/Präzisionsbohrungen, CNC Ultrasonic www.KaPe-erodiertechnik.de

Founded

98

Employees

10 - 20

Certifications

Ostbevern

Germany - 48346

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

We enable you to focus on the essentials. The production of your parts and assemblies you provide to us, the Roeder GmbH & Co. KG is your competent partner for precision.

Founded

1999

Employees

10 - 20

Certifications

Biebergemünd

Germany - 63599

We are a medium-sized company in the field of metal processing. Our core competencies include the production of series parts and assemblies for industry and plant and mechanical engineering, in particular the food and beverage industry. For over 75 years, Lungmetall OHG has stood for efficiency, flexibility and competence in steel, stainless steel and aluminum. Whether individual or series production, with our modern machine park tailored to the requirements of our customers, we manufacture for you flexibly, inexpensively and quickly. We are lean enough to flexibly implement your ideas and wishes, but also large enough to provide you with the capacity you need, even for large series. Thanks to our high level of vertical integration, we appear on the market as a system supplier, as we are not dependent on other trades. This manifests itself in short delivery times and a high quality standard. With our currently 60 employees and our in-house design office, we offer you an extensive service portfolio and reliable processing of your orders! We would be happy to win you as a valued customer and assure you of a partnership and team-oriented cooperation.

Founded

1924

Employees

50 - 100

Certifications

Kottenheim

Germany - 56736

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

Magepa offers advice as strong precision engineering partners, among others Spacers, leaf springs and metal liners for mechanical engineering at. With over 50 years experience in stamping and forming, we have a deep understanding of the needs shall our customers. We also carry pipe bending by and manufacture precision sheet metal parts made of spring steel strip. With our expertise and our technical creativity, we provide our customers with solutions such as individual leaf springs, shims unique, special spacers, etc. Our standards are high. We want to understand you and your machine exactly. Together we will develop ideas and implement them with the latest technology. Precision engineering products for engineering such as metal liners and precision sheet metal parts made of spring steel strip, etc. are available in commercial quantities or as special.

Founded

1963

Employees

10 - 20

Certifications

Koberg

Germany - 23881

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We are a medium-sized company based in Ganderkesee and have been producing sophisticated sheet metal and formed parts for our customers for over 65 years. Our customer base includes the automotive, mechanical engineering, electrical, marine and aircraft industries, where we are listed as an A-supplier and have already received several awards as a 0-ppm supplier. Our company is fundamentally different from other companies that can produce either only large or only small series at low cost. We are proficient in both technologies. Since we are convinced that only holistic quality and sustainability can lead to success today and in the future, we have a certified integrated management system in accordance with the requirements of IATF 16949, DIN EN ISO 9001 and DIN EN ISO 14001 established. (ext. TÜV Cert link). Our homepage is intended to give you a brief overview of our diverse production options. We would be delighted to work for you too. Give us a chance to do that.

Founded

1948

Employees

20 - 50

Certifications

Ganderkesee

Germany - 27777

On 16.01.2007, the Sole proprietorship “Michael Otto CAD/CAM Services” founded. About 1 year later, this results in: OTTO TECHNOLOGY-Johannes & Michael Otto GbR We are a family business, consisting of: 10 highly motivated permanent employees employees and 5 temporary workers. 7 milling and programming experts (including the management), all with roots in Tool and mold making 3 administrative workers with education in the foreign language secretariat 5 temporary workers (students and students)

Founded

2007

Employees

10 - 20

Certifications

Bad Endbach

Germany - 35050

The company Fetec Engelhardt GmbH is a modern enterprise specializing in CNC milling and turning as well as the construction of complete functional units. For the 2D and 3D Complete machining of simple to extremely complex workpieces made of steel, stainless steel, aluminum, plastic, etc. we are the right partner for you. Even sophisticated operations such as the production of free-form surfaces, supported by a CAD-CAM programming system belong to our services. Business The company FETEC Engelhardt GmbH was established on 1 Founded in May 1997 in Ruhla / Thuringia as a civil law and on 1 July 2005 umformiert into a GmbH. Starting point of the company producing basic turning and milling parts, the one manufactured in order for suppliers to the automotive industry. With the move in January 2001 in a new building, the production of parts, prototypes, small batches in contract manufacturing as well as complete assemblies and devices has been made possible.The expansion of contract manufacturing required on 1 July 2006 another move to a larger and also its own production facility. The workforce of FETEC Engelhardt GmbH consists of seven employees and three apprentices. Managing directors are Gerald and Ursula Engelhardt. Products Because of our diverse experience in the field of metal machining, we are able to offer comprehensive services. These range from performing individual work steps bishin for assembly of complete functional units. Turn 1 Turning the conventional way ----- BRAND NEW ------- Lathe with bar feeder 3m to 32mm diameter x / y machining with driven tools * Between centers 1000mm x D 220mm * In feed D 300mm * From the rod D 47mm 2 CNC turning with counter-spindle, Y-axis and bar feeder * Maximum diameter D 100mm (45mmStange) * Maximum turning length D500mm Mill 1Milling in a conventional manner * X-, Y, - Z-direction 300 mm x 220 mm x 300 mm 2 CNC milling Maximum travel: * DMU 60T monoblock (five axes) / X 500 mm, 400 mm, Y-, Z-400mm * Hurco VMX 42t (3-axis) / X 1060mm Devices Production of complete functional units * Devices * Tools * Assembly workstations * Special Machines * Prototypes * Items * Small series * And much more

Founded

1997

Employees

10 - 20

Certifications

Ruhla

Germany - 99842

Our company was founded on 28.02.2005. It builds on the experiences that have been collected for years in the FIRE tool-und Maschinenbau GmbH in the field of stamping production. The acquisition of new hydraulic presses and the investment in a new Production facility enables us your client's wishes and not least Your product innovations enhanced implementation. We will advise you in the choice of materials and develop with you a tool concept. This can be thanks to the close cooperation with the FIRE tool and Maschinenbau GmbH are implemented quickly and effectively. Production of stamped parts Stampings band Stamping parts with thread Pressed, stamped and drawn parts connected tooling with 35 employees since 1992 CNC milling 3/5-Achs CAD CAM CNC turning CNC Wire EDM CNC sinker EDM List of machines We can customize your stampings on the following machines: Belt systems - 600mm width 8mm tape cross-section Eccentric EBU 1000 KN 80Hub/min Eccentric PME 2000 CN 80Hub/min Eccentric EBU 2000 CN 80Hub/min Eccentric PME 3150 CN 60Hub/min Insert presses: Eccentric Helmerding 850KN 60Hub/min Hydraulic press 250 kN 2x Hydraulic Press 400-630

Founded

2005/1992

Employees

10 - 20

Certifications

Oederan

Germany - 09569

Since 1986 we have been working as injection molding manufacturers serving a variety of local and international companies which operate in various fields and need molds either for big productions and limited edition products. What we do is easily explained. We design, manufacture and supply injection molds for the production of high-precision thermoplastic parts with exceptional aesthetic demands. We are specialized in the production of high-precision technical parts and multiple-impression molds for high production requirements, but we also supply prototypes and pilot molds for small and medium series that requires complex and intricate geometries – for instance, for limited editions. The headquarters are located in the Italian city of Rovereto, just 30 km from Trento, on the Brenner motorway link. This is the ideal crossroads between the major industrial districts in Northern Italy, such as the manufacturing (Lombardy, Vicenza) and optical (Belluno) ones, and important European countries such as Austria, Germany and Switzerland. However, there is more. We also work with factories based in the US and in the rest of the world. The know-how we developed over the years of experience in the field allows us to identify the most suitable kinds of injection molds on the base of your production types and aesthetic needs.

Founded

1986

Employees

20 - 50

Certifications

Rovereto

Italy - 38068

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge