Sintering: get complete market transparency

Discover specialized suppliers for sintering on Techpilot. Our platform connects buyers with suppliers who use this technique to manufacture complex and high-strength parts. Use the e-sourcing process to find the best suppliers and secure the best conditions.

103 suppliers for Sintering

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

Besides our wide-ranging portfolio of standard components, the development of customized products and solutions is a central part of our scope of capabilities. To make you and your company successful, we harness all of our expertise and experience. We join forces and develop tailor-made modifications and innovative solutions that cover your requirements and support your ambitions in a smooth, reliable, and purpose-driven manner. The first step is to get a solid understanding of your needs and possibilities. We want to ensure that we have perceived your present situation correctly and that we have a common understanding of your overall objectives. Our experts will then present a detailed customized solution to meet your needs and an implementation plan. In search of the optimum solution, no challenge is too great for our Solutionists.

Founded

1977

Employees

> 1000

Certifications

Mörfelden-Walldorf

Germany - 64546

Founded

2001

Employees

20 - 50

Certifications

Dornhan

Germany - 72175

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

YOUR GENERAL CONTRACTOR FOR FORMING and MOLDING! FORGING, HOT PRESSES KALTFLIESSPRESSSEN, FREE FORM FORGING IN STEEL, STAINLESS, ALUMINUM, BUNTMETALL, TITAN, FLANGE, RING, TRIMS, Longitudinally PIPES, FEINGUSS, SAND CASTING, DIE CASTING MACHINING PARTS OF FORM PART, OR FROM THE FULL PROFILE

Founded

1961

Employees

5 - 10

Certifications

Liestal

Switzerland - 4410

The medium-sized enterprises THIERBACH from Lower Hall near Heilbronn supplies Companies from all industries as tailored solutions for the Parts subject. TURNING AND MILLING PARTS THIERBACH processed according to your specifications, all machinable materials, including steel, stainless steel, brass, aluminum and bronze and precious metals and special materials for the aerospace industry. SINTERFACE PARTS For the production of sintered parts THIERBACH used exclusively powder with demonstrated high quality. Depending on requirements, the base material of various alloying elements are added. Formed In the area of formed THIERBACH offers various production options such as cold and hot extrusion. In addition, a mechanical, metal-cutting rework is possible. PUNCHING AND BENDING PARTS In the field of stamping and bending parts offers THIERBACH solutions of metallic and non-metallic materials that are manufactured on CNC machines.In addition, welding can be performed. LASER COMPONENTS In the area of laser parts are available from THIERBACH steel, stainless steel or aluminum products with extremely high precision contours in different thicknesses. CASTINGS In THIERBACH you get castings in all major manufacturing processes: aluminum die-casting, aluminum sand casting, zinc die casting, copper sand castings or precision castings. DEEP DRAWN PARTS THIERBACH provides you with high quality deep drawn parts made of stainless steel, aluminum, brass, bronze, iron, chromium or copper, either as a single function template or as a large series. ASSEMBLIES Not just when you need a single part, but even with demanding assemblies, you can count on THIERBACH: in partnership, economic and logistical point of view. CERTIFIED QUALITY An important part of THIERBACH quality philosophy is the maximum quality assurance in the production of your parts and assemblies. FACTS: QUALTÄTSSICHERUNG - Certification according to DIN EN ISO 9001:2008 - Erstmusterprüfberichtenach VDA - PPAP documentation - IMDS entries - Uniformity measurements - Surface measurements - Length measurements - Measuring equipment management - Sampling inspection according to AQL 1 - SPC tests Possibilities of surface and heat treatments Even when it comes ächen to the finishing of surfaces, THIERBACH provides organizational and economic advantages: Through partnerships with reputable companies you get: - Modern production techniques - Everything from prototype to mass production - Different machining options and THIERBACH all the possible rework and surfaces.In this way long and expensive transport routes and the total cost per piece If omitted significantly reduced. THIERBACH offers: Galvanizing / / Copper Passivation / / hard chrome plating Burnishing / / Gilding Dacromet / / Geomet coating Cadmium / / Nickel Chromate / / anodizing Phosphating / / pickling / / Silver Case hardening / / Inductive Glow / / start / / Slot Embossing / / Bending / / rubbing Lapping / / honing / / punching Engraving / / brushes Polishing / / electropolishing Grinding / / trowalizing Sand and glass bead blasting Flexible Logistics THIERBACH is not content to create the correct part, but is only satisfied when you is this the right time and at the right place. Thus, for example, already taken in the packaging that it contains all the elements for a smooth production: Logo, number, barcode.

Founded

1999

Employees

20 - 50

Certifications

Künzelsau

Germany - 74653

CASTING and FORGING PARTS BY CUSTOMER Together with our partner companies ISG industry service and Geiger Berger Industries, we offer you the opportunity to access from a wide range of different foundries, forging and machining company from Germany, Spain, Hungary and China. We take care of you this vendor selection, request, technical clarification, quality assurance, packaging, shipping and timely delivery of your products according to your drawings and specifications. Through our three locations in Germany, we are always in their vicinity: CFT Hanseatic Guss GmbH, 28195 Bremen ISG industry service Geiger e.Kfm., 73491 Neuler Berger Industries K., 50668 Cologne You have a question or want to get to know us? Please contact one of the below mentioned contact, we'll take care of everything else.

Founded

2004

Employees

10 - 20

Certifications

Bremen

Germany - 28197

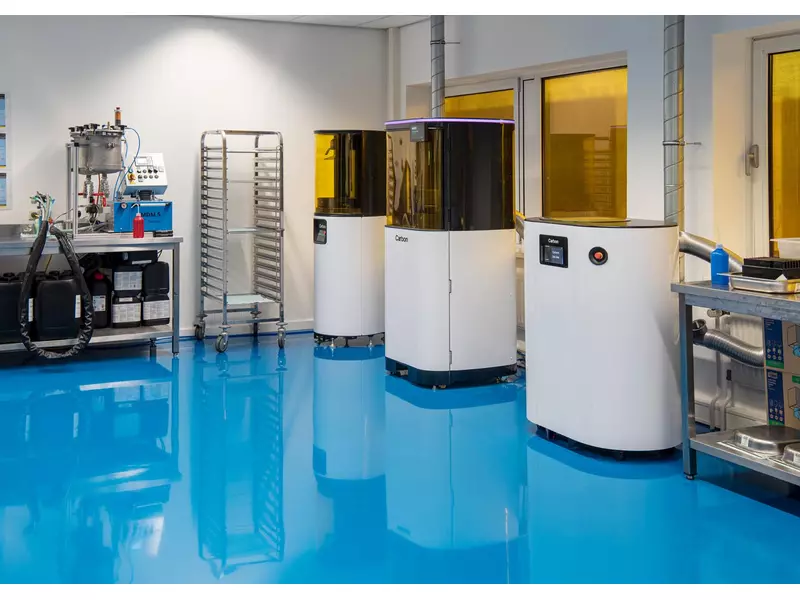

We specialize in Additive Manufacturing - particularly DMLS and precision CNC processes. From design conceptualization to AM, modeling, prototyping, serial production, and post-processing, we offer comprehensive Engineering and Manufacturing solutions tailored to drive your success.

Founded

Employees

5 - 10

Certifications

Valencia

Spain - 46013

We, Metallbau Schmalenbach, specialize in manufacturing a wide variety of high-quality and tasteful stainless steel and corten steel accessories. Years of experience in working with metal products, experienced know-how and the gift for exceptional design give our products uniqueness. The focus is on narrowing down to the essentials. In a charmingly flooded world, peace and relaxation are important to us. Simplicity is the goal and with it the uniqueness of our products. In addition to our wide range of products, we also offer you the opportunity to have your ideas implemented. We offer you custom-made custom-made products. You are welcome to visit us at Linienstr.14 in 42289 Wuppertal.

Founded

2022

Employees

5 - 10

Certifications

Wuppertal

Germany - 42289

Melchers Components GmbH

C. Melchers & Co. was established on January 1, 1806 in Bremen, where the global company still maintains its headquarters to this very day. In the first few decades of the company’s history, over 30 ships sailed the oceans of the world under the Melchers flag, linking the ports of Europe, America and the Pacific. In the 1860s, C. Melchers & Co set up operations in Asia, where all its trading interests swiftly moved. At the same time, with the onset of steam ships, it abandoned its own shipping business to devote itself entirely to extending its trading operations. 1866 saw the establishment of the first branch in Hong Kong, in the wake of which China began to develop into a key lynchpin for the company’s business. The ensuing decades were a period of rapid growth for Melchers in China, with over 2,000 people employed at 12 branches and plants throughout the country. The First World War proved to be a setback for business relations, although business quickly recovered. It was not until the end of the Second World War in 1945 that business came to an almost complete halt. Even so, the company continued to survive, re-opening its first branches in Hong Kong, Singapore and Kuala Lumpur in the early fifties and gradually extending its branch network across Asia. Following the opening of the Chinese markets at the end of the seventies, Melchers set up branches here again, underscoring the significance of Chinese business for the company. With the establishment of a branch in San Francisco in the early eighties, the company also started to engage in US-Asian trade so as to gain a share of the rapidly growing trading relations between these two regions. Trade with China remains a key focus of the company’s overall business, comprising as it does imports of special natural products and finished goods on the one hand and exports of plant, machinery and supplies for the Asian industry on the other. Yet, business with South East Asia has since also come to the fore, with the company amassing broad-based expertise in marketing and selling consumer goods in particular. There are special departments for each article group in Bremen as well as at the foreign branches. They work largely independently within the overall company and are staffed by highly qualified experts. Over 1,000 employees in Germany and abroad assist customers and suppliers with their specialist knowledge. Rather than being based at the company’s headquarters, most of these employees are now stationed at subsidiaries, something which in turn reflects the company’s further development and the strategic alliances which it has forged.

Founded

1806

Employees

> 1000

Certifications

Bremen

Germany - 28195

Founded

1948

Employees

20 - 50

Certifications

Fellbach

Germany - 70736

Production of mechanical components made of mechanical processing (turned; milled; sintered; gears)

Founded

Employees

500 - 1000

Certifications

Mestrino

Italy - 35035

We are a small company, founded in 2007 company based in the center of Cologne. We are specialized in the production of precision parts from all areas and materials. From a single prototype to series, we use the most modern equipment of the highest quality.

Founded

2007

Employees

10 - 20

Certifications

Reichshof

Germany - 51580

Welcome to the UF Industries GbR. For more than 20 years, we have been bundling the necessary skills for everything to do with drawing parts in a separate department. Our employees advise and support you in the procurement of tailor-made special and drawing parts and produce high-quality and precise turned, milled and combination parts for you according to drawings - even in demanding geometries and in small batch sizes. Quality and function are our top priority. In order to achieve this, we are constantly developing ourselves and our portfolio. True to the motto: If you stop getting better, you stop being good! Our aim is to be able to offer an efficient and optimal solution for every specific, mechanical-technical requirement based on a drawing or sample. If required, we offer you fast and goal-oriented support in the realization of your constructions. Especially in the project phase, it is of crucial importance to choose the best, most modern and at the same time most cost-effective production technology. We would also be happy to optimize existing construction parts together with you.

Founded

2020

Employees

5 - 10

Certifications

Espelkamp

Germany - 32339

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

JG AUTOMOTIVE: Developer and Supplier in the manufacture of metal parts JG Automotive was founded in 1982, dedicated to the manufacturing, development and supply of metal components for the automotive and industrial sector. Thanks to the mastery of the technologies of manufacturing of metal products specifications provided by clients, we have diversified the industrial sectors of performance and optimized our work processes. In 2002, together with 18 international partners, we created Global Alliance, a large group with 230 cooperative engineers, manufacturers in Brazil, Germany, China, India, Italy, Japan, Korea and USA, among others, managing a joint turnover of € 1,720 M. Dozens of companies in the automotive, energy, railway, agricultural, elevation, etc. sectors, are already among our customers and fortunately for us every year we continue to grow thanks to the trust of our customers and the incorporation of new ones. Our products are presented with their corresponding quality certificates (IATF / TS / ISO / CE / PPAP). In short Technology and high competitiveness in products to specifications provided by clients. TECHNOLOGIES: Forging, Casting, Machining, Stamping, Laser cut, Welding, Raw Material, Microforge, Microfusion, Fasteners, High Pressure Cylinders, Hydrogen cylinders for hydrogen filling stations, Toolings, Precision Bar Turning and Special Parts, Inserts and Profiles, Tubes SW and DW and Rod Formers, Springs, E-mobility, Precision Gears, Bearings, automotive plastic injection parts and Returnable packaging of metal parts.

Founded

1982

Employees

50 - 100

Certifications

Madrid

Spain - 28108

We are German manufacturer of high quality aluminum castings, which are mainly produced in permanent mold. We have a separate tool and model. We are in Werdohl in the Sauerland in the state of North Rhine-Westphalia. Our standard range includes machines keypads in the materials, aluminum, steel, plastic, cast iron, ductile iron and corrosion-resistant steel castings. We manufacture in particular handwheels in sizes 55-800 mm diam. aluminum and cast iron, and in sizes 80-400 mm diam. made of stainless steel castings. The individual one-off production of welded steel pipes and corrosion-resistant steel pipe handwheels is possible. Steel hand wheels made of stainless steel and powder coated steel are also available in sizes 100 - available as standard production parts 400 mm. We have delivery options for various casting, forging, sintering metal and plastic parts of almost all technologies. We offer these parts also processed completely finished. We do wage-clearing in the size range 3-45 mm through. We provide certified quality. Our customer base includes clients across the EU, Switzerland and Japan. With us you can correspond in German, English and Russian. Machine controls 1 Hand wheels made of stainless steel sheet 2 Hand wheels made of stainless steel casting 3 Hand wheels made of aluminum 4 Hand wheels made of cast iron 5 Handles 6 Ball Knobs 7 Clamping Levers 8 Star Cross Handles 9 Fittings made of aluminum handwheels 10 Valves made of cast iron handwheels Material size range [mm] 1 1.4571 Ø 80-400 2 1.4301 Ø 70, 160, 200, 250 3 GK-AlSi9Cu3 Ø 55-800 GK-AlSi 12 (Cu) ditto 4 EN-GJL 200 (GG 20) Ø 80-800 5 Thermoplastic M 6 - M 12; thermoset M 6 - M 16; Aluminum M 6 - M 16; steel M 6 - M 16 6 Thermoplastic Ø 16 - 32; thermoset Ø 12-60; Aluminium Ø 16 - 50; steel Ø 16-50 7 Steel Ø 16-50 1.4305 / 14301 Ø 16-40 8 Thermoplastic Ø 25 - 80; thermoset Ø 25 - 80; Aluminium Ø 40 - 80, gray cast iron Ø 32-100 9 Ripple ring DIN 390 Ø 63-200; spokes DIN 3220 Ø 160-280; spokes DIN 3319 Ø 125-315 630 + 10 Ripple ring DIN 390 Ø 63-160; spokes DIN 3220 Ø 120-500; spokes DIN 3319 Ø 100-630 METHOD Everything from one source, that is your advantage We have to bring several ways your castings in the form. Depending on the product we produce in gravity die casting, sand casting or wax molding process (Lost Wax). The planning and production of the mold is the task of our tool. Here in close collaboration with you the special form. We manufacture, depending on quantity and casting molds, models or lost duration models. The casting material is melted in our Crucible and then shaped. The further processing takes place primarily in the company. PRODUCTS Diversity is our program We operate in our own company and foundry melt. We manufacture machines keypads from the materials aluminum, steel, plastic, cast iron (gray iron and ductile iron), cast steel, brass, bronze and corrosion-resistant steel casting (stainless NiCr cast). We have a lot in store for you Many of our machines controls are stored as semi-finished goods. We deliver fast and customized according to your special requirements. A few product groups we keep in stock as blanks. Here is an even greater diversity processing is given. They are processed in our production according to your specifications: eg provided with abnormal bores, four edges or a special ...

Founded

1928

Employees

10 - 20

Certifications

Werdohl (Deutschland)

Germany - 58791

The Anant GmbH is a marketing subsidiary for own products & representation for few well-selected Indian manufacturing units. We have a good knowledge + experience for quality systems & supervised manufacturing outsourcing from India. Our German representation offers a potential to take up a responsibility to supply the article as door delivered & being your contact/contract partner. whereas our Indian technical team offers possibly of economical in-house manufacturing as well as local outsourcing under our supervision & our own quality control. At Patel Technomation - India, We have the experience and capability of sub-contract CNC machining including supply/procuring of foundry and forging products in small batches as well in large quantity. We follow the TÜV SÜD ISO 9001-2000 quality system and are dedicated to providing excellent customer service, and the timely delivery of quality products. Our Manufacturing unit is located at major Auto-parts manufacturing, Casting, Forging & engineering hub in India; which offers us a good development possibility for any specific/special part manufacturing possibility in a most economical manner.

Founded

2006

Employees

200 - 500

Certifications

Oberschleissheim

Germany - 85764

Dear Ladies and Gentlemen, Please, read the brief description of our company. The H2A Kft is a commercial agency for several Hungarian companies in German-speaking countries. Be Represented companies in the metalworking, steel construction and chipping range, which are active both in engineering and in general steel construction. What makes the H2A Kft? - Excellent trained staff - Flexibility - Reliability: Time commitments are guaranteed to be met, your schedule for the use of your parts is not messed up. H2A is only satisfied when you are! Put them to the test and you will see that reliably at any time all the promises be redeemed: Quality that convinces! We look forward to hearing from you! Sincerely, Tamas Horvath Manager

Founded

2009

Employees

< 5

Certifications

Gyöngyössolymos

Hungary - 3231

Welcome We see ourselves as an average modern operating company, based in Istanbul. Our company is working successfully in different industries (mechanical engineering, textile machinery, medical instrument industry, automotive industry, construction industry, graphic and optical industry, etc.) whose requirements are as varied as your products. In our mechanical production, we offer you virtually all machining manufacturing processes. Drilling, turning, milling and external cylindrical grinding in conventional production, milling and turning on modern CNC machines. That is our guarantee for your series production. With us you always get a completely finished product. Whether small series or prototype, whether raw or finished coating, whether or Kuststoff steel - all orders we finished quickly, reliably and accurately measured. Take advantage of our many years of experience and learn in the following pages to know our wide program. We are happy to await your inquiries and would be pleased if we could count you among our satisfied customers and your company. We support each other. The quality of our work ensured the success of our company. "Everyone is for each model, with production processes, each of the customer of the neighbor." About us The company Integral Makina sees itself with its long-standing and qualified staff as a traditional but modern positioned and competitive manufacturer of components for the Maschienenbau, Textilmaschienen, Medical Instrument Industry, Mechanical biomedical sector, automotive industry, construction industry, graphic and optical industry, etc. The technological requirements are determined by modern CNC machining centers. As the material in addition to steel and cast iron, aluminum, plastic and stainless steel, etc. is processed. Through close cooperation with companies from the region, we are able to manufacture complementary areas, suchEtc. to use as sheet metal processing (laser cutting), Hardening, Surface Finishing, external and internal cylindrical grinding, surface grinding, welding, assembly in a variety of ways and included in our manufacturing facilities. Customer-oriented quality assurance and on-time delivery are our determined measure of performance.

Founded

2010

Employees

10 - 20

Certifications

Maltepe - İstanbul

Turkey - 34843

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge