Spinning: benefit from Techpilot's efficient e-sourcing process

Discover specialized suppliers for spinning on Techpilot. Our platform connects buyers with suppliers who use advanced spinning technologies to manufacture precise metal parts. Use the e-sourcing process to find the best suppliers.

288 suppliers for Spinning

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

Short YOUTUBE Video: https://youtu.be/FzPtBnGDq2Q?si=E-E8EgaQiIz05Aov Our company is located in eastern Slovakia, in the industrial district of Široké village. Our over 7000 m2 of working area is divided among seven halls that are utilised for production, storage and offices. We are able to provide the best possible solutions for your needs, since we constantly invest in state of the art technologies and have extensive company expertise. In addition to Slovakia, we work with several businesses around Europe. We always strive to improve ourselves and to adjust technology to the newest trends. We are looking forward to cooperation!

Founded

2017

Employees

50 - 100

Certifications

Siroke

Slovakia - 08237

Customised production of housings and steel solutions based on intelligent metal processing. Our experienced specialists work together with you on the development of prototypes and support you in the implementation of your projects through to series production with a wide range of services such as planning, construction, manufacturing and logistics. At the same time, we meet even the highest quality requirements thanks to our strict controls. A modern production site in Poland is the basis for being able to respond flexibly, quickly and economically to your needs. A constantly growing machine park and a highly qualified team are the key to success and enable us to offer competitive prices using the latest technology.

Founded

2008

Employees

50 - 100

Certifications

Stammham

Germany - 85134

Consortium of companies active in the development of foreign markets. It acts as an export sales department for a number of SMEs located in Italy, all operating in sub-supply in the mechanical engineering industry. Our partners can offer, among others, the following main operations - Turning - Milling - Grinding - Sheet metal cutting and bending - Sheet metal forming - Assembling - Complete sub-assemblies - Sheet metal forming - Welded construction - Assembly of assemblies

Founded

2011

Employees

20 - 50

Certifications

Vicenza

Italy - 36100

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Bauflaschnerei Winter GmbH is one of the leading companies in sheet metal technology and sheet metal processing. We have established ourselves in the fields of plumbing, roofing and façade construction. In addition, the brands Bleche-nach-mass.de and Magnetwandshop.de offer individual solutions according to customer requirements for B2B and B2C. Sheet metal technology at the highest level with the latest machinery.

Founded

1986

Employees

20 - 50

Certifications

Essingen

Germany - 73457

Manufacture of metal press members on a rotating basis, a variety of materials from CNS to copper to 3mm

Founded

1990

Employees

20 - 50

Certifications

Imst

Austria - 6460

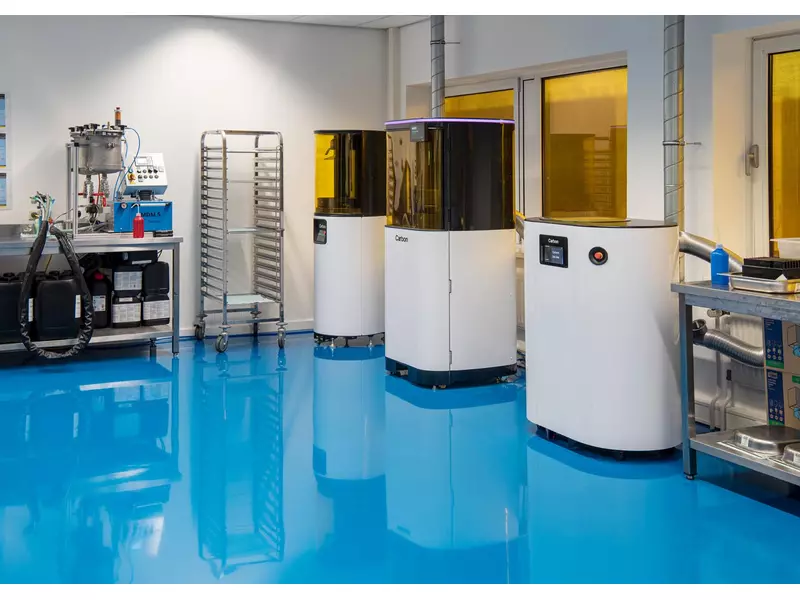

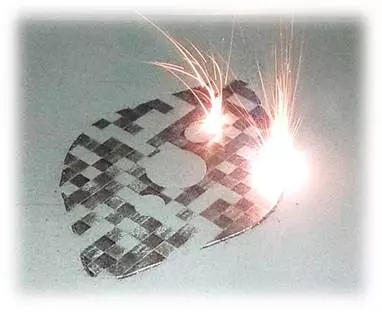

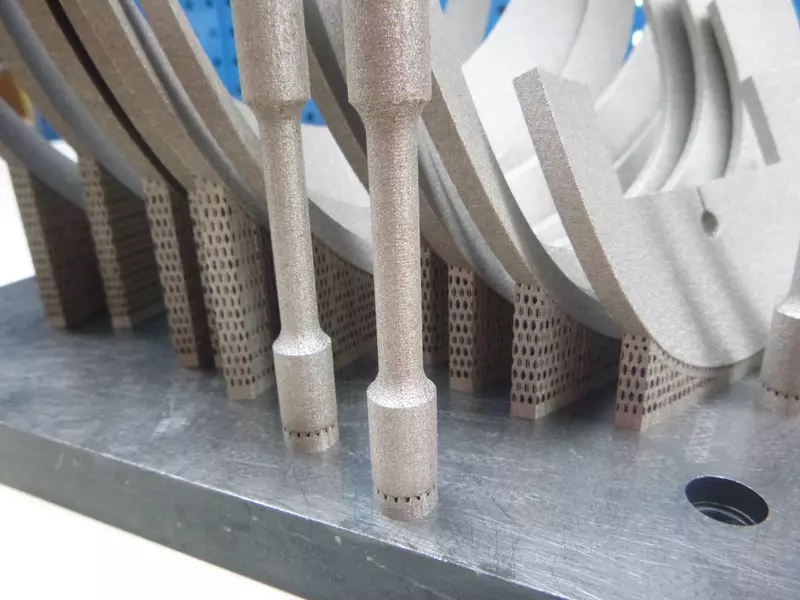

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Founded

Employees

5 - 10

Certifications

Amstetten

Austria - 3300

We serve as Automotive , HVAC applications , Sheet - Metal box Set. , Machining. and White goods sub-industry with Laser Cutting, Press Bending, Welding and Assembly processes. We process all quality stainless steel, aluminum, galvanized, titanium, lead and black materials in the most precise way within the desired dimensions and tolerances.

Founded

2015

Employees

20 - 50

Certifications

Yunusemre

Turkey - 45140

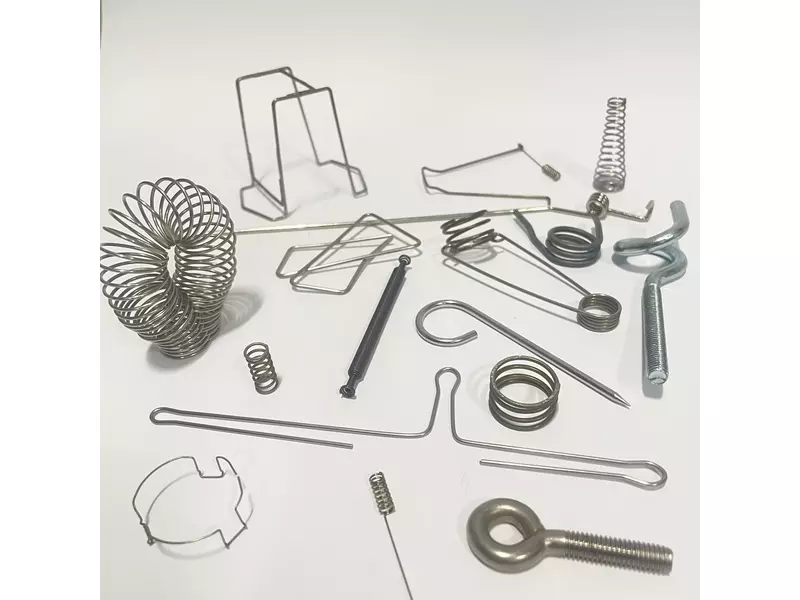

- Manufacture of stamping parts according to sample or drawing to 1250 kN - Manufacture of stamping parts made of copper, brass, aluminum, bronze, steel, stainless steel up to 3mm thickness from tape using electronic feed, up to 6mm from sheets or strip - Manufacture of stamping parts made of non-metallic materials - Point-and inert gas welding (MAG, TIG) - Drilling - Tapping - Thread rolling, knurling + - High gloss polishing by polishing rotary table (6 stations) or manually - Supplier `s and-drag to 80 mm in length (even more grooves per part possible) - Belt loops - Mounting (single and assembly) - Cleaning of stampings using cleaning machine - Special solutions In cooperation: Laser technology (also 3D) laser, laser welding, Bending, CNC punching nibbling, turning and milling parts, surface finishing, tool - Quantities of 100 units to 5 million units

Founded

1937

Employees

10 - 20

Certifications

Schwarzenberg/OT Pöhla

Germany - 08340

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

Culobel Group is an international technology partner with production facilities in Belgium and the Czech Republic and a sourcing office in China. We provide total solutions in sheet metal stamping, deep drawing, pressure vessels and assembly. Our constant innovation, a feel for creativity, and know-how built up over many years ensure outstanding quality. We assist you from the outset in the development of your product and possess the latest software with which to conduct feasibility studies. Over 50 automated mechanical and hydraulic presses up to 1000 ton are testament to the state-of-the-art machinery we have in house.

Founded

1929

Employees

100 - 200

Certifications

Frydlant - Ostrava

Czech Republic - 73911

LIGHT STAINLESS STEEL SHEET SPECIAL PARTS FOR MACHINE CONSTRUCTION Family-run, flexible company with a total of 20 employees. Manufacturer of apparatus / devices, machines and systems for machine tools, packaging and food industries. Focus on Ni-ro steel processing.

Founded

1990

Employees

20 - 50

Certifications

Vedelago

Italy - 31050

Tools of GDH Need smart tool solutions or the realization of complicated processing problems? From planning and design through the development of the individual components to the construction of the finished tool: GDH is in the design and manufacture of tools for sheet metal processing since 1992 competent partner. Our strengths are our deep-drawing tools especially when multiple trains are required. Tools we manufacture as an insert, consequential, Progressive and transfer dies, both for prototypes, as well as for series production up to a maximum weight of 10 tons. Deep-drawn parts of GDH We manufacture drawn parts made of all metal forming materials to be processed. Materials such as steel, stainless steel and nonferrous metals are brought with us into the right shape. The processing at a material thickness of 0.3 mm - 10 mm thickness up to a pressure of 800 tons possible. We manufacture according to your drawings, CAD data, and according to your samples.Their tools are taken or produced in-house. In addition, we offer the possibility of deep drawing simulation with single trains in our house. Pressed parts of GDH With us you get spun parts from all metal forming materials to be processed. Materials such as copper, brass, steel, aluminum, stainless steel, tin, and zinc are staying with us in the right shape. Rotationally symmetrical workpieces are to oä to a round plate size of 800 mm in diameter with an initial sheet thickness of 6 mm in St, 4 mm in VA, 8 mm in CU / CnZu. and 10 mm in Al manufactured as pressed parts. We manufacture according to your drawings, CAD data, and according to your samples. Their tools are taken or produced in-house. Laser Technology at GDH Lasers: We laser in 2D technology in possible sizes 3000 x 1500 mm. maximum thickness * In VA to 12 mm * St to 20 mm * Al to 6 mm In 3D technology routes of sizes 3200 x 1525 x 600 mm are possible. Maximum thickness here * In VA to 4 mm * St to 8 mm * Al to 3 mm Punch Technology GDH Punching: Up to a print capacity of 120 tons from the tape. Up to 800 tonnes in the insertion process.

Founded

1992

Employees

100 - 200

Certifications

Bad Marienberg

Germany - 56470

Know-how - know how You have the idea, we'll do the rest: We are your competent partner when it comes to outsourcing. From services such as design or individual processing steps to the complete production process from A to Z including pre-assembly. Just ask us!

Founded

Employees

100 - 200

Certifications

Lauchheim

Germany - 73466

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1992

Employees

20 - 50

Certifications

Jena

Germany - 07745

Metal spinning: - Diameter of D = 10mm to D = 1'500mm - Material thickness of s = s = 0.5mm to 6.0mm - All metals (aluminum, stainless steel, steel, titanium, silver, gold ...) Deep drawing: - Width across corners component of E = E = 10mm to 1'800mm - Material thickness of s = s = 0.5mm to 6.0mm - All metals (aluminum, stainless steel, steel, titanium, silver, gold ...) Metal spinning: (Http://www.metallumformung.ch/de-de/metalldr% C3% BCcken / beschrieb.aspx) Take advantage of the possibilities of this interesting process. If the metal press used by specialists, achieved by no other forming process particularly for single pieces or small series its economy. Deep drawing: (Http://www.metallumformung.ch/de-de/tiefziehen/beschrieb.aspx) Less is often more! With the possibilities of deep drawing we can produce items where other methods are dependent on the assembly of several parts long. Use this advantage with integrated cost reduction.

Founded

1957

Employees

10 - 20

Certifications

Hombrechtikon

Switzerland - 8634

Features Quality Management zertfiziert according to ISO / TS 16949:2002 including ISO 9001:2000 Measurement: Zeiss CNC 3D coordinate measuring machine, Mitutoyo 2D metrology Production range: Stamped, pressed and drawn parts, assembly, welding joints, joints Materials: Varieties: steel, stainless steel, aluminum, brass Dimensions: Coil: Bandwidth up to 800mm - strap thickness up to 6mm - Weight 5.000kg to Customers: Automotive, electrical, construction, camping and leisure industry, child safety Machine types: Stamping presses, eccentric presses, hydraulic presses, Orbital, MAG-welding robots, press welding machines, stud welding machines Dimensions: Punching machines: 40 - 400 tonnes Eccentric: 10 - 160t Hydraulic Presses: 40 - 160to Own tool: Wire EDM, sinker EDM, CNC milling, drilling, grinding Development and design: CAD - CAM System VISI-CAD Interfaces: DXF, IGES, VDA, CATIA V4, Parasolid Data exchange: E-mail, Odette

Founded

1956

Employees

20 - 50

Certifications

Lennestadt

Germany - 57368

Our company, whose 1,200m2 is closed, serving in a total area of 1,500m2, continues to metal processing and shaping works with the knowledge and experience of its founders, today has undertaken to fulfill the requirements of the ISO 9001: 2015 quality management system standard and to continuously improve its effectiveness.

Founded

Employees

20 - 50

Certifications

EYÜP

Turkey - 34055

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge