Worm gear: realize better purchase prices

Discover specialized suppliers for worm gears on Techpilot. Our platform connects buyers with suppliers who manufacture precise worm gears for various applications. Use the e-sourcing process to find suitable suppliers in real-time and reduce your production costs.

109 suppliers for Worm gear

We have been in operation since 1980, specializing in the manufacturing of machinery and spare parts. We are equipped with CNC lathes, CNC milling machine, conventional lathes and milling machines, grinding machines and drilling planes. We pride ourselves in taking on all kinds of extras and machines, tailored to the needs of each customer. Precision, productivity, professionalism are features that make up the company profile, which is based on our evolving mechanical perception. Our industries: •Aerospace and aviation industry •Packaging industry •Military engineering •Fittings engineering •Air conditioning •Automation and control engineering •Special purpose machinery manufacturing • Drive and gear engineering • Apparatus engineer • Textile • Telecommunications • Canning •Agricultural machinery • Packaging • Manufacturers of electrical appliances • Food processing industries • Clothing industries

Founded

1981

Employees

20 - 50

Certifications

Naousa

Greece - 59200

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

We are an innovative company has been established specialised in the sector of precision parts for machine construction. Customer orientation, quality, respectful labour relations. We are specialised in turning, milling, and grinding processes of mechanical parts.

Founded

1994

Employees

50 - 100

Certifications

Çorlu - Tekirdağ

Turkey - 59850

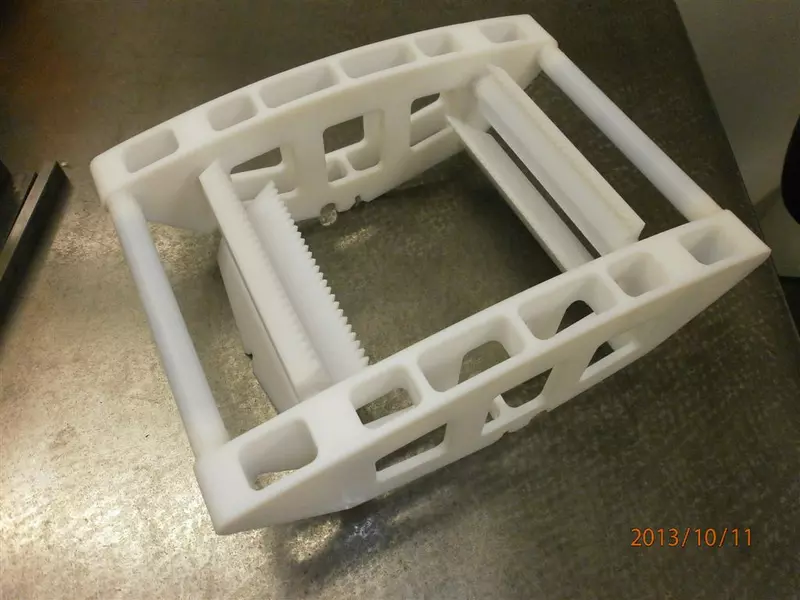

Company Profile Since 1991 Our family manufactures customized solutions made of plastic. In Gornau at Chemnitz today about 50 employees in the fields of semi-finished product processing, container and equipment construction, plant construction and cleanroom technology operate. Our solutions are used in industries such as machine and plant engineering, medical and environmental technology, the semiconductor industry and photovoltaics. The high quality of our products and services is evidenced by the certification of our company according to ISO 9001:2008. The internal design office as well as the technically and technologically advanced manufacturing guarantee our customers a comprehensive and high-quality advice and support. Involve us when planning your plastic just solution. Illustrate With our experience and the available CAD technology and we work out the best solution. We are happy to solve with our know-how your challenges. Products / Services Semi-finished processing Behälter-/Apparatebau Transparent Plastics Wasser-/Labortechnik Cleanroom technology Semiconductor engineering / photovoltaics Piping systems / special fittings Prototyping / Rapid Prototyping Machine technology With a well-equipped and very broad machinery, we can meet diverse customer needs. CNC lathe turning length up to 500 m 2 Milling Machine CNC 3-axis 1000 x 1300 x 160 Milling Machine CNC 3-axis 2300 x 1300 x 160 Milling Machine

Founded

2001

Employees

50 - 100

Certifications

Gornau

Germany - 09405

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

2011

Employees

10 - 20

Certifications

Láb

Slovakia - 900 67

FS Gear is a outsorcing company founded in the early 90s by the technical and commercial experience of the founders in the field of precision machining for third parties. The flexibility of a constantly updated and avant-garde machine park, and an organizational structure composed of specialized personnel are the strengths. Over the years, the company has made various investments in machinery and infrastructure to respond to market demands and establish itself in sectors such as oil & gas, iron and steel, machine tools and construction. The continuous search for improvement and the predisposition to follow the new technologies available on the market allows the FS to rationalize the production processes. In order to offer a complete service to its customers right from the planning stages, the company uses a technical office equipped with cad-cam stations.

Founded

1992

Employees

10 - 20

Certifications

Urago d´Oglio

Italy - 25030

Company ZUT "PROJEKT" offers services in: Processing of metal - milling, turning, Inen and outer grinding, Surface grinding, cutting, welding - steel, aluminum, stainless steel, Engineering, manufacturing spare parts and machine elements We offer: - Turning - Automatic turning (bar) - Hard roes - Milling - .... etc.

Founded

1991

Employees

10 - 20

Certifications

Konarzewo

Poland - 62-070

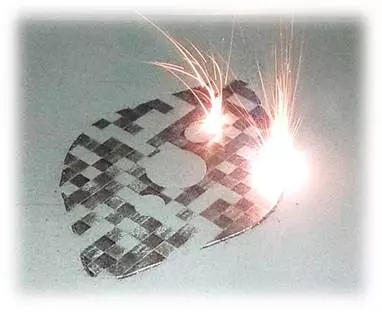

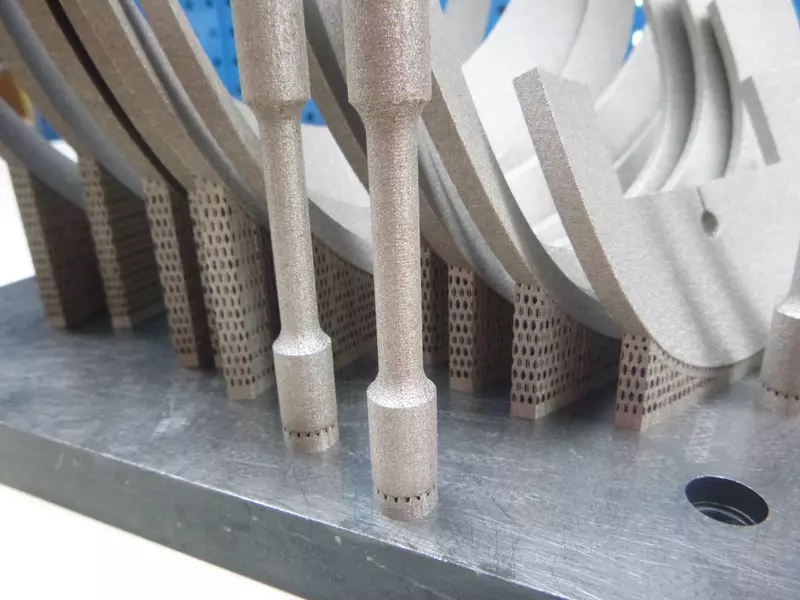

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Our goal is to convince our customers through our performance, which is always oriented towards our customers' high requirements regarding quality and on-time delivery. The most modern production equipment, quality assurance during production, and optimized processes make it possible for us to produce with speed, precision, and cost efficiency, all at the same time. Regardless of whether we mass-produce for you, deliver popular models on short-term notice, or manufacture individualized single components according to your specifications - we are consistently working on optimizing our customer-oriented service. Bevel gears Hobbing max. Ø 250 mm, up to module 6 Splines Hobbing Grinding upon request up tp 1200 mm in length max. distance between centers: 1250 mm Sprockets Hobbing Shaping max. Ø 400 mm, up to 1 inch up to 1 inch Worms Chasing Milling Whirling Grinding up to module 3 up to module 6 up to module 6 up to module 7 Worm wheels Hobbing upon request Helical gears Tooth flank grinding max. Ø 300 mm, module 6 Spur gears Hobbing Shaping max. Ø 600 mm, module 6 max. Ø 500 mm, module 6 Timing gears Milling available on short notice, in stock: from module 0,5 to 10 mm and from partition 2 - 10 mm; up to 3000 mm in length External grinding up tp max. 270 mm, max. distance between centers: 1000 mm CNC drilling upon request CNC and conventional turning up to Ø 400 mm, length 1200 mm Surface grinding max. length 2000 mm CNC and conventional milling upon request Thread grinding upon request Internal grinding max. grinding Ø 200 mm, max. grinding depth 250 mm Grooving: milling, cutting, reaming up to 28 mm Surface treatment such as hardening, nitriding, etc. Centerless cylindrical grinding max. Ø 70 mm Racks (High-Precision Racks) Type of Machining Machining Sizes Milling available on short notice, in stock: from module 0,5 to 10 and from partition 2-10 mm up to 3000 mm in length Delivery program: Gear wheels, spur wheels, racks, snails, worm gears, worm shafts, chain wheels, toothed belt wheels, helical gears, bevel gears, splined shafts, pump impellers, any waves, flange. Nearly everything with teeth. Materials: Steel, high-grade steels, non-ferrous metals is processed such as copper, brass, aluminum and plastics in complete and wage labours. Thermal treatment and surface coating: Additionally to our achievements we offer still any surface treatments. Case-harden, nitrating, Nitrocarburieren, carburizing, sandblast, TENNIFER QPQ, as well as galvanizing, burnishing and the like. Our customers expect to get low-priced precision products from us, with short delivery times, reliable service, and constant high quality. This is exactly our strength - which is based on state-of-the-art production equipment, quality assurance during production, and optimized processes!

Founded

1957

Employees

200 - 500

Certifications

Kohlberg

Germany - 72664

Trasmissions Buzzolan Srl is a mechanical workshop that manufactures straight-tooth and helical gears, grooved shafts and high-precision mechanical components, through turning, milling, broaching, slotting and toothing. The experience gained over the years in the field of mechanical transmissions makes it possible to offer a highly technological production cycle accompanied by structured quality controls. To create our products, we start from materials such as common and alloy steels, aluminum, bronze, cast iron, brass and plastic materials. The company also offers heat and surface treatment and welding processes that are carried out by sought after and trusted external partners. Our Metrology room provides our team with innovative machinery and control tools throughout the processing cycle, from the start to the finished product. The company's goal is to guarantee products that meet the required quality standards with timely deliveries, offering accurate and attentive tailor-made technical advice if necessary.

Founded

1998

Employees

20 - 50

Certifications

Thiene

Italy - 36016

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

We manufacture for you in the areas of sawing, turning, milling, drilling, grinding, gear cutting and grooving. In all areas we have experienced employees who have been loyal to us since the company was founded. In order to preserve and pass on this experience, we regularly train successfully. Big and small, we can do both. Regardless of whether it is a small turned part or a large welded construction, we will manufacture it for you. Thanks to our wide range of machines, we have a high level of vertical integration, which enables us to offer our customers a wide range of components.

Founded

1994

Employees

50 - 100

Certifications

Wiesmoor

Germany - 26639

We, Metallbau Schmalenbach, specialize in manufacturing a wide variety of high-quality and tasteful stainless steel and corten steel accessories. Years of experience in working with metal products, experienced know-how and the gift for exceptional design give our products uniqueness. The focus is on narrowing down to the essentials. In a charmingly flooded world, peace and relaxation are important to us. Simplicity is the goal and with it the uniqueness of our products. In addition to our wide range of products, we also offer you the opportunity to have your ideas implemented. We offer you custom-made custom-made products. You are welcome to visit us at Linienstr.14 in 42289 Wuppertal.

Founded

2022

Employees

5 - 10

Certifications

Wuppertal

Germany - 42289

Gear and transmission construction according to customer requirements Prototype and series production Bevel gears and various other products

Founded

Employees

10 - 20

Certifications

Hausen

Switzerland - 5212

Your partner in manufacturing technology Using state-of-the-art and networked CAD systems, our engineers and designers develop efficient and innovative solutions for the diverse requirements of our customers. We produce quality. Are you looking for an individual solution? Our technologies are designed to meet all customer requirements With our diverse range of technologies, we offer you tailor-made solutions that are precisely tailored to your needs. Rely on our expertise and flexibility in the following areas: - Drilling mill work - welding - Spin - Milling - Grooves - Interlocking - deep hole drilling - Assembly - Mobile spindles Our range of services includes the construction of special custom-made products, the processing and production of prototypes, individual pieces and series, and the repair of damaged or worn tools and components. Let's talk about your project: Simply contact us or talk to your contact person directly. Our experienced team is happy to hear from you!

Founded

2000

Employees

50 - 100

Certifications

Papenburg

Germany - 26871

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Whether assembling components, manufacturing individual, small or large series parts, we are your ideal partner for complete solutions and contract work in a wide range of materials, shapes and quantities with an impressive price-performance ratio. Quality, service and a high level of technology are our traditions. Our know-how — for your success!

Founded

1946

Employees

10 - 20

Certifications

Herzogenbuchsee

Switzerland - 3360

We are a company with a tradition dating back to 1974 in the metal industry. Only our assistant tells you a lot about our work. To date, we have gained a lot of experience in manufacturing gears, reduction gears and steel construction. Our work is based on modern development, employee knowledge, clear goals and our vision. We are looking for new opportunities in the development of and for the modern production of high-quality products. We put a lot of work into developing new, better machines with a longer lifespan. Due to strict environmental policy, we attach great importance to the use of environmentally friendly materials as well as environmentally friendly end products

Founded

Employees

10 - 20

Certifications

Ptuj

Slovenia - 2250

Development at the highest level No compromises in quality and performance From transmissions, axles, vehicle components, systems and kits to entire vehicles in the area of very small and small series, Oberaigner can draw on decades of experience and expertise. Our expertise lies particularly in the entire vehicle powertrain, including axles and axle suspension, in particular in the area of all-wheel drive technology and special transmissions for special applications. Oberaigner is a long-standing system supplier to the automotive industry, certified in accordance with IATF 16949. Through continuous development of our management and QA system, we can ensure the provision of services using the latest facilities and methods, both for our own developments and for our customers. The components, aggregates, systems and vehicles developed by Oberaigner are subjected to extensive testing and testing in accordance with the latest standards in the automotive industry and in accordance with the specifications of our customers. When carrying out various tests and evaluating the results, we work closely with both clients and competent service providers, partners and scientific institutions in order to be able to offer our customers the best and safest product.

Founded

2002

Employees

100 - 200

Certifications

Nebelberg

Austria - 4155

The Anant GmbH is a marketing subsidiary for own products & representation for few well-selected Indian manufacturing units. We have a good knowledge + experience for quality systems & supervised manufacturing outsourcing from India. Our German representation offers a potential to take up a responsibility to supply the article as door delivered & being your contact/contract partner. whereas our Indian technical team offers possibly of economical in-house manufacturing as well as local outsourcing under our supervision & our own quality control. At Patel Technomation - India, We have the experience and capability of sub-contract CNC machining including supply/procuring of foundry and forging products in small batches as well in large quantity. We follow the TÜV SÜD ISO 9001-2000 quality system and are dedicated to providing excellent customer service, and the timely delivery of quality products. Our Manufacturing unit is located at major Auto-parts manufacturing, Casting, Forging & engineering hub in India; which offers us a good development possibility for any specific/special part manufacturing possibility in a most economical manner.

Founded

2006

Employees

200 - 500

Certifications

Oberschleissheim

Germany - 85764

DIM.KO ENGINEERING , is a CNC machining and more subcontracting business with ISO 9001:2015 certificate and quality control room with CMM machine based in Thessaloniki, Greece and is housed in privately owned premises of 2.500 sq.m. Since 1987, we have been supplying industrial companies with innovative industrial components of high precision, productivity and complexity, consistently meeting the most specialized and demanding customer needs. Our services include: Manufacturing of high precision parts & from a wide range of materials, through the use of CNC machines Design of industrial components Machining and repair of industrial components The success of our company is due to a combination of factors: It has specialised and modern mechanical equipment It is staffed by personnel with excellent expertise, a customer-oriented approach and commitment to the goal. It invests in the human factor, building strong, trusting relationships with its customers

Founded

1987

Employees

5 - 10

Certifications

THESSALONIKI

Greece - 57013

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge