Chromatizing: get complete market transparency

Discover specialized suppliers for chromatizing on Techpilot. Our platform connects buyers with suppliers who use this surface treatment to enhance corrosion resistance and aesthetics. Benefit from better purchase prices by comparing multiple offers.

299 suppliers for Chromatizing

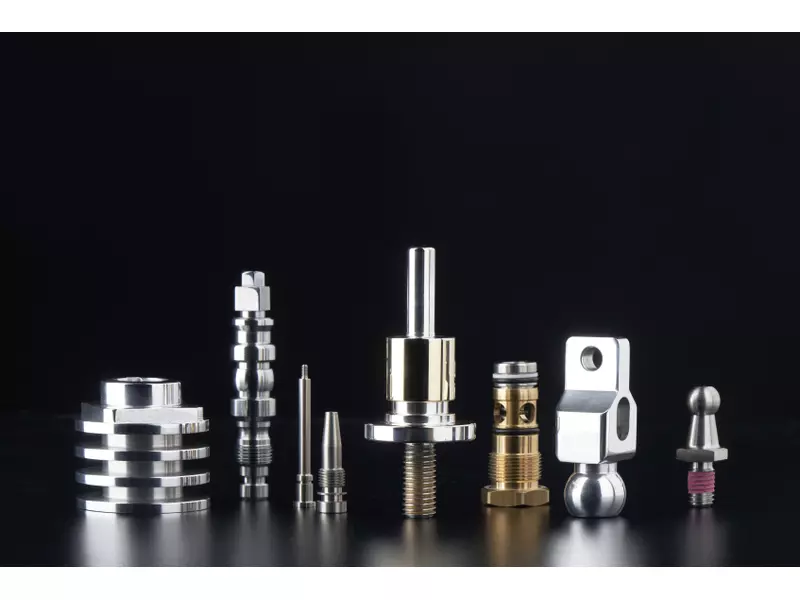

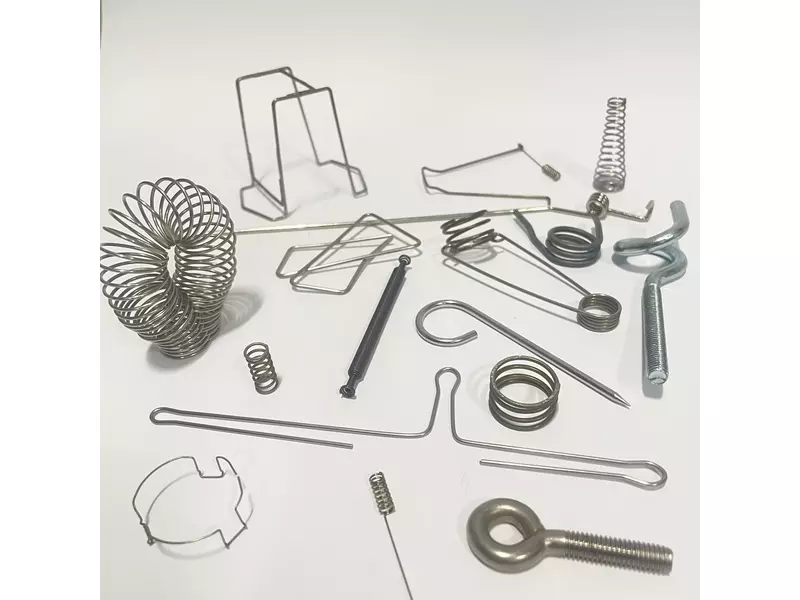

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

Manufacturer of series turned parts from all cut materials according to your specifications. In addition to being a reliable supplier, our major passion is the development of optimum solutions.

Founded

1971

Employees

50 - 100

Certifications

Gunningen

Germany - 78594

Founded

1933

Employees

20 - 50

Certifications

Forchheim

Germany - 91301

KALİBRE MAKİNA TAAHHÜT TİC.LTD.ŞTİ. Köseköy San.Sit.M Blok No: 248 ZIP: 41250 Kartepe / KOCAELİ / TURKEY Tel: +90262 373 52 52 kalibre.mak@hotmail.com

Founded

2010

Employees

10 - 20

Certifications

Bornova-İzmir

Turkey - 35040

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Your partner for fine sheet metal work - competent, innovative and flexible We are a family owned company in the field of sheet metal processing. As a system supplier, we specialize in the custom case production and the Production of sheet metal parts, assemblies and mechanical systems specializes. We manufacture the most modern equipment parts in the technologies stamping, punching lasers, laser (Trumpf), bending (trump), stud welding (Soyer) and Bolzeneinpressen (PEM, Haeger), milling (DMG), riveting, spot welding and welding. We have all the options to implement high-precision and highly complex designs. The own 3D design processes all common file formats. We design, of course, optimized for production in-house. We offer not only the powder coating on all major galvanic surfaces and screen printing. In our assembly we assemble electronic components to building complete electronic devices including commissioning, packaging and shipping. United with our qualified staff we offer you high quality products from prototypes to series production. B & S is a powerful partner from the idea to series production. We have the know-how, the capacity and the associated technology to deliver from simple stamping, laser part to the complex case or cabinet, all from one source.

Founded

2004

Employees

100 - 200

Certifications

Grafenau

Germany - 94481

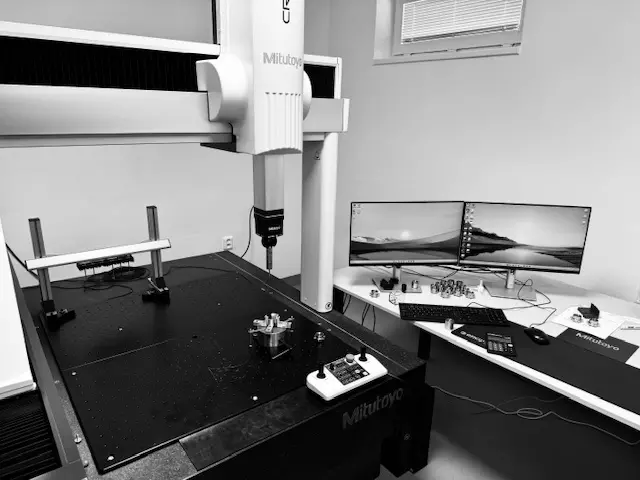

Our mission is to provide first-class services in the field of CNC machining. Thanks to our passion for technological progress and continuous improvement of production processes, we are able to meet even the most demanding requirements of our customers. Our customers demand not only high quality and precision, but also flexibility and the ability to quickly respond to changes in production requirements. We are proud to be able to offer comprehensive services from technology design through production to final quality control. Our customers particularly appreciate our professionalism, technological equipment and ability to meet even the strictest deadlines. We have a production capacity of 400 hours per week, which enables us to efficiently respond to the demands of our clients. Our 960 m² production facilities are equipped with the latest machines and technologies that ensure high precision and product quality. Our customers include : Siemens s.r.o., Flowserve s.r.o. John Crane Škoda Transportation a.s. DPOV a.s. Excalibur army spol. s.r.o. Company Technology : Metalworking - CNC turning , CNC milling , CNC measuring , conventional turning and milling. Cutting work on CNC plotter. 3D printing. Production of hydraulic hoses - industrial hoses, air hoses, rubber and flooring + accessories. MIG/MAG and TIG welding. Locksmith works. We also provide : - Heat treatment of metals (hardening, annealing..) - Casting (cast iron, steel, aluminium) - Forgings, forgings... - Surface treatment (comaxite, zinc, etc..) - Grinding Translated with www.DeepL.com/Translator (free version)

Founded

2021

Employees

10 - 20

Certifications

Šternberk

Czech Republic - 78501

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

Othni employs about 100 people and manufactures over 6000 square meters of production space parts made of steel, stainless steel and aluminum sheet. We see ourselves as an active partner system. Customer proximity is lived. From the development, the first prototype of complex assemblies, through to series production, we offer our services. A certified quality management completes our range of services.

Founded

1996

Employees

100 - 200

Certifications

Borchen

Germany - 33178

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

We are a company dedicated to ugarisches sheet metal processing and exciting machining by machining centers for small and medium series .. The focus of our work lies in the production of complex assemblies including assembly such as FTS, Heber and packaging machines. Our machinery, we continuously expand and modernize one of the most modern in Hungary. From single part production through installation to commissioning of the modules and machines, we can offer the full range of services you need. Give us a try. We put an offer below that will convince you.

Founded

1993

Employees

50 - 100

Certifications

Kiskörös

Hungary - 6200

SINCE 2009 .... The company was founded in 2009 by Mrs. Bettina Landgraf-Kaiser, storage capacity today is about 3000 m² in three halls. As a leading warehouse distributors constantly about 100 cars and well-preserved machines of best brands offered. State of the art warehouses with crane capacity up to 10 tons and forklift capacities up to 7 and highly trained staff are the benefits for potential customers to find the "perfect machine". Complete "all-inclusive" packages (eg transport, introduction, installation Complete training) are developed and implemented according to your. MEMBER OF: Since 2009 FDM - Germany Since 2009 EAMTM - Brussels (International) SPECIALITY: Cutting metal-working machines Our specialty is the trade used machines from metal cutting. Whether conventional or CNC - controlled, we each offer the right machine for you.In CNC - area we act almost exclusively with the control type Fanuc & Heidenhain. Here we can give you the best - provide service, whether coverage with qualified staff, service staff or software solutions. OTHER: Furthermore, even spare parts - remakes produced directly in the house with us. Through years of experience of our employees in the cutting process on Fanuc & Heidenhain controls, we can therefore offer cost effective replacement parts alternatives you.

Founded

2009

Employees

5 - 10

Certifications

Bruchsal-Büchenau

Germany - 76646

We manufacture various plastic components individually according to your wishes and requirements, as well as support you with our know-how in the planning and implementation of your project. With our various processing methods, we have the possibility to carry out the entire component processing. Alternatively, we will be glad to assist you in subsequent work such as contour adjustments or deburring of existing components.

Founded

2017

Employees

10 - 20

Certifications

Murr

Germany - 71711

A Czech-growing small businesses (20 staff) offers its services in the metal working, equipped with modern machine stock. - CNC milling - Wire EDM - CNC Turning - Drilling - Grinding, etc. We process Alumunium, steel, brass, copper. We provide the best price, highest quality and reliable deliveries.

Founded

2000

Employees

10 - 20

Certifications

Trutnov

Czech Republic - 541 01

We are a machine manufacturer with over 18 years of experience in manufacturing technical parts for various industries in the Czech Republic and abroad. Our focus is on producing smaller series. We also offer complex services for every sector.

Founded

2005

Employees

20 - 50

Certifications

Veselí nad Moravou

Czech Republic - 69801

High-quality products – from the concept to the finished part. EVN Blechverarbeitung manufactures individual parts and series production from aluminum, stainless steel, and steel for the mechanical engineering and automotive industries. Our machinery includes high-tech laser and bending machines, such as the Trumpf Fiber, which operate with the highest precision. With 24 kW of power, we can cut sheet metal up to 60 mm thick.

Founded

2000

Employees

10 - 20

Certifications

Peißenberg

Germany - 82380

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Medium-sized company near Chemnitz (Germany) Products: Sheet metal parts and components (Laser cutting, stamping, bending, welding, surface coating) Complete machines und machine components incl. electrical, hydraulical and air compression components according to customers' drawings

Founded

1990

Employees

100 - 200

Certifications

Frankenberg / Sachsen

Germany - 09669

MAKROSAN was founded as a family company with the production experience of more than 30 years and is mainly focused in turning & milling, sheet-metal cutting, laser cutting, sheet bending, pipe and profile bending, welding and assembly operations for the automotive, furniture, mechanical engineering, construction, agriculture and supplier industries. We manufacture according to your drawing specifications many varied parts: from aluminum to titanium. In the metal sector, we know almost no limits. We started with CNC laser cutting. Encouraged by the growing demands of our customers, we have added more technologies to our production spectrum over time; CNC bending, hand welding and robot welding, assembly assembly and CNC profile and tube bending. We can also offer CNC tube laser, CNC machining / milling / turning. We also have other business partnerships that we have been working together for years in the metal sector as well as the stamping, pressing parts and fasteners and tooling. We also have cold and hot formed parts made. Our company is located in Bursa, in the heart of the Turkish industry. Our company is certified by PCA to ISO 9001. MAKROSAN PROMOTION FILM: https://www.youtube.com/watch?v=Wn_3hNaqo5I As a competent supplier of sheet metal and metalworking and other areas, we work nationwide with well-known companies. We also export to several companies throughout Europe. We are interested in a long-term, strategic cooperation with your company. Best regards from Bursa! Murat RAHİMOĞLU Managing Sales Manager / Managing Director MAKROSAN METAL - Flexible Sheet & Metal Processing Mobile: +90 542 360 45 12 Mail: mr@makrosanmetal.com.tr MAKROSAN METAL San. & Tic. Ltd. Şti. Kayapa Sanayi Bölgesi, Orkide Cad. No: 9 16315 Bursa / TURKEY

Founded

2012

Employees

20 - 50

Certifications

BURSA

Turkey - 16315

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

The company The "Heinz Rohrich GmbH" comes from the existing company since 1981 "Heinz Rohrich - racing" out. In 1996 the company was renamed "memotec metal and motorcycle technology" and continued in the current premises. Due to the rapid expansion was relocated to Untergruppenbach 1998. The new facilities now offered the possibility to accommodate two separate departments. Both divisions developed continuously in size and amenities. In 2005 the name was changed to "Heinz Rohrich GmbH" was. Due to continued growth, we were able in March 2007 relate a large private building in mite (commercial fishing area fields). Currently, the Heinz Rohrich GmbH employs 10 qualified employees, which by means of continuing education for the best execution of all tasks. Services In the area of metal art welding structures of steel, stainless steel and aluminum are mainly manufactured.For use MIG, MAG and TIG processes come. The maximum component size is about 3000x1500x1500 mm. The unit weight is up to 5t. All welding work is performed on SYSTEM TABLES and ensure the best possible dimensional accuracy and angularity. Our service includes material procurement, preparation, welding, straightening and plastering. Mechanical processing - including surface coating or surface coatings-is performed by partner organizations. Another field of activity is the order and repair welding at nearly all weldable materials. A special case forms DC welding of aluminum (reduced delay on machined parts) The company Heinz Rhrich GmbH offers the following activities: - TIG and MIG welding of aluminum and wrought alloys - TIG and MIG welding of Cr Ni steels - Repair and surfacing - Manufacturing of complete assemblies - Jig and troubleshooting - Single and series production

Founded

1996

Employees

10 - 20

Certifications

Flein

Germany - 74223

As a solid, medium-sized company, we have been manufacturing for national and international customers since 1998. Top quality precision parts on reliable dates Are you looking for a reliable partner for your production orders? Then you've come to the right place! Customer satisfaction is our top priority. Rely on our experience and excellent service For your inquiries, we only need the PDF and step files of your parts. We are always happy to provide you with advice and assistance. Two automated 5-axis milling centers produce serial parts with us unmanned around the clock

Founded

1998

Employees

5 - 10

Certifications

Weingarten (Baden)

Germany - 76356

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge