Carbide tipped contour cutting: find suppliers on Techpilot

Discover specialized suppliers for carbide tipped contour cutting tools on Techpilot. Our platform connects buyers with suppliers who manufacture precise tools for various applications. Benefit from free use of the platform and efficient supplier search.

94 suppliers for Carbide tipped contour cutting

Koutsogiannis LTD – Steel Workshop was founded in 1994 by Mr. Koutsogiannis and Ms. Christofi. The company has been active for 24 years in the fields of mechanical engineering and repairs, emphasizing in the high quality and fast delivery times. We are a company overlooking the sea, just 10 km from the port of Volos and above us the Mountain of Centaurs. We are a small team. Titles and positions are of secondary importance for us. Fostering long-term relationships with a diverse mix of latest technology and highly skilled employees. Building on our long experience and in-depth know-how proven in numerous reference projects. Team spirit is lived every day. We pull together in the same direction. Together we have overcome any economic crisis. We have no perfect marketing, but great products and a good advice for our customers. Our success is confidence in our people and not their control. Quality is the pride of every employee and not just a corporate goal. A machining piece which is supplied to the customer is at first a piece from Kostas, Giannis, Nikos etc., and only secondarily one from Koutsogiannis LTD. Customers are our friends and partners. Each employee is responsible for the future of Koutsogiannis LTD.

Founded

1994

Employees

20 - 50

Certifications

Volos

Greece - 38500

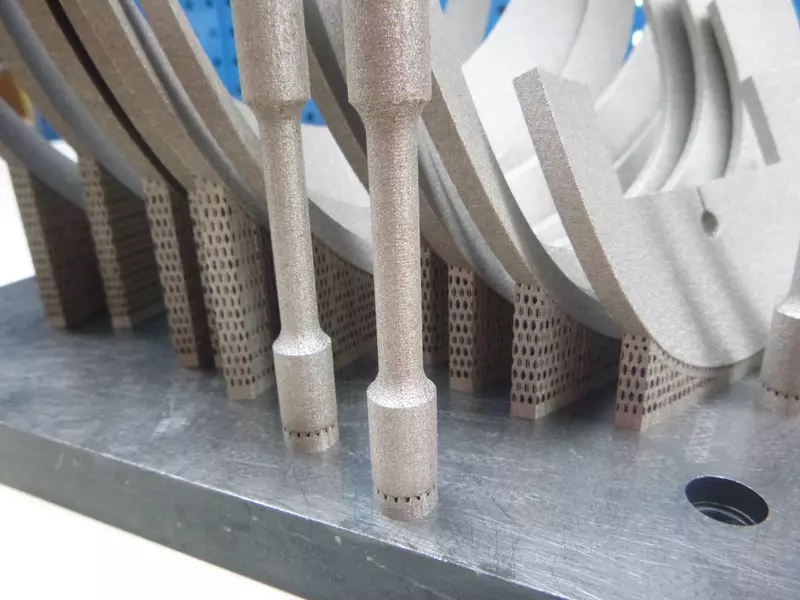

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Founding of the company 2002 First commercial premises in Lovrenc na Dravskem polje Experiences mean the future We work with 15 years of experience and are constantly investing in new technologies. We manufacture high-quality and sophisticated machine parts and offer a complete service.

Founded

2002

Employees

5 - 10

Certifications

Kidričevo

Slovenia - 2325

Our production range is metal sheet production, CNC laser cutting, CNC metal sheet bending, MIG welding. Continuously look for ways to improve our quality, process efficiency, training, working conditions, equipment, and technology. Long lasting relationships with our customers and vendors is a fundamental goal at Montmetal. Our company has many years of experience with customers like you. We are located in Croatia and we can export anywhere in Europe. Feel free to contact us and send us your inquiries, we will answer you within 24 h

Founded

1996

Employees

10 - 20

Certifications

Benkovac

Croatia - 23420

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1974

Employees

10 - 20

Certifications

Lana

Italy - 39011

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

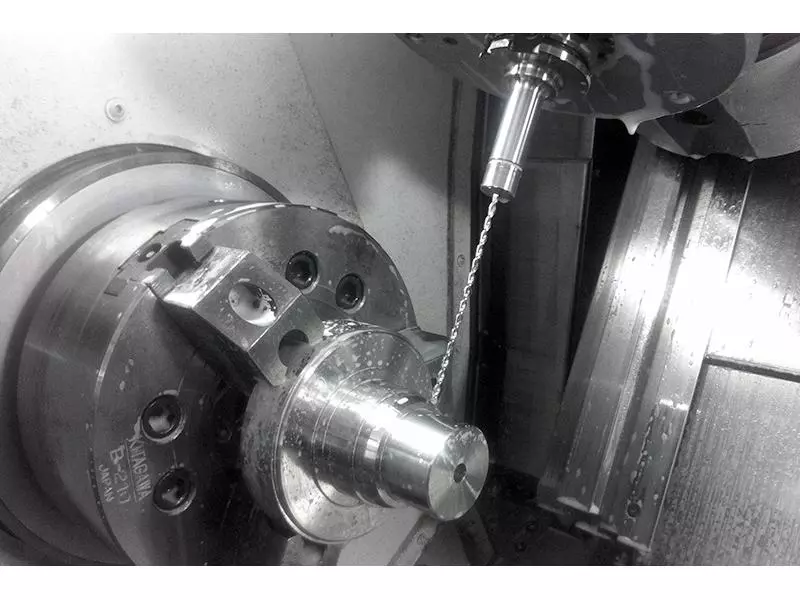

Precision rotary parts, - milling and ground parts (Ground parts) - Transmission shafts (drive shafts) to 1500 mm, hollow shafts, rotor shafts - Flanges (Intermediate), bolts, fittings, machine components - Cells wheels, worm shafts, knife shafts. - Guide rails, shaped pillars Machine Knives Knives industrial Press Brake - Perforating, squeezing knives, shear blades, packaging knives. Knives for plastics industry, mill knives, textile knives, sheeter knives, crush cutter, foil knife, knives, tungsten carbide blades, serrated blades, welded-on blades, slitter knives, Plotter and other machinery knives. Circular knife round knife Circle diameter (round blade) are rotating tools that can be (with counter-blade) was used with a knife cut or shear cut method. Circle diameter (round blade) can be produced for different applications from different materials (stainless steel, tool steel, HSS or stainless steel).The particular design can customized (eg ground on both sides, toothed, 2-wading, etc.). There arise because different names such as, crush cutter, top cutter, bottom cutter, pen-knife, plate diameter, perforating circular knives, rotor diameter, roller blades, etc. In addition, we also manufacture the knife holder and knife shafts and induviduelle cutting devices. The regrinding of circular knives is almost always worthwhile. Punching tools Punching diameter: Punching knife and cutting die are made from solid steel (eg tool steel 1.2379). The blades are hardened and ground. Punching blade made of solid material, are especially suitable for punching work with very precise contours as well as for long-term use, as they can be reground. Made of solid steel, we can also very small and precise punching knife and punching iron manufacture (eg samples dancing). Dies: We manufacture cutting knife and cutting dies from hardened steel strip and for a variety of punching tasks.Depending on the application, band knife made of spring steel, carbon steel, tool steel, stainless steel. Compared with the cutting knives made of solid steel, they are affordable and are suitable especially for disposable knives as well as large punch surfaces. We have stamping tools for individual tasks. - Cutting die, die cutting knife, cutting knife for test specimens, punches, punching, stamping dies, Steel rule dies, punches, - Cutting rollers, cutting mills, crushing blade - Punches and dies, punches, forming punches Flat - and cylindrical grinding - Surface grinding, surface grinding up to 3000 mm length - Cylindrical grinding up to 400 mm diameter - Fine grinding, lapping, polishing - Carbide Grinding Roll manufacturing roll grinding and - Rolls, roll cores, drive rollers, winding rollers, form rollers, fluted rollers Nippers, the cutting rollers, roll forming, turning rolls

Founded

Employees

Certifications

Schenefeld (bei Hamburg)

Germany - 22869

The Techno Trans GmbH making for over forty years (emerged from the former "screw") Quality and precision work and is dedicated to the manufacture of special tools a) for chipless forming for hot and cold forming presses: such as matrices, and Matritzenfassungen - inserts, extrusion rams, hole and Auswerfernadeln b.) for metal shaping for single - and multi-spindle automatic lathes and fitting and special machines. eg clamping and feeding tongs, clamps, steel holder and smaller devices. Round shape chisel, flat chisel shape, Tangentialmeißel, inner shape chisel, shaping tools and countersink. We also accept Turning-milling and drilling operations outside round, inside round and Flaschleifarbeiten, and profile grinding As a service we also offer the repositioning of tools to

Founded

1992

Employees

10 - 20

Certifications

Hildburghausen

Germany - 98646

As an innovative company and a partner in industry, we manufacture since 1990 complex CNC turned and milled parts in highest precision out of all machinable materials in small, medium and large series ago. We provide our customers with our years of experience and an extensive expertise in the manufacture of complex supply parts and assemblies. Our precision work is appreciated by many industries such as Automotive and vehicle construction, furniture industry or the machinery and plant, at home and abroad. Our machinery consists mainly of modern CNC precision lathes, CNC milling as well as the form and bar lathes. These mechanical equipment ermöglischt us not only an appropriate standard of quality, but also a high degree of flexibility in meeting individual customer requirements.

Founded

1990

Employees

5 - 10

Certifications

Fambach

Germany - 98597

QBER Srl, a consolidated company in the production of high quality mechanical parts. For over 50 years we have been working with important Italian and foreign companies that need reliable and serious partners, managing to guarantee them an excellent level of technological performance at low costs and fast delivery times. Our production is directed to the petrochemical, energy, automotive, pipe mills and wire technology sectors. The experience gained allows us to work different types of materials: steel, stainless steel, cast iron, non-ferrous materials and heat-resistant alloys. We also process materials for the production of tools such as hard metal and ceramics. A team that collaborates with commitment and a fleet of machines in continuous renewal and expansion are our response to the continuous challenges that the market offers us. From design to production, from outbound quality control to after-sales assistance. The entire production cycle takes place within our facility, which provides both single special mechanical processing and mass production.

Founded

Employees

5 - 10

Certifications

Mapello

Italy - 24030

Manufacturer of assemblies, sub-assemblies and single or serial parts from steel, aluminum and stainless steel for domestic, commercial and industrial use. Automatic Laser and plasma cutting machine Automatic Punching presses Automatic Sheet metal bending presses - Abkant Milling and turning machines Sheet metal rolling machine Welding machines (Tig, Mig-Mag, MMA) Bohrwerk Band saw Spot welding machine Sandblasting Electrostatic powder coating

Founded

1992

Employees

20 - 50

Certifications

Huedin

Romania - 405400

We are a company located in Koszalin, Poland. We operate on Polish market as well as in Western European countries. We offer a wide range of services in the field of metal processing: welding, metal sheet cutting, bending, machining, painting. We provide comprehensive service at all stages of implementation. You can count on consulting in the field of technology and construction, as well as the exact implementation of even the most difficult projects (including details with a high degree of complexity and accuracy). We are ready to cooperate with You.

Founded

2014

Employees

20 - 50

Certifications

Koszalin

Poland - 75-132

We, Metallbau Schmalenbach, specialize in manufacturing a wide variety of high-quality and tasteful stainless steel and corten steel accessories. Years of experience in working with metal products, experienced know-how and the gift for exceptional design give our products uniqueness. The focus is on narrowing down to the essentials. In a charmingly flooded world, peace and relaxation are important to us. Simplicity is the goal and with it the uniqueness of our products. In addition to our wide range of products, we also offer you the opportunity to have your ideas implemented. We offer you custom-made custom-made products. You are welcome to visit us at Linienstr.14 in 42289 Wuppertal.

Founded

2022

Employees

5 - 10

Certifications

Wuppertal

Germany - 42289

We are a company from Serbia specializing in laser cutting, stamping, and metal bending. With modern equipment and an experienced team, we provide precise and efficient metal processing services to meet various industrial needs. To better serve our European clients, we have a department in Austria that ensures smooth communication and prompt service.

Founded

2022

Employees

5 - 10

Certifications

Pukovac,Nis

Serbia - 18255

Your partner in manufacturing technology Using state-of-the-art and networked CAD systems, our engineers and designers develop efficient and innovative solutions for the diverse requirements of our customers. We produce quality. Are you looking for an individual solution? Our technologies are designed to meet all customer requirements With our diverse range of technologies, we offer you tailor-made solutions that are precisely tailored to your needs. Rely on our expertise and flexibility in the following areas: - Drilling mill work - welding - Spin - Milling - Grooves - Interlocking - deep hole drilling - Assembly - Mobile spindles Our range of services includes the construction of special custom-made products, the processing and production of prototypes, individual pieces and series, and the repair of damaged or worn tools and components. Let's talk about your project: Simply contact us or talk to your contact person directly. Our experienced team is happy to hear from you!

Founded

2000

Employees

50 - 100

Certifications

Papenburg

Germany - 26871

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We are Slovak company with 28years of experience in producing of parts for boilers and boilers itself, we have a lot of cappabilities in technical production. Our technologies: Laser cutting of sheets - 3 machines are available / max. dimensions of the semi-finished product 1500x3000 / Sheet metal punching - 1 machine is available / max. dimensions of the semi-finished product 1500x3000 / Sheet metal shears - 1 machine is available / max. edge length 600 mm / Sawing of material - 3 machines are available / up to D260 mm / Sheet metal edging - 4 machines are available - automated edging is also possible / max. hemming length of the semi-finished product 1000 mm 1x 2500 mm 2x, 3000 mm 1x / Sheet metal bending - 2 machines are available / diameter D70 mm - D1000 mm, max. edge width up to 1000 mm / Pipe bending - 1 machine is available / dimensions 1/2" to 1" / Thread cutting - 1 machine is available /from M5 to 6/4"/ Assembly welding - robotic - 4 machines / 8 workstations / / max. reach radius 1500 mm / Assembly welding - by hand / 11 workplaces / / MIG - MAG, TIG welding technologies / Spot welding of subassemblies - 2 spotting machines are available Bolt spot welding - 2 machines are available Air and water pressurization Painting with wet paint / water-dilutable ecological paint is used / Powder coating - varnish. line / max. part size 1500x1800 mm / Assembling assemblies and subassemblies / area - 1200 m2 / Final packaging of products - 2 machines are available

Founded

1995

Employees

100 - 200

Certifications

Vrútky

Slovakia - 03861

SPR GmbH is a service provider for the production of turned and milled parts and your reliable contract manufacturer! The strengths of our production lie in the production of individual parts and small series. Regardless of whether it's turning, milling or turn-milling combinations, our machinery allows us to be very flexible for you. The maximum travel distances for milling are 1,100 x 600mm and with 5-axis simultaneous machining, we can process workpieces of up to 1.2 tons. On our lathes, we can produce chuck parts from the smallest diameters up to Ø800 mm. Shafts up to Ø500 mm and a length of 2000 mm can be produced. We have had our quality standards certified in accordance with ISO 9001:2015 with our QM system!

Founded

2013

Employees

10 - 20

Certifications

Albershausen

Germany - 73095

We offer laser processing of metal components incl. CAD design on. Flexible production in shifts is possible.

Founded

2011

Employees

20 - 50

Certifications

Wissen

Germany - 57537

JG AUTOMOTIVE: Developer and Supplier in the manufacture of metal parts JG Automotive was founded in 1982, dedicated to the manufacturing, development and supply of metal components for the automotive and industrial sector. Thanks to the mastery of the technologies of manufacturing of metal products specifications provided by clients, we have diversified the industrial sectors of performance and optimized our work processes. In 2002, together with 18 international partners, we created Global Alliance, a large group with 230 cooperative engineers, manufacturers in Brazil, Germany, China, India, Italy, Japan, Korea and USA, among others, managing a joint turnover of € 1,720 M. Dozens of companies in the automotive, energy, railway, agricultural, elevation, etc. sectors, are already among our customers and fortunately for us every year we continue to grow thanks to the trust of our customers and the incorporation of new ones. Our products are presented with their corresponding quality certificates (IATF / TS / ISO / CE / PPAP). In short Technology and high competitiveness in products to specifications provided by clients. TECHNOLOGIES: Forging, Casting, Machining, Stamping, Laser cut, Welding, Raw Material, Microforge, Microfusion, Fasteners, High Pressure Cylinders, Hydrogen cylinders for hydrogen filling stations, Toolings, Precision Bar Turning and Special Parts, Inserts and Profiles, Tubes SW and DW and Rod Formers, Springs, E-mobility, Precision Gears, Bearings, automotive plastic injection parts and Returnable packaging of metal parts.

Founded

1982

Employees

50 - 100

Certifications

Madrid

Spain - 28108

PE "NARYZHNYI INDUSTRIES GROUP" is one of the largest Ukrainian suppliers of spare parts for fuel equipment. . NARYZHNYI INDUSTRIES GROUP has been operating in the market of fuel equipment and spare parts for trucks and agricultural machinery since 1996. Since 2000, we have started our own production of plunger pairs and high pressure sections. img Why NARYZHNYI INDUSTRIES GROUP? The machine park of our company numbers more than 100 units and includes a full range of processing equipment: 20 turning and milling CNC machines, grinding, horizontal boring and others. The plungers are ground at high-precision Swiss equipment. Most of our employees were trained in Germany, where they gained incomparable experience. The company has implemented a system of international quality standard ISO 9001 certificate В№ UA2.003.03554-09. Our specialists are constantly researching new advanced technologies for manufacturing plunger pairs, studying consumer demand for fuel equipment, and working on improving the products in accordance with world standards. We have our own tool shop where sharpening, regrinding and manufacturing of metal-cutting tools, both carbide and high-speed steel, are carried out.

Founded

1996

Employees

20 - 50

Certifications

Chuguev

Ukraine - 63506

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge