Coating technique: Find suppliers on Techpilot

Discover specialized suppliers for coating techniques on Techpilot. Our platform connects buyers with suppliers who use various surface coatings to meet your requirements. Benefit from comprehensive market transparency and optimize your supplier selection.

1624 suppliers for Coating technique

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

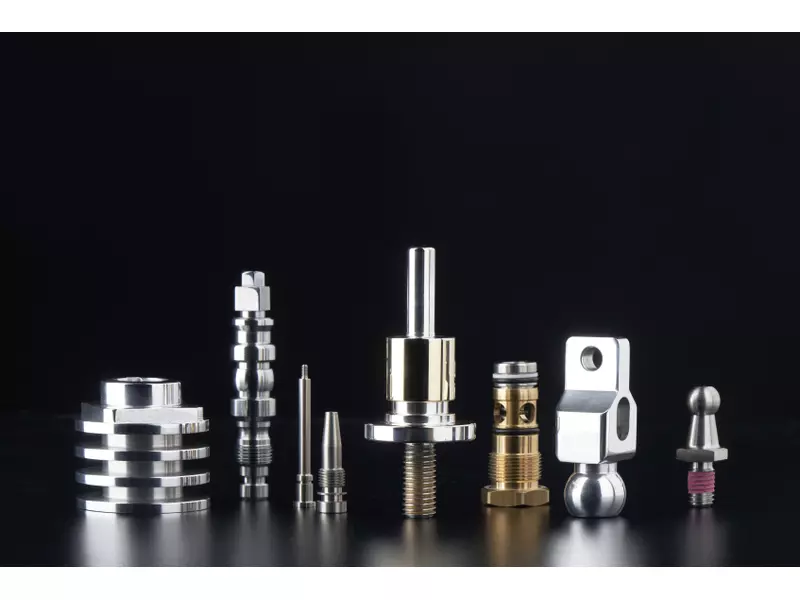

"A systematic approach to solution" The company PRO CNC GmbH & Co. KG was founded on 01.12.1990 by Michael Pfeiff under the name Michael Pfeiff. The company's headquarters was first in Varl and was moved in 1994 after Luebbecke. On 01.09.2003, the company was acquired by the current owner Volker Meier kink and then operated under the name Pfeiff toolmaking. Since 01.09.2013 we now operate under PRO CNC GmbH & Co. KG - Production Engineering and Mechanical Engineering. Mr. Meier is one kink with the company since the very beginning. The company PRO CNC GmbH & Co. KG deals with the full range of mechanical manufacturing (turning, milling, drilling, grinding) and the assembly of components and machines. Focus here is the contract manufacturing in the milling, especially the production of small parts. Cubic parts up to an edge length of 1000x600mm currently can be handled in-house CNC PRO GmbH & Co. KG. The company PRO CNC GmbH & Co. KG is able to deliver to the customer from the initial sample to mass production all.The range of parts includes the classic item to automobiles mass part. Is manufactured to eleven computer-controlled machine tools and machining centers the latest generation with up to four axes and two spindles. Some of the machines are equipped with rotary tables change. As a manufacturer, we would like to mention, among others, Bridgeport, Brother, YCM and Swabian machine tools here. The rotation range is among other things a lathe with driven tools, Y-axis and bar feeder (Biglia B650Y-turning diameter over bed max. 400mm) are available. Programming is based on dialogue and DIN controllers and by means of a CAD-CAM work on SolidWorks basis. Currently, the company PRO CNC GmbH & Co. KG two masters, a mechanical engineer, eight skilled workers, five assistants and a force in the commercial sector employs. The customer base includes about 30 customers from all sectors of the craft and the industry (electrical, mechanical, automobiles, pharmaceuticals, chemicals) in regional areas. Its customers include names like: VW, AEG, Federal Mogul, Faurecia (automotive sector) Harting, IMA, Kolbus, Oystar (engineering sector) VTG wagon Graaff, EuroMaint Rail (rail-rail vehicles) In May 2004, the company has been certified according to DIN ISO 9001-2000 since 2010, accordingly to DIN-ISO 9001-2008.

Founded

1989

Employees

20 - 50

Certifications

Lübbecke

Germany - 32312

Manufacturer of series turned parts from all cut materials according to your specifications. In addition to being a reliable supplier, our major passion is the development of optimum solutions.

Founded

1971

Employees

50 - 100

Certifications

Gunningen

Germany - 78594

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Metalkor’s core competence is plate conformation, especially laser cutting. Metalkor was founded in 1999 and is ISO 9001:2015 certified. Around 35 employees work for the company in the Júndiz Business Park in Vitoria-Gasteiz in northern Spain. We offer contract manufacturing, from individual parts to large series. Thanks to our experienced staff and modern machinery, we can offer our customers integrated solutions in the following sheet metal working processes: - Laser cutting and punching in one operation - Shearing and bending CNC - NC cutting and pressing - MIG and TIG welding. - Robotic and precision welding In addition, we also take care of the final processing of the metal parts: - Galvanised, zinc plated, brown burnished, tempered and painted (epoxy or liquid), etc. If necessary, we organise the transport of the products to our customers. Further information can be found at: www.lasermetalkor.com

Founded

1999

Employees

20 - 50

Certifications

Vitoria-Gasteiz

Spain - 01015

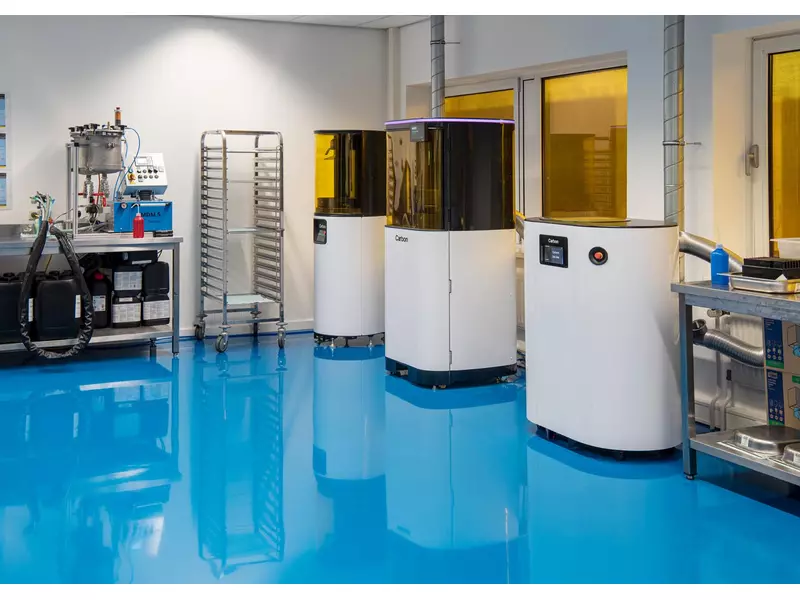

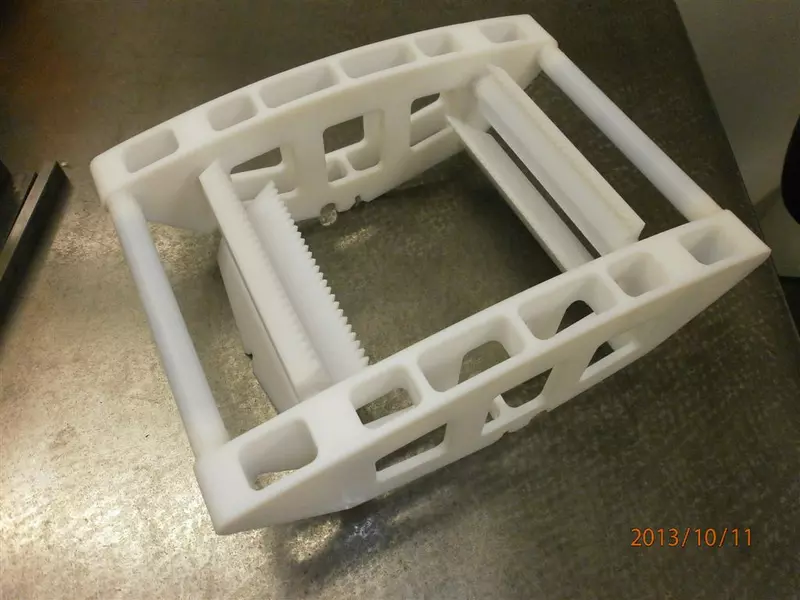

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

Company Profile Since 1991 Our family manufactures customized solutions made of plastic. In Gornau at Chemnitz today about 50 employees in the fields of semi-finished product processing, container and equipment construction, plant construction and cleanroom technology operate. Our solutions are used in industries such as machine and plant engineering, medical and environmental technology, the semiconductor industry and photovoltaics. The high quality of our products and services is evidenced by the certification of our company according to ISO 9001:2008. The internal design office as well as the technically and technologically advanced manufacturing guarantee our customers a comprehensive and high-quality advice and support. Involve us when planning your plastic just solution. Illustrate With our experience and the available CAD technology and we work out the best solution. We are happy to solve with our know-how your challenges. Products / Services Semi-finished processing Behälter-/Apparatebau Transparent Plastics Wasser-/Labortechnik Cleanroom technology Semiconductor engineering / photovoltaics Piping systems / special fittings Prototyping / Rapid Prototyping Machine technology With a well-equipped and very broad machinery, we can meet diverse customer needs. CNC lathe turning length up to 500 m 2 Milling Machine CNC 3-axis 1000 x 1300 x 160 Milling Machine CNC 3-axis 2300 x 1300 x 160 Milling Machine

Founded

2001

Employees

50 - 100

Certifications

Gornau

Germany - 09405

The company Rauscher has been active for different industries since 1984th The realization of specific customer requirements We achieve this through our modern and diverse machinery. Fully automated loading and unloading systems, we ensure a high Productivity in the production of turned parts. Do you have technical questions or want more detailed information? Then call us on the number 089/793 20 41, or send an email to: info@cnc-dreherei.com We advise you individually and in detail in your affairs. Translation by Google Translate

Founded

1984

Employees

5 - 10

Certifications

Putzbrunn

Germany - 85640

High-quality contract manufacturing in milling and turning area, component manufacturing, Punches for plastic films, repairs, Design and construction of special machines, PU and silicone plastic coatings

Founded

1995

Employees

20 - 50

Certifications

Euskirchen

Germany - 53881

UNGVÁRI WORKS Kft has been operating for 29 years. The company is a 100% hungarian-owned family business, it's founder and owner is Ferenc Ungvári. The company has 37 employees. The company's activity is the production of parts and components for the machine industry. Most of our product are manufactured in unique, small and medium quantities, our portfolio does not include mass-produced products. We supply 90% of our products to Western European machine manufacturers, we have clients in Germany, Austria, France, Switzerland and in Sweden. Presently, the production is performed in a plant with a floor space of 1200m2. In addition to our modern machinery and highly qualified colleagues, our production is supported by an integrated corporate management system, as well as by CAD and CAM softwares. Our processes are designed to satisfy the ISO 9001:2015 standard. Our activities: -machine parts and units production with CNC and traditional turning, milling and cutting technologies -welding -assembly -surface treathments -measurement -planning

Founded

1990

Employees

20 - 50

Certifications

Kiskőrös

Hungary - 6200

Short YOUTUBE Video: https://youtu.be/FzPtBnGDq2Q?si=E-E8EgaQiIz05Aov Our company is located in eastern Slovakia, in the industrial district of Široké village. Our over 7000 m2 of working area is divided among seven halls that are utilised for production, storage and offices. We are able to provide the best possible solutions for your needs, since we constantly invest in state of the art technologies and have extensive company expertise. In addition to Slovakia, we work with several businesses around Europe. We always strive to improve ourselves and to adjust technology to the newest trends. We are looking forward to cooperation!

Founded

2017

Employees

50 - 100

Certifications

Siroke

Slovakia - 08237

Welcome to our Techpilot page - I am glad that they visit us! The company Ing Marc Gruber KG -. Tirolaser is a medium-sized company from Lower Tyrol, more precisely the Zillertal, which specializes in the field of contract manufacturing in the field of sheet metal technology. Our core competencies lie in the field of laser cutting of metal sheets and pipes (steel, stainless steel, aluminum, copper, brass and titanium) and in the further processing of these blanks by bending, welding, surface treatment and assembly etc. We are happy to support them in carrying out their projects in the field of development / design and prototype production through our affiliated engineering office for mechanical engineering. they too can benefit from our 20 years mittlwerweile experience in this area. Solletn you have any questions, do not hesitate and grab them to the phone - we will be happy to give them help and advice! Your TiroLaser team Marc Gruber

Founded

2015

Employees

20 - 50

Certifications

Zell am Ziller

Austria - 6280

Established in 2004, Kurutlu Technologies is a leading CNC Precision Machining Service provider in Turkey. With 18 years of expertise in the field and high skilled production planning, Kurutlu can supply low and high volume of components including complex parts with its CNC milling and CNC turning services with 3-4-5 axis machining centers. The company is certified according to ISO 9001: 2015 and ISO 14001. Our Website is; www.kurutlu.com

Founded

2004

Employees

50 - 100

Certifications

ISTANBUL

Turkey - 34956

Since its inception in 1999 we have specialized in the manufacture of parts and series in the area of turning and milling, and are active throughout Europe. Regular investment in new technologies and manufacturing capabilities ensure optimal quality and customer satisfaction. Good Quality begins with a high-quality production equipment, efficient processes and a clear structure. Continuous development is the foundation of our success. We employ 35 employees in administration, construction and manufacturing. Join our 4 trainees for precision mechanics and in administration. The cooperation with TME is open, direct and uncomplicated. Our clients include companies in the areas of: Engineering, tooling, laser technology, and aerospace and automotive industries. Service overview Production / manufacture of components We manufacture parts, spare parts and small series to mass production according to your drawings or a pattern. Our machining capabilities include CNC-controlled milling, drilling, turning, wire EDM, surface grinding and conventional crafts and sheet metal processing. We can use our processing centers, parts machining, up to the size: L = about 2100, W= about 1000 B =, H = about 600 and up to a weight of 6500 lbs. Construction Design of tools, fixtures and equipment. 3D modeling for prototyping. Support for design tasks and advice on cost-effective and production-oriented manufacturing of your parts during development. CAD / CAM Acquisition and processing of all popular file formats such as : STEP, SAT, IGES, DWG and DXF programming with our CAM system. Welding / Heat treatment The welding of steel and heat treatment (hardening, tempering and annealing) are also of parts of the scope of our processing. Surface treatment Surface treatments, we can perform at our partner companies. Assembly Assembly of parts, components, tools and equipment. Reports On request, we create initial sample inspection reports and test protocols. Delivery We deliver your products on time with shipping or parcel service. We are a professional partner, trust TME!

Founded

1999

Employees

20 - 50

Certifications

Simmern

Germany - 55469

Torneria OML is specialized in high precision CNC machining. Since 1982 we have been specialized in the processing of any type of metal. Thanks to the use of the latest generation and highly technological machinery, we are able to guarantee the highest quality and precision, always offering an excellent quality / price ratio. Our qualified and constantly updated staff is able to quickly manage any type of order, from small and medium-sized production to high-precision machining. Thanks to the adoption of modern CNC technologies, we have considerably reduced production times, greatly increasing the reliability of the productions themselves. To always guarantee quality products, we have introduced systematic checks according to UNI and ISO 9001: 2015 and ISO 14001: 2015 regulations. Our company is part of the ATI set up for participation in the project “Venetian mechanical manufacturers on behalf of third parties present themselves in Europe”, which will be implemented using the POR Veneto region funding, part of the ERDF. Thanks to the use of the latest generation and highly technological machinery, we are able to guarantee the highest quality and precision, always offering an excellent quality / price ratio. Our qualified and constantly updated staff is able to quickly manage any type of order, from small and medium-sized production to high-precision machining. We are specialized in the creation of components for the sectors: Valves, Gas Components, Pneumatic Components, Automotive, Hydraulics, Hydraulic, Naval, Nuclear, Oil.

Founded

1982

Employees

20 - 50

Certifications

Castelgomberto

Italy - 36070

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1933

Employees

20 - 50

Certifications

Forchheim

Germany - 91301

Founded

1976

Employees

200 - 500

Certifications

Höchstädt a.d. Donau

Germany - 89420

KALİBRE MAKİNA TAAHHÜT TİC.LTD.ŞTİ. Köseköy San.Sit.M Blok No: 248 ZIP: 41250 Kartepe / KOCAELİ / TURKEY Tel: +90262 373 52 52 kalibre.mak@hotmail.com

Founded

2010

Employees

10 - 20

Certifications

Bornova-İzmir

Turkey - 35040

Manufacture of precision machined parts and milling parts from all machinable materials. CNC turning (up to D 90 mm rod) CNC turning (up to 250 mm in the feed) CNC long turning CNC multi-spindle turning (32 axes) CNC Machining Centers (5-Axis) Batch sizes up to 1000 pieces .... Piece including all subsequent operations up to the assembly In the field of machining there are many different ways of working. One is the CNC machining. Through this method, the milled parts get even complicated 3D contours. The CNC machining is done with machines with up to 8 axes. CNC turned parts can be made of different materials. For machining titanium, copper, brass, plastic, aluminum, stainless steel and other materials are suitable. Rotating parts in general can assume unusual shapes. In particular, the CNC milled parts often see pretty spectacular. Through its 3D contours CNC turned parts have a special effect.The machining is extremely versatile. Machining technology is used in various fields. Lathe parts, especially CNC lathe parts, are very expensive to manufacture. To produce a CNC lathe part, one special machines and more time than the normal CNC turned parts needed. The machining and especially the CNC machining requires a good education in the field. The partially very complex turned parts and just the CNC lathe parts require a tremendous expertise. A single CNC lathe part caused enormous amount of time. For these special turned parts, a particularly accurate work is absolutely necessary. For the purposes of machining are all chip forming materials. Depending on the material, the cutting is performed with different speeds. Are the turned parts made of wood, the cutting is done with high cutting speed and without cooling lubricants.Turned parts made of plastics, however, are processed at medium cutting speed. When machining water or alcohol are used for cooling. A special product from the metal cutting machines is the rotating part. Such automatic turned parts can be made from almost all machinable materials. Just like the CNC long turning parts of the screw-cutting without technical knowledge can not be produced. All machined parts require special machinery for the production. Rotating parts are to be finished by hand hardly. Are the turned parts made of wood or plastic, the machining is possibly still done manually, but with harder materials the use of expensive machining is necessary. To establish automatic turned parts, can not be dispensed with the machines. Automatic turned parts are usually ordered in enormous quantities and from extremely strong materials. Also for CNC turned parts is similar. This machining is simply too specific. CNC turned parts requiring extreme precision. Turned parts of this type are mainly used in machine and plant engineering. These industries would not do without CNC turned parts, turned parts, and the entire range of machining technology. Milling Services, CNC turned parts, turned parts, and just such special products as a CNC lathe part are absolute precision products. As simple as the concept sounds cutting, this process but it is not. Cutting sounds like simple separation that hide behind it but also things like complex CNC turned parts or automatic turned parts, no one thinks at first. Without these highly intricate parts, especially without the screw-cutting work would be impossible in some areas.

Founded

1938

Employees

50 - 100

Certifications

Wehingen

Germany - 78564

Metalex is a metal working company from Croatia, which is continuation of family company Gumex Eko, founded in 1990. Our production site is located 50 kilometers from the capital – Zagreb, and 5 kilometers away from the highway. We have 1270m2 of indoor production facility space, and professional staff who can respond to any of your request. Our main activity is producing metal construction, laser cutting, bending and other metal processing. Our laser has dimension of the table 4000x2000mm and our bigger press brake is 4300mm long. We also have our own powder coating line with curing oven of 7 meter long. We are working in whole Croatian market, but we also export in Slovenia, Austria and Germany. Mostly of our products are powder coated, but we are also producing items which are electro galvanized, hot dip galvanized and made of stainless steel or aluminium. Laser Concept is a brand name for our products. Our production range is metal sheet production, CNC laser cutting, CNC metal sheet bending, MIG and TIG welding, tube cutting, tube bending, punching of holes and profiles, notching, and POWDER COATING. Continuously look for ways to improve our quality, process efficiency, training, working conditions, equipment, and technology. Long lasting relationships with our customers and vendors is a fundamental goal at Metalex. Metalex d.o.o. Nikola Devčić, managing director

Founded

2013

Employees

10 - 20

Certifications

Dubrava

Croatia - 10342

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge