Stamping and bending: find suitable suppliers in real time

Find specialized suppliers for stamping and bending on Techpilot. Our platform offers access to suppliers who use advanced stamping and bending technologies to manufacture precise and durable components. Benefit from comprehensive market transparency and optimize your supplier selection.

491 suppliers for Stamping and bending

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

WKK Kaltbrunn AG - enormously in form The beginning of the WKK Brunn AG is founded in 1967. As a dedicated tooling the company had at that time only one purpose: the production of cutting, bending and forming tools. Shortly thereafter, the fabrication shop was put into operation and some ten years later, the company introduced her first own product. By continuity, innovation and perfection was out of the formerly peaceful Toolmaking a successful SME with about 45 employees.Today, the CHP is an international punching operation with most modern manufacturing methods in the supplier sector. enormously complete - from the first idea to the final series, we offer comprehensive services - Consulting: individual and professional, on-site or at our - Construction: in-house with 3D Autodesk Inventor - Prototyping: short to illustrate your ideas - Tool: for punching tool and teaching building, with modern machinery - Series production: stamping products of all types up to 250 tons of pressure and up to 300 mm width at 3 mm thickness (up to 5 mm after consultation) made of steel, stainless steel, non-ferrous and light metals - Component manufacture: Total manufacturer of your products, automated assembly - Post-Processing: Heat and surface treatments for partners near - Finish machining: by machining (milling, turning, drilling), eroding and vibratory finishing - Did you know? Also welding

Founded

1967

Employees

20 - 50

Certifications

Kaltbrunn

Switzerland - CH-8722

Short YOUTUBE Video: https://youtu.be/FzPtBnGDq2Q?si=E-E8EgaQiIz05Aov Our company is located in eastern Slovakia, in the industrial district of Široké village. Our over 7000 m2 of working area is divided among seven halls that are utilised for production, storage and offices. We are able to provide the best possible solutions for your needs, since we constantly invest in state of the art technologies and have extensive company expertise. In addition to Slovakia, we work with several businesses around Europe. We always strive to improve ourselves and to adjust technology to the newest trends. We are looking forward to cooperation!

Founded

2017

Employees

50 - 100

Certifications

Siroke

Slovakia - 08237

Founded

1933

Employees

20 - 50

Certifications

Forchheim

Germany - 91301

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our core competencies are: Tools - Hard Metal Processing - Sheet metal rounds - Punching / pressing (tool Falling) - Punching-bending (Bihler machine) - Stamping - Injection molding, extruding - injection molding - Encapsulation of inserts - To water - Die-casting - Ingot - Machine molding (sand casting) Translation by Google Translate

Founded

2003

Employees

5 - 10

Certifications

Offenburg

Germany - 77652

Customised production of housings and steel solutions based on intelligent metal processing. Our experienced specialists work together with you on the development of prototypes and support you in the implementation of your projects through to series production with a wide range of services such as planning, construction, manufacturing and logistics. At the same time, we meet even the highest quality requirements thanks to our strict controls. A modern production site in Poland is the basis for being able to respond flexibly, quickly and economically to your needs. A constantly growing machine park and a highly qualified team are the key to success and enable us to offer competitive prices using the latest technology.

Founded

2008

Employees

50 - 100

Certifications

Stammham

Germany - 85134

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

Consortium of companies active in the development of foreign markets. It acts as an export sales department for a number of SMEs located in Italy, all operating in sub-supply in the mechanical engineering industry. Our partners can offer, among others, the following main operations - Turning - Milling - Grinding - Sheet metal cutting and bending - Sheet metal forming - Assembling - Complete sub-assemblies - Sheet metal forming - Welded construction - Assembly of assemblies

Founded

2011

Employees

20 - 50

Certifications

Vicenza

Italy - 36100

Bauflaschnerei Winter GmbH is one of the leading companies in sheet metal technology and sheet metal processing. We have established ourselves in the fields of plumbing, roofing and façade construction. In addition, the brands Bleche-nach-mass.de and Magnetwandshop.de offer individual solutions according to customer requirements for B2B and B2C. Sheet metal technology at the highest level with the latest machinery.

Founded

1986

Employees

20 - 50

Certifications

Essingen

Germany - 73457

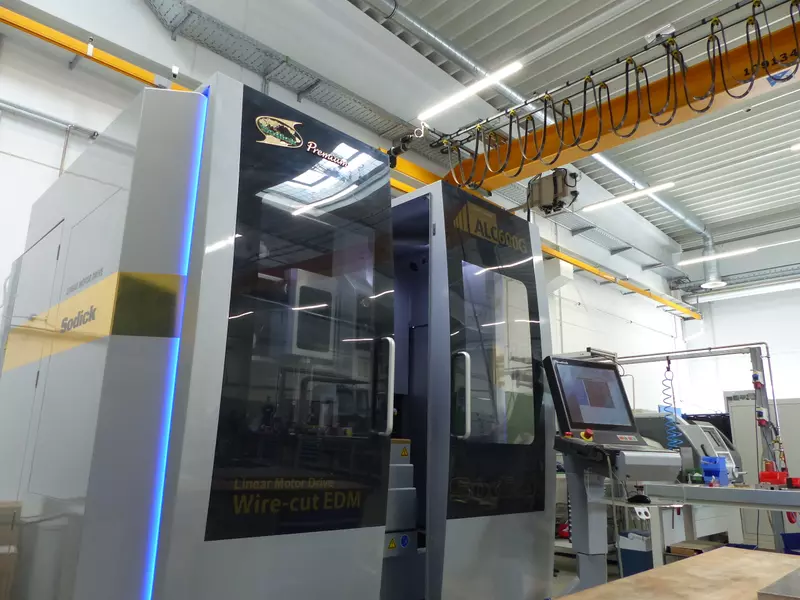

Our company was founded on 28.02.2005. It builds on the experiences that have been collected for years in the FIRE tool-und Maschinenbau GmbH in the field of stamping production. The acquisition of new hydraulic presses and the investment in a new Production facility enables us your client's wishes and not least Your product innovations enhanced implementation. We will advise you in the choice of materials and develop with you a tool concept. This can be thanks to the close cooperation with the FIRE tool and Maschinenbau GmbH are implemented quickly and effectively. Production of stamped parts Stampings band Stamping parts with thread Pressed, stamped and drawn parts connected tooling with 35 employees since 1992 CNC milling 3/5-Achs CAD CAM CNC turning CNC Wire EDM CNC sinker EDM List of machines We can customize your stampings on the following machines: Belt systems - 600mm width 8mm tape cross-section Eccentric EBU 1000 KN 80Hub/min Eccentric PME 2000 CN 80Hub/min Eccentric EBU 2000 CN 80Hub/min Eccentric PME 3150 CN 60Hub/min Insert presses: Eccentric Helmerding 850KN 60Hub/min Hydraulic press 250 kN 2x Hydraulic Press 400-630

Founded

2005/1992

Employees

10 - 20

Certifications

Oederan

Germany - 09569

SYS Pres company is metal fabrication company which spealizes in laser cutting, laser welding, welding, bending, and surface treatment operations. Surface treatments are automatic sand blasting, zinc plate, copper plate and etc. SYS Pres company's facility is 3000 sq. Our export countries are Austria, Germany, England, Netherlands, Belgium, Israel.

Founded

1992

Employees

50 - 100

Certifications

Manisa

Turkey - 45400

Cutting and non-cutting machining (sawing-milling-drilling-turning-tapping ...) of aluminum profiles on rotary indexing and CNC processing machines, up to 5 axes and partly with robot support

Founded

1985

Employees

50 - 100

Certifications

Herborn

Germany - 35745

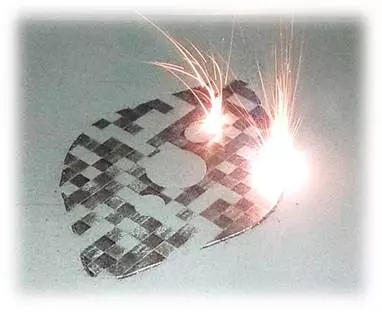

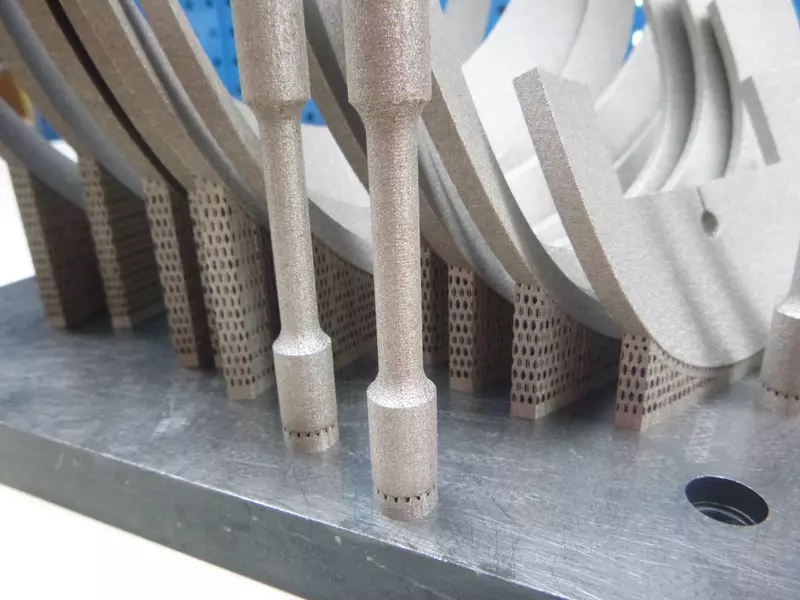

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Founded

Employees

5 - 10

Certifications

Amstetten

Austria - 3300

We serve as Automotive , HVAC applications , Sheet - Metal box Set. , Machining. and White goods sub-industry with Laser Cutting, Press Bending, Welding and Assembly processes. We process all quality stainless steel, aluminum, galvanized, titanium, lead and black materials in the most precise way within the desired dimensions and tolerances.

Founded

2015

Employees

20 - 50

Certifications

Yunusemre

Turkey - 45140

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

741/5000 we are a family company based in Slovakia. Our company is located in an industrial area in the city of Skalica. We are looking for more business partners. We deal with the technology of forming and offer free capacities in the areas of punching, cutting, bending, folding, riveting, assembly and various control activities (measurement, sorting, etc.) We also produce metal parts that are then coated with plastic. We deliver among other things Customers in the automotive, electrical and furniture industries. The ISO certificate 9001: 2015 is a matter of course for us. You can find more detailed information on our website. We would be glad about your answer.

Founded

1998

Employees

20 - 50

Certifications

Skalica

Slovakia - 90901

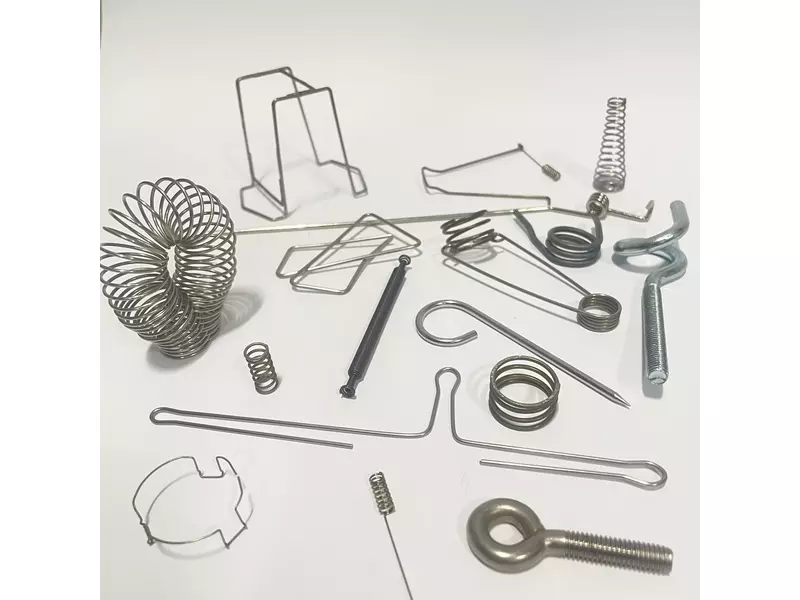

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

Miglio has been operating since 1971 in the progressive die construction, stamping and sheet metal processing sector, providing turnkey solutions for customised products. What we offer - Co-design of Products with the customer - Prime project management of assembled parts - Collaboration on process development - Production of small and large batches of stamped and assembled products - Complete control of the entire production process: > Die design: 3D software, Cad-Cam, prototyping; > Die construction; > Die maintenance: dedicated internal tooling. Miglio is focused on the customer, people and the environment. Our customer approach is based on relationships and the continuous exchange of information, which allows us to offer a precise and “tailor-made” service based on specific needs. Therefore, solid and trusting relationships are established with the customer, which make Miglio not just a simple supplier, rather a strategic partner. Another of Miglio’s founding principles is attention to the environment in all phases of work, from the pursuit of the most innovative solutions for machinery dedicated to production to company and plant management. Our strength, in addition to the high technical skills of our personnel and our instrumental equipment, is largely thanks to the people who collaborate in the company and in whom we continuously invest in order to organise a satisfying and engaging work environment. A note of interest: the staff turnover within the company is very low, if not almost non-existent.

Founded

1971

Employees

20 - 50

Certifications

Gera Lario (Como)

Italy - 22010

As a system supplier for electromechanical assemblies, we manufacture plastic and metal components using hybrid technology. This means that we concentrate on the production technologies of plastic injection moulding and punching and bending of metal components. The advantage for you is that you can obtain ready-assembled assemblies of the most diverse production processes from one source. By moving Friedrich Joerg GmbH in 2016 to newly built production and office premises, we were able to create a capacitive buffer. Thanks to a high degree of automation, we can offer you particularly competitive prices. We manufacture manually in small series up to large series fully automated and pre-assemble all components for you. In short, we adapt flexibly to your requirements. We provide support as early as the product development stage in order to take into account quality, cost and tool-specific aspects in the early phase. We manufacture the necessary tools or devices in our own tool shop. This also allows us to increase our flexibility, for example in case of short-term changes. Furthermore, we also offer finishing processes such as: printing on plastic parts (cliché/pad printing), hot foil stamping for a particularly noble appearance of the products, machining and ultrasonic welding. It goes without saying that we are certified according to ISO 9001:2015 and deliver a very high and consistent quality. We would be pleased if you contact us. categories: Electromechanical assemblies; Foil hot stamping; Customised plastic mouldings; Plastic optical fibres; Optical fibre components; Optical fibre systems; Optical fibre technology; Optical fibre transmission systems; Pre-assembly Assembly of small parts for industry; Assembly of plastic components; Assembly of mechanical components; Stamp-bending parts made of stainless steel, non-ferrous metal, steel; Stamp-bending tools; Connectors; Connectors for surface mounting; Complete plug connections; Pad printing; Thermoplastic precision mouldings; Thermoplastic overmoulding with plastic; ultrasonic welding of plastics; overmoulding tools for insert parts; 3-D MID components; connecting terminals for power cables low voltage & high voltage; component assembly; die casting; mould making; housings for the electrical industry; terminals for electrical cables; plastic injection moulded parts; plastic injection moulded parts with metal insert; electrotechnical plastic parts; technical plastic parts; plastic processing; multi-component injection-moulded parts; plastic-injected metal parts; product development; prototype construction; terminal blocks; technical injection-moulded parts; thermoplastic elastomer (TPE) moulded parts; jig and fixture construction; toolmaking; two-component injection-moulded parts; Imprint: https://www.friedrich-joerg.com/kontakt/impressum/ Privacy policy: https://www.friedrich-joerg.com/kontakt/datenschutzerklaerung/

Founded

1920

Employees

50 - 100

Certifications

Marktrodach

Germany - 96364

Culobel Group is an international technology partner with production facilities in Belgium and the Czech Republic and a sourcing office in China. We provide total solutions in sheet metal stamping, deep drawing, pressure vessels and assembly. Our constant innovation, a feel for creativity, and know-how built up over many years ensure outstanding quality. We assist you from the outset in the development of your product and possess the latest software with which to conduct feasibility studies. Over 50 automated mechanical and hydraulic presses up to 1000 ton are testament to the state-of-the-art machinery we have in house.

Founded

1929

Employees

100 - 200

Certifications

Frydlant - Ostrava

Czech Republic - 73911

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge