Pressure die cast molds: get complete market transparency

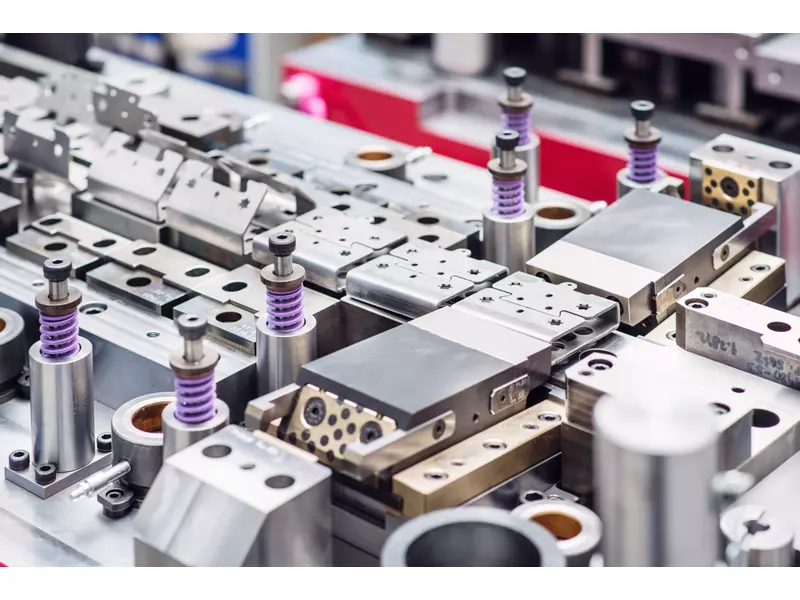

Find specialized suppliers for pressure die casting molds on Techpilot. Our platform offers access to suppliers who manufacture high-quality molds for various applications. Benefit from comprehensive market transparency and optimize your supplier selection.

431 suppliers for Pressure die cast molds

Inter Technic sro has developed in more than 5 years into a powerful company. If you are interested, we work for you as an extended workbench or can help reduce overcapacity, then ask us. In January 2015, our machinery was another new and powerful 5-axis simultaneous milling extended Hermle C42. We have currently in another, new DMG CNC milling machine invested. - Table load up to 2,000 kg - Table size 1700 x 750 mm - Travel X = 1450 mm, Y = 700 mm, Z = 550 mm This machine is our production in addition to available from the KW22 / 15th A robot welding system was installed. This brings us to weld able TIG and MAG. We are very well set up for you to produce tools and jigs. We are happy to customize items, zero series, production parts or assemble complete modules. With two new wire EDM machines we can in 2-shift operation for you. Our machinery has been almost entirely reinvested. For quality assurance, is from March 2016 new Zeiss measuring machine available! For programming we use two CAD CAM - Siemens NX Unigraphics, Version: 8.5 programming stations and enables us to offer services to the 3-D machining. Another added advantage of unsrem companies: All contacts at Inter Technic spoke German except Slovak, English.

Founded

2010

Employees

100 - 200

Certifications

Liptovsky Mikulas

Slovakia - 03101

Our history dates back to 1990, when engineer Dimitar Karagyozov laid the foundations for our company. In 2006, the company was re-registered as EOOD, and since then we have continued to develop and expand our offering. We specialize in manufacturing high-quality injection molds and plastic products that are used in medical technology, electronics and many other industries. Our experience and expertise enable us to develop tailor-made solutions for the individual requirements of our customers. In doing so, we attach great importance to quality, precision and reliability. We are proud to be a company that continuously strives to exceed customer expectations and drive innovation. Our mission is to add value through our products and services and to build long-term partnerships.

Founded

1990

Employees

5 - 10

Certifications

Sofia

Bulgaria - 1510

We are a company that has been the right partner for 14 years now when it comes to prototypes, tools and devices for the mobile sector. General contract manufacturing in the areas of HSC machining, mold making and model making complete our offering.

Founded

Employees

10 - 20

Certifications

Sarntal

Italy - 39058

We are a medium-sized company in the field of metal processing. Our core competencies include the production of series parts and assemblies for industry and plant and mechanical engineering, in particular the food and beverage industry. For over 75 years, Lungmetall OHG has stood for efficiency, flexibility and competence in steel, stainless steel and aluminum. Whether individual or series production, with our modern machine park tailored to the requirements of our customers, we manufacture for you flexibly, inexpensively and quickly. We are lean enough to flexibly implement your ideas and wishes, but also large enough to provide you with the capacity you need, even for large series. Thanks to our high level of vertical integration, we appear on the market as a system supplier, as we are not dependent on other trades. This manifests itself in short delivery times and a high quality standard. With our currently 60 employees and our in-house design office, we offer you an extensive service portfolio and reliable processing of your orders! We would be happy to win you as a valued customer and assure you of a partnership and team-oriented cooperation.

Founded

1924

Employees

50 - 100

Certifications

Kottenheim

Germany - 56736

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1980

Employees

5 - 10

Certifications

Nürnberg

Germany - 90431

Since 1986 we have been working as injection molding manufacturers serving a variety of local and international companies which operate in various fields and need molds either for big productions and limited edition products. What we do is easily explained. We design, manufacture and supply injection molds for the production of high-precision thermoplastic parts with exceptional aesthetic demands. We are specialized in the production of high-precision technical parts and multiple-impression molds for high production requirements, but we also supply prototypes and pilot molds for small and medium series that requires complex and intricate geometries – for instance, for limited editions. The headquarters are located in the Italian city of Rovereto, just 30 km from Trento, on the Brenner motorway link. This is the ideal crossroads between the major industrial districts in Northern Italy, such as the manufacturing (Lombardy, Vicenza) and optical (Belluno) ones, and important European countries such as Austria, Germany and Switzerland. However, there is more. We also work with factories based in the US and in the rest of the world. The know-how we developed over the years of experience in the field allows us to identify the most suitable kinds of injection molds on the base of your production types and aesthetic needs.

Founded

1986

Employees

20 - 50

Certifications

Rovereto

Italy - 38068

SINCE 2009 .... The company was founded in 2009 by Mrs. Bettina Landgraf-Kaiser, storage capacity today is about 3000 m² in three halls. As a leading warehouse distributors constantly about 100 cars and well-preserved machines of best brands offered. State of the art warehouses with crane capacity up to 10 tons and forklift capacities up to 7 and highly trained staff are the benefits for potential customers to find the "perfect machine". Complete "all-inclusive" packages (eg transport, introduction, installation Complete training) are developed and implemented according to your. MEMBER OF: Since 2009 FDM - Germany Since 2009 EAMTM - Brussels (International) SPECIALITY: Cutting metal-working machines Our specialty is the trade used machines from metal cutting. Whether conventional or CNC - controlled, we each offer the right machine for you.In CNC - area we act almost exclusively with the control type Fanuc & Heidenhain. Here we can give you the best - provide service, whether coverage with qualified staff, service staff or software solutions. OTHER: Furthermore, even spare parts - remakes produced directly in the house with us. Through years of experience of our employees in the cutting process on Fanuc & Heidenhain controls, we can therefore offer cost effective replacement parts alternatives you.

Founded

2009

Employees

5 - 10

Certifications

Bruchsal-Büchenau

Germany - 76646

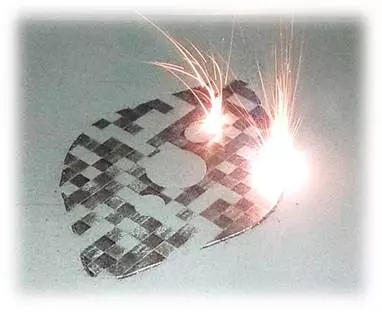

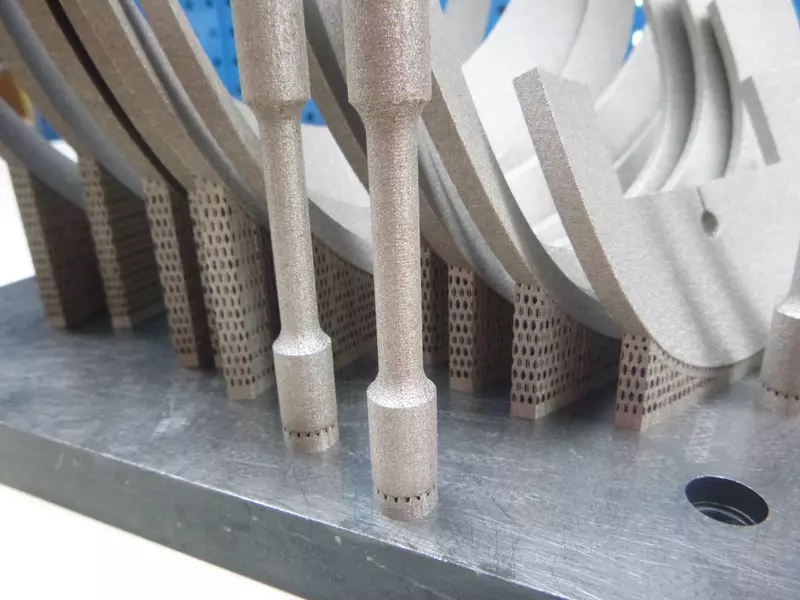

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

we are a young and dynamic company. our company was founded and collaborates with a company with over 30 years of experience in the mechanical processing sector and in the construction of molds for the injection of plastic materials.

Founded

2022

Employees

5 - 10

Certifications

Gradiska

Bosnia & Herzegovina - 78400

Company with over 60 years of history in hot forging. It currently has 5+1 forging lines. The production departments are mainly these: 1 - steel warehouse 2 - cutting department 3 - DIES construction and assembly tooling 4 - hot forging steel 5 - heat treatment 6 - warehouse and shipping Other important departments : - Quality department - Technical Office - Work shop - Maintenance department.

Founded

1960

Employees

100 - 200

Certifications

SUMIRAGO

Italy - 21040

Since its founding in 2006 as a contract manufacturer, we produce complex components for mechanical engineering, mold design and the industry. The latest CNC milling machines are programmed in our production systems using CAD-CAM and operated by qualified personnel. As a reliable and competent partner, we offer you the complete solution from prototype through items / small lots up to the assembly production! Our young team guaranteed by well-coordinated workflows timely and reliable completion of your order. Not only our expertise and years of experience but also our lean corporate structure allows flexibly and quickly to meet individual customer requirements.

Founded

2006

Employees

10 - 20

Certifications

Matrei

Austria - 9971

3D laser accompanies your ideas from prototypes to series if. In the design or production Project Management / Consulting - Consulting for the optimal manufacturing process of your components if sand casting, investment casting, metal laser melting, 3D plastic printing or from the full milling - Feasibility study for the respective process - Procurement of plastic parts in PA2200, PA3200GF, Alumide, DuraForm ® Flex - Procurement of castings (sand casting, investment casting) Construction - Component development of plastic, sand or die casting components - Prototype tools, special machine, fixture, equipment - FEM calculations - Deriving electrodes - Interpretation of contour-hugging cooling for mold - Optimize the components on the metal laser melting process Metall-Laserschmelzen/LaserCUSING ® / SLM - Production of functional prototypes - Production of mold inserts with conformal cooling

Founded

2011

Employees

5 - 10

Certifications

Kirchheim u. Teck

Germany - 73230

Klücher Tech competence in milling technology Founded in 2021, Klücher Tech produces components for you in the areas of tool and mold construction as well as machine and plant construction. The range of services includes extensive 3D geometries, custom-made products or individual parts through to small series parts. Equipped with modern production machines, Klücher Tech is ideally equipped for your order and offers a wide range of services. Great importance is attached to precision and short lead times. I would also be happy to manufacture your component according to your wishes

Founded

1991

Employees

5 - 10

Certifications

Hildesheim

Germany - 31137

Founding of the company 2002 First commercial premises in Lovrenc na Dravskem polje Experiences mean the future We work with 15 years of experience and are constantly investing in new technologies. We manufacture high-quality and sophisticated machine parts and offer a complete service.

Founded

2002

Employees

5 - 10

Certifications

Kidričevo

Slovenia - 2325

We accept work from the simple to the complex metal processing. The Fa. Jelen has an intensive cooperation with well-known form and engineering companies, which are in turn working for the automotive industry and automation technology. Our team would be happy to introduce you to prove our quality and reliability. At our CAD / CAM work significantly reduced downtime are achieved by efficient programming with the Mazak camware and Mastercam for our CNC machines.

Founded

1996

Employees

5 - 10

Certifications

Espelkamp

Germany - 32339

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We are an owner-managed company, the engineering services, manufacturing, finishing, assembly and product delivery offers everything from a single source. This concerns both the wage and foreign manufacturing and the manufacturing our own special equipment for the paper and paperboard manufacturing industry as well as special solutions for safety-relevant area. With our security products, we are also the owner of many national and international patents. Our machinery is constantly being renewed and the education and training of our highly qualified staff are constantly adapted to customer requirements. The high degree of vertical in almost all of the processing steps to make us a reliable A suppliers. Benefit also from the high Hennig and comprehensive know-how. Flexible and perfectly tailored to your needs. Our CNC milling machines can sizes up to 3600 x 2200 mm 5-axis milling process at the Round Table has 500 mm. The rotary department has combined rotary milling machines with Y axis and driven tools and sub spindle. Sheet metal working medium format and folding up to 3000 mm. Powder coating 3000 x 1200 x 2000 mm unit weight up to 1000 Kg Final inspection with Zeiss measuring machine Accura

Founded

1986

Employees

50 - 100

Certifications

Markt Schwaben

Germany - 85570

Founded

2001

Employees

20 - 50

Certifications

Dornhan

Germany - 72175

Founded

2024

Employees

5 - 10

Certifications

Bad Salzuflen

Germany - 32108

Our company, whose 1,200m2 is closed, serving in a total area of 1,500m2, continues to metal processing and shaping works with the knowledge and experience of its founders, today has undertaken to fulfill the requirements of the ISO 9001: 2015 quality management system standard and to continuously improve its effectiveness.

Founded

Employees

20 - 50

Certifications

EYÜP

Turkey - 34055

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge