Find suppliers for injection mould around inserts

Discover specialized suppliers for insert molding on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to manufacture multi-functional parts. Use the e-sourcing process to find the best suppliers.

690 suppliers for Injection mould around inserts

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

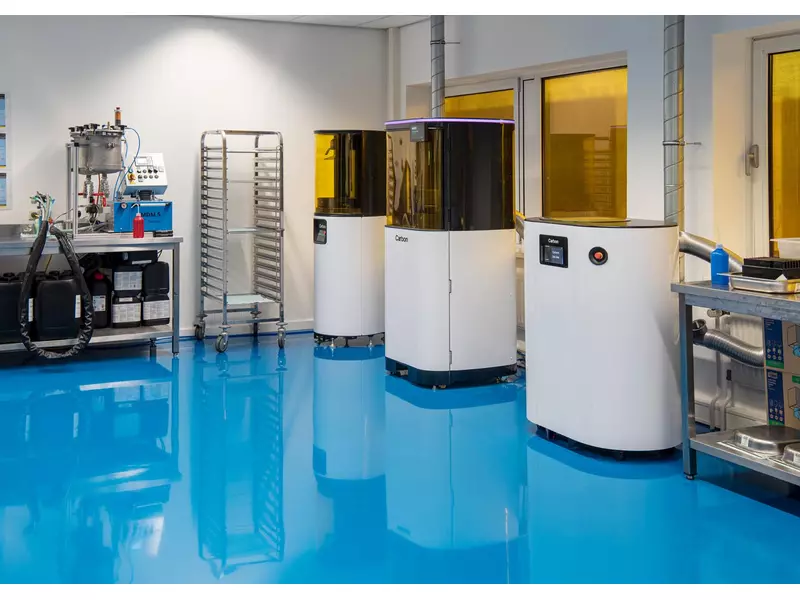

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

Our history dates back to 1990, when engineer Dimitar Karagyozov laid the foundations for our company. In 2006, the company was re-registered as EOOD, and since then we have continued to develop and expand our offering. We specialize in manufacturing high-quality injection molds and plastic products that are used in medical technology, electronics and many other industries. Our experience and expertise enable us to develop tailor-made solutions for the individual requirements of our customers. In doing so, we attach great importance to quality, precision and reliability. We are proud to be a company that continuously strives to exceed customer expectations and drive innovation. Our mission is to add value through our products and services and to build long-term partnerships.

Founded

1990

Employees

5 - 10

Certifications

Sofia

Bulgaria - 1510

N&H Technology – Your Development Partner for Custom Components, HMI Solutions and Electromechanical Assemblies Since 2001, N&H Technology has been your certified system supplier for tailor-made electromechanical assemblies, technical components and HMI solutions. Our focus lies in the development and serial production of plastic, elastomer and metal parts – including multi-component solutions (e.g. 2K/3K technology, rubber-metal combinations). Our portfolio is complemented by customized input systems such as silicone and membrane keypads as well as cable assemblies and connectors. Whether precision-molded parts, elastomeric functional elements or complete input units – we realize your project reliably from concept to series production. ++++ Our Capabilities: ++++ Technical Components & Housings • Injection-molded parts made of thermoplastics, high-performance polymers and fiber-reinforced materials • Silicone and rubber components incl. seals, protective covers, keycaps • Die-cast, milled, stamped and turned parts made of metal • 2K/3K components and hybrid solutions (plastic/metal, rubber/metal) ---- HMI Components & Input Systems • Silicone rubber keypads, membrane keypads, capacitive keyboards • Stainless steel and hygiene keyboards • Touch display units & full HMI assemblies ---- Connectors & Cable Assemblies • Spring-loaded contacts, magnetic connectors, custom plug solutions • Cable assemblies: data, coaxial, ribbon and hybrid cables • Assemblies with integrated interconnect systems ++++ Our Services: ++++ Engineering & Development • CAD design, feasibility studies, DFM optimization • Prototyping using 3D printing, silicone casting or small series production • Tool design including mold-flow simulation ---- Project Support & Quality • Technical consulting from initial concept to series approval • In-house testing laboratories (mechanical, electrical, optical) • Certified & exclusive supplier network according to ISO 9001 and ISO 14001, optionally IATF 16949 and ISO 13485 ---- Procurement & Logistics • Procurement of third-party components & system integration • Final assembly, end-of-line testing and logistics including buffer warehouse in Germany ++++ Industries We Serve: Automotive · Medical Technology · Telecommunications · Building Automation · Industrial Electronics · Measurement & Control Technology ++++ N&H Technology stands for engineering expertise, flexibility and trusted partnership. We combine customer-specific product development with efficient manufacturing – delivering reliable and cost-effective solutions in series.

Founded

2001

Employees

50 - 100

Certifications

Willich

Germany - 47877

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our core competencies are: Tools - Hard Metal Processing - Sheet metal rounds - Punching / pressing (tool Falling) - Punching-bending (Bihler machine) - Stamping - Injection molding, extruding - injection molding - Encapsulation of inserts - To water - Die-casting - Ingot - Machine molding (sand casting) Translation by Google Translate

Founded

2003

Employees

5 - 10

Certifications

Offenburg

Germany - 77652

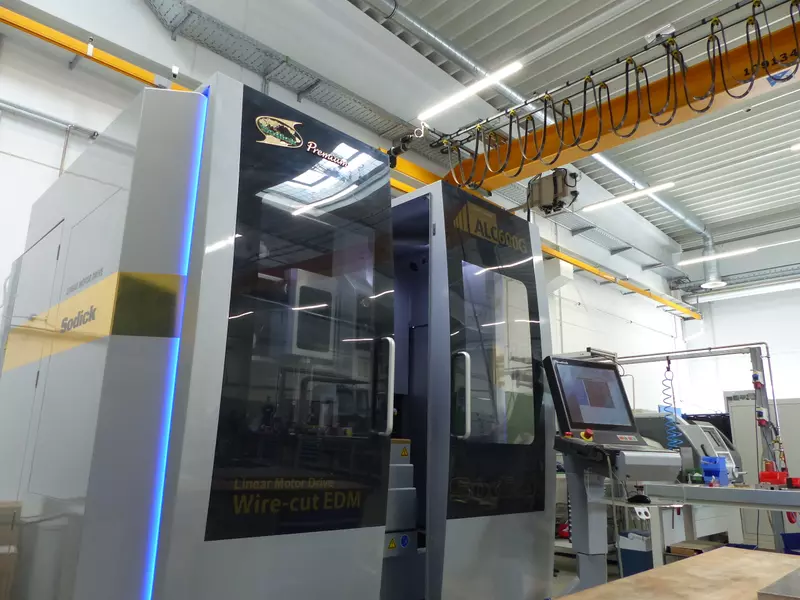

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

On 16.01.2007, the Sole proprietorship “Michael Otto CAD/CAM Services” founded. About 1 year later, this results in: OTTO TECHNOLOGY-Johannes & Michael Otto GbR We are a family business, consisting of: 10 highly motivated permanent employees employees and 5 temporary workers. 7 milling and programming experts (including the management), all with roots in Tool and mold making 3 administrative workers with education in the foreign language secretariat 5 temporary workers (students and students)

Founded

2007

Employees

10 - 20

Certifications

Bad Endbach

Germany - 35050

Since 1986 we have been working as injection molding manufacturers serving a variety of local and international companies which operate in various fields and need molds either for big productions and limited edition products. What we do is easily explained. We design, manufacture and supply injection molds for the production of high-precision thermoplastic parts with exceptional aesthetic demands. We are specialized in the production of high-precision technical parts and multiple-impression molds for high production requirements, but we also supply prototypes and pilot molds for small and medium series that requires complex and intricate geometries – for instance, for limited editions. The headquarters are located in the Italian city of Rovereto, just 30 km from Trento, on the Brenner motorway link. This is the ideal crossroads between the major industrial districts in Northern Italy, such as the manufacturing (Lombardy, Vicenza) and optical (Belluno) ones, and important European countries such as Austria, Germany and Switzerland. However, there is more. We also work with factories based in the US and in the rest of the world. The know-how we developed over the years of experience in the field allows us to identify the most suitable kinds of injection molds on the base of your production types and aesthetic needs.

Founded

1986

Employees

20 - 50

Certifications

Rovereto

Italy - 38068

Company HAPLAST d.o.o was established on March 12th 2015 as a continuation of a family business. It specializes in production and sales of products made from plastic. The company offers a service starting from the conceptual idea to the production of an end product available to one-time customers or mass production of million item series. We produce integral parts and components for the production of automotive batterys and industrial batteries, plastic casings for small kitchen appliances, parts for builders’ plastic joinery and other plastic components. Our machine park consists of 14 injection molding machines with a clamping force between 15 to 450 tons. In cooperation with a contractual partner, we offer product development, making of 3D prototype and tool development. We are aware of the significance of partnership with the customers, where the response time is very important. In accordance with our business philosophy, we have put the wishes and expectations of the customers in the center of our business performance. By doing so we have gained trust and managed to create a good reputation, which has contributed to our business success so far. Our company emphasizes and prioritizes customer satisfaction, which is the reason why we continue to look for ways how to meet the highest expectations of even the most demanding customers. The results of active sales participation reflect expected results in the development. Production and sales segment of the company is roughly divided into the following areas: • Injection of plastic materials • Assembly of compounds • Prototype production Company references Our company takes pride in quality products which are the result of our own knowledge in development and are aimed at satisfying the needs of our customers at the highest level possible. HAPLAST d.o.o’s main references are: • Development-based cooperation with the internationally renowned company TAB. d.d with established long-term business relationship. • Cooperation with other clients, such as LWTechnik gmbh, Tehnoplast Povše d.o.o. etc. In 2019 the company has acquired a certificate of quality ISO 9001:2015 for injection of plastic materials and has therefore opened its door to more demanding clients. Company's vision The vision of our company is to become an established manufacturer and vendor of more intricate and demanding products made from plastic in Slovenia, as well as outside its borders, such as Austria and Germany. In the long run, we intend to export at least 50 % of all manufactured products. We are strategically positioned among smaller manufacturers of plastic products with our own knowledge in development and sales of middle and high-quality assortment of products. We see our mission in a continuous process of development and following the trends in the field of plastic masses. We want to create not only higher added value on the company level but also achieve higher use value for our customers. We would like to place products on the market that will meet the expectations of our clients or even try to exceed them, and by doing so guarantee a long-term strategic position in the market.

Founded

2015

Employees

10 - 20

Certifications

Mežica

Slovenia - 2392

Innovative plastic products since 1989 The BÖHL-plastic GmbH & Co. KG specializes in the production certified technical precision injection molded thermoplastics. We cooperate with raw material manufacturers, but also with colleges and universities. Because the plastic processing is a challenging topic. Individual solutions are our strength. Our activities span the injection molding production for the lighting and automotive supplier industry. We are also working for the industries fittings, electrical and electronics, medical, furniture, steel and textiles. The headquarters of our plastic processing company located in southern Westphalia. Here we present for you since 1989 plastic parts from all common thermoplastics ago. We are supported by our own mold.

Founded

1989

Employees

20 - 50

Certifications

Bad Berleburg-Aue

Germany - 57319

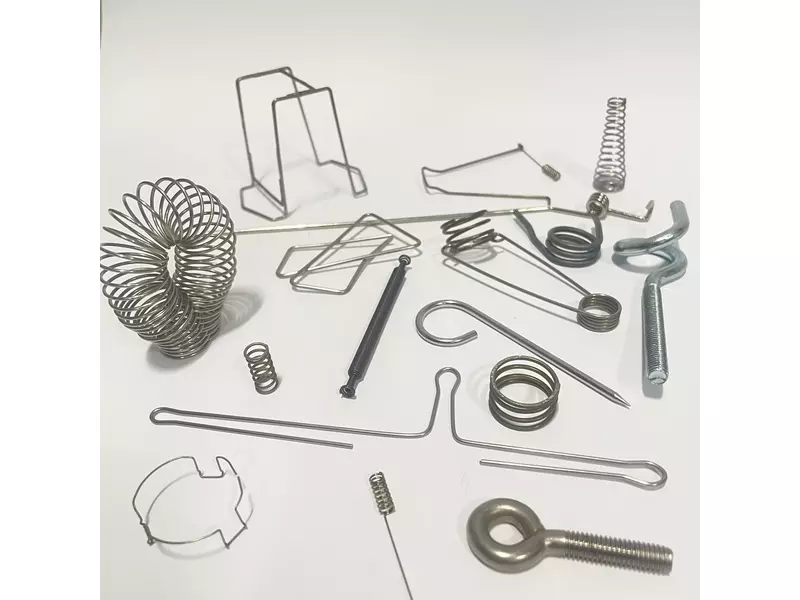

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

Jakob Plastic Processing Co. Ltd. Manufacturer of technical injection molding parts Our passion are thermoplastic resins. Our strength the processing of high-performance plastics, especially LCP - "Zenite® 6330" Our machinery includes injection units of the brand Arburg S and U with 15 to 250 tons clamping and swivel locking and injection units. Thus, we are optimally equipped for all needs and include for each task on the right machine.

Founded

1997

Employees

10 - 20

Certifications

Mels

Switzerland - CH-8887

Klücher Tech competence in milling technology Founded in 2021, Klücher Tech produces components for you in the areas of tool and mold construction as well as machine and plant construction. The range of services includes extensive 3D geometries, custom-made products or individual parts through to small series parts. Equipped with modern production machines, Klücher Tech is ideally equipped for your order and offers a wide range of services. Great importance is attached to precision and short lead times. I would also be happy to manufacture your component according to your wishes

Founded

1991

Employees

5 - 10

Certifications

Hildesheim

Germany - 31137

As a system supplier for electromechanical assemblies, we manufacture plastic and metal components using hybrid technology. This means that we concentrate on the production technologies of plastic injection moulding and punching and bending of metal components. The advantage for you is that you can obtain ready-assembled assemblies of the most diverse production processes from one source. By moving Friedrich Joerg GmbH in 2016 to newly built production and office premises, we were able to create a capacitive buffer. Thanks to a high degree of automation, we can offer you particularly competitive prices. We manufacture manually in small series up to large series fully automated and pre-assemble all components for you. In short, we adapt flexibly to your requirements. We provide support as early as the product development stage in order to take into account quality, cost and tool-specific aspects in the early phase. We manufacture the necessary tools or devices in our own tool shop. This also allows us to increase our flexibility, for example in case of short-term changes. Furthermore, we also offer finishing processes such as: printing on plastic parts (cliché/pad printing), hot foil stamping for a particularly noble appearance of the products, machining and ultrasonic welding. It goes without saying that we are certified according to ISO 9001:2015 and deliver a very high and consistent quality. We would be pleased if you contact us. categories: Electromechanical assemblies; Foil hot stamping; Customised plastic mouldings; Plastic optical fibres; Optical fibre components; Optical fibre systems; Optical fibre technology; Optical fibre transmission systems; Pre-assembly Assembly of small parts for industry; Assembly of plastic components; Assembly of mechanical components; Stamp-bending parts made of stainless steel, non-ferrous metal, steel; Stamp-bending tools; Connectors; Connectors for surface mounting; Complete plug connections; Pad printing; Thermoplastic precision mouldings; Thermoplastic overmoulding with plastic; ultrasonic welding of plastics; overmoulding tools for insert parts; 3-D MID components; connecting terminals for power cables low voltage & high voltage; component assembly; die casting; mould making; housings for the electrical industry; terminals for electrical cables; plastic injection moulded parts; plastic injection moulded parts with metal insert; electrotechnical plastic parts; technical plastic parts; plastic processing; multi-component injection-moulded parts; plastic-injected metal parts; product development; prototype construction; terminal blocks; technical injection-moulded parts; thermoplastic elastomer (TPE) moulded parts; jig and fixture construction; toolmaking; two-component injection-moulded parts; Imprint: https://www.friedrich-joerg.com/kontakt/impressum/ Privacy policy: https://www.friedrich-joerg.com/kontakt/datenschutzerklaerung/

Founded

1920

Employees

50 - 100

Certifications

Marktrodach

Germany - 96364

Techpilot GmbH - DEMO

We are Europe's largest platform for the manufacturing industry.Since 2000, we have been connecting matching suppliers, buyers and manufacturers and enabling you to determine the right price of drawing parts. Every year, over 16,000 registered buyers inquire about more than 30,000 different parts on our platform with an average order value of 35,000 EUR. Registered suppliers can take advantage of strong online visibility, media reach and are given a lucrative sales channel.We serve the entire market for mechanical components and is the European market leader with 280 supported manufacturing technologies.

Founded

2000

Employees

20 - 50

Certifications

München

Germany - 81379

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1974

Employees

5 - 10

Certifications

Winden im Elztal

Germany - 79297

Our corporate philosophy FAST Easy quoting and fast order processing characterize our customer relationships. FLEXIBLE Together with our customers solutions are fast and often unconventional developed on a partnership basis. RELIABLE We produce according to the requirements of ISO / TS 16949: 2009; delivery commitments are adhered to - guaranteed. We are an approved supplier for the metal processing industry: Building industry Furniture industry Automotive industry Office equipment industry Shipbuilding Handling / logistics With motivated employees, we produce on our modern machines and equipment important supplier products.

Founded

1880

Employees

100 - 200

Certifications

Marienberg

Germany - 09496

Founded

2001

Employees

20 - 50

Certifications

Dornhan

Germany - 72175

Injection We squirt for you all on behalf of small batches to larger blanket orders. Moldings with insert (eg metal) are possible. Upon request, we also take over the complete material management for your production order, and store the injection molding tools for you. You only call from, we do the rest for you. Mould With a choice of partner companies in Germany, Europe and Asia, we are able to create you an offer for your individual molding tool you define the number of cycles, number of cavities, as 1k / 2k tool etc. mounting service If you already have a fully developed product and are still looking for a suitable partner for the assembly of sub-groups or complex assemblies, we are pleased to offer our services. Our strength lies in a very precise mounting. Here we are particularly specialized in the soldering and bonding, accurate mounting crafted and reliable final inspection.

Founded

2013

Employees

20 - 50

Certifications

Meschede-Berge

Germany - 59872

We are a company in 72622 Nürtingen, finished thermoplastics by injection molding, attached in the annex, our company profile and machine list as a PDF. Our core competence is gushing: • Visible parts (glossy) for medical applications • Technical injection molded parts Ex. Gears etc. • Visible parts for interior parts - automotive industry • Plastic parts for Radträger- / transport systems • pad printing, screen printing, ultrasonic welding • assembly The efforts within this core competency with the latest technical and professional status to be stands at the center. Flexible production processes in 3-shift operation. With advanced technology and highly automated processes, we meet the highest quality standards. Fully automatic handling equipment to almost all injection molding machines ensure a continuous product quality. We process all common thermoplastics and special compounds.

Founded

1977

Employees

10 - 20

Certifications

Nürtingen

Germany - 72622

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge