Forging: Manufacturers for robust parts

Discover specialized suppliers for forging on Techpilot. Our platform connects buyers with suppliers who apply advanced forging techniques to manufacture robust and customized parts. Use the e-sourcing process to find suitable suppliers in real time.

103 suppliers for Forging

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

Company with over 60 years of history in hot forging. It currently has 5+1 forging lines. The production departments are mainly these: 1 - steel warehouse 2 - cutting department 3 - DIES construction and assembly tooling 4 - hot forging steel 5 - heat treatment 6 - warehouse and shipping Other important departments : - Quality department - Technical Office - Work shop - Maintenance department.

Founded

1960

Employees

100 - 200

Certifications

SUMIRAGO

Italy - 21040

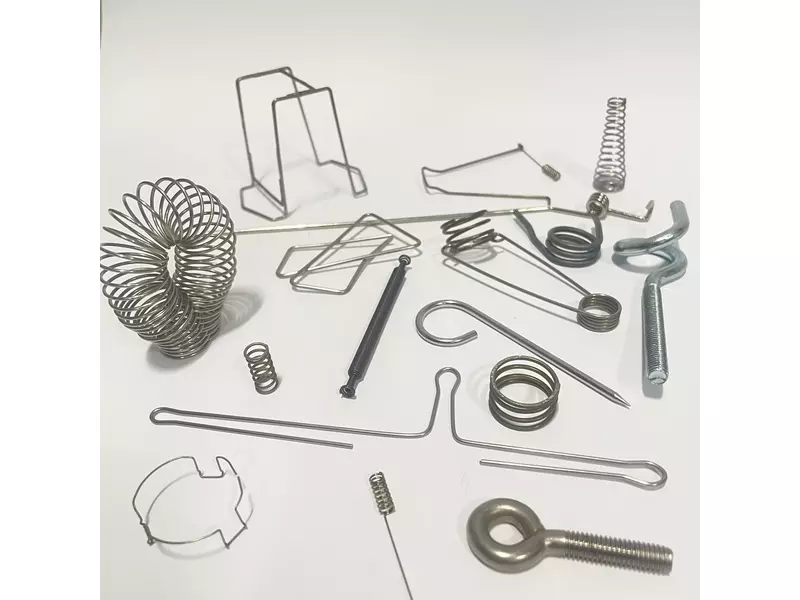

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

YOUR GENERAL CONTRACTOR FOR FORMING and MOLDING! FORGING, HOT PRESSES KALTFLIESSPRESSSEN, FREE FORM FORGING IN STEEL, STAINLESS, ALUMINUM, BUNTMETALL, TITAN, FLANGE, RING, TRIMS, Longitudinally PIPES, FEINGUSS, SAND CASTING, DIE CASTING MACHINING PARTS OF FORM PART, OR FROM THE FULL PROFILE

Founded

1961

Employees

5 - 10

Certifications

Liestal

Switzerland - 4410

The medium-sized enterprises THIERBACH from Lower Hall near Heilbronn supplies Companies from all industries as tailored solutions for the Parts subject. TURNING AND MILLING PARTS THIERBACH processed according to your specifications, all machinable materials, including steel, stainless steel, brass, aluminum and bronze and precious metals and special materials for the aerospace industry. SINTERFACE PARTS For the production of sintered parts THIERBACH used exclusively powder with demonstrated high quality. Depending on requirements, the base material of various alloying elements are added. Formed In the area of formed THIERBACH offers various production options such as cold and hot extrusion. In addition, a mechanical, metal-cutting rework is possible. PUNCHING AND BENDING PARTS In the field of stamping and bending parts offers THIERBACH solutions of metallic and non-metallic materials that are manufactured on CNC machines.In addition, welding can be performed. LASER COMPONENTS In the area of laser parts are available from THIERBACH steel, stainless steel or aluminum products with extremely high precision contours in different thicknesses. CASTINGS In THIERBACH you get castings in all major manufacturing processes: aluminum die-casting, aluminum sand casting, zinc die casting, copper sand castings or precision castings. DEEP DRAWN PARTS THIERBACH provides you with high quality deep drawn parts made of stainless steel, aluminum, brass, bronze, iron, chromium or copper, either as a single function template or as a large series. ASSEMBLIES Not just when you need a single part, but even with demanding assemblies, you can count on THIERBACH: in partnership, economic and logistical point of view. CERTIFIED QUALITY An important part of THIERBACH quality philosophy is the maximum quality assurance in the production of your parts and assemblies. FACTS: QUALTÄTSSICHERUNG - Certification according to DIN EN ISO 9001:2008 - Erstmusterprüfberichtenach VDA - PPAP documentation - IMDS entries - Uniformity measurements - Surface measurements - Length measurements - Measuring equipment management - Sampling inspection according to AQL 1 - SPC tests Possibilities of surface and heat treatments Even when it comes ächen to the finishing of surfaces, THIERBACH provides organizational and economic advantages: Through partnerships with reputable companies you get: - Modern production techniques - Everything from prototype to mass production - Different machining options and THIERBACH all the possible rework and surfaces.In this way long and expensive transport routes and the total cost per piece If omitted significantly reduced. THIERBACH offers: Galvanizing / / Copper Passivation / / hard chrome plating Burnishing / / Gilding Dacromet / / Geomet coating Cadmium / / Nickel Chromate / / anodizing Phosphating / / pickling / / Silver Case hardening / / Inductive Glow / / start / / Slot Embossing / / Bending / / rubbing Lapping / / honing / / punching Engraving / / brushes Polishing / / electropolishing Grinding / / trowalizing Sand and glass bead blasting Flexible Logistics THIERBACH is not content to create the correct part, but is only satisfied when you is this the right time and at the right place. Thus, for example, already taken in the packaging that it contains all the elements for a smooth production: Logo, number, barcode.

Founded

1999

Employees

20 - 50

Certifications

Künzelsau

Germany - 74653

We produce since 1969 quality hot forged parts according to our customers’ drawings and specifications. Our plants are organised around high performing presses with force from 650 to 1.300 tons: we can therefore manufacture parts with finished product weight from 0,15 up to 5 kg. for almost all industrial branches, such as energy, industrial plants, agricultural machines and commercial vehicles. In order to assure the best quality of our products, all forging and production tools are developed and manufactured in our works and by a motivated team.

Founded

1969

Employees

20 - 50

Certifications

Proserpio (Como)

Italy - 22030

CASTING and FORGING PARTS BY CUSTOMER Together with our partner companies ISG industry service and Geiger Berger Industries, we offer you the opportunity to access from a wide range of different foundries, forging and machining company from Germany, Spain, Hungary and China. We take care of you this vendor selection, request, technical clarification, quality assurance, packaging, shipping and timely delivery of your products according to your drawings and specifications. Through our three locations in Germany, we are always in their vicinity: CFT Hanseatic Guss GmbH, 28195 Bremen ISG industry service Geiger e.Kfm., 73491 Neuler Berger Industries K., 50668 Cologne You have a question or want to get to know us? Please contact one of the below mentioned contact, we'll take care of everything else.

Founded

2004

Employees

10 - 20

Certifications

Bremen

Germany - 28197

We, Metallbau Schmalenbach, specialize in manufacturing a wide variety of high-quality and tasteful stainless steel and corten steel accessories. Years of experience in working with metal products, experienced know-how and the gift for exceptional design give our products uniqueness. The focus is on narrowing down to the essentials. In a charmingly flooded world, peace and relaxation are important to us. Simplicity is the goal and with it the uniqueness of our products. In addition to our wide range of products, we also offer you the opportunity to have your ideas implemented. We offer you custom-made custom-made products. You are welcome to visit us at Linienstr.14 in 42289 Wuppertal.

Founded

2022

Employees

5 - 10

Certifications

Wuppertal

Germany - 42289

Founded

1921

Employees

20 - 50

Certifications

Wetter

Germany - 58300

Melchers Components GmbH

C. Melchers & Co. was established on January 1, 1806 in Bremen, where the global company still maintains its headquarters to this very day. In the first few decades of the company’s history, over 30 ships sailed the oceans of the world under the Melchers flag, linking the ports of Europe, America and the Pacific. In the 1860s, C. Melchers & Co set up operations in Asia, where all its trading interests swiftly moved. At the same time, with the onset of steam ships, it abandoned its own shipping business to devote itself entirely to extending its trading operations. 1866 saw the establishment of the first branch in Hong Kong, in the wake of which China began to develop into a key lynchpin for the company’s business. The ensuing decades were a period of rapid growth for Melchers in China, with over 2,000 people employed at 12 branches and plants throughout the country. The First World War proved to be a setback for business relations, although business quickly recovered. It was not until the end of the Second World War in 1945 that business came to an almost complete halt. Even so, the company continued to survive, re-opening its first branches in Hong Kong, Singapore and Kuala Lumpur in the early fifties and gradually extending its branch network across Asia. Following the opening of the Chinese markets at the end of the seventies, Melchers set up branches here again, underscoring the significance of Chinese business for the company. With the establishment of a branch in San Francisco in the early eighties, the company also started to engage in US-Asian trade so as to gain a share of the rapidly growing trading relations between these two regions. Trade with China remains a key focus of the company’s overall business, comprising as it does imports of special natural products and finished goods on the one hand and exports of plant, machinery and supplies for the Asian industry on the other. Yet, business with South East Asia has since also come to the fore, with the company amassing broad-based expertise in marketing and selling consumer goods in particular. There are special departments for each article group in Bremen as well as at the foreign branches. They work largely independently within the overall company and are staffed by highly qualified experts. Over 1,000 employees in Germany and abroad assist customers and suppliers with their specialist knowledge. Rather than being based at the company’s headquarters, most of these employees are now stationed at subsidiaries, something which in turn reflects the company’s further development and the strategic alliances which it has forged.

Founded

1806

Employees

> 1000

Certifications

Bremen

Germany - 28195

Welcome to the UF Industries GbR. For more than 20 years, we have been bundling the necessary skills for everything to do with drawing parts in a separate department. Our employees advise and support you in the procurement of tailor-made special and drawing parts and produce high-quality and precise turned, milled and combination parts for you according to drawings - even in demanding geometries and in small batch sizes. Quality and function are our top priority. In order to achieve this, we are constantly developing ourselves and our portfolio. True to the motto: If you stop getting better, you stop being good! Our aim is to be able to offer an efficient and optimal solution for every specific, mechanical-technical requirement based on a drawing or sample. If required, we offer you fast and goal-oriented support in the realization of your constructions. Especially in the project phase, it is of crucial importance to choose the best, most modern and at the same time most cost-effective production technology. We would also be happy to optimize existing construction parts together with you.

Founded

2020

Employees

5 - 10

Certifications

Espelkamp

Germany - 32339

Kettling GmbH & Co.KG is one of the leading manufacturers of precision turned parts and complex assemblies. Our solutions are used in the automotive industry, mechanical engineering, the mobility sector and in numerous other industrial applications. Our work focuses on maximum precision, efficiency and technological innovation. We would be delighted to demonstrate our know-how to you as well.

Founded

Employees

100 - 200

Certifications

Lennestadt

Germany - 57368

The Anant GmbH is a marketing subsidiary for own products & representation for few well-selected Indian manufacturing units. We have a good knowledge + experience for quality systems & supervised manufacturing outsourcing from India. Our German representation offers a potential to take up a responsibility to supply the article as door delivered & being your contact/contract partner. whereas our Indian technical team offers possibly of economical in-house manufacturing as well as local outsourcing under our supervision & our own quality control. At Patel Technomation - India, We have the experience and capability of sub-contract CNC machining including supply/procuring of foundry and forging products in small batches as well in large quantity. We follow the TÜV SÜD ISO 9001-2000 quality system and are dedicated to providing excellent customer service, and the timely delivery of quality products. Our Manufacturing unit is located at major Auto-parts manufacturing, Casting, Forging & engineering hub in India; which offers us a good development possibility for any specific/special part manufacturing possibility in a most economical manner.

Founded

2006

Employees

200 - 500

Certifications

Oberschleissheim

Germany - 85764

CNC contract manufacturing for tool, machine and plant construction. Do you build tools, machines or special machines? Do you need precision parts for your machines and systems? We take over the CNC manufacturing. Contract manufacturing for mechanical engineering, tool making or mold making. Take a look at our manufacturing examples! We manufacture highly efficiently on modern machining centers quickly with high quality and on time. Leading machine manufacturers have been relying on our production since 1989.

Founded

Employees

Certifications

Vrnjacka Banja

Serbia - 36210

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

GPP (Global Precision Printing) provides FDM 3D printing with CFF technology. “Composite Base” • Onyx is a micro carbon fiber filled nylon. It’s 1.4 times stronger and stiffer than ABS and can be reinforced with any continuous fiber. Onyx sets the bar for surface finish, chemical resistivity, and heat tolerance. • Onyx FR is a Blue Card certified UL94 V-0 material that possesses similar mechanical properties to Onyx. It’s best for applications in which flame retardancy, light weight, and strength are required. • Onyx ESD is a static dissipative safe variant of Onyx — meeting stringent ESD safety requirements while offering excellent strength, stiffness, and surface finish. It’s best used in applications that require ESD safe materials. • Nylon White parts are smooth, non-abrasive, and easily painted. They can be reinforced with any continuous fiber and work best for non-marring work holding, repeated handling, and cosmetic parts. • Smooth TPU 95A is a rubber-like material that when used with Markforged composite printers offers product developers and manufacturers the ability to create flexible, impact-absorbent parts on demand. • Precise PLA is our easy-to-print plastic for precision concept modeling and validation. Based on the most common 3D printing prototyping material, Precise PLA 3D prints without warping and comes in a variety of colors. Best of all, it’s affordable. So you can use as much as you need to fine-tune your designs before implementation. “Continuous Fiber“ • Carbon Fiber has the highest strength-to-weight ratio of our reinforcing fibers. Six times stronger and eighteen times stiffer than Onyx, Carbon Fiber reinforcement is commonly used for parts that replace machined aluminum. • Fiberglass is our entry level continuous fiber, providing high strength at an accessible price. 2.5 times stronger and eight times stiffer than Onyx, Fiberglass reinforcement results in strong, robust tools. •Kevlar® possesses excellent durability, making it optimal for parts that experience repeated and sudden loading. As stiff as fiberglass and much more ductile, it can be used for a wide variety of applications. • High Strength High Temperature (HSHT) Fiberglass exhibits aluminum strength and high heat tolerance. Five times as strong and seven times as stiff as Onyx, it’s best used for parts loaded in high operating temperatures.

Founded

2024

Employees

5 - 10

Certifications

Kuldiga

Latvia - LV3301

Welcome We see ourselves as an average modern operating company, based in Istanbul. Our company is working successfully in different industries (mechanical engineering, textile machinery, medical instrument industry, automotive industry, construction industry, graphic and optical industry, etc.) whose requirements are as varied as your products. In our mechanical production, we offer you virtually all machining manufacturing processes. Drilling, turning, milling and external cylindrical grinding in conventional production, milling and turning on modern CNC machines. That is our guarantee for your series production. With us you always get a completely finished product. Whether small series or prototype, whether raw or finished coating, whether or Kuststoff steel - all orders we finished quickly, reliably and accurately measured. Take advantage of our many years of experience and learn in the following pages to know our wide program. We are happy to await your inquiries and would be pleased if we could count you among our satisfied customers and your company. We support each other. The quality of our work ensured the success of our company. "Everyone is for each model, with production processes, each of the customer of the neighbor." About us The company Integral Makina sees itself with its long-standing and qualified staff as a traditional but modern positioned and competitive manufacturer of components for the Maschienenbau, Textilmaschienen, Medical Instrument Industry, Mechanical biomedical sector, automotive industry, construction industry, graphic and optical industry, etc. The technological requirements are determined by modern CNC machining centers. As the material in addition to steel and cast iron, aluminum, plastic and stainless steel, etc. is processed. Through close cooperation with companies from the region, we are able to manufacture complementary areas, suchEtc. to use as sheet metal processing (laser cutting), Hardening, Surface Finishing, external and internal cylindrical grinding, surface grinding, welding, assembly in a variety of ways and included in our manufacturing facilities. Customer-oriented quality assurance and on-time delivery are our determined measure of performance.

Founded

2010

Employees

10 - 20

Certifications

Maltepe - İstanbul

Turkey - 34843

We are committed to improve and strengthen your products. We place at your disposal and to the service of your projects the whole of our company: design, technology and quality. Let us be a part of your team. Our company Factor is a company whose activity is the in-line machining of special parts using CNC spindle lathes (bar cutting) and the cold stamping of screws. We have had both national and international market presence for more than thirty years in sectors which require a technological product with a high added value. Our corporate strategy is based on 4 pillars: Continuous investment which guarantees the continuity of our project. Innovation as the culture of continued improvement. Industry for our passion of creating components which materialize our customers’ ideas. Internationalization as vocation for the geographical expansion of our management model. Among the advantages for our customers, we highlight the following: Cutting-edge equipment which guarantees a high reliability, repeatability and competitive finishes and prices. Know-how and experience gained during our wide track record make us posses a high level of product knowledge and processes. Highly qualified staff and focused on customer satisfaction. More than 50% of our staff are university graduates and have specific training in the machining sector.

Founded

1982

Employees

50 - 100

Certifications

Puzol

Spain - 46530

We expert in working on the projects which located in Kaarst (near Düsseldorf in Germany). We are a high-tech enterprise that provides one stop service including product R&D, mass production, sale and after-sales service. Reliable quality, stable function, timely and effective service is our permanent object. We supply our customers' machines from all around the world with our systems and associated components, especially, power train engineering, adjustable coolant hoses, high-pressure coolant nozzles, precision locknuts, tool clamping systems, workpiece clamping systems and also complete centralized lubrication systems. The serial production will be accomplished reliably by our main production and associated companies in the Far East. It is worth to be mentioned that our main production can provide the competitive price for your required components and complete product line. Our main production has been certified to ISO 9001:2008. As support by local qualified and experienced engineers we could check the components and terms of delivery constantly. As support by our warehouse in Germany we could guarantee deliverability accuracy and reliability. The German and European industrial middle class companies, as well as large industrial companies and international corporations trust our quality standard.

Founded

1986

Employees

500 - 1000

Certifications

Neuss

Germany - 41469

Founded

1999

Employees

< 5

Certifications

Efringen-Kirchen

Germany - 79588

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge