Gear making: Techpilot - free for buyers

Discover specialized suppliers for gear making on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to manufacture precise gears. Use the e-sourcing process to find the best suppliers.

396 suppliers for Gear making

The ... Vielfätigkeit of mechanical engineering. For 35 years, our company has been working in the engineering industry. Always the goal in mind, independent and flexible manufacture our workpieces and to expand our product range, we manufacture to the highest quality standards and precision. With a modern and versatile machinery, we offer our customers experience and commitment in the development and production of their mission. Our handicraft business with about 20 employees specializing in the manufacture of parts, components and assemblies; manufacture both single and serial production are possible. We process a wide variety of metals and plastics - from 3D - CAD - design to the finished product. We design and manufacture - take your product ready for installation in reception, thus saving costs and time. As an experienced Hertseller of turned and milled parts in machinery and mold with a variety of materials, we guarantee quality, precision and flexibility. With CNC machines from renowned manufacturers in the field of machining, we produce from prototype to series production of technically demanding parts with consistent quality in 2D and 3D. Our modern CNC lathes are equipped with automatic bar feeder, driven tools, Y-axis and sub-spindle, so they allow the individual and series production of complex parts in a single pass. New in our machine park is a 5 - axis "Millturn" machining center with which we completely finished workpieces in one set-up, which leads to a significant reduction of the idle times and the precision significantly increases. With corresponding 5 - a pallet exchange system and a total of 90 tool places, we are well prepared for series production. - CNC Milling - 3-D mold - Vermessarbeiten and quality control

Founded

1978

Employees

20 - 50

Certifications

Sterzing (BZ)

Italy - 39049

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

Your expert for complicated components and very critical applications • Beutter is a supplier of fine mechanical components with a high production depth in small batch series. • Beutter was founded in 1909, and is located in Baden-Württemberg, very close to the A81 motorway, 60km south of Stuttgart. • We have about 125 employees. Of our production staff, over 90 % are skilled workers. • We have the capability to perform, in-house, all machining processes (turning, milling, grinding, honing), while for special processes and surface and heat treatment processes we use competent third-party suppliers. • For us, the ideal is small- to medium-sized production runs with a lot size of between 20 and 1,000 pieces. • Beutter is particularly capable within the manufacturing of components with close production tolerances. • We process all machinable materials, and are particularly experienced in processing high-alloyed steels (stainless steel, V2A, V4A, 1.4441, 17-4PH), titanium and special materials (inconel, hasteloy, Ni-base alloy, chromium molybdenum steel, tantalum, platinum-iridium, PEEK). • Our main fields of activity are: Medical technology, aeronautics, hydraulics, military engineering, mechanical engineering and measuring equipment technology. • Our quality management system is certified according to DIN EN ISO 9001:2008, DIN EN 13485 (medical products) and DIN EN ISO 9100 (aeronautics). • We can process your data via our CAD system “SolidWorks“.

Founded

1909

Employees

100 - 200

Certifications

Rosenfeld

Germany - 72348

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

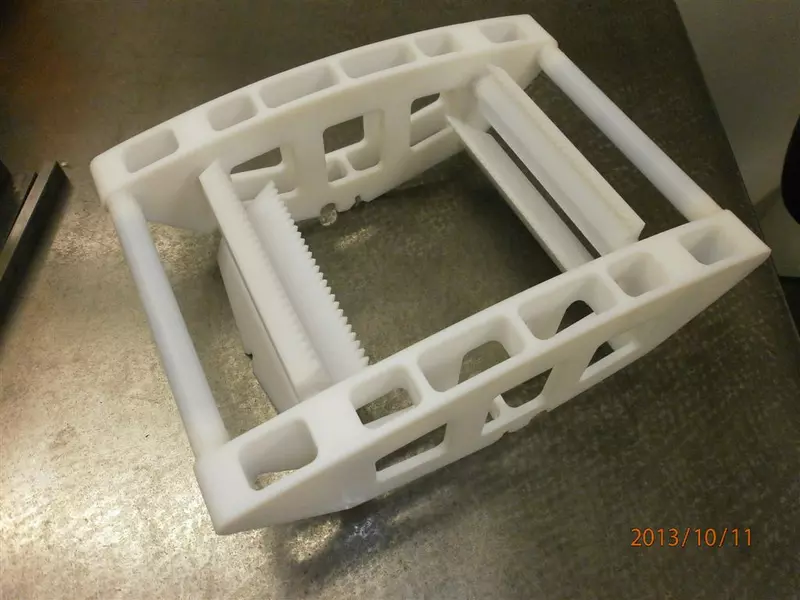

Company Profile Since 1991 Our family manufactures customized solutions made of plastic. In Gornau at Chemnitz today about 50 employees in the fields of semi-finished product processing, container and equipment construction, plant construction and cleanroom technology operate. Our solutions are used in industries such as machine and plant engineering, medical and environmental technology, the semiconductor industry and photovoltaics. The high quality of our products and services is evidenced by the certification of our company according to ISO 9001:2008. The internal design office as well as the technically and technologically advanced manufacturing guarantee our customers a comprehensive and high-quality advice and support. Involve us when planning your plastic just solution. Illustrate With our experience and the available CAD technology and we work out the best solution. We are happy to solve with our know-how your challenges. Products / Services Semi-finished processing Behälter-/Apparatebau Transparent Plastics Wasser-/Labortechnik Cleanroom technology Semiconductor engineering / photovoltaics Piping systems / special fittings Prototyping / Rapid Prototyping Machine technology With a well-equipped and very broad machinery, we can meet diverse customer needs. CNC lathe turning length up to 500 m 2 Milling Machine CNC 3-axis 1000 x 1300 x 160 Milling Machine CNC 3-axis 2300 x 1300 x 160 Milling Machine

Founded

2001

Employees

50 - 100

Certifications

Gornau

Germany - 09405

Short YOUTUBE Video: https://youtu.be/FzPtBnGDq2Q?si=E-E8EgaQiIz05Aov Our company is located in eastern Slovakia, in the industrial district of Široké village. Our over 7000 m2 of working area is divided among seven halls that are utilised for production, storage and offices. We are able to provide the best possible solutions for your needs, since we constantly invest in state of the art technologies and have extensive company expertise. In addition to Slovakia, we work with several businesses around Europe. We always strive to improve ourselves and to adjust technology to the newest trends. We are looking forward to cooperation!

Founded

2017

Employees

50 - 100

Certifications

Siroke

Slovakia - 08237

Founded

1976

Employees

200 - 500

Certifications

Höchstädt a.d. Donau

Germany - 89420

Manufacture of precision machined parts and milling parts from all machinable materials. CNC turning (up to D 90 mm rod) CNC turning (up to 250 mm in the feed) CNC long turning CNC multi-spindle turning (32 axes) CNC Machining Centers (5-Axis) Batch sizes up to 1000 pieces .... Piece including all subsequent operations up to the assembly In the field of machining there are many different ways of working. One is the CNC machining. Through this method, the milled parts get even complicated 3D contours. The CNC machining is done with machines with up to 8 axes. CNC turned parts can be made of different materials. For machining titanium, copper, brass, plastic, aluminum, stainless steel and other materials are suitable. Rotating parts in general can assume unusual shapes. In particular, the CNC milled parts often see pretty spectacular. Through its 3D contours CNC turned parts have a special effect.The machining is extremely versatile. Machining technology is used in various fields. Lathe parts, especially CNC lathe parts, are very expensive to manufacture. To produce a CNC lathe part, one special machines and more time than the normal CNC turned parts needed. The machining and especially the CNC machining requires a good education in the field. The partially very complex turned parts and just the CNC lathe parts require a tremendous expertise. A single CNC lathe part caused enormous amount of time. For these special turned parts, a particularly accurate work is absolutely necessary. For the purposes of machining are all chip forming materials. Depending on the material, the cutting is performed with different speeds. Are the turned parts made of wood, the cutting is done with high cutting speed and without cooling lubricants.Turned parts made of plastics, however, are processed at medium cutting speed. When machining water or alcohol are used for cooling. A special product from the metal cutting machines is the rotating part. Such automatic turned parts can be made from almost all machinable materials. Just like the CNC long turning parts of the screw-cutting without technical knowledge can not be produced. All machined parts require special machinery for the production. Rotating parts are to be finished by hand hardly. Are the turned parts made of wood or plastic, the machining is possibly still done manually, but with harder materials the use of expensive machining is necessary. To establish automatic turned parts, can not be dispensed with the machines. Automatic turned parts are usually ordered in enormous quantities and from extremely strong materials. Also for CNC turned parts is similar. This machining is simply too specific. CNC turned parts requiring extreme precision. Turned parts of this type are mainly used in machine and plant engineering. These industries would not do without CNC turned parts, turned parts, and the entire range of machining technology. Milling Services, CNC turned parts, turned parts, and just such special products as a CNC lathe part are absolute precision products. As simple as the concept sounds cutting, this process but it is not. Cutting sounds like simple separation that hide behind it but also things like complex CNC turned parts or automatic turned parts, no one thinks at first. Without these highly intricate parts, especially without the screw-cutting work would be impossible in some areas.

Founded

1938

Employees

50 - 100

Certifications

Wehingen

Germany - 78564

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

Founded

2011

Employees

10 - 20

Certifications

Láb

Slovakia - 900 67

We are a small family business that was founded in 1995. Currently, six people are employed by us. Our core competence is the mechanical processing of metals on CNC machines: * Rotate * Automatic turning (bar) * Long-turn * Polygonal / Umrunddrehen * Teeth * Milling Our products are used: Apparatus * Auto industry, * Railway industry and Schin vehicle * Hydraulic us pneumatics industry * Mechanical engineering * Paper and printing machines - (rolling diameter from 10 mm to 2000 mm in length) * Control technology, * Integration of the verschieder axes

Founded

1995

Employees

10 - 20

Certifications

Mezica

Slovenia - Glančnik 1a

We are a medium-sized company in the field of metal processing. Our core competencies include the production of series parts and assemblies for industry and plant and mechanical engineering, in particular the food and beverage industry. For over 75 years, Lungmetall OHG has stood for efficiency, flexibility and competence in steel, stainless steel and aluminum. Whether individual or series production, with our modern machine park tailored to the requirements of our customers, we manufacture for you flexibly, inexpensively and quickly. We are lean enough to flexibly implement your ideas and wishes, but also large enough to provide you with the capacity you need, even for large series. Thanks to our high level of vertical integration, we appear on the market as a system supplier, as we are not dependent on other trades. This manifests itself in short delivery times and a high quality standard. With our currently 60 employees and our in-house design office, we offer you an extensive service portfolio and reliable processing of your orders! We would be happy to win you as a valued customer and assure you of a partnership and team-oriented cooperation.

Founded

1924

Employees

50 - 100

Certifications

Kottenheim

Germany - 56736

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

metal cutting technology, Steel, stainless-, brass turning, milling, grinding, inductive hardening, assembling

Founded

1969

Employees

50 - 100

Certifications

Winden

Germany - 79297

FS Gear is a outsorcing company founded in the early 90s by the technical and commercial experience of the founders in the field of precision machining for third parties. The flexibility of a constantly updated and avant-garde machine park, and an organizational structure composed of specialized personnel are the strengths. Over the years, the company has made various investments in machinery and infrastructure to respond to market demands and establish itself in sectors such as oil & gas, iron and steel, machine tools and construction. The continuous search for improvement and the predisposition to follow the new technologies available on the market allows the FS to rationalize the production processes. In order to offer a complete service to its customers right from the planning stages, the company uses a technical office equipped with cad-cam stations.

Founded

1992

Employees

10 - 20

Certifications

Urago d´Oglio

Italy - 25030

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

On 16.01.2007, the Sole proprietorship “Michael Otto CAD/CAM Services” founded. About 1 year later, this results in: OTTO TECHNOLOGY-Johannes & Michael Otto GbR We are a family business, consisting of: 10 highly motivated permanent employees employees and 5 temporary workers. 7 milling and programming experts (including the management), all with roots in Tool and mold making 3 administrative workers with education in the foreign language secretariat 5 temporary workers (students and students)

Founded

2007

Employees

10 - 20

Certifications

Bad Endbach

Germany - 35050

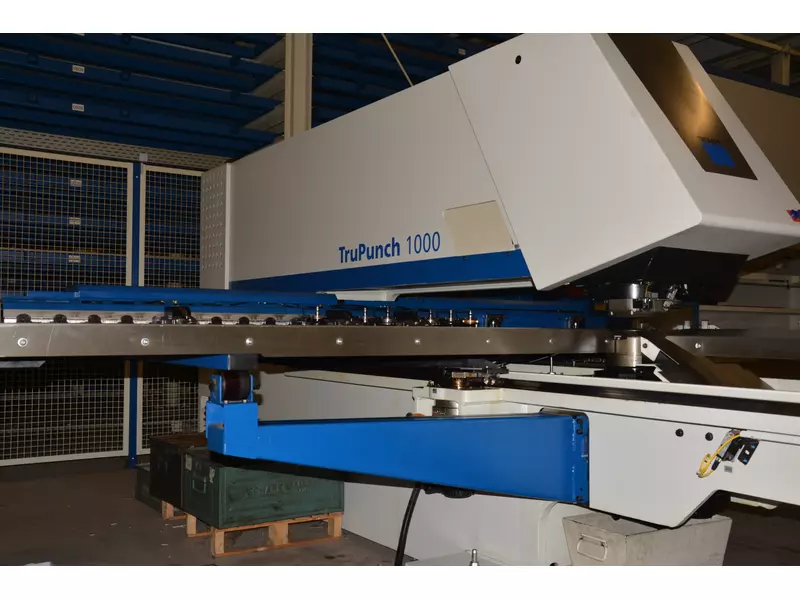

Cutting and non-cutting machining (sawing-milling-drilling-turning-tapping ...) of aluminum profiles on rotary indexing and CNC processing machines, up to 5 axes and partly with robot support

Founded

1985

Employees

50 - 100

Certifications

Herborn

Germany - 35745

Company ZUT "PROJEKT" offers services in: Processing of metal - milling, turning, Inen and outer grinding, Surface grinding, cutting, welding - steel, aluminum, stainless steel, Engineering, manufacturing spare parts and machine elements We offer: - Turning - Automatic turning (bar) - Hard roes - Milling - .... etc.

Founded

1991

Employees

10 - 20

Certifications

Konarzewo

Poland - 62-070

Nuova CAM has more than 40 years of experience in the fabrication of high-quality metal products from sheet metal, tube and box sections. We work with leading Italian and European customers within diverse sectors, including but not limited to food processing, packaging, medical, farmaceutical, personal hygiene and sanitation sectors. At our modern facility located in Bastiglia (North Italy), in addition to standard metal fabrication services including CNC machining we offer also product design, assembly and integration and metal finishing. Thanks to our engineering expertise, and manufacturing resources we can create extra value to our customers managing your supply chain and/or acting as a single source manufacturing solution for customers requiring complex sourcing, manufacturing and assembly. Our customers can rely on our complete service from concept advice and prototypes to continuous manufacturing and supply.

Founded

1968

Employees

50 - 100

Certifications

Bastiglia

Italy - 41030

- Manufacture of stamping parts according to sample or drawing to 1250 kN - Manufacture of stamping parts made of copper, brass, aluminum, bronze, steel, stainless steel up to 3mm thickness from tape using electronic feed, up to 6mm from sheets or strip - Manufacture of stamping parts made of non-metallic materials - Point-and inert gas welding (MAG, TIG) - Drilling - Tapping - Thread rolling, knurling + - High gloss polishing by polishing rotary table (6 stations) or manually - Supplier `s and-drag to 80 mm in length (even more grooves per part possible) - Belt loops - Mounting (single and assembly) - Cleaning of stampings using cleaning machine - Special solutions In cooperation: Laser technology (also 3D) laser, laser welding, Bending, CNC punching nibbling, turning and milling parts, surface finishing, tool - Quantities of 100 units to 5 million units

Founded

1937

Employees

10 - 20

Certifications

Schwarzenberg/OT Pöhla

Germany - 08340

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge