Embossing swage dies: find the best suppliers in real time

Find specialized suppliers for embossing and swage dies on Techpilot. Our platform offers access to suppliers who manufacture customized tools for precise embossing and swaging processes. Benefit from comprehensive market transparency and efficient supplier search.

233 suppliers for Embossing swage dies

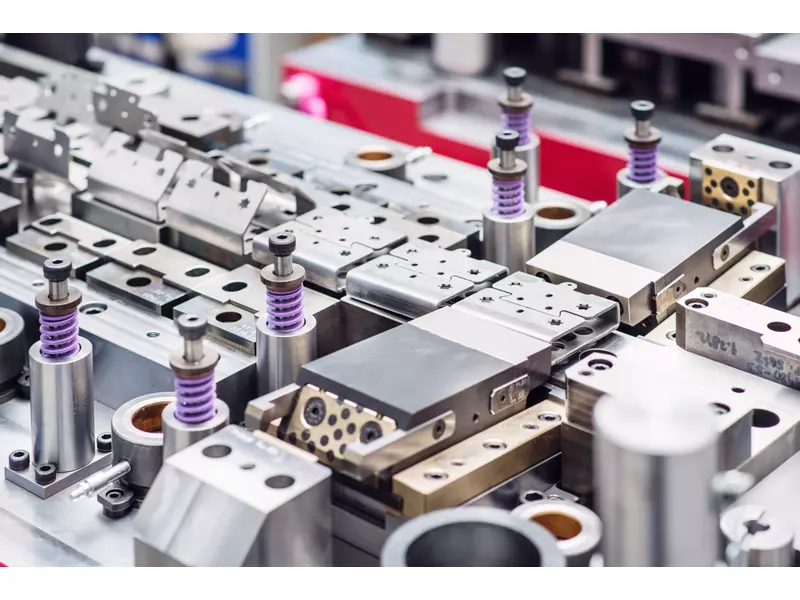

WKK Kaltbrunn AG - enormously in form The beginning of the WKK Brunn AG is founded in 1967. As a dedicated tooling the company had at that time only one purpose: the production of cutting, bending and forming tools. Shortly thereafter, the fabrication shop was put into operation and some ten years later, the company introduced her first own product. By continuity, innovation and perfection was out of the formerly peaceful Toolmaking a successful SME with about 45 employees.Today, the CHP is an international punching operation with most modern manufacturing methods in the supplier sector. enormously complete - from the first idea to the final series, we offer comprehensive services - Consulting: individual and professional, on-site or at our - Construction: in-house with 3D Autodesk Inventor - Prototyping: short to illustrate your ideas - Tool: for punching tool and teaching building, with modern machinery - Series production: stamping products of all types up to 250 tons of pressure and up to 300 mm width at 3 mm thickness (up to 5 mm after consultation) made of steel, stainless steel, non-ferrous and light metals - Component manufacture: Total manufacturer of your products, automated assembly - Post-Processing: Heat and surface treatments for partners near - Finish machining: by machining (milling, turning, drilling), eroding and vibratory finishing - Did you know? Also welding

Founded

1967

Employees

20 - 50

Certifications

Kaltbrunn

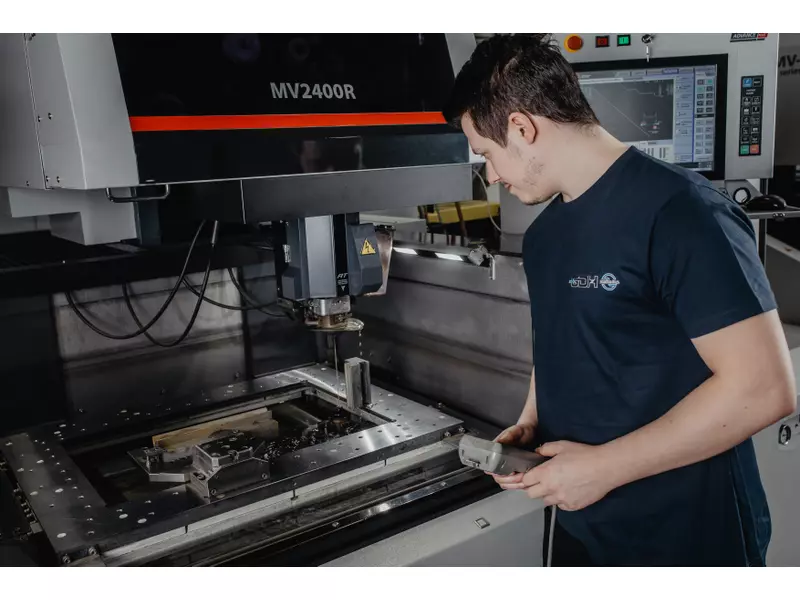

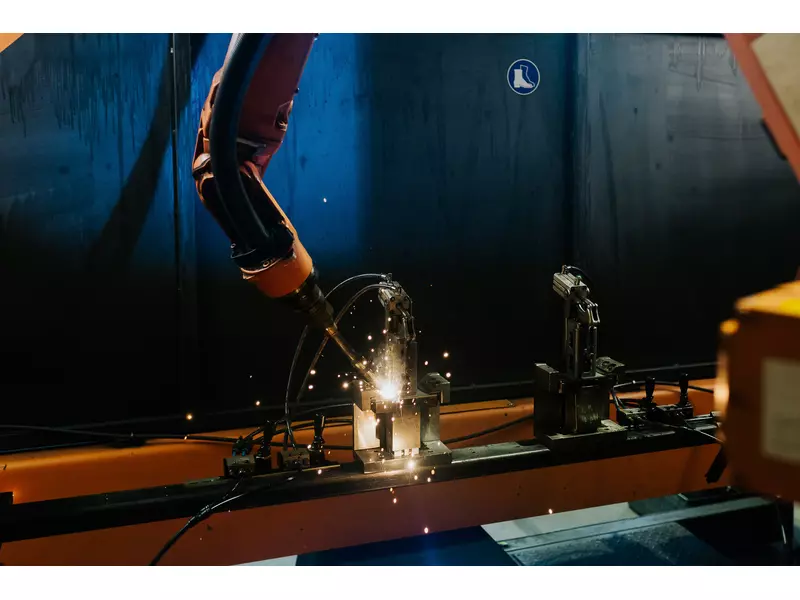

Switzerland - CH-8722

Inter Technic sro has developed in more than 5 years into a powerful company. If you are interested, we work for you as an extended workbench or can help reduce overcapacity, then ask us. In January 2015, our machinery was another new and powerful 5-axis simultaneous milling extended Hermle C42. We have currently in another, new DMG CNC milling machine invested. - Table load up to 2,000 kg - Table size 1700 x 750 mm - Travel X = 1450 mm, Y = 700 mm, Z = 550 mm This machine is our production in addition to available from the KW22 / 15th A robot welding system was installed. This brings us to weld able TIG and MAG. We are very well set up for you to produce tools and jigs. We are happy to customize items, zero series, production parts or assemble complete modules. With two new wire EDM machines we can in 2-shift operation for you. Our machinery has been almost entirely reinvested. For quality assurance, is from March 2016 new Zeiss measuring machine available! For programming we use two CAD CAM - Siemens NX Unigraphics, Version: 8.5 programming stations and enables us to offer services to the 3-D machining. Another added advantage of unsrem companies: All contacts at Inter Technic spoke German except Slovak, English.

Founded

2010

Employees

100 - 200

Certifications

Liptovsky Mikulas

Slovakia - 03101

About us Kreutz & Mock is a medium-sized company and the leading manufacturers of wire bending parts of all types. With over 3000 different articles we can offer our customers a wide and diverse range of different wire products. The necessary machines for the production are developed and built in-house by our own engineering department which gives us the possibility to always be flexible according to our customer's needs. You can find further details about us and our philosophy on our website. Products We manufacture wire bending parts in all sorts of variations and models. We supply many industries with our products like the automotive industry, construction industry, agriculture, blinds manufacturers and many more. We also have numerous technical bent parts in our repertoire. We are happy to try to achieve your specific needs and requirements, because quality, punctuality and being in step with actual practice are our basic principles to deliver high quality as well as best functionality products. It does not matter whether they are single quantities, small quantities or a large series. We are flexible and deliver quality at fair conditions. We offer + Qualitycertficate DIN ISO 9001:2008 + in-house specified tool construction + in-house machinery construction + quick production of samples + technical and experienced know how + skilled telephone service + large production spectrum Materials Every material processed in our factory has a dedicated inspection certificate that will be provided with your delivery on request. We manufacture bent wire components for you in all variants and materials. Here a selection of the materials used: + Stainless steel wire 1.4301, 1.4310, 1.4362, 1.4401, 1.4404, 1.4571 in different tensile strengths + Spring steel wire 0.9 mm to 6.0 mm. Qualities A, B, C, D + Steel wire C9D bare or copper-plated. C9D soft galvanised in 1.0 mm to 8.0 mm + Crapal wire + Becrosi valve spring wire + Silver and Palladium wire

Founded

1934

Employees

20 - 50

Certifications

Neuendorf

Germany - 97788

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Magepa offers advice as strong precision engineering partners, among others Spacers, leaf springs and metal liners for mechanical engineering at. With over 50 years experience in stamping and forming, we have a deep understanding of the needs shall our customers. We also carry pipe bending by and manufacture precision sheet metal parts made of spring steel strip. With our expertise and our technical creativity, we provide our customers with solutions such as individual leaf springs, shims unique, special spacers, etc. Our standards are high. We want to understand you and your machine exactly. Together we will develop ideas and implement them with the latest technology. Precision engineering products for engineering such as metal liners and precision sheet metal parts made of spring steel strip, etc. are available in commercial quantities or as special.

Founded

1963

Employees

10 - 20

Certifications

Koberg

Germany - 23881

We are a medium-sized company based in Ganderkesee and have been producing sophisticated sheet metal and formed parts for our customers for over 65 years. Our customer base includes the automotive, mechanical engineering, electrical, marine and aircraft industries, where we are listed as an A-supplier and have already received several awards as a 0-ppm supplier. Our company is fundamentally different from other companies that can produce either only large or only small series at low cost. We are proficient in both technologies. Since we are convinced that only holistic quality and sustainability can lead to success today and in the future, we have a certified integrated management system in accordance with the requirements of IATF 16949, DIN EN ISO 9001 and DIN EN ISO 14001 established. (ext. TÜV Cert link). Our homepage is intended to give you a brief overview of our diverse production options. We would be delighted to work for you too. Give us a chance to do that.

Founded

1948

Employees

20 - 50

Certifications

Ganderkesee

Germany - 27777

VS steel GmbH has been active in the domestic market since 2012. Our core competencies are in the field of metalworking and toolmaking. Since the founding of the company we are constantly developing and expanding. We are constantly working on improving our production processes, increasing the production area and investing in state-of-the-art production technologies. With us you get from prototypes to small series up to long-term serial deliveries. The company caters to all its customers, whether they are individuals, craft businesses or well-known clients in the automotive sector. Your satisfaction is our goal. Reliability, precision and high quality are our top priority. We have many years of experience in the automotive industry, which enables us to put our customers' orders into practice using state-of-the-art technologies. Thanks to our many years of experience, we are able to develop unique solutions for the customer according to their requirements. We accompany you from the primary idea to the final product. For reference, we refer to Skoda Auto AG. We are one of two companies that provides tooling services for the production of stamping tools for new models for Skoda Auto AG.

Founded

2012

Employees

20 - 50

Certifications

Prag

Czech Republic - 10000

SINCE 2009 .... The company was founded in 2009 by Mrs. Bettina Landgraf-Kaiser, storage capacity today is about 3000 m² in three halls. As a leading warehouse distributors constantly about 100 cars and well-preserved machines of best brands offered. State of the art warehouses with crane capacity up to 10 tons and forklift capacities up to 7 and highly trained staff are the benefits for potential customers to find the "perfect machine". Complete "all-inclusive" packages (eg transport, introduction, installation Complete training) are developed and implemented according to your. MEMBER OF: Since 2009 FDM - Germany Since 2009 EAMTM - Brussels (International) SPECIALITY: Cutting metal-working machines Our specialty is the trade used machines from metal cutting. Whether conventional or CNC - controlled, we each offer the right machine for you.In CNC - area we act almost exclusively with the control type Fanuc & Heidenhain. Here we can give you the best - provide service, whether coverage with qualified staff, service staff or software solutions. OTHER: Furthermore, even spare parts - remakes produced directly in the house with us. Through years of experience of our employees in the cutting process on Fanuc & Heidenhain controls, we can therefore offer cost effective replacement parts alternatives you.

Founded

2009

Employees

5 - 10

Certifications

Bruchsal-Büchenau

Germany - 76646

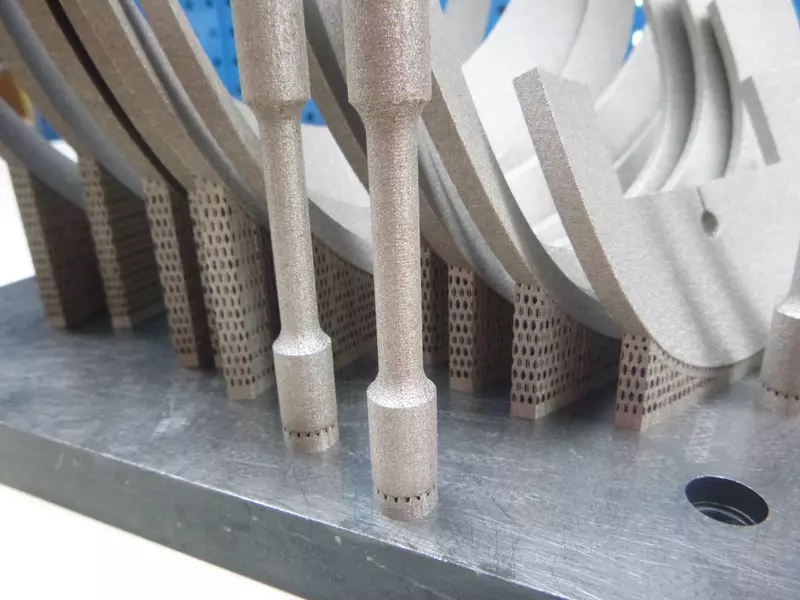

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

- Manufacture of stamping parts according to sample or drawing to 1250 kN - Manufacture of stamping parts made of copper, brass, aluminum, bronze, steel, stainless steel up to 3mm thickness from tape using electronic feed, up to 6mm from sheets or strip - Manufacture of stamping parts made of non-metallic materials - Point-and inert gas welding (MAG, TIG) - Drilling - Tapping - Thread rolling, knurling + - High gloss polishing by polishing rotary table (6 stations) or manually - Supplier `s and-drag to 80 mm in length (even more grooves per part possible) - Belt loops - Mounting (single and assembly) - Cleaning of stampings using cleaning machine - Special solutions In cooperation: Laser technology (also 3D) laser, laser welding, Bending, CNC punching nibbling, turning and milling parts, surface finishing, tool - Quantities of 100 units to 5 million units

Founded

1937

Employees

10 - 20

Certifications

Schwarzenberg/OT Pöhla

Germany - 08340

Founding of the company 2002 First commercial premises in Lovrenc na Dravskem polje Experiences mean the future We work with 15 years of experience and are constantly investing in new technologies. We manufacture high-quality and sophisticated machine parts and offer a complete service.

Founded

2002

Employees

5 - 10

Certifications

Kidričevo

Slovenia - 2325

Fischer-Brodbeck GmbH (FIBRO) was founded in Weinsberg in 1958 and has been part of the LÄPPLE Group since 1974. Today, 610 employees worldwide work in the standard parts division. FIBRO at a glance: - 610 employees - own subsidiaries in France, Poland, the USA, India, Malaysia, Korea and China - Over 70 agencies and service centres worldwide - Quality management system according to DIN ISO 9001 - Environmental management system according to DIN EN ISO 14001

Founded

1958

Employees

500 - 1000

Certifications

Hassmersheim

Germany - 74855

TROB Tröstler & Oberbauer GmbH

PRECISION COMPONENTS FOR SONDERMASCHINENBAU Spectrum: wear and replacement tools, cutting, bending, crimping, anvil, embossing and drawing tools. Management and feed rails and all other parts that may be in the range of tolerance to UNDER 0.005 mm. SPECIAL TOOLS FOR PRECISION MASS PARTS MANUFACTURER Range: indoor and outdoor round mold steels, Flachformmeissel, shape inserts, Abstechklingen, flanging, roll forming, punch and matrices. MANUFACTURING SECTORS IN PRECISION MACHINING CNC Flat, round and Optical profile grinding, full-cut grinding, wire and sinker EDM, milling and turning machining centers. CNC 3D measuring and CNC Optical fairs. Materials: carbide, ceramic, HSS, titanium, PM and VA-steels, aluminum.

Founded

1984

Employees

20 - 50

Certifications

Rohrbach

Germany - 85296

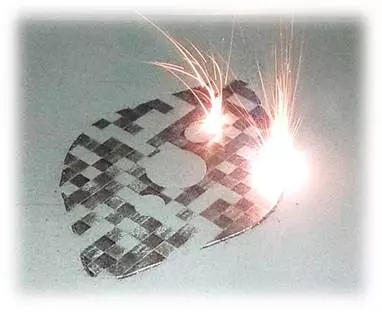

Tools of GDH Need smart tool solutions or the realization of complicated processing problems? From planning and design through the development of the individual components to the construction of the finished tool: GDH is in the design and manufacture of tools for sheet metal processing since 1992 competent partner. Our strengths are our deep-drawing tools especially when multiple trains are required. Tools we manufacture as an insert, consequential, Progressive and transfer dies, both for prototypes, as well as for series production up to a maximum weight of 10 tons. Deep-drawn parts of GDH We manufacture drawn parts made of all metal forming materials to be processed. Materials such as steel, stainless steel and nonferrous metals are brought with us into the right shape. The processing at a material thickness of 0.3 mm - 10 mm thickness up to a pressure of 800 tons possible. We manufacture according to your drawings, CAD data, and according to your samples.Their tools are taken or produced in-house. In addition, we offer the possibility of deep drawing simulation with single trains in our house. Pressed parts of GDH With us you get spun parts from all metal forming materials to be processed. Materials such as copper, brass, steel, aluminum, stainless steel, tin, and zinc are staying with us in the right shape. Rotationally symmetrical workpieces are to oä to a round plate size of 800 mm in diameter with an initial sheet thickness of 6 mm in St, 4 mm in VA, 8 mm in CU / CnZu. and 10 mm in Al manufactured as pressed parts. We manufacture according to your drawings, CAD data, and according to your samples. Their tools are taken or produced in-house. Laser Technology at GDH Lasers: We laser in 2D technology in possible sizes 3000 x 1500 mm. maximum thickness * In VA to 12 mm * St to 20 mm * Al to 6 mm In 3D technology routes of sizes 3200 x 1525 x 600 mm are possible. Maximum thickness here * In VA to 4 mm * St to 8 mm * Al to 3 mm Punch Technology GDH Punching: Up to a print capacity of 120 tons from the tape. Up to 800 tonnes in the insertion process.

Founded

1992

Employees

100 - 200

Certifications

Bad Marienberg

Germany - 56470

Metal spinning: - Diameter of D = 10mm to D = 1'500mm - Material thickness of s = s = 0.5mm to 6.0mm - All metals (aluminum, stainless steel, steel, titanium, silver, gold ...) Deep drawing: - Width across corners component of E = E = 10mm to 1'800mm - Material thickness of s = s = 0.5mm to 6.0mm - All metals (aluminum, stainless steel, steel, titanium, silver, gold ...) Metal spinning: (Http://www.metallumformung.ch/de-de/metalldr% C3% BCcken / beschrieb.aspx) Take advantage of the possibilities of this interesting process. If the metal press used by specialists, achieved by no other forming process particularly for single pieces or small series its economy. Deep drawing: (Http://www.metallumformung.ch/de-de/tiefziehen/beschrieb.aspx) Less is often more! With the possibilities of deep drawing we can produce items where other methods are dependent on the assembly of several parts long. Use this advantage with integrated cost reduction.

Founded

1957

Employees

10 - 20

Certifications

Hombrechtikon

Switzerland - 8634

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

HELLO WE ARE A COMPANY THAT HAS SET OUT TO SERVE OUR CUSTOMERS AROUND THE WORLD WITH OUR 15 YEARS OF EXPERIENCE IN OUR BUSINESS LIFE AND TRIES TO COMBINE THIS SERVICE WITH THE HIGHEST LEVEL OF QUALITY, TIMELY DELIVERY AND REASONABLE PRICE POLICY. OUR GOAL IS ALWAYS TO REACH BETTER QUALITY

Founded

2023

Employees

5 - 10

Certifications

İstanbul / Tuzla

Turkey - 34940

Precision rotary parts, - milling and ground parts (Ground parts) - Transmission shafts (drive shafts) to 1500 mm, hollow shafts, rotor shafts - Flanges (Intermediate), bolts, fittings, machine components - Cells wheels, worm shafts, knife shafts. - Guide rails, shaped pillars Machine Knives Knives industrial Press Brake - Perforating, squeezing knives, shear blades, packaging knives. Knives for plastics industry, mill knives, textile knives, sheeter knives, crush cutter, foil knife, knives, tungsten carbide blades, serrated blades, welded-on blades, slitter knives, Plotter and other machinery knives. Circular knife round knife Circle diameter (round blade) are rotating tools that can be (with counter-blade) was used with a knife cut or shear cut method. Circle diameter (round blade) can be produced for different applications from different materials (stainless steel, tool steel, HSS or stainless steel).The particular design can customized (eg ground on both sides, toothed, 2-wading, etc.). There arise because different names such as, crush cutter, top cutter, bottom cutter, pen-knife, plate diameter, perforating circular knives, rotor diameter, roller blades, etc. In addition, we also manufacture the knife holder and knife shafts and induviduelle cutting devices. The regrinding of circular knives is almost always worthwhile. Punching tools Punching diameter: Punching knife and cutting die are made from solid steel (eg tool steel 1.2379). The blades are hardened and ground. Punching blade made of solid material, are especially suitable for punching work with very precise contours as well as for long-term use, as they can be reground. Made of solid steel, we can also very small and precise punching knife and punching iron manufacture (eg samples dancing). Dies: We manufacture cutting knife and cutting dies from hardened steel strip and for a variety of punching tasks.Depending on the application, band knife made of spring steel, carbon steel, tool steel, stainless steel. Compared with the cutting knives made of solid steel, they are affordable and are suitable especially for disposable knives as well as large punch surfaces. We have stamping tools for individual tasks. - Cutting die, die cutting knife, cutting knife for test specimens, punches, punching, stamping dies, Steel rule dies, punches, - Cutting rollers, cutting mills, crushing blade - Punches and dies, punches, forming punches Flat - and cylindrical grinding - Surface grinding, surface grinding up to 3000 mm length - Cylindrical grinding up to 400 mm diameter - Fine grinding, lapping, polishing - Carbide Grinding Roll manufacturing roll grinding and - Rolls, roll cores, drive rollers, winding rollers, form rollers, fluted rollers Nippers, the cutting rollers, roll forming, turning rolls

Founded

Employees

Certifications

Schenefeld (bei Hamburg)

Germany - 22869

Founded

1994

Employees

20 - 50

Certifications

Gotha

Germany - 99867

Glatec is your reliable partner for manufacturing subassemblies from metal. Glatec collaborates with companies from the electronic, machine building, home appliance and furniture industries. Glatec is one of the leading producers of fittings for beds and kitchen appliances in Europe. Our production is set up for manufacturing components and subassemblies in order quantities from 5000 to 500’000 articles. This allows us to react promptly and flexibly to your requirements. We focus on processing sheet metal, varying in thickness from 1 to 5 mm, coils up to 400 mm wide. We operate three automatic feed presses with a pressure range from 630 to 2500 kN. For separate operations, presses varying from 100 to 2500 kN in force are available. Stamping, bending and progressive dies are designed and produced in our own tool making shop. We also produce our automation solutions inhouse. For quality assurance 3D measuring equipment is available in-house. All CNC controls are linked into the company network. Programming of the machines is done with NX CAM Express.

Founded

2005

Employees

100 - 200

Certifications

Kostievo

Bulgaria - 4205

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge