Request quotes for cogged belt pulley

Are you looking for specialized suppliers for cogged belt pulleys? Techpilot helps you find suitable suppliers who manufacture these specific drive components. Use our platform to gain complete market transparency and reduce your procurement costs.

126 suppliers for Cogged belt pulley

We have been in operation since 1980, specializing in the manufacturing of machinery and spare parts. We are equipped with CNC lathes, CNC milling machine, conventional lathes and milling machines, grinding machines and drilling planes. We pride ourselves in taking on all kinds of extras and machines, tailored to the needs of each customer. Precision, productivity, professionalism are features that make up the company profile, which is based on our evolving mechanical perception. Our industries: •Aerospace and aviation industry •Packaging industry •Military engineering •Fittings engineering •Air conditioning •Automation and control engineering •Special purpose machinery manufacturing • Drive and gear engineering • Apparatus engineer • Textile • Telecommunications • Canning •Agricultural machinery • Packaging • Manufacturers of electrical appliances • Food processing industries • Clothing industries

Founded

1981

Employees

20 - 50

Certifications

Naousa

Greece - 59200

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

We are an innovative company has been established specialised in the sector of precision parts for machine construction. Customer orientation, quality, respectful labour relations. We are specialised in turning, milling, and grinding processes of mechanical parts.

Founded

1994

Employees

50 - 100

Certifications

Çorlu - Tekirdağ

Turkey - 59850

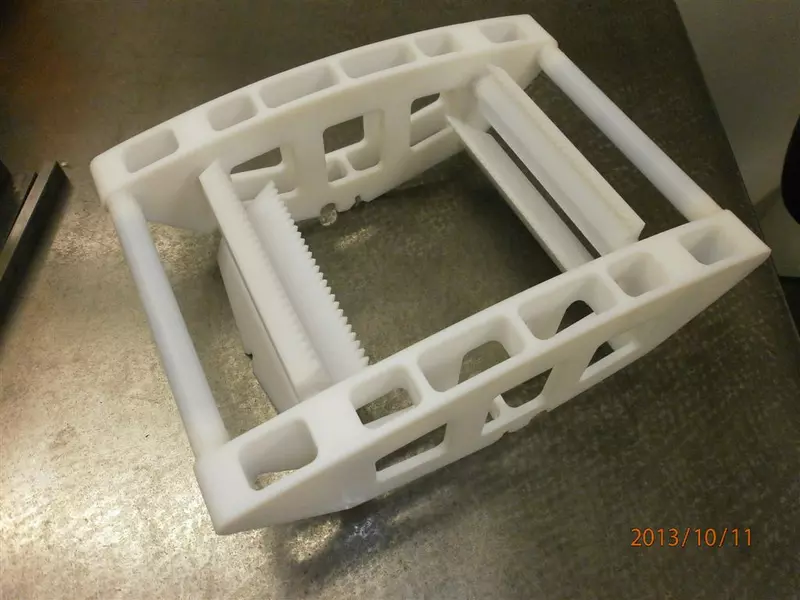

Company Profile Since 1991 Our family manufactures customized solutions made of plastic. In Gornau at Chemnitz today about 50 employees in the fields of semi-finished product processing, container and equipment construction, plant construction and cleanroom technology operate. Our solutions are used in industries such as machine and plant engineering, medical and environmental technology, the semiconductor industry and photovoltaics. The high quality of our products and services is evidenced by the certification of our company according to ISO 9001:2008. The internal design office as well as the technically and technologically advanced manufacturing guarantee our customers a comprehensive and high-quality advice and support. Involve us when planning your plastic just solution. Illustrate With our experience and the available CAD technology and we work out the best solution. We are happy to solve with our know-how your challenges. Products / Services Semi-finished processing Behälter-/Apparatebau Transparent Plastics Wasser-/Labortechnik Cleanroom technology Semiconductor engineering / photovoltaics Piping systems / special fittings Prototyping / Rapid Prototyping Machine technology With a well-equipped and very broad machinery, we can meet diverse customer needs. CNC lathe turning length up to 500 m 2 Milling Machine CNC 3-axis 1000 x 1300 x 160 Milling Machine CNC 3-axis 2300 x 1300 x 160 Milling Machine

Founded

2001

Employees

50 - 100

Certifications

Gornau

Germany - 09405

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our mission is to provide first-class services in the field of CNC machining. Thanks to our passion for technological progress and continuous improvement of production processes, we are able to meet even the most demanding requirements of our customers. Our customers demand not only high quality and precision, but also flexibility and the ability to quickly respond to changes in production requirements. We are proud to be able to offer comprehensive services from technology design through production to final quality control. Our customers particularly appreciate our professionalism, technological equipment and ability to meet even the strictest deadlines. We have a production capacity of 400 hours per week, which enables us to efficiently respond to the demands of our clients. Our 960 m² production facilities are equipped with the latest machines and technologies that ensure high precision and product quality. Our customers include : Siemens s.r.o., Flowserve s.r.o. John Crane Škoda Transportation a.s. DPOV a.s. Excalibur army spol. s.r.o. Company Technology : Metalworking - CNC turning , CNC milling , CNC measuring , conventional turning and milling. Cutting work on CNC plotter. 3D printing. Production of hydraulic hoses - industrial hoses, air hoses, rubber and flooring + accessories. MIG/MAG and TIG welding. Locksmith works. We also provide : - Heat treatment of metals (hardening, annealing..) - Casting (cast iron, steel, aluminium) - Forgings, forgings... - Surface treatment (comaxite, zinc, etc..) - Grinding Translated with www.DeepL.com/Translator (free version)

Founded

2021

Employees

10 - 20

Certifications

Šternberk

Czech Republic - 78501

Company ZUT "PROJEKT" offers services in: Processing of metal - milling, turning, Inen and outer grinding, Surface grinding, cutting, welding - steel, aluminum, stainless steel, Engineering, manufacturing spare parts and machine elements We offer: - Turning - Automatic turning (bar) - Hard roes - Milling - .... etc.

Founded

1991

Employees

10 - 20

Certifications

Konarzewo

Poland - 62-070

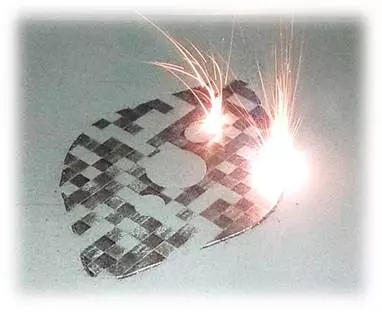

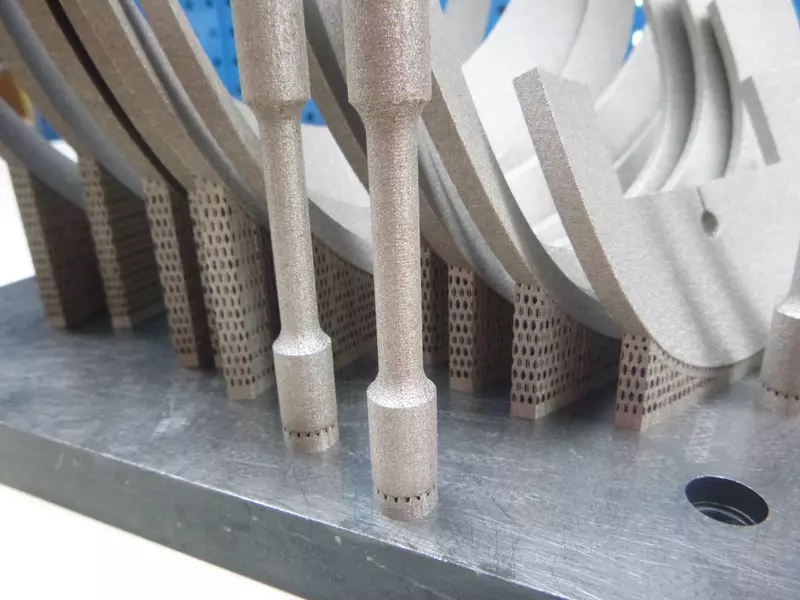

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Our goal is to convince our customers through our performance, which is always oriented towards our customers' high requirements regarding quality and on-time delivery. The most modern production equipment, quality assurance during production, and optimized processes make it possible for us to produce with speed, precision, and cost efficiency, all at the same time. Regardless of whether we mass-produce for you, deliver popular models on short-term notice, or manufacture individualized single components according to your specifications - we are consistently working on optimizing our customer-oriented service. Bevel gears Hobbing max. Ø 250 mm, up to module 6 Splines Hobbing Grinding upon request up tp 1200 mm in length max. distance between centers: 1250 mm Sprockets Hobbing Shaping max. Ø 400 mm, up to 1 inch up to 1 inch Worms Chasing Milling Whirling Grinding up to module 3 up to module 6 up to module 6 up to module 7 Worm wheels Hobbing upon request Helical gears Tooth flank grinding max. Ø 300 mm, module 6 Spur gears Hobbing Shaping max. Ø 600 mm, module 6 max. Ø 500 mm, module 6 Timing gears Milling available on short notice, in stock: from module 0,5 to 10 mm and from partition 2 - 10 mm; up to 3000 mm in length External grinding up tp max. 270 mm, max. distance between centers: 1000 mm CNC drilling upon request CNC and conventional turning up to Ø 400 mm, length 1200 mm Surface grinding max. length 2000 mm CNC and conventional milling upon request Thread grinding upon request Internal grinding max. grinding Ø 200 mm, max. grinding depth 250 mm Grooving: milling, cutting, reaming up to 28 mm Surface treatment such as hardening, nitriding, etc. Centerless cylindrical grinding max. Ø 70 mm Racks (High-Precision Racks) Type of Machining Machining Sizes Milling available on short notice, in stock: from module 0,5 to 10 and from partition 2-10 mm up to 3000 mm in length Delivery program: Gear wheels, spur wheels, racks, snails, worm gears, worm shafts, chain wheels, toothed belt wheels, helical gears, bevel gears, splined shafts, pump impellers, any waves, flange. Nearly everything with teeth. Materials: Steel, high-grade steels, non-ferrous metals is processed such as copper, brass, aluminum and plastics in complete and wage labours. Thermal treatment and surface coating: Additionally to our achievements we offer still any surface treatments. Case-harden, nitrating, Nitrocarburieren, carburizing, sandblast, TENNIFER QPQ, as well as galvanizing, burnishing and the like. Our customers expect to get low-priced precision products from us, with short delivery times, reliable service, and constant high quality. This is exactly our strength - which is based on state-of-the-art production equipment, quality assurance during production, and optimized processes!

Founded

1957

Employees

200 - 500

Certifications

Kohlberg

Germany - 72664

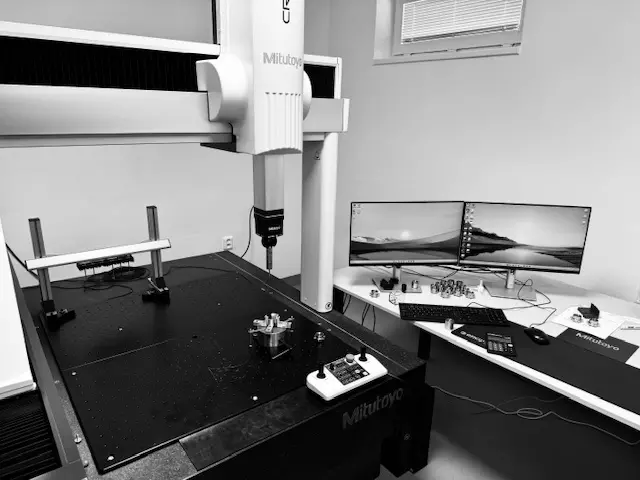

Trasmissions Buzzolan Srl is a mechanical workshop that manufactures straight-tooth and helical gears, grooved shafts and high-precision mechanical components, through turning, milling, broaching, slotting and toothing. The experience gained over the years in the field of mechanical transmissions makes it possible to offer a highly technological production cycle accompanied by structured quality controls. To create our products, we start from materials such as common and alloy steels, aluminum, bronze, cast iron, brass and plastic materials. The company also offers heat and surface treatment and welding processes that are carried out by sought after and trusted external partners. Our Metrology room provides our team with innovative machinery and control tools throughout the processing cycle, from the start to the finished product. The company's goal is to guarantee products that meet the required quality standards with timely deliveries, offering accurate and attentive tailor-made technical advice if necessary.

Founded

1998

Employees

20 - 50

Certifications

Thiene

Italy - 36016

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

Diene production services Precision and experience. manroland is the world's second-largest press manufacturer with about 900 employees. The printing presses lives of precision. You can profetieren it, for manroland has many years of expertise as a world leader not only in sophisticated printing machines: Our professionals bring their years of experience with a manufacturing services for you. Quality testing and certification. manroland is certified according to DIN EN ISO 9001:2000 and DIN EN ISO 14001:2005. Annual audits ensure the honing demands on the processes safely. With our machines almost every feature can be verifizeirt professional manner. In addition, our laboratories provide materials analysis and Schlissbilder. Own foundry. The foundry with integrated model for large parts in Offenbach with an annual volume of up to 17,000 tonnes of cast iron saves valuable time in the match between model-making, foundry and manufacturing.For shorter lead times and lower costs for our customers. Diverse range of parts. From the lever through gears in Meisterradqualität to extremely heavy side walls, with tolerances of a few microns, thanks to a modern machine park. Also the production of any workpieces from batch size one is in the fast group everyday. Rotary bulk of production Rollers and cylinders. manroland offers the complete process chain for machining of cylinders and rollers: Turning, milling and drilling into a voltage on modern CNC machining centers and final grinding. There are also successful partnerships for gavanische surface finishing. Non-circular grinding. The special features of the machinery for rolling and the cylinder with appropriate controls is also the non-circular machining of precisely defined contours no problem. Prismatic large-part manufacturing Bulk of production.manroland manufacture components with size 2.2 meters wide x 2.5 meters long x 2 meters in height and weighing up to 2 tons. In the doubles table operating a processing to eleven meters in length. Our machines operate with a capacity of up to 100 kilowatts. Tools with a diameter up to 315 mm cutting depths allow con about 15 to 20 millimeters compared Gussverzüge and cast tension, with high-precision manufacturing of drilling intervals. Flat part manufacturing. CNC machine tools allow the highly efficient production of cubic flat parts with a machining of up to five pages in one setting. The machine tools are mostly equipped with special Ganauigkeitspakete ensure the highest quality for large component dimensions. Prismatic workpieces geometry primarily by complete machining on special parts that meet any of aluminum are in high quality requirements for CE-safety-related parts.For this we use a moderene five-axis machining round. Complete production Complete machining. The device construction, the tool engineering and CNC programming are aligned short response time for changes and new parts. Complex cubic workpieces are manufactured in several setups in multi-range operating on different processing centers: Small series of cast blanks with complex hole pattern and high quality requirements (up to it5) are among the references (levers, rails, slats and gear housing). Turned parts. Rings, flanges and wheels of medium dimensions are produced, but also gear shafts or special Exzentergleitlager with tolerance ranges of up to seven microns, including modern external and internal cylindrical grinding techno...

Founded

1871

Employees

> 1000

Certifications

Offenbach am Main

Germany - 63075

Company description Looking the whole manufacturing from a single source? Put on the right partner, because it gives you the necessary freedom for your core business. Send us your drawing. We procure materials, rework the parts, ensure the coating and monitor the entire production process until you can use the pre-finished workpiece on time available. Mcon GmbH (Austria) has specialized as a supplier of high-quality production parts. With years of experience in mechanical engineering, we were able to establish ourselves very well in the domestic and European market. Our strengths are high quality associated with punctuality, expertise on our part as well as those of our contractors. With this basis, we like to solve your challenges! OUR SKILLS We put our focus on products that we have been perfecting. In order to offer our customers perfect products, we focus on the following areas of expertise: • Frästeile • Turned parts • weldments Especially in the mechanical engineering, plant engineering, transmission engineering, railway and traffic systems, renewable energy and medical customers appreciate our expertise, as well as the perfectly manufactured products and the fast service. Frästeile: Quantities: Small, medium and large series Dimension: Max. 500 x 1200 mm Material: Steel, stainless steel, nonferrous metals, plastics surface treatment Curing, painting, nitration, anodizing, coating, Brin Irish. Turned parts: Quantities: Small, medium and large series Dimension: Conventional machining: max. D = 220mm Material: Steel, stainless steel, nonferrous metals, plastics Surface treatment: possible in cooperation with long-standing and reliable partners Welding: Quantities: Small series Weight: Max. 3000 kg Material: Steel, stainless steel Welding Types: After method E111, TIG / 141, MIG / 131, MAG135 / 136 Welders have valid certificates according to EN 287/1 Surface treatment: possible in cooperation with long-time partners. Surface treatment: anodizing Chromium Blacking paint galvanize Wärmebechandlung: gas nitriding vacuum hardening are also possible on request quality responsibility "The customer comes back, not the product" So simple and clear aptly is our internal motto. Achieving this does not succeed by means of regulations, but only by really motivated and well trained staff. So is the ultimate goal for us to provide a secure future for employees and company. We intend to achieve by careful and constant growth of the company and by absolute customer satisfaction. Challenge us with your requests!

Founded

2024

Employees

5 - 10

Certifications

Stnkt Kathrein am Offenegg

Austria - 8171

SPANPOWER CNC Precision Parts is the manufacturing specialist for high-quality CNC-manufactured components and assemblies. With our modern machinery, we produce prototypes and series. Our services include CNC turning and milling and wire EDM. Customer-specific surface treatments and module assembly round off our manufacturing options. Our customers come from the fields of plant engineering, mechanical engineering, optics, automotive and aerospace.

Founded

2024

Employees

10 - 20

Certifications

Rednitzhembach

Germany - 91126

Johann B. Waas GmbH has been a production company for metal and plastic components and assemblies for the automotive, medical technology and general mechanical engineering industries since 1967. Specializing in complex turned and turned-milled parts, we manufacture on state-of-the-art CNC machines in small and medium series according to the current standards of our industry and the automotive industry as a Tier 3 supplier.

Founded

1967

Employees

10 - 20

Certifications

Fürstenfeldbruck

Germany - 82256

We manufacture for you in the areas of sawing, turning, milling, drilling, grinding, gear cutting and grooving. In all areas we have experienced employees who have been loyal to us since the company was founded. In order to preserve and pass on this experience, we regularly train successfully. Big and small, we can do both. Regardless of whether it is a small turned part or a large welded construction, we will manufacture it for you. Thanks to our wide range of machines, we have a high level of vertical integration, which enables us to offer our customers a wide range of components.

Founded

1994

Employees

50 - 100

Certifications

Wiesmoor

Germany - 26639

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We, Metallbau Schmalenbach, specialize in manufacturing a wide variety of high-quality and tasteful stainless steel and corten steel accessories. Years of experience in working with metal products, experienced know-how and the gift for exceptional design give our products uniqueness. The focus is on narrowing down to the essentials. In a charmingly flooded world, peace and relaxation are important to us. Simplicity is the goal and with it the uniqueness of our products. In addition to our wide range of products, we also offer you the opportunity to have your ideas implemented. We offer you custom-made custom-made products. You are welcome to visit us at Linienstr.14 in 42289 Wuppertal.

Founded

2022

Employees

5 - 10

Certifications

Wuppertal

Germany - 42289

Gear and transmission construction according to customer requirements Prototype and series production Bevel gears and various other products

Founded

Employees

10 - 20

Certifications

Hausen

Switzerland - 5212

CNC: 5-axis milling, turning, wire EDM ///prototypes + series special devices ///Design + Construction + Manufacturing

Founded

2012

Employees

5 - 10

Certifications

Markgröningen

Germany - 71706

TURNING & MILLING experience since 1998 On our modern machinery Our experienced team manufactures your turning and Milled parts made of aluminum or plastic exactly according to your specifications. Specialized in opto-mechanical In this area, we support our customers as reliable partner with extensive manufacturing expertise. MODERN MACHINERY Automated manufacturing Our experienced machine operators (f/m/d) use modern and automated turning and Milling machines for every day, workpiece for the highest quality workpiece for our to manufacture customers. In addition to manufacturing turning and We carry out milled parts for our Customers like to organize surface finishing by suppliers and others accompanying services.

Founded

2006

Employees

10 - 20

Certifications

Ottobrunn bei München

Germany - 85521

Your partner in manufacturing technology Using state-of-the-art and networked CAD systems, our engineers and designers develop efficient and innovative solutions for the diverse requirements of our customers. We produce quality. Are you looking for an individual solution? Our technologies are designed to meet all customer requirements With our diverse range of technologies, we offer you tailor-made solutions that are precisely tailored to your needs. Rely on our expertise and flexibility in the following areas: - Drilling mill work - welding - Spin - Milling - Grooves - Interlocking - deep hole drilling - Assembly - Mobile spindles Our range of services includes the construction of special custom-made products, the processing and production of prototypes, individual pieces and series, and the repair of damaged or worn tools and components. Let's talk about your project: Simply contact us or talk to your contact person directly. Our experienced team is happy to hear from you!

Founded

2000

Employees

50 - 100

Certifications

Papenburg

Germany - 26871

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge