Handling technology: find new suppliers

Discover specialized suppliers for handling technology on Techpilot. Our platform connects buyers with suppliers who offer innovative solutions for your production processes. Optimize your processes and receive an average of 7 offers per request.

369 suppliers for Handling technology

As an industry partner, we offer a wide range of services. We provide assistance with repairs, maintenance on production machines and testing of work equipment. In addition, we offer our customers in-house fixture construction with machining and welding technology. If required, we can offer one-off production of spare parts including delivery and assembly from a single source, for example to repair an acute defect as quickly as possible. Individual solutions in production Handling tools - Lifting tools - trusses - Turning devices - transport devices exams - Lifts - Water squeegee - Shelving systems - ladders - Lifting equipment - DGUVv3 checks von der Heyde is certified - DIN EN ISO 9001 - DIN EN 45001 - DIN EN 1090-1 - DIN EN ISO 3834 In-house production - metal and sheet metal processing - turning, milling, drilling - surface treatment (external processing) - welding of individual parts and structures made of steel, stainless steel and aluminum - 3D measurement technology - Own design with Catia V5 or EPLAN - Automation solutions with Siemens Tia Portal and other PLC solutions

Founded

1986

Employees

50 - 100

Certifications

Stade

Germany - 21682

"A systematic approach to solution" The company PRO CNC GmbH & Co. KG was founded on 01.12.1990 by Michael Pfeiff under the name Michael Pfeiff. The company's headquarters was first in Varl and was moved in 1994 after Luebbecke. On 01.09.2003, the company was acquired by the current owner Volker Meier kink and then operated under the name Pfeiff toolmaking. Since 01.09.2013 we now operate under PRO CNC GmbH & Co. KG - Production Engineering and Mechanical Engineering. Mr. Meier is one kink with the company since the very beginning. The company PRO CNC GmbH & Co. KG deals with the full range of mechanical manufacturing (turning, milling, drilling, grinding) and the assembly of components and machines. Focus here is the contract manufacturing in the milling, especially the production of small parts. Cubic parts up to an edge length of 1000x600mm currently can be handled in-house CNC PRO GmbH & Co. KG. The company PRO CNC GmbH & Co. KG is able to deliver to the customer from the initial sample to mass production all.The range of parts includes the classic item to automobiles mass part. Is manufactured to eleven computer-controlled machine tools and machining centers the latest generation with up to four axes and two spindles. Some of the machines are equipped with rotary tables change. As a manufacturer, we would like to mention, among others, Bridgeport, Brother, YCM and Swabian machine tools here. The rotation range is among other things a lathe with driven tools, Y-axis and bar feeder (Biglia B650Y-turning diameter over bed max. 400mm) are available. Programming is based on dialogue and DIN controllers and by means of a CAD-CAM work on SolidWorks basis. Currently, the company PRO CNC GmbH & Co. KG two masters, a mechanical engineer, eight skilled workers, five assistants and a force in the commercial sector employs. The customer base includes about 30 customers from all sectors of the craft and the industry (electrical, mechanical, automobiles, pharmaceuticals, chemicals) in regional areas. Its customers include names like: VW, AEG, Federal Mogul, Faurecia (automotive sector) Harting, IMA, Kolbus, Oystar (engineering sector) VTG wagon Graaff, EuroMaint Rail (rail-rail vehicles) In May 2004, the company has been certified according to DIN ISO 9001-2000 since 2010, accordingly to DIN-ISO 9001-2008.

Founded

1989

Employees

20 - 50

Certifications

Lübbecke

Germany - 32312

About us Kreutz & Mock is a medium-sized company and the leading manufacturers of wire bending parts of all types. With over 3000 different articles we can offer our customers a wide and diverse range of different wire products. The necessary machines for the production are developed and built in-house by our own engineering department which gives us the possibility to always be flexible according to our customer's needs. You can find further details about us and our philosophy on our website. Products We manufacture wire bending parts in all sorts of variations and models. We supply many industries with our products like the automotive industry, construction industry, agriculture, blinds manufacturers and many more. We also have numerous technical bent parts in our repertoire. We are happy to try to achieve your specific needs and requirements, because quality, punctuality and being in step with actual practice are our basic principles to deliver high quality as well as best functionality products. It does not matter whether they are single quantities, small quantities or a large series. We are flexible and deliver quality at fair conditions. We offer + Qualitycertficate DIN ISO 9001:2008 + in-house specified tool construction + in-house machinery construction + quick production of samples + technical and experienced know how + skilled telephone service + large production spectrum Materials Every material processed in our factory has a dedicated inspection certificate that will be provided with your delivery on request. We manufacture bent wire components for you in all variants and materials. Here a selection of the materials used: + Stainless steel wire 1.4301, 1.4310, 1.4362, 1.4401, 1.4404, 1.4571 in different tensile strengths + Spring steel wire 0.9 mm to 6.0 mm. Qualities A, B, C, D + Steel wire C9D bare or copper-plated. C9D soft galvanised in 1.0 mm to 8.0 mm + Crapal wire + Becrosi valve spring wire + Silver and Palladium wire

Founded

1934

Employees

20 - 50

Certifications

Neuendorf

Germany - 97788

ENGLİSH AND GERMAN-SPEAKING CUSTOMER CARE TAŞKIRAN MAKINE started producing machine parts in 2009. Since 2018 we have been working with 8 machines in a closed 600 m2 work area. All of our 13 employees are innovative and customer-oriented. Our principle is to provide quality at good prices.

Founded

2009

Employees

10 - 20

Certifications

ISTANBUL

Turkey - 34776

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

The specialists for CNC-Milling and the assembly of complete modules and systems. We are specialists in machine cutting with CNC-Milling Machines. Milled parts from Switzerland. We are specialized in contract manufacturing of fine mechanical components and of diverse assembly works including cables and electronics. Our products belongs to miscellaneous automation systems, car industry and apparatus building. Pohland AG is assembling a large variety of mechanical and electronical units, cables and mechanical apparatus for automation systems, automotive industry and apparatus building. Our long-term experience, well trained personal and knowledge enabled us to get a solid position in these high competing markets and to deserve appreciation of our customers. We have obtained knowledge of a variety of supporting processes to our main production technologies that makes our commercial offers to be complete and better satisfy our customer needs. * IGES, Step, Parasolid Files and 3-D surface data management * Surface profile, 3 dimensional with solid modeling CAD systems * DNC systems for high-speed machining and large part file * Multiple axis machining, 2, 3, 4 & 4 1/2 Axis * 5 sided machining * High Strength Components and Sub-Assemblies * High strength and exotic alloys Production milling of metal and plastics can be done accurately and quickly on new CNC precision machining centers. Precision parts of aluminum, assorted tool-steel, stainless steel, and plastic are CNC milled to close tolerances. Pohland AG is assembling a large variety of mechanical and electronical units, cables and mechanical apparatus for automation systems, automotive industry and apparatus building. Our long-term experience, well trained personal and knowledge enabled us to get a solid position in these high competing markets and to deserve appreciation of our customers.

Founded

1984

Employees

10 - 20

Certifications

Sempach

Switzerland - 6204

Company ZUT "PROJEKT" offers services in: Processing of metal - milling, turning, Inen and outer grinding, Surface grinding, cutting, welding - steel, aluminum, stainless steel, Engineering, manufacturing spare parts and machine elements We offer: - Turning - Automatic turning (bar) - Hard roes - Milling - .... etc.

Founded

1991

Employees

10 - 20

Certifications

Konarzewo

Poland - 62-070

We are a company dedicated to ugarisches sheet metal processing and exciting machining by machining centers for small and medium series .. The focus of our work lies in the production of complex assemblies including assembly such as FTS, Heber and packaging machines. Our machinery, we continuously expand and modernize one of the most modern in Hungary. From single part production through installation to commissioning of the modules and machines, we can offer the full range of services you need. Give us a try. We put an offer below that will convince you.

Founded

1993

Employees

50 - 100

Certifications

Kiskörös

Hungary - 6200

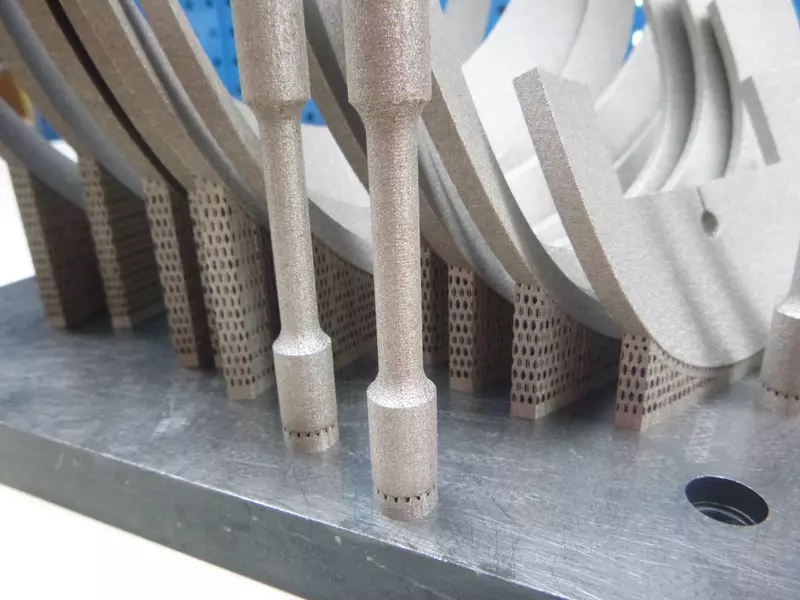

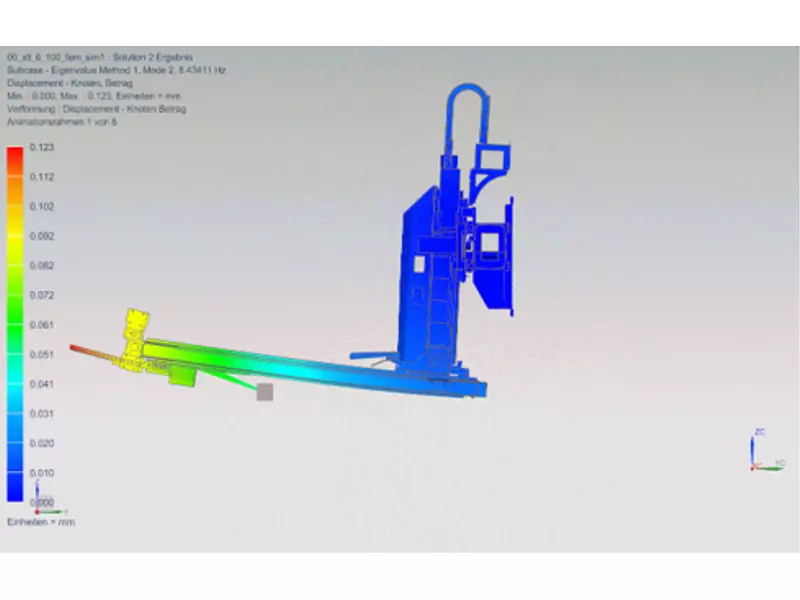

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Klücher Tech competence in milling technology Founded in 2021, Klücher Tech produces components for you in the areas of tool and mold construction as well as machine and plant construction. The range of services includes extensive 3D geometries, custom-made products or individual parts through to small series parts. Equipped with modern production machines, Klücher Tech is ideally equipped for your order and offers a wide range of services. Great importance is attached to precision and short lead times. I would also be happy to manufacture your component according to your wishes

Founded

1991

Employees

5 - 10

Certifications

Hildesheim

Germany - 31137

Aschaffenburger Maschinenfabrik Johann Modler GmbH is a manufacturer of high-precision grinding machines with particular expertise in external round processing, profile and end surface processing of workpieces of the highest precision and surface quality. In addition to our portfolio of high-precision production grinding machines, we offer our customers the entire manufacturing depth to produce high-precision series workpieces. We are a manufacturer of ultra-precision grinding machines with particular expertise in O.D., profile and end-face grinding of workpieces with highest precision and surface quality. In addition to our portfolio of ultra-precision production grinding machines, we offer to our customers our entire vertical range of manufacturing for the production of high-precision series workpieces.

Founded

1921

Employees

50 - 100

Certifications

Aschaffenburg

Germany - 63741

Founding of the company 2002 First commercial premises in Lovrenc na Dravskem polje Experiences mean the future We work with 15 years of experience and are constantly investing in new technologies. We manufacture high-quality and sophisticated machine parts and offer a complete service.

Founded

2002

Employees

5 - 10

Certifications

Kidričevo

Slovenia - 2325

We at Ransberger Metalltechnik GmbH would like to introduce ourselves as a system supplier for CNC components. Automated production has resulted in large capacities, especially in 5-axis machining. With cutting-edge automation solutions, we can also guarantee cost-effective and efficient series production in Germany. However, we can offer you fast and uncomplicated order processing at any time, even when manufacturing individual parts. We process almost all materials and work with the latest CAD/CAM systems. On request, we can also offer the assembly of components and complete machines through our experienced fitters/electricians. Quality is very important to us, which is why we also use the ISO 9001 quality management system. For further questions or information, simply contact us or visit our homepage.

Founded

Employees

5 - 10

Certifications

Bad Feilnbach

Germany - 83075

We are an owner-managed company, the engineering services, manufacturing, finishing, assembly and product delivery offers everything from a single source. This concerns both the wage and foreign manufacturing and the manufacturing our own special equipment for the paper and paperboard manufacturing industry as well as special solutions for safety-relevant area. With our security products, we are also the owner of many national and international patents. Our machinery is constantly being renewed and the education and training of our highly qualified staff are constantly adapted to customer requirements. The high degree of vertical in almost all of the processing steps to make us a reliable A suppliers. Benefit also from the high Hennig and comprehensive know-how. Flexible and perfectly tailored to your needs. Our CNC milling machines can sizes up to 3600 x 2200 mm 5-axis milling process at the Round Table has 500 mm. The rotary department has combined rotary milling machines with Y axis and driven tools and sub spindle. Sheet metal working medium format and folding up to 3000 mm. Powder coating 3000 x 1200 x 2000 mm unit weight up to 1000 Kg Final inspection with Zeiss measuring machine Accura

Founded

1986

Employees

50 - 100

Certifications

Markt Schwaben

Germany - 85570

CADYOU Development and Construction was founded in 2008 and is successfully active in the construction and manufacture of special machines and devices. (CATIA, SolidWorks, Inventor) Contract manufacturing of individual parts and assemblies is a very important part of our company. The very motivated and highly experienced designers plan and construct their sophisticated special machines and systems. You get everything from a single source! Equipment and devices are designed and manufactured by us! We have welding workstations and are able to offer processed welded assemblies. we have 4-axis machines and can therefore manufacture complex parts. Our business model allows us to offer you very sophisticated solutions at very low cost. ask us! You will immediately receive a non-binding offer. We look forward to cooperation.

Founded

2008

Employees

20 - 50

Certifications

Ebersberg

Germany - 85560

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Laser Schnitt Center GmbH has been an experienced partner in sheet metal processing and metal technology in several industries for over 30 years. Would you like to know more about us? Then simply ask, we will be happy to help you. MFG The team from the Laser Cut Center

Founded

1990

Employees

5 - 10

Certifications

Kundl

Austria - 6250

With the experienced team at HORSTKEMPER, you are in competent hands right from the start. The company's over 70 years of experience provides a strong basis for the success of our customers from a wide range of industries. Good quality and well-founded qualifications are important components of our daily work. As a holistically oriented company, we offer all services from a single source. From planning, construction and project development to manufacturing and assembly to comprehensive after-sales service. And that at any time flexibly, quickly and with tailor-made solutions. New technologies and innovations are constantly being considered. Always up to date, this is how we face the constantly growing challenges of the market. manufacturing Modern machining centers achieve maximum precision and efficiency. From precisely cutting the materials to turning, milling, bending and drilling to the perfect surface, all work steps are carried out directly. Experience flows from production flow directly into the design and form the basis for a high-quality yet economical machine. Right up to the precise assembly, the high level of competence of our employees shapes the production results.

Founded

1952

Employees

50 - 100

Certifications

Rietberg

Germany - 33397

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

Customer-oriented contract manufacturing in the wage since 1983. We Ship To request items, assemblies through to complete systems for: automotive, packaging machinery, food processing, transmission, papermaking, printing machinery, agricultural machinery, metal working machinery (machine tools), Wrappers for film or paper, tooling, wood industry. Complete execution of projects including assembly (mechanical / electrical / pneumatic / hydraulic). Equipped with advanced CNC machine tools produced ERKA precision turned parts, precision machined parts in wholesale as well as in small series. Products: We manufacture turned parts with a diameter of 1 mm to 600 mm and lengths from 1 mm to 4500 mm. We manufacture milled parts up to 1000 x 1200 x 5000 mm. Processing methods: Our modern machinery enables the complete machining of complex turning and milling parts. Delivery program: pistons, bushings, washers, rings, screws, cones, control parts, tubes, sleeve, shaft, axle, hub, drum, cylinder, cross beams, flanges, rollers, nozzles, weldments, panels, spindles, assembly, painting, signing, welding, consoles Wämebehandlungsverfahren, surface coating: KTL paint, 2K paint, priming, powder coating, galvanizing, burnishing, Phospahtieren, chrome plating, case hardening, nitriding, nitro-carburizing, Certified quality: Qualified employees, structured processes and the use of modern technology are the building blocks for the quality, which satisfy our products. Furthermore

Founded

1984

Employees

50 - 100

Certifications

Ahaus

Germany - 48683

TOKARMET deals in the production of metal elements by machining on CNC lathes and mills. Highly qualified staff and years of experience in the field of machining makes us one of the most reliable companies in the region. We specialize in the production of parts, subassemblies and components for industrial automation, hydraulics and the gas industry. We are currently looking for regular customers in Western Europe. I would like to invite you to cooperation. Witold Piasecki - (owner)

Founded

2001

Employees

10 - 20

Certifications

Wysocko Male

Poland - 63-421

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge