Adhesive bonding: efficient e-sourcing process

Discover specialized suppliers for adhesive bonding on Techpilot. Our platform connects buyers with suppliers who offer advanced adhesive solutions for your production processes. Optimize your processes and receive an average of 7 offers per request.

467 suppliers for Adhesive bonding

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

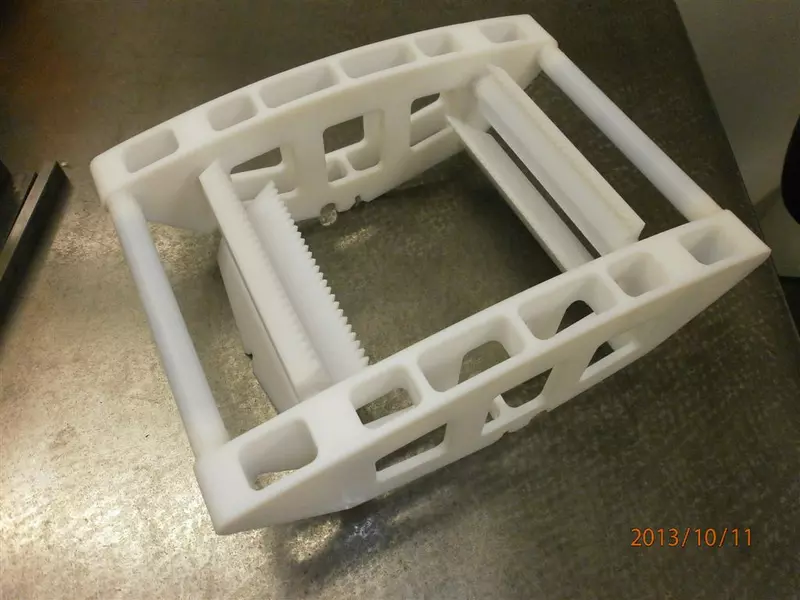

Company Profile Since 1991 Our family manufactures customized solutions made of plastic. In Gornau at Chemnitz today about 50 employees in the fields of semi-finished product processing, container and equipment construction, plant construction and cleanroom technology operate. Our solutions are used in industries such as machine and plant engineering, medical and environmental technology, the semiconductor industry and photovoltaics. The high quality of our products and services is evidenced by the certification of our company according to ISO 9001:2008. The internal design office as well as the technically and technologically advanced manufacturing guarantee our customers a comprehensive and high-quality advice and support. Involve us when planning your plastic just solution. Illustrate With our experience and the available CAD technology and we work out the best solution. We are happy to solve with our know-how your challenges. Products / Services Semi-finished processing Behälter-/Apparatebau Transparent Plastics Wasser-/Labortechnik Cleanroom technology Semiconductor engineering / photovoltaics Piping systems / special fittings Prototyping / Rapid Prototyping Machine technology With a well-equipped and very broad machinery, we can meet diverse customer needs. CNC lathe turning length up to 500 m 2 Milling Machine CNC 3-axis 1000 x 1300 x 160 Milling Machine CNC 3-axis 2300 x 1300 x 160 Milling Machine

Founded

2001

Employees

50 - 100

Certifications

Gornau

Germany - 09405

Founded

1933

Employees

20 - 50

Certifications

Forchheim

Germany - 91301

Manufacture of precision machined parts and milling parts from all machinable materials. CNC turning (up to D 90 mm rod) CNC turning (up to 250 mm in the feed) CNC long turning CNC multi-spindle turning (32 axes) CNC Machining Centers (5-Axis) Batch sizes up to 1000 pieces .... Piece including all subsequent operations up to the assembly In the field of machining there are many different ways of working. One is the CNC machining. Through this method, the milled parts get even complicated 3D contours. The CNC machining is done with machines with up to 8 axes. CNC turned parts can be made of different materials. For machining titanium, copper, brass, plastic, aluminum, stainless steel and other materials are suitable. Rotating parts in general can assume unusual shapes. In particular, the CNC milled parts often see pretty spectacular. Through its 3D contours CNC turned parts have a special effect.The machining is extremely versatile. Machining technology is used in various fields. Lathe parts, especially CNC lathe parts, are very expensive to manufacture. To produce a CNC lathe part, one special machines and more time than the normal CNC turned parts needed. The machining and especially the CNC machining requires a good education in the field. The partially very complex turned parts and just the CNC lathe parts require a tremendous expertise. A single CNC lathe part caused enormous amount of time. For these special turned parts, a particularly accurate work is absolutely necessary. For the purposes of machining are all chip forming materials. Depending on the material, the cutting is performed with different speeds. Are the turned parts made of wood, the cutting is done with high cutting speed and without cooling lubricants.Turned parts made of plastics, however, are processed at medium cutting speed. When machining water or alcohol are used for cooling. A special product from the metal cutting machines is the rotating part. Such automatic turned parts can be made from almost all machinable materials. Just like the CNC long turning parts of the screw-cutting without technical knowledge can not be produced. All machined parts require special machinery for the production. Rotating parts are to be finished by hand hardly. Are the turned parts made of wood or plastic, the machining is possibly still done manually, but with harder materials the use of expensive machining is necessary. To establish automatic turned parts, can not be dispensed with the machines. Automatic turned parts are usually ordered in enormous quantities and from extremely strong materials. Also for CNC turned parts is similar. This machining is simply too specific. CNC turned parts requiring extreme precision. Turned parts of this type are mainly used in machine and plant engineering. These industries would not do without CNC turned parts, turned parts, and the entire range of machining technology. Milling Services, CNC turned parts, turned parts, and just such special products as a CNC lathe part are absolute precision products. As simple as the concept sounds cutting, this process but it is not. Cutting sounds like simple separation that hide behind it but also things like complex CNC turned parts or automatic turned parts, no one thinks at first. Without these highly intricate parts, especially without the screw-cutting work would be impossible in some areas.

Founded

1938

Employees

50 - 100

Certifications

Wehingen

Germany - 78564

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

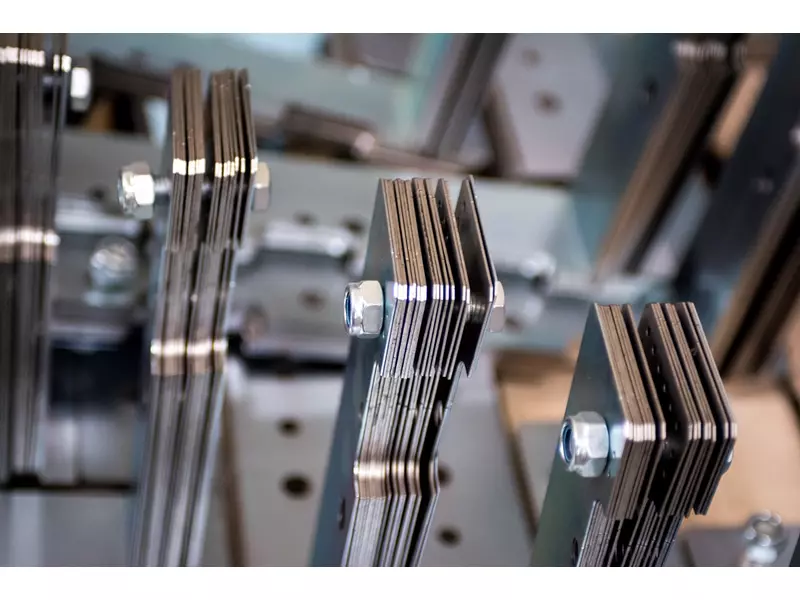

Your partner for fine sheet metal work - competent, innovative and flexible We are a family owned company in the field of sheet metal processing. As a system supplier, we specialize in the custom case production and the Production of sheet metal parts, assemblies and mechanical systems specializes. We manufacture the most modern equipment parts in the technologies stamping, punching lasers, laser (Trumpf), bending (trump), stud welding (Soyer) and Bolzeneinpressen (PEM, Haeger), milling (DMG), riveting, spot welding and welding. We have all the options to implement high-precision and highly complex designs. The own 3D design processes all common file formats. We design, of course, optimized for production in-house. We offer not only the powder coating on all major galvanic surfaces and screen printing. In our assembly we assemble electronic components to building complete electronic devices including commissioning, packaging and shipping. United with our qualified staff we offer you high quality products from prototypes to series production. B & S is a powerful partner from the idea to series production. We have the know-how, the capacity and the associated technology to deliver from simple stamping, laser part to the complex case or cabinet, all from one source.

Founded

2004

Employees

100 - 200

Certifications

Grafenau

Germany - 94481

Customised production of housings and steel solutions based on intelligent metal processing. Our experienced specialists work together with you on the development of prototypes and support you in the implementation of your projects through to series production with a wide range of services such as planning, construction, manufacturing and logistics. At the same time, we meet even the highest quality requirements thanks to our strict controls. A modern production site in Poland is the basis for being able to respond flexibly, quickly and economically to your needs. A constantly growing machine park and a highly qualified team are the key to success and enable us to offer competitive prices using the latest technology.

Founded

2008

Employees

50 - 100

Certifications

Stammham

Germany - 85134

We are a metal-working craft business with the advantages of a medium-sized company for 40 years, the second generation in the market. Flexibility, accuracy, timeliness are just a part of our strengths. Our customer base includes steel and engineering firms, manufacturers of special machines, piston manufacturers and retail customers. We process sheets from 0.5 to 160 mm thickness, profiles and pipes with a Konstruktionsgewischt from 100 gr to 5 tons of - Steel - stainless steel - aluminum - copper - Our qualified, experienced staff meet your tasks carefully and with high precision. Our products range from pure weldments on sheet metal parts, sheet metal panels complete, tubular structures, to install machined and finished part. In solving your technical problems, we are a competent partner for you.

Founded

1971

Employees

20 - 50

Certifications

Gingen / Fils

Germany - 73333

SLT Bauer intralogistics Your vision, our solution: Tailored intralogistics and steel construction for every project Your expert for tailor-made intralogistics solutions and steel construction projects that meet the highest standards in both the industrial and private sectors. Our company stands for quality, precision and reliability in every step of your project planning and implementation. With our comprehensive range of services, we are able to implement a wide range of individual solutions that make your processes more efficient and ensure greater safety. Our range of services... comprises a variety of offers that are tailored to a wide range of requirements. This includes our sturdy and safe railings & gates, which not only offer protection and safety, but also impress with their attractive design. With special load carriers, we offer you tailor-made transport and storage solutions that are developed to meet the specific requirements of your products. However, our commitment goes far beyond that — we also offer high-quality platforms to create additional space and greater efficiency in your work areas, as well as individually planned halls that are ideal for industrial use or for private projects. Our steel structures are known for their durability, flexibility and exceptional load capacity. Whether you want to build a complex structure, a warehouse or another construction project — we are here to support you with comprehensive know-how. Our high-quality coatings also provide the necessary protection against external influences such as corrosion and weather to extend the life of your structures.

Founded

2012

Employees

5 - 10

Certifications

Hagen im Bremischen

Germany - 27628

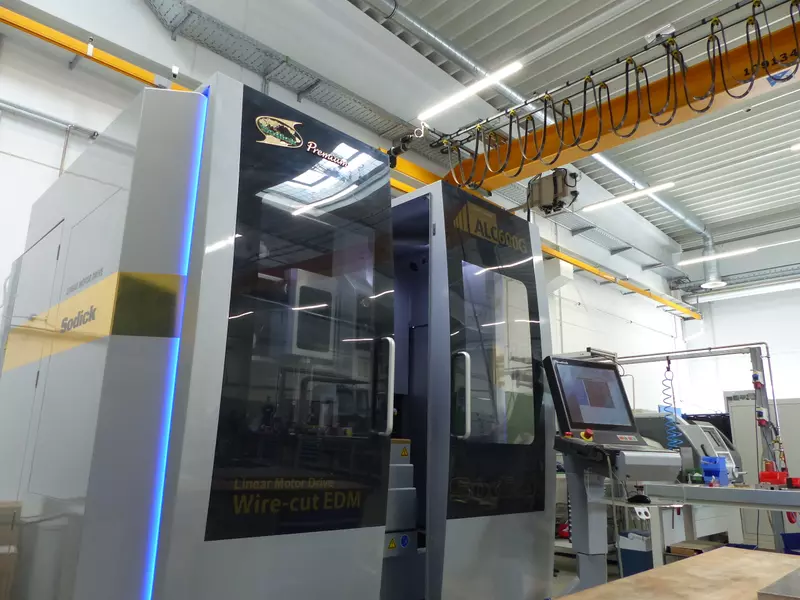

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

Sheet metal processing, surface processing and Zerpanung everything from one source. Sheet metal fabrication - CNC laser cutting / CNC punching - Edges and rollers - CNC stud welding Welding steel / stainless steel / aluminum - Separate production halls for Stainless Steel (Food & Pharma) - TIG / MIG / MAG - Laserwelding with 6-axis Roboter - Sheet metal supply parts to complex housing Surface treatment - Steel / Aluminium * Our own powder coating * Zinc plating / anodizing / barrel finishing (with partner companies) - Stainless Steel * Glass bead blasting * Grinding / Brush * High gloss polishing Machining - Turning * CNC turning up to 12 driven tools * NC turning - Milling * CNC milling with up to 5 axes. Special precision even at Langen components (up to 2.6 meters) * NC milling Assembly - Pre and final assembly - side assembly - Enduser and oversee packing Construction on behalf of customers - Over 20 CAD workstations Translation by Google Translate

Founded

1982

Employees

100 - 200

Certifications

Everswinkel

Germany - 48351

Founded

1966

Employees

50 - 100

Certifications

Lübbecke

Germany - 32312

Nuova CAM has more than 40 years of experience in the fabrication of high-quality metal products from sheet metal, tube and box sections. We work with leading Italian and European customers within diverse sectors, including but not limited to food processing, packaging, medical, farmaceutical, personal hygiene and sanitation sectors. At our modern facility located in Bastiglia (North Italy), in addition to standard metal fabrication services including CNC machining we offer also product design, assembly and integration and metal finishing. Thanks to our engineering expertise, and manufacturing resources we can create extra value to our customers managing your supply chain and/or acting as a single source manufacturing solution for customers requiring complex sourcing, manufacturing and assembly. Our customers can rely on our complete service from concept advice and prototypes to continuous manufacturing and supply.

Founded

1968

Employees

50 - 100

Certifications

Bastiglia

Italy - 41030

Rope clamps for chair lifts and cable cars, T-bar lifts Components for cable car construction, drive technology Camshafts, rocker arms, finger followers Shift forks Clutch baskets Precision parts for mechanical engineering Steel and aluminum snap hooks Belt buckles Drop forged parts machined Peening machine

Founded

1953

Employees

50 - 100

Certifications

Fulpmes

Austria - 6166

Our goal is to convince our customers through our performance, which is always oriented towards our customers' high requirements regarding quality and on-time delivery. The most modern production equipment, quality assurance during production, and optimized processes make it possible for us to produce with speed, precision, and cost efficiency, all at the same time. Regardless of whether we mass-produce for you, deliver popular models on short-term notice, or manufacture individualized single components according to your specifications - we are consistently working on optimizing our customer-oriented service. Bevel gears Hobbing max. Ø 250 mm, up to module 6 Splines Hobbing Grinding upon request up tp 1200 mm in length max. distance between centers: 1250 mm Sprockets Hobbing Shaping max. Ø 400 mm, up to 1 inch up to 1 inch Worms Chasing Milling Whirling Grinding up to module 3 up to module 6 up to module 6 up to module 7 Worm wheels Hobbing upon request Helical gears Tooth flank grinding max. Ø 300 mm, module 6 Spur gears Hobbing Shaping max. Ø 600 mm, module 6 max. Ø 500 mm, module 6 Timing gears Milling available on short notice, in stock: from module 0,5 to 10 mm and from partition 2 - 10 mm; up to 3000 mm in length External grinding up tp max. 270 mm, max. distance between centers: 1000 mm CNC drilling upon request CNC and conventional turning up to Ø 400 mm, length 1200 mm Surface grinding max. length 2000 mm CNC and conventional milling upon request Thread grinding upon request Internal grinding max. grinding Ø 200 mm, max. grinding depth 250 mm Grooving: milling, cutting, reaming up to 28 mm Surface treatment such as hardening, nitriding, etc. Centerless cylindrical grinding max. Ø 70 mm Racks (High-Precision Racks) Type of Machining Machining Sizes Milling available on short notice, in stock: from module 0,5 to 10 and from partition 2-10 mm up to 3000 mm in length Delivery program: Gear wheels, spur wheels, racks, snails, worm gears, worm shafts, chain wheels, toothed belt wheels, helical gears, bevel gears, splined shafts, pump impellers, any waves, flange. Nearly everything with teeth. Materials: Steel, high-grade steels, non-ferrous metals is processed such as copper, brass, aluminum and plastics in complete and wage labours. Thermal treatment and surface coating: Additionally to our achievements we offer still any surface treatments. Case-harden, nitrating, Nitrocarburieren, carburizing, sandblast, TENNIFER QPQ, as well as galvanizing, burnishing and the like. Our customers expect to get low-priced precision products from us, with short delivery times, reliable service, and constant high quality. This is exactly our strength - which is based on state-of-the-art production equipment, quality assurance during production, and optimized processes!

Founded

1957

Employees

200 - 500

Certifications

Kohlberg

Germany - 72664

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Gersfelder Metallwaren GmbH has stood for innovative manufacturing solutions for over 50 years and is now one of the leading manufacturers of assembly and welded components, bent and turned parts in Germany. Gersfelder Metallwaren GmbH is based in Gersfeld in the Hessian Rhön near Fulda and, with around 250 employees, is one of the largest employers in the region.

Founded

Employees

200 - 500

Certifications

Gersfeld

Germany - 36129

HKR GmbH & Co. KG The HKR GmbH & Co. KG is a subsidiary of Vaillant GmbH. This medium-sized companies went on 01 January 2006 from the previous profit center heating at the location Roding forth. The reliable service manager of the parent company also acts as a competent partner and supplier for external customers of the heating industry, automotive engineering, and for the sanitary sector. The 317 employees achieved a turnover of 52 million euros in fiscal 2007. Core competence is the development and production of components, gas and water leading assemblies and turning and forgings for the heating industry and the assembly of modules. The products are manufactured with an annual capacity of 8,000 tons per year, mainly made of brass but also made of steel and aluminum. WE PRODUCE SUCCESS! Experience the precision and the success with the products of HKR.Put your project with confidence in our hands. We support all around - from design, through production to installation. With over 40 years experience we can convince mainly in the following areas: · Production and development of components · Construction and installation of gas and water leading assemblies · Turning and forging production for heating · Assembly Your success is accurately measurable with us! WE QUALITY OF LIFE! We take responsibility! But we live in an integrated quality management system, which we constantly improve and control. In the production test systems integrated and systematic and methodological measures guarantee us to produce the highest standard. Quality means for us to deal responsibly with natural resources. Environmental protection and safeguarding the future are critical components of our quality management.As our customer you are in working with us, especially one who: Complete security, they have made us the right choice! Sustainable quality - piece by piece - sets us apart. For us, this also the appreciation and development of our employees. They turn us into what our customers expect from us, suppliers of living and quality of lived from production to assembly to delivery! WE MAKE THE POTENTIAL TO LIFE! Rigid routine is not us. We go off the front and living innovation through and through. Years of experience and the latest techniques to help us not to stop, but always think one step ahead for our customers. Sophisticated programs and structured processes enable a consistent production chain. Right from the start, we can rule out this way many sources of error. A direct access of the employees involved in each project can be short-term changes at any time, allowing the use of different concepts. We recognize your potential and develop together with you further. Experience completely new with HKR precision. We are your competent partner from the initial idea to the production stage!

Founded

1965

Employees

100 - 200

Certifications

Roding

Germany - 93426

As a system supplier for electromechanical assemblies, we manufacture plastic and metal components using hybrid technology. This means that we concentrate on the production technologies of plastic injection moulding and punching and bending of metal components. The advantage for you is that you can obtain ready-assembled assemblies of the most diverse production processes from one source. By moving Friedrich Joerg GmbH in 2016 to newly built production and office premises, we were able to create a capacitive buffer. Thanks to a high degree of automation, we can offer you particularly competitive prices. We manufacture manually in small series up to large series fully automated and pre-assemble all components for you. In short, we adapt flexibly to your requirements. We provide support as early as the product development stage in order to take into account quality, cost and tool-specific aspects in the early phase. We manufacture the necessary tools or devices in our own tool shop. This also allows us to increase our flexibility, for example in case of short-term changes. Furthermore, we also offer finishing processes such as: printing on plastic parts (cliché/pad printing), hot foil stamping for a particularly noble appearance of the products, machining and ultrasonic welding. It goes without saying that we are certified according to ISO 9001:2015 and deliver a very high and consistent quality. We would be pleased if you contact us. categories: Electromechanical assemblies; Foil hot stamping; Customised plastic mouldings; Plastic optical fibres; Optical fibre components; Optical fibre systems; Optical fibre technology; Optical fibre transmission systems; Pre-assembly Assembly of small parts for industry; Assembly of plastic components; Assembly of mechanical components; Stamp-bending parts made of stainless steel, non-ferrous metal, steel; Stamp-bending tools; Connectors; Connectors for surface mounting; Complete plug connections; Pad printing; Thermoplastic precision mouldings; Thermoplastic overmoulding with plastic; ultrasonic welding of plastics; overmoulding tools for insert parts; 3-D MID components; connecting terminals for power cables low voltage & high voltage; component assembly; die casting; mould making; housings for the electrical industry; terminals for electrical cables; plastic injection moulded parts; plastic injection moulded parts with metal insert; electrotechnical plastic parts; technical plastic parts; plastic processing; multi-component injection-moulded parts; plastic-injected metal parts; product development; prototype construction; terminal blocks; technical injection-moulded parts; thermoplastic elastomer (TPE) moulded parts; jig and fixture construction; toolmaking; two-component injection-moulded parts; Imprint: https://www.friedrich-joerg.com/kontakt/impressum/ Privacy policy: https://www.friedrich-joerg.com/kontakt/datenschutzerklaerung/

Founded

1920

Employees

50 - 100

Certifications

Marktrodach

Germany - 96364

Precision meets innovation. We are your partner for high-precision CNC-manufactured individual parts and specialized special parts for aerospace, and all demanding industries. We have the latest technology and produce according to your data, drawings, samples or ideas. Team and solidarity define work that is fun and develops the full potential of commitment, creativity and enthusiasm.

Founded

2024

Employees

10 - 20

Certifications

Varel

Germany - 26316

We work in contract manufacturing, manufacture products according to customer's drawing, made of steel, stainless steel, aluminum, etc. We have our own design department and offer a complete service, including surface treatment and shipping. We love challenges! Our priority is our satisfied customers.

Founded

2012

Employees

50 - 100

Certifications

Aldeia de Paio Pires

Portugal - 2840-050

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge