Elektrotechnische Fabrik Friedrich Joerg GmbH

Contacts

Martin Pfadenhauer

Phone:

E-Mail:

Tobias Püls

Owner, company manager, member of the board

Phone:

E-Mail:

Matthias Langheinrich

Technical management

Phone:

E-Mail:

Thomas Püls

Owner, company manager, member of the board

Phone:

E-Mail:

Ruth Schneider

Phone:

E-Mail:

Heiko Wich

Phone:

E-Mail:

Hempfling Sebastian

Phone:

E-Mail:

Nicole Springmeier

Phone:

E-Mail:

Competencies

Parts (6)

Technologies

Cutting dies / deep drawing dies

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / Cutting tools | - | 1 - 500 | 1 - 500 | 1 - 500 | - | 0.0005 - 0.3 | - |

Fineblanking tools | - | 1 - 500 | 1 - 500 | 1 - 500 | - | 0.0005 - 0.3 | - |

Company description

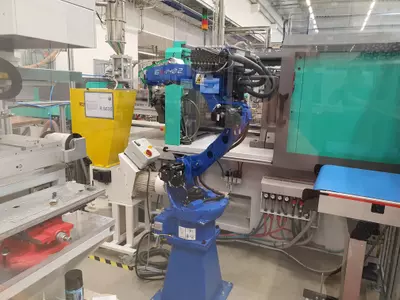

As a system supplier for electromechanical assemblies, we manufacture plastic and metal components using hybrid technology. This means that we concentrate on the production technologies of plastic injection moulding and punching and bending of metal components. The advantage for you is that you can obtain ready-assembled assemblies of the most diverse production processes from one source. By moving Friedrich Joerg GmbH in 2016 to newly built production and office premises, we were able to create a capacitive buffer. Thanks to a high degree of automation, we can offer you particularly competitive prices. We manufacture manually in small series up to large series fully automated and pre-assemble all components for you. In short, we adapt flexibly to your requirements. We provide support as early as the product development stage in order to take into account quality, cost and tool-specific aspects in the early phase. We manufacture the necessary tools or devices in our own tool shop. This also allows us to increase our flexibility, for example in case of short-term changes. Furthermore, we also offer finishing processes such as: printing on plastic parts (cliché/pad printing), hot foil stamping for a particularly noble appearance of the products, machining and ultrasonic welding. It goes without saying that we are certified according to ISO 9001:2015 and deliver a very high and consistent quality. We would be pleased if you contact us. categories: Electromechanical assemblies; Foil hot stamping; Customised plastic mouldings; Plastic optical fibres; Optical fibre components; Optical fibre systems; Optical fibre technology; Optical fibre transmission systems; Pre-assembly Assembly of small parts for industry; Assembly of plastic components; Assembly of mechanical components; Stamp-bending parts made of stainless steel, non-ferrous metal, steel; Stamp-bending tools; Connectors; Connectors for surface mounting; Complete plug connections; Pad printing; Thermoplastic precision mouldings; Thermoplastic overmoulding with plastic; ultrasonic welding of plastics; overmoulding tools for insert parts; 3-D MID components; connecting terminals for power cables low voltage & high voltage; component assembly; die casting; mould making; housings for the electrical industry; terminals for electrical cables; plastic injection moulded parts; plastic injection moulded parts with metal insert; electrotechnical plastic parts; technical plastic parts; plastic processing; multi-component injection-moulded parts; plastic-injected metal parts; product development; prototype construction; terminal blocks; technical injection-moulded parts; thermoplastic elastomer (TPE) moulded parts; jig and fixture construction; toolmaking; two-component injection-moulded parts; Imprint: https://www.friedrich-joerg.com/kontakt/impressum/ Privacy policy: https://www.friedrich-joerg.com/kontakt/datenschutzerklaerung/

Machines (3)

Copmany images

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Light metals

Aluminium and aluminium alloys

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Industries

Railway and rail vehicles industry

Furniture industry

Apparatus engineering

Lighting industry

Automation and control engineering

Building, agricultural and forestry machinery manufacturing

Measurement and control technique, laboratory equipment

Construction and architectural supplies

Household appliance industry

Paper and printing machinery industry

Mechanical engineering

Precision engineering, mechatronics and optics

Electrical industry

Hydraulic and pneumatic industry

Power generation and transmission industry

Plant engineering and construction

Office machinery and supplies

Special purpose machinery manufacturing

Drive and gear engineering

Automotive and vehicle construction

Air conditioning, refrigeration and ventilation industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.