Forging dies: get complete market transparency

Find specialized suppliers for forging dies on Techpilot. Our platform offers access to suppliers who use advanced technologies to manufacture high-quality dies for forging processes. Benefit from comprehensive market transparency and optimize your supplier selection.

296 suppliers for Forging dies

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

Our history dates back to 1990, when engineer Dimitar Karagyozov laid the foundations for our company. In 2006, the company was re-registered as EOOD, and since then we have continued to develop and expand our offering. We specialize in manufacturing high-quality injection molds and plastic products that are used in medical technology, electronics and many other industries. Our experience and expertise enable us to develop tailor-made solutions for the individual requirements of our customers. In doing so, we attach great importance to quality, precision and reliability. We are proud to be a company that continuously strives to exceed customer expectations and drive innovation. Our mission is to add value through our products and services and to build long-term partnerships.

Founded

1990

Employees

5 - 10

Certifications

Sofia

Bulgaria - 1510

We are a company that has been the right partner for 14 years now when it comes to prototypes, tools and devices for the mobile sector. General contract manufacturing in the areas of HSC machining, mold making and model making complete our offering.

Founded

Employees

10 - 20

Certifications

Sarntal

Italy - 39058

The company Fetec Engelhardt GmbH is a modern enterprise specializing in CNC milling and turning as well as the construction of complete functional units. For the 2D and 3D Complete machining of simple to extremely complex workpieces made of steel, stainless steel, aluminum, plastic, etc. we are the right partner for you. Even sophisticated operations such as the production of free-form surfaces, supported by a CAD-CAM programming system belong to our services. Business The company FETEC Engelhardt GmbH was established on 1 Founded in May 1997 in Ruhla / Thuringia as a civil law and on 1 July 2005 umformiert into a GmbH. Starting point of the company producing basic turning and milling parts, the one manufactured in order for suppliers to the automotive industry. With the move in January 2001 in a new building, the production of parts, prototypes, small batches in contract manufacturing as well as complete assemblies and devices has been made possible.The expansion of contract manufacturing required on 1 July 2006 another move to a larger and also its own production facility. The workforce of FETEC Engelhardt GmbH consists of seven employees and three apprentices. Managing directors are Gerald and Ursula Engelhardt. Products Because of our diverse experience in the field of metal machining, we are able to offer comprehensive services. These range from performing individual work steps bishin for assembly of complete functional units. Turn 1 Turning the conventional way ----- BRAND NEW ------- Lathe with bar feeder 3m to 32mm diameter x / y machining with driven tools * Between centers 1000mm x D 220mm * In feed D 300mm * From the rod D 47mm 2 CNC turning with counter-spindle, Y-axis and bar feeder * Maximum diameter D 100mm (45mmStange) * Maximum turning length D500mm Mill 1Milling in a conventional manner * X-, Y, - Z-direction 300 mm x 220 mm x 300 mm 2 CNC milling Maximum travel: * DMU 60T monoblock (five axes) / X 500 mm, 400 mm, Y-, Z-400mm * Hurco VMX 42t (3-axis) / X 1060mm Devices Production of complete functional units * Devices * Tools * Assembly workstations * Special Machines * Prototypes * Items * Small series * And much more

Founded

1997

Employees

10 - 20

Certifications

Ruhla

Germany - 99842

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded

1980

Employees

5 - 10

Certifications

Nürnberg

Germany - 90431

Since 1986 we have been working as injection molding manufacturers serving a variety of local and international companies which operate in various fields and need molds either for big productions and limited edition products. What we do is easily explained. We design, manufacture and supply injection molds for the production of high-precision thermoplastic parts with exceptional aesthetic demands. We are specialized in the production of high-precision technical parts and multiple-impression molds for high production requirements, but we also supply prototypes and pilot molds for small and medium series that requires complex and intricate geometries – for instance, for limited editions. The headquarters are located in the Italian city of Rovereto, just 30 km from Trento, on the Brenner motorway link. This is the ideal crossroads between the major industrial districts in Northern Italy, such as the manufacturing (Lombardy, Vicenza) and optical (Belluno) ones, and important European countries such as Austria, Germany and Switzerland. However, there is more. We also work with factories based in the US and in the rest of the world. The know-how we developed over the years of experience in the field allows us to identify the most suitable kinds of injection molds on the base of your production types and aesthetic needs.

Founded

1986

Employees

20 - 50

Certifications

Rovereto

Italy - 38068

SINCE 2009 .... The company was founded in 2009 by Mrs. Bettina Landgraf-Kaiser, storage capacity today is about 3000 m² in three halls. As a leading warehouse distributors constantly about 100 cars and well-preserved machines of best brands offered. State of the art warehouses with crane capacity up to 10 tons and forklift capacities up to 7 and highly trained staff are the benefits for potential customers to find the "perfect machine". Complete "all-inclusive" packages (eg transport, introduction, installation Complete training) are developed and implemented according to your. MEMBER OF: Since 2009 FDM - Germany Since 2009 EAMTM - Brussels (International) SPECIALITY: Cutting metal-working machines Our specialty is the trade used machines from metal cutting. Whether conventional or CNC - controlled, we each offer the right machine for you.In CNC - area we act almost exclusively with the control type Fanuc & Heidenhain. Here we can give you the best - provide service, whether coverage with qualified staff, service staff or software solutions. OTHER: Furthermore, even spare parts - remakes produced directly in the house with us. Through years of experience of our employees in the cutting process on Fanuc & Heidenhain controls, we can therefore offer cost effective replacement parts alternatives you.

Founded

2009

Employees

5 - 10

Certifications

Bruchsal-Büchenau

Germany - 76646

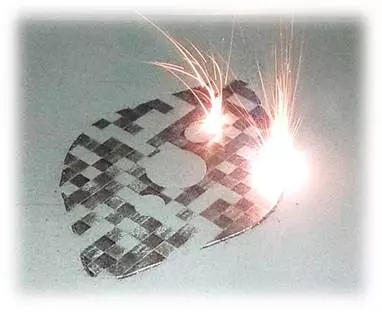

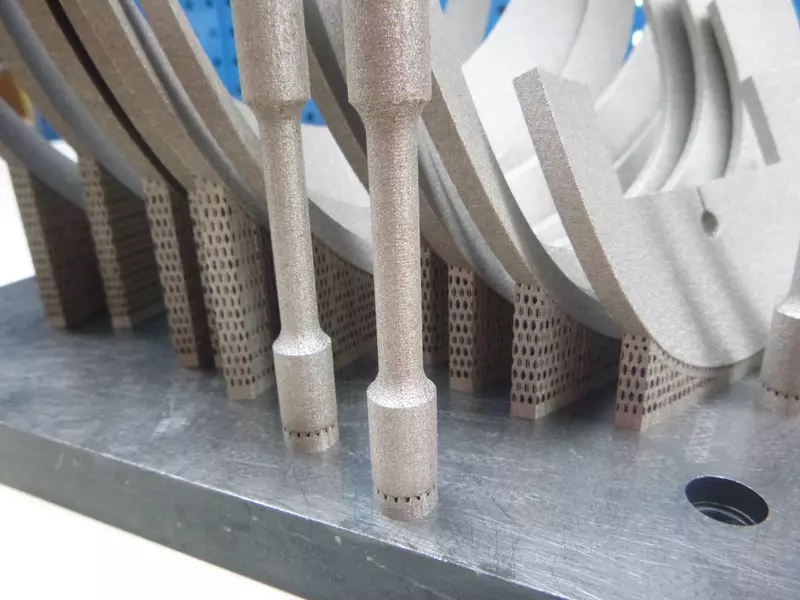

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

we are a young and dynamic company. our company was founded and collaborates with a company with over 30 years of experience in the mechanical processing sector and in the construction of molds for the injection of plastic materials.

Founded

2022

Employees

5 - 10

Certifications

Gradiska

Bosnia & Herzegovina - 78400

Company with over 60 years of history in hot forging. It currently has 5+1 forging lines. The production departments are mainly these: 1 - steel warehouse 2 - cutting department 3 - DIES construction and assembly tooling 4 - hot forging steel 5 - heat treatment 6 - warehouse and shipping Other important departments : - Quality department - Technical Office - Work shop - Maintenance department.

Founded

1960

Employees

100 - 200

Certifications

SUMIRAGO

Italy - 21040

3D laser accompanies your ideas from prototypes to series if. In the design or production Project Management / Consulting - Consulting for the optimal manufacturing process of your components if sand casting, investment casting, metal laser melting, 3D plastic printing or from the full milling - Feasibility study for the respective process - Procurement of plastic parts in PA2200, PA3200GF, Alumide, DuraForm ® Flex - Procurement of castings (sand casting, investment casting) Construction - Component development of plastic, sand or die casting components - Prototype tools, special machine, fixture, equipment - FEM calculations - Deriving electrodes - Interpretation of contour-hugging cooling for mold - Optimize the components on the metal laser melting process Metall-Laserschmelzen/LaserCUSING ® / SLM - Production of functional prototypes - Production of mold inserts with conformal cooling

Founded

2011

Employees

5 - 10

Certifications

Kirchheim u. Teck

Germany - 73230

Founding of the company 2002 First commercial premises in Lovrenc na Dravskem polje Experiences mean the future We work with 15 years of experience and are constantly investing in new technologies. We manufacture high-quality and sophisticated machine parts and offer a complete service.

Founded

2002

Employees

5 - 10

Certifications

Kidričevo

Slovenia - 2325

Founded

2024

Employees

5 - 10

Certifications

Bad Salzuflen

Germany - 32108

We, the Raskopf company, have been working in tool and mold construction at our location since 1923. It all began with forging dies for the massive forming industry. We have been manufacturing permanent molds for aluminum casting since the 1990s. Here, the production of molds for car wheels has become a special focus of our company. In recent years, however, the proportion of other cast aluminum molds has grown steadily. Our sales markets are Germany and the EU, e.g. Denmark and Austria.

Founded

1919

Employees

20 - 50

Certifications

Hagen

Germany - 58089

Our company, whose 1,200m2 is closed, serving in a total area of 1,500m2, continues to metal processing and shaping works with the knowledge and experience of its founders, today has undertaken to fulfill the requirements of the ISO 9001: 2015 quality management system standard and to continuously improve its effectiveness.

Founded

Employees

20 - 50

Certifications

EYÜP

Turkey - 34055

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

HELLO WE ARE A COMPANY THAT HAS SET OUT TO SERVE OUR CUSTOMERS AROUND THE WORLD WITH OUR 15 YEARS OF EXPERIENCE IN OUR BUSINESS LIFE AND TRIES TO COMBINE THIS SERVICE WITH THE HIGHEST LEVEL OF QUALITY, TIMELY DELIVERY AND REASONABLE PRICE POLICY. OUR GOAL IS ALWAYS TO REACH BETTER QUALITY

Founded

2023

Employees

5 - 10

Certifications

İstanbul / Tuzla

Turkey - 34940

For many well-known customers, JP-Industrieanlagen has been the Partners for solutions. We are a national and international company in the field of special machine construction, automation technology and contract manufacturing. Everything from a single source and with the highest precision and reliability. Our delivery portfolio: • Contract manufacturing, parts to be machined according to drawings (build to print) • Construction and construction of assembly aids, assembly devices and clamping devices, • Construction of base frames, frames, consoles, turntables for robot cells • Turning and milling in our own turning and milling centers • Welded constructions for the highest demands • Welded constructions for static and dynamic loads according to DIN EN 1090ff EXC 1...2 / ISO 3834, for black steel, stainless steel, aluminium. • Large part processing • Optical measurement and testing • Construction • Engineering • System integration • Assembly • Services Your advantages with us as your partner at your side: From the first consultation to the realization of your project, JP-Industrieanlagen GmbH is your partner for solutions. .• From the first consultation to the realization of your project, JP-Industrieanlagen GmbH is your partner for solutions. • We offer you alternatives for cost-effective production/implementation of your production orders. • We support you in reducing costs and adding value to your production. • We also automate your manufacturing and assembly processes in the context of Industry 4.0 • We are a full-service provider and deliver everything from a single source, independent and flexible, not tied to a specific manufacturer.

Founded

1999

Employees

50 - 100

Certifications

Straubing

Germany - 94315

Company Description Since our founding, Protec Industries has been a leading company in plastics processing and mechanical engineering. With a focus on innovation and customer satisfaction, we set standards in precision and quality. Our core competencies include plastics technology, particularly thermoforming and injection molding. From prototypes to large-scale production, we manufacture high-precision injection-molded and thermoformed parts from a wide range of thermoplastics, thermosets, and elastomers. Our modern injection molding machines, with clamping forces from 30 to 600 tons, enable the production of complex components with tolerances as tight as ±0.08 mm, ideal for industries such as automotive, medical technology, electronics, and mechanical engineering. In tool and mold making, we develop customized injection molds and thermoforming tools that meet the highest standards. With over 30 years of experience, state-of-the-art 3D CAD software, and Moldflow simulation, we ensure durable, precise tools for both series and prototype production. Our 5-axis and 3-axis CNC contract manufacturing enables the production of sophisticated components with exceptional accuracy. We offer full-service solutions: from product development, design, and tool making to manufacturing, post-processing (e.g., painting, grinding), and assembly of complete modules. Our customers benefit from personalized consulting, fast quote turnaround, and sustainable processes, including the use of recycled plastics. Protec Industries – Your partner for innovative plastics solutions and mechanical engineering. Contact us for tailored injection molding and thermoforming solutions!

Founded

1968

Employees

5 - 10

Certifications

Röttenbach

Germany - 91341

Fully equipped tool shop Every year, we build between 40 and 60 new injection molding tools. Tool relocations Experience from over 250 injection molding tools purchased. We would be happy to assist you with our experience to fully maintain your ability to deliver and to solve previous problems. SPECIALIST IN MAKING Each injection molding project is a very individual, often very wide-ranging project, which must be completely thought through in all areas. This is the only way to avoid unnecessary follow-up costs, coordination difficulties, delays in deadlines and quality problems. Hoffner plans the entire project with foresight, consistently supervises and usually implements it himself. innovative & reliable over 55 years of experience and know-how Why us Generational change completed. Average age of leadership 41 years. Average age of skilled workers 33 years. Highly competent contacts Our own, fully equipped tool shop PVC specialist State-of-the-art technology. Average age of machinery approx. 8 years. We consider injection molding to be sustainable. Classic & with bioplastics What you get from us: We show you the options, think with you Plan with foresight and implement reliably. Highly innovative in the required quality and in the best possible cooperation and communication with you. You'll get what we promised you. Tailored... at best with a positive surprise or two. “Work is love made visible” (Robert Betz) Hoffner-colleagues (4) At a glance Our strengths Experience with all thermoplastics Specializing in PVC processing 27 injection molding machines, average age 7 years Deliberately not automotive 2 component articles semi- and fully automatic Insert technology In-house fully equipped tool shop A strong family of companies, with fun for your own development With experience from over 2,000 tool projects, with experts in every required subject area and With over 55 years of company history, we provide you with our know-how for your success. Hoffner plans the entire project with foresight, consistently supervises and implements it himself.

Founded

1955

Employees

50 - 100

Certifications

Waghäusel

Germany - 68753

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge