Blacking: receive an avg. of 7 offers per request

Discover specialized suppliers for blacking on Techpilot. Our platform connects buyers with suppliers who use this surface treatment to protect and enhance metals. Use the e-sourcing process to find the best suppliers.

455 suppliers for Blacking

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

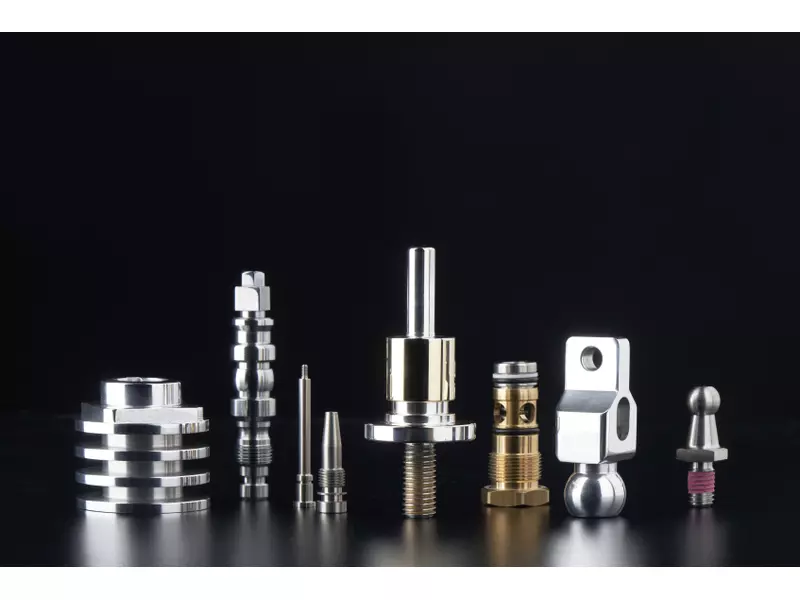

Manufacturer of series turned parts from all cut materials according to your specifications. In addition to being a reliable supplier, our major passion is the development of optimum solutions.

Founded

1971

Employees

50 - 100

Certifications

Gunningen

Germany - 78594

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

The company Rauscher has been active for different industries since 1984th The realization of specific customer requirements We achieve this through our modern and diverse machinery. Fully automated loading and unloading systems, we ensure a high Productivity in the production of turned parts. Do you have technical questions or want more detailed information? Then call us on the number 089/793 20 41, or send an email to: info@cnc-dreherei.com We advise you individually and in detail in your affairs. Translation by Google Translate

Founded

1984

Employees

5 - 10

Certifications

Putzbrunn

Germany - 85640

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

UNGVÁRI WORKS Kft has been operating for 29 years. The company is a 100% hungarian-owned family business, it's founder and owner is Ferenc Ungvári. The company has 37 employees. The company's activity is the production of parts and components for the machine industry. Most of our product are manufactured in unique, small and medium quantities, our portfolio does not include mass-produced products. We supply 90% of our products to Western European machine manufacturers, we have clients in Germany, Austria, France, Switzerland and in Sweden. Presently, the production is performed in a plant with a floor space of 1200m2. In addition to our modern machinery and highly qualified colleagues, our production is supported by an integrated corporate management system, as well as by CAD and CAM softwares. Our processes are designed to satisfy the ISO 9001:2015 standard. Our activities: -machine parts and units production with CNC and traditional turning, milling and cutting technologies -welding -assembly -surface treathments -measurement -planning

Founded

1990

Employees

20 - 50

Certifications

Kiskőrös

Hungary - 6200

Torneria OML is specialized in high precision CNC machining. Since 1982 we have been specialized in the processing of any type of metal. Thanks to the use of the latest generation and highly technological machinery, we are able to guarantee the highest quality and precision, always offering an excellent quality / price ratio. Our qualified and constantly updated staff is able to quickly manage any type of order, from small and medium-sized production to high-precision machining. Thanks to the adoption of modern CNC technologies, we have considerably reduced production times, greatly increasing the reliability of the productions themselves. To always guarantee quality products, we have introduced systematic checks according to UNI and ISO 9001: 2015 and ISO 14001: 2015 regulations. Our company is part of the ATI set up for participation in the project “Venetian mechanical manufacturers on behalf of third parties present themselves in Europe”, which will be implemented using the POR Veneto region funding, part of the ERDF. Thanks to the use of the latest generation and highly technological machinery, we are able to guarantee the highest quality and precision, always offering an excellent quality / price ratio. Our qualified and constantly updated staff is able to quickly manage any type of order, from small and medium-sized production to high-precision machining. We are specialized in the creation of components for the sectors: Valves, Gas Components, Pneumatic Components, Automotive, Hydraulics, Hydraulic, Naval, Nuclear, Oil.

Founded

1982

Employees

20 - 50

Certifications

Castelgomberto

Italy - 36070

Founded

1976

Employees

200 - 500

Certifications

Höchstädt a.d. Donau

Germany - 89420

KALİBRE MAKİNA TAAHHÜT TİC.LTD.ŞTİ. Köseköy San.Sit.M Blok No: 248 ZIP: 41250 Kartepe / KOCAELİ / TURKEY Tel: +90262 373 52 52 kalibre.mak@hotmail.com

Founded

2010

Employees

10 - 20

Certifications

Bornova-İzmir

Turkey - 35040

Manufacture of precision machined parts and milling parts from all machinable materials. CNC turning (up to D 90 mm rod) CNC turning (up to 250 mm in the feed) CNC long turning CNC multi-spindle turning (32 axes) CNC Machining Centers (5-Axis) Batch sizes up to 1000 pieces .... Piece including all subsequent operations up to the assembly In the field of machining there are many different ways of working. One is the CNC machining. Through this method, the milled parts get even complicated 3D contours. The CNC machining is done with machines with up to 8 axes. CNC turned parts can be made of different materials. For machining titanium, copper, brass, plastic, aluminum, stainless steel and other materials are suitable. Rotating parts in general can assume unusual shapes. In particular, the CNC milled parts often see pretty spectacular. Through its 3D contours CNC turned parts have a special effect.The machining is extremely versatile. Machining technology is used in various fields. Lathe parts, especially CNC lathe parts, are very expensive to manufacture. To produce a CNC lathe part, one special machines and more time than the normal CNC turned parts needed. The machining and especially the CNC machining requires a good education in the field. The partially very complex turned parts and just the CNC lathe parts require a tremendous expertise. A single CNC lathe part caused enormous amount of time. For these special turned parts, a particularly accurate work is absolutely necessary. For the purposes of machining are all chip forming materials. Depending on the material, the cutting is performed with different speeds. Are the turned parts made of wood, the cutting is done with high cutting speed and without cooling lubricants.Turned parts made of plastics, however, are processed at medium cutting speed. When machining water or alcohol are used for cooling. A special product from the metal cutting machines is the rotating part. Such automatic turned parts can be made from almost all machinable materials. Just like the CNC long turning parts of the screw-cutting without technical knowledge can not be produced. All machined parts require special machinery for the production. Rotating parts are to be finished by hand hardly. Are the turned parts made of wood or plastic, the machining is possibly still done manually, but with harder materials the use of expensive machining is necessary. To establish automatic turned parts, can not be dispensed with the machines. Automatic turned parts are usually ordered in enormous quantities and from extremely strong materials. Also for CNC turned parts is similar. This machining is simply too specific. CNC turned parts requiring extreme precision. Turned parts of this type are mainly used in machine and plant engineering. These industries would not do without CNC turned parts, turned parts, and the entire range of machining technology. Milling Services, CNC turned parts, turned parts, and just such special products as a CNC lathe part are absolute precision products. As simple as the concept sounds cutting, this process but it is not. Cutting sounds like simple separation that hide behind it but also things like complex CNC turned parts or automatic turned parts, no one thinks at first. Without these highly intricate parts, especially without the screw-cutting work would be impossible in some areas.

Founded

1938

Employees

50 - 100

Certifications

Wehingen

Germany - 78564

TMV Vago is a company located close to Milano, specialized in precision mechanical machining. Born as a mechanical turning shop, over the time it has developed a set of technologies and skills that now collaborate in the mass production of mechanical components for various sectors: Turning, milling, laser cutting and welding. Machining from solid of multiple metals, some plastic materials, and sheet metal and three-dimensional laser cutting is carried out. Additionl services such ad mechanical assembly, laser marking, finishing are provided.

Founded

1991

Employees

5 - 10

Certifications

Gerenzano (VA)

Italy - 21040

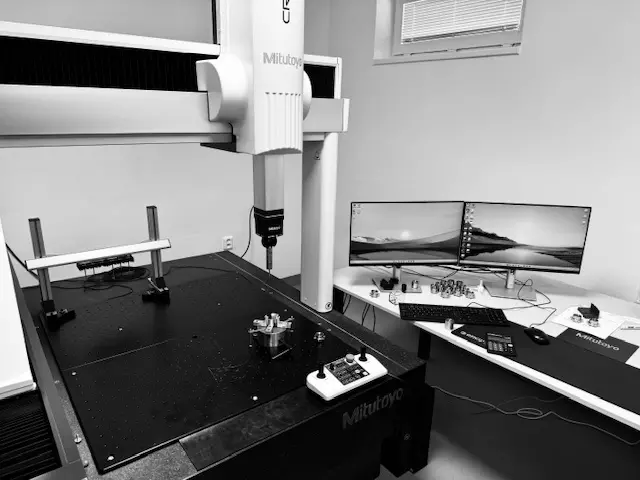

Our mission is to provide first-class services in the field of CNC machining. Thanks to our passion for technological progress and continuous improvement of production processes, we are able to meet even the most demanding requirements of our customers. Our customers demand not only high quality and precision, but also flexibility and the ability to quickly respond to changes in production requirements. We are proud to be able to offer comprehensive services from technology design through production to final quality control. Our customers particularly appreciate our professionalism, technological equipment and ability to meet even the strictest deadlines. We have a production capacity of 400 hours per week, which enables us to efficiently respond to the demands of our clients. Our 960 m² production facilities are equipped with the latest machines and technologies that ensure high precision and product quality. Our customers include : Siemens s.r.o., Flowserve s.r.o. John Crane Škoda Transportation a.s. DPOV a.s. Excalibur army spol. s.r.o. Company Technology : Metalworking - CNC turning , CNC milling , CNC measuring , conventional turning and milling. Cutting work on CNC plotter. 3D printing. Production of hydraulic hoses - industrial hoses, air hoses, rubber and flooring + accessories. MIG/MAG and TIG welding. Locksmith works. We also provide : - Heat treatment of metals (hardening, annealing..) - Casting (cast iron, steel, aluminium) - Forgings, forgings... - Surface treatment (comaxite, zinc, etc..) - Grinding Translated with www.DeepL.com/Translator (free version)

Founded

2021

Employees

10 - 20

Certifications

Šternberk

Czech Republic - 78501

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

Founded

2011

Employees

10 - 20

Certifications

Láb

Slovakia - 900 67

Production of complex CNC turned parts with bar feed, lathe parts, shafts up to 1000mm, thermowells for temperature measurement, machined parts and complete assemblies for measuring and control technology industry and the energy sector

Founded

1919

Employees

10 - 20

Certifications

Cunewalde

Germany - 02733

Founded

2013

Employees

20 - 50

Certifications

Wiehl

Germany - 51674

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

Since 2006, the company Bergbauer has established itself as a flexible and competent supplier of engineering and electronics industry in the field of metal cutting. With modern machining centers and tools to the latest technology, we can meet the different requirements. Our expertise lies in milling and turning of the item production to series production. The range of services covers the entire range of cutting tools to be processed materials, from plastics to aluminum, all kinds of non-ferrous metals and steels. Our young and flexible team of qualified staff is made up of technicians, skilled workers and trainees in the fields of mechanical engineering and machining Through continuous quality control, modern measuring devices and controlled manufacturing processes from receiving to shipping, it is possible always deliver us high and consistent quality.

Founded

1994

Employees

20 - 50

Certifications

Arnbruck

Germany - 93471

The company EDS-Maschinenbau GmbH was founded in 1989 as a contract manufacturer founded. At about 30 lathes and milling machines of different equipment produziern 35 employees and series parts.

Founded

1989

Employees

20 - 50

Certifications

Linnich

Germany - 52441

SYS Pres company is metal fabrication company which spealizes in laser cutting, laser welding, welding, bending, and surface treatment operations. Surface treatments are automatic sand blasting, zinc plate, copper plate and etc. SYS Pres company's facility is 3000 sq. Our export countries are Austria, Germany, England, Netherlands, Belgium, Israel.

Founded

1992

Employees

50 - 100

Certifications

Manisa

Turkey - 45400

We are a company dedicated to ugarisches sheet metal processing and exciting machining by machining centers for small and medium series .. The focus of our work lies in the production of complex assemblies including assembly such as FTS, Heber and packaging machines. Our machinery, we continuously expand and modernize one of the most modern in Hungary. From single part production through installation to commissioning of the modules and machines, we can offer the full range of services you need. Give us a try. We put an offer below that will convince you.

Founded

1993

Employees

50 - 100

Certifications

Kiskörös

Hungary - 6200

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge