Drop forging: Techpilot - free for buyers

Discover specialized suppliers for drop forging on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to manufacture high-quality drop-forged parts. Use the e-sourcing process to find suitable suppliers in real time.

151 suppliers for Drop forging

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

Company with over 60 years of history in hot forging. It currently has 5+1 forging lines. The production departments are mainly these: 1 - steel warehouse 2 - cutting department 3 - DIES construction and assembly tooling 4 - hot forging steel 5 - heat treatment 6 - warehouse and shipping Other important departments : - Quality department - Technical Office - Work shop - Maintenance department.

Founded

1960

Employees

100 - 200

Certifications

SUMIRAGO

Italy - 21040

MAKROSAN was founded as a family company with the production experience of more than 30 years and is mainly focused in turning & milling, sheet-metal cutting, laser cutting, sheet bending, pipe and profile bending, welding and assembly operations for the automotive, furniture, mechanical engineering, construction, agriculture and supplier industries. We manufacture according to your drawing specifications many varied parts: from aluminum to titanium. In the metal sector, we know almost no limits. We started with CNC laser cutting. Encouraged by the growing demands of our customers, we have added more technologies to our production spectrum over time; CNC bending, hand welding and robot welding, assembly assembly and CNC profile and tube bending. We can also offer CNC tube laser, CNC machining / milling / turning. We also have other business partnerships that we have been working together for years in the metal sector as well as the stamping, pressing parts and fasteners and tooling. We also have cold and hot formed parts made. Our company is located in Bursa, in the heart of the Turkish industry. Our company is certified by PCA to ISO 9001. MAKROSAN PROMOTION FILM: https://www.youtube.com/watch?v=Wn_3hNaqo5I As a competent supplier of sheet metal and metalworking and other areas, we work nationwide with well-known companies. We also export to several companies throughout Europe. We are interested in a long-term, strategic cooperation with your company. Best regards from Bursa! Murat RAHİMOĞLU Managing Sales Manager / Managing Director MAKROSAN METAL - Flexible Sheet & Metal Processing Mobile: +90 542 360 45 12 Mail: mr@makrosanmetal.com.tr MAKROSAN METAL San. & Tic. Ltd. Şti. Kayapa Sanayi Bölgesi, Orkide Cad. No: 9 16315 Bursa / TURKEY

Founded

2012

Employees

20 - 50

Certifications

BURSA

Turkey - 16315

Rope clamps for chair lifts and cable cars, T-bar lifts Components for cable car construction, drive technology Camshafts, rocker arms, finger followers Shift forks Clutch baskets Precision parts for mechanical engineering Steel and aluminum snap hooks Belt buckles Drop forged parts machined Peening machine

Founded

1953

Employees

50 - 100

Certifications

Fulpmes

Austria - 6166

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

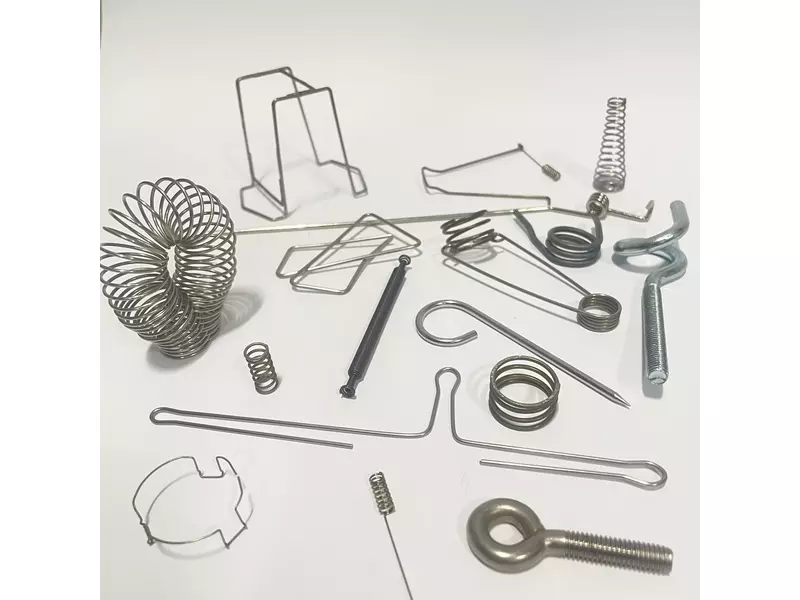

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

When working in higher levels we are RELIABLE yours. Tiger Lift is a subsidiary of the company Paksan in Turkey. Our parent company is 32 years active in the Turkish market for metal processing and is represented in more than 50 countries. Tiger Lift is a further development of the Turkish mother and is active in both down- and upstream active activities for metalworking and for crane and lift design. We offer extensive services around the material to metal as well as in the processing of. We also use our expertise in materials processing as well as in mechanical and automotive engineering to our customers reduce anew with tailored solutions always ahead. We are of the opinion that German craftsmanship is combined bring additional value with our international experience to our customers. We do not only follow the latest developments in our fields, we also develop self-innovation. Especially in mechanical and automotive engineering company Paksan has its research and development work massive boost to lay already the breeding ground for the work of tomorrow. Also in the metalworking sector, we are constantly keen to improve and expand our expertise. We are in constant contact with renowned research institutes in Turkey. This high demand is supported by the large number of certificates that have gotten our products. We strive every day with our successful staff who is always trying to improve and our products, yet offer you better services. When working in higher levels we are RELIABLE yours.

Founded

2013

Employees

50 - 100

Certifications

Wannweil

Germany - 72827

HKR GmbH & Co. KG The HKR GmbH & Co. KG is a subsidiary of Vaillant GmbH. This medium-sized companies went on 01 January 2006 from the previous profit center heating at the location Roding forth. The reliable service manager of the parent company also acts as a competent partner and supplier for external customers of the heating industry, automotive engineering, and for the sanitary sector. The 317 employees achieved a turnover of 52 million euros in fiscal 2007. Core competence is the development and production of components, gas and water leading assemblies and turning and forgings for the heating industry and the assembly of modules. The products are manufactured with an annual capacity of 8,000 tons per year, mainly made of brass but also made of steel and aluminum. WE PRODUCE SUCCESS! Experience the precision and the success with the products of HKR.Put your project with confidence in our hands. We support all around - from design, through production to installation. With over 40 years experience we can convince mainly in the following areas: · Production and development of components · Construction and installation of gas and water leading assemblies · Turning and forging production for heating · Assembly Your success is accurately measurable with us! WE QUALITY OF LIFE! We take responsibility! But we live in an integrated quality management system, which we constantly improve and control. In the production test systems integrated and systematic and methodological measures guarantee us to produce the highest standard. Quality means for us to deal responsibly with natural resources. Environmental protection and safeguarding the future are critical components of our quality management.As our customer you are in working with us, especially one who: Complete security, they have made us the right choice! Sustainable quality - piece by piece - sets us apart. For us, this also the appreciation and development of our employees. They turn us into what our customers expect from us, suppliers of living and quality of lived from production to assembly to delivery! WE MAKE THE POTENTIAL TO LIFE! Rigid routine is not us. We go off the front and living innovation through and through. Years of experience and the latest techniques to help us not to stop, but always think one step ahead for our customers. Sophisticated programs and structured processes enable a consistent production chain. Right from the start, we can rule out this way many sources of error. A direct access of the employees involved in each project can be short-term changes at any time, allowing the use of different concepts. We recognize your potential and develop together with you further. Experience completely new with HKR precision. We are your competent partner from the initial idea to the production stage!

Founded

1965

Employees

100 - 200

Certifications

Roding

Germany - 93426

After many years of experience in drive technology and gear construction, Net-Components GmbH was founded in 2003 by Dipl.-Ing. Tarkan Peker. It is a DIN EN ISO 9001:2008 certified company. With our knowledge of the international market and with the goal-oriented way of working, we always strive for market-driven and customer-oriented solutions. The execution of complex tasks in series production, medium and small series production, as well as prototyping is carried out on modern machining centers, which guarantee a consistently high quality and flexibly realize customer requirements. We are able to make short-term as well as long-term investments depending on the order situation and thus secure the production with regard to quality, deadlines and prices. One of the company's principles is to manufacture our products economically using safe and environmentally friendly processes and to meet high quality standards. Our striving for constant improvement and cost-effective production leads to the competitiveness of our customers. We offer: - Turned parts - Milled parts - Forged parts - Complete assemblies Small or large series

Founded

2003

Employees

50 - 100

Certifications

Wustermark

Turkey - 14641

We offer you solutions in high precision turning and milling technologies on Techpilot. Our meticulous approach to our clients and our order processing at each stage of cooperation - from analysis of customer needs to the final product - is what makes us stand out from the rest. Our affiliation to Mangata holding and the company's development over the years created the opportunity for modern machinery and equipment, expanding staff competencies and adjustment to marked needs. Our innovated technical facilities and richly equipped measurement laboratory and numerically controlled devices reduce our production cost. We specialize in the production of complex, precision elements with complex design, without any shortcuts. Our quality is confirmed with our numerous certificates and implementation of projects with our Polish and foreign customers. We manufacture, among other things, parts for vacuum pumps, compressors, brake systems, hydraulic pumps, vehicle suspension components, car seat components and servomotors. We are happy to support the medical industry by becoming suppliers to the medical industry.

Founded

1985

Employees

100 - 200

Certifications

Swiebodzice

Poland - 58-160

Techpilot GmbH - DEMO

We are Europe's largest platform for the manufacturing industry.Since 2000, we have been connecting matching suppliers, buyers and manufacturers and enabling you to determine the right price of drawing parts. Every year, over 16,000 registered buyers inquire about more than 30,000 different parts on our platform with an average order value of 35,000 EUR. Registered suppliers can take advantage of strong online visibility, media reach and are given a lucrative sales channel.We serve the entire market for mechanical components and is the European market leader with 280 supported manufacturing technologies.

Founded

2000

Employees

20 - 50

Certifications

München

Germany - 81379

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

YOUR GENERAL CONTRACTOR FOR FORMING and MOLDING! FORGING, HOT PRESSES KALTFLIESSPRESSSEN, FREE FORM FORGING IN STEEL, STAINLESS, ALUMINUM, BUNTMETALL, TITAN, FLANGE, RING, TRIMS, Longitudinally PIPES, FEINGUSS, SAND CASTING, DIE CASTING MACHINING PARTS OF FORM PART, OR FROM THE FULL PROFILE

Founded

1961

Employees

5 - 10

Certifications

Liestal

Switzerland - 4410

Bianchi Angelo is a company that produces precision metal parts, mainly specializing in the electrical, automotive and home furnishings sector. For the supply of raw materials, BIANCHI METALLI SRL makes use of an associated company, leader in the marketing of ferrous and non-ferrous materials, which guarantees the possibility of always having supplies in less time than competitors. Bianchi Angelo is located in the center of the Lombard industrial area (between Bergamo, Milan and Brescia), spread over an area of 3,600 sq m, of which 2,800 sq m production and 800 sq m of services and offices. It also makes use of highly technological systems and highly qualified personnel. Bianchi Angelo SRL is an Enel approved company for the production of terminal blocks, sockets, plugs and turned small metal parts. All our turning items (more than 7,000,000 annually) are made to customer specifications and designs.

Founded

1988

Employees

10 - 20

Certifications

Brignano Gera d'Adda

Italy - 24053

The medium-sized enterprises THIERBACH from Lower Hall near Heilbronn supplies Companies from all industries as tailored solutions for the Parts subject. TURNING AND MILLING PARTS THIERBACH processed according to your specifications, all machinable materials, including steel, stainless steel, brass, aluminum and bronze and precious metals and special materials for the aerospace industry. SINTERFACE PARTS For the production of sintered parts THIERBACH used exclusively powder with demonstrated high quality. Depending on requirements, the base material of various alloying elements are added. Formed In the area of formed THIERBACH offers various production options such as cold and hot extrusion. In addition, a mechanical, metal-cutting rework is possible. PUNCHING AND BENDING PARTS In the field of stamping and bending parts offers THIERBACH solutions of metallic and non-metallic materials that are manufactured on CNC machines.In addition, welding can be performed. LASER COMPONENTS In the area of laser parts are available from THIERBACH steel, stainless steel or aluminum products with extremely high precision contours in different thicknesses. CASTINGS In THIERBACH you get castings in all major manufacturing processes: aluminum die-casting, aluminum sand casting, zinc die casting, copper sand castings or precision castings. DEEP DRAWN PARTS THIERBACH provides you with high quality deep drawn parts made of stainless steel, aluminum, brass, bronze, iron, chromium or copper, either as a single function template or as a large series. ASSEMBLIES Not just when you need a single part, but even with demanding assemblies, you can count on THIERBACH: in partnership, economic and logistical point of view. CERTIFIED QUALITY An important part of THIERBACH quality philosophy is the maximum quality assurance in the production of your parts and assemblies. FACTS: QUALTÄTSSICHERUNG - Certification according to DIN EN ISO 9001:2008 - Erstmusterprüfberichtenach VDA - PPAP documentation - IMDS entries - Uniformity measurements - Surface measurements - Length measurements - Measuring equipment management - Sampling inspection according to AQL 1 - SPC tests Possibilities of surface and heat treatments Even when it comes ächen to the finishing of surfaces, THIERBACH provides organizational and economic advantages: Through partnerships with reputable companies you get: - Modern production techniques - Everything from prototype to mass production - Different machining options and THIERBACH all the possible rework and surfaces.In this way long and expensive transport routes and the total cost per piece If omitted significantly reduced. THIERBACH offers: Galvanizing / / Copper Passivation / / hard chrome plating Burnishing / / Gilding Dacromet / / Geomet coating Cadmium / / Nickel Chromate / / anodizing Phosphating / / pickling / / Silver Case hardening / / Inductive Glow / / start / / Slot Embossing / / Bending / / rubbing Lapping / / honing / / punching Engraving / / brushes Polishing / / electropolishing Grinding / / trowalizing Sand and glass bead blasting Flexible Logistics THIERBACH is not content to create the correct part, but is only satisfied when you is this the right time and at the right place. Thus, for example, already taken in the packaging that it contains all the elements for a smooth production: Logo, number, barcode.

Founded

1999

Employees

20 - 50

Certifications

Künzelsau

Germany - 74653

We produce since 1969 quality hot forged parts according to our customers’ drawings and specifications. Our plants are organised around high performing presses with force from 650 to 1.300 tons: we can therefore manufacture parts with finished product weight from 0,15 up to 5 kg. for almost all industrial branches, such as energy, industrial plants, agricultural machines and commercial vehicles. In order to assure the best quality of our products, all forging and production tools are developed and manufactured in our works and by a motivated team.

Founded

1969

Employees

20 - 50

Certifications

Proserpio (Como)

Italy - 22030

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

CASTING and FORGING PARTS BY CUSTOMER Together with our partner companies ISG industry service and Geiger Berger Industries, we offer you the opportunity to access from a wide range of different foundries, forging and machining company from Germany, Spain, Hungary and China. We take care of you this vendor selection, request, technical clarification, quality assurance, packaging, shipping and timely delivery of your products according to your drawings and specifications. Through our three locations in Germany, we are always in their vicinity: CFT Hanseatic Guss GmbH, 28195 Bremen ISG industry service Geiger e.Kfm., 73491 Neuler Berger Industries K., 50668 Cologne You have a question or want to get to know us? Please contact one of the below mentioned contact, we'll take care of everything else.

Founded

2004

Employees

10 - 20

Certifications

Bremen

Germany - 28197

Delivery of castings and forgings including processing in Asia. The Asian partners have the appropriate approvals. ISO 9001: 2008 is granted. Approvals under the Pressure Equipment Directive (PED / AD 2000) or ship classification approval LRS, GL, DNV, BV available. Certificates available on request. Partner agencies on site to monitor the production as an indispensable part of our quality philosophy. Material: cast iron, ductile iron, cast steel, cast stainless steel, duplex Casting processes: investment casting, sand casting Form process: Hand molds and machinery forms Models: wood or metal

Founded

2010

Employees

< 5

Certifications

Hofheim am Taunus

Germany - 65719

We are an industrial and commercial agency with direct suppliers and production facilities in Poland, Czech Republic, China, Italy, Taiwan, India, Turkey and Germany. We design and produce together with our partners to our customers in the following areas: Welded structures such as caddies, storage racks, long-product pallets. Steel construction, welding in general. Surfaces such as rays, galvanizing, painting, powders. Sheet metal processing all materials: CNC punching, nibbling, edges, laser welding, cutting Fully automated bending center, powder coating, Deep drawing, laser cutting, punching from coil, components, Services according to customer requirements Turned parts, milled parts made of all materials Castings and their processing Plastic injection molded parts up to 2,500 grams weighing, + Toolmaking Extrusion plastic profiles Aluminum profiles and their processing Cable assemblies, wire harnesses, control boxes and control cabinets completely Agricultural Engineering Bent wire parts Diecast Bend and process tubes

Founded

1986

Employees

5 - 10

Certifications

Hörstel - Bevergern

Germany - 48477

We, Metallbau Schmalenbach, specialize in manufacturing a wide variety of high-quality and tasteful stainless steel and corten steel accessories. Years of experience in working with metal products, experienced know-how and the gift for exceptional design give our products uniqueness. The focus is on narrowing down to the essentials. In a charmingly flooded world, peace and relaxation are important to us. Simplicity is the goal and with it the uniqueness of our products. In addition to our wide range of products, we also offer you the opportunity to have your ideas implemented. We offer you custom-made custom-made products. You are welcome to visit us at Linienstr.14 in 42289 Wuppertal.

Founded

2022

Employees

5 - 10

Certifications

Wuppertal

Germany - 42289

For 50 years, the Heckler AG is a powerful company in the field of cold forming of steel and aluminum. High flexibility and widespread awareness of quality have made us a global supplier of automotive and architectural hardware industry. With the use of the latest extrusion technology, we deliver cost Kaltformteile of superior quality and strength. Our certificate according to ISO / TS 16949 is quality consciousness.

Founded

1950

Employees

200 - 500

Certifications

Niefern-Öschelbronn

Germany - 75223

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge