Measurement device test device: get complete market transparency

Discover specialized suppliers for measuring and testing devices on Techpilot. Our platform connects buyers with suppliers who manufacture customized solutions for quality control. Use the e-sourcing process to find the best suppliers.

553 suppliers for Measurement device test device

As an industry partner, we offer a wide range of services. We provide assistance with repairs, maintenance on production machines and testing of work equipment. In addition, we offer our customers in-house fixture construction with machining and welding technology. If required, we can offer one-off production of spare parts including delivery and assembly from a single source, for example to repair an acute defect as quickly as possible. Individual solutions in production Handling tools - Lifting tools - trusses - Turning devices - transport devices exams - Lifts - Water squeegee - Shelving systems - ladders - Lifting equipment - DGUVv3 checks von der Heyde is certified - DIN EN ISO 9001 - DIN EN 45001 - DIN EN 1090-1 - DIN EN ISO 3834 In-house production - metal and sheet metal processing - turning, milling, drilling - surface treatment (external processing) - welding of individual parts and structures made of steel, stainless steel and aluminum - 3D measurement technology - Own design with Catia V5 or EPLAN - Automation solutions with Siemens Tia Portal and other PLC solutions

Founded

1986

Employees

50 - 100

Certifications

Stade

Germany - 21682

"A systematic approach to solution" The company PRO CNC GmbH & Co. KG was founded on 01.12.1990 by Michael Pfeiff under the name Michael Pfeiff. The company's headquarters was first in Varl and was moved in 1994 after Luebbecke. On 01.09.2003, the company was acquired by the current owner Volker Meier kink and then operated under the name Pfeiff toolmaking. Since 01.09.2013 we now operate under PRO CNC GmbH & Co. KG - Production Engineering and Mechanical Engineering. Mr. Meier is one kink with the company since the very beginning. The company PRO CNC GmbH & Co. KG deals with the full range of mechanical manufacturing (turning, milling, drilling, grinding) and the assembly of components and machines. Focus here is the contract manufacturing in the milling, especially the production of small parts. Cubic parts up to an edge length of 1000x600mm currently can be handled in-house CNC PRO GmbH & Co. KG. The company PRO CNC GmbH & Co. KG is able to deliver to the customer from the initial sample to mass production all.The range of parts includes the classic item to automobiles mass part. Is manufactured to eleven computer-controlled machine tools and machining centers the latest generation with up to four axes and two spindles. Some of the machines are equipped with rotary tables change. As a manufacturer, we would like to mention, among others, Bridgeport, Brother, YCM and Swabian machine tools here. The rotation range is among other things a lathe with driven tools, Y-axis and bar feeder (Biglia B650Y-turning diameter over bed max. 400mm) are available. Programming is based on dialogue and DIN controllers and by means of a CAD-CAM work on SolidWorks basis. Currently, the company PRO CNC GmbH & Co. KG two masters, a mechanical engineer, eight skilled workers, five assistants and a force in the commercial sector employs. The customer base includes about 30 customers from all sectors of the craft and the industry (electrical, mechanical, automobiles, pharmaceuticals, chemicals) in regional areas. Its customers include names like: VW, AEG, Federal Mogul, Faurecia (automotive sector) Harting, IMA, Kolbus, Oystar (engineering sector) VTG wagon Graaff, EuroMaint Rail (rail-rail vehicles) In May 2004, the company has been certified according to DIN ISO 9001-2000 since 2010, accordingly to DIN-ISO 9001-2008.

Founded

1989

Employees

20 - 50

Certifications

Lübbecke

Germany - 32312

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

Inter Technic sro has developed in more than 5 years into a powerful company. If you are interested, we work for you as an extended workbench or can help reduce overcapacity, then ask us. In January 2015, our machinery was another new and powerful 5-axis simultaneous milling extended Hermle C42. We have currently in another, new DMG CNC milling machine invested. - Table load up to 2,000 kg - Table size 1700 x 750 mm - Travel X = 1450 mm, Y = 700 mm, Z = 550 mm This machine is our production in addition to available from the KW22 / 15th A robot welding system was installed. This brings us to weld able TIG and MAG. We are very well set up for you to produce tools and jigs. We are happy to customize items, zero series, production parts or assemble complete modules. With two new wire EDM machines we can in 2-shift operation for you. Our machinery has been almost entirely reinvested. For quality assurance, is from March 2016 new Zeiss measuring machine available! For programming we use two CAD CAM - Siemens NX Unigraphics, Version: 8.5 programming stations and enables us to offer services to the 3-D machining. Another added advantage of unsrem companies: All contacts at Inter Technic spoke German except Slovak, English.

Founded

2010

Employees

100 - 200

Certifications

Liptovsky Mikulas

Slovakia - 03101

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

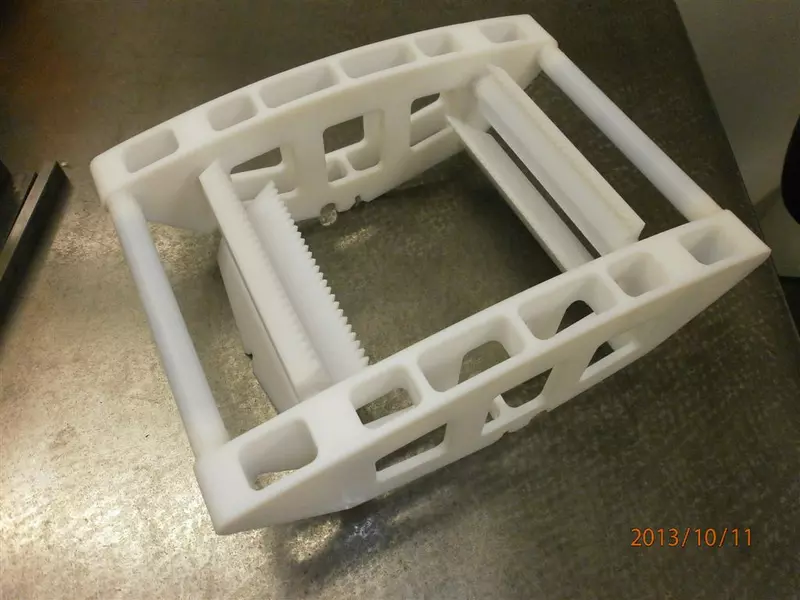

Company Profile Since 1991 Our family manufactures customized solutions made of plastic. In Gornau at Chemnitz today about 50 employees in the fields of semi-finished product processing, container and equipment construction, plant construction and cleanroom technology operate. Our solutions are used in industries such as machine and plant engineering, medical and environmental technology, the semiconductor industry and photovoltaics. The high quality of our products and services is evidenced by the certification of our company according to ISO 9001:2008. The internal design office as well as the technically and technologically advanced manufacturing guarantee our customers a comprehensive and high-quality advice and support. Involve us when planning your plastic just solution. Illustrate With our experience and the available CAD technology and we work out the best solution. We are happy to solve with our know-how your challenges. Products / Services Semi-finished processing Behälter-/Apparatebau Transparent Plastics Wasser-/Labortechnik Cleanroom technology Semiconductor engineering / photovoltaics Piping systems / special fittings Prototyping / Rapid Prototyping Machine technology With a well-equipped and very broad machinery, we can meet diverse customer needs. CNC lathe turning length up to 500 m 2 Milling Machine CNC 3-axis 1000 x 1300 x 160 Milling Machine CNC 3-axis 2300 x 1300 x 160 Milling Machine

Founded

2001

Employees

50 - 100

Certifications

Gornau

Germany - 09405

Since its inception in 1999 we have specialized in the manufacture of parts and series in the area of turning and milling, and are active throughout Europe. Regular investment in new technologies and manufacturing capabilities ensure optimal quality and customer satisfaction. Good Quality begins with a high-quality production equipment, efficient processes and a clear structure. Continuous development is the foundation of our success. We employ 35 employees in administration, construction and manufacturing. Join our 4 trainees for precision mechanics and in administration. The cooperation with TME is open, direct and uncomplicated. Our clients include companies in the areas of: Engineering, tooling, laser technology, and aerospace and automotive industries. Service overview Production / manufacture of components We manufacture parts, spare parts and small series to mass production according to your drawings or a pattern. Our machining capabilities include CNC-controlled milling, drilling, turning, wire EDM, surface grinding and conventional crafts and sheet metal processing. We can use our processing centers, parts machining, up to the size: L = about 2100, W= about 1000 B =, H = about 600 and up to a weight of 6500 lbs. Construction Design of tools, fixtures and equipment. 3D modeling for prototyping. Support for design tasks and advice on cost-effective and production-oriented manufacturing of your parts during development. CAD / CAM Acquisition and processing of all popular file formats such as : STEP, SAT, IGES, DWG and DXF programming with our CAM system. Welding / Heat treatment The welding of steel and heat treatment (hardening, tempering and annealing) are also of parts of the scope of our processing. Surface treatment Surface treatments, we can perform at our partner companies. Assembly Assembly of parts, components, tools and equipment. Reports On request, we create initial sample inspection reports and test protocols. Delivery We deliver your products on time with shipping or parcel service. We are a professional partner, trust TME!

Founded

1999

Employees

20 - 50

Certifications

Simmern

Germany - 55469

HMT Inside. Jung.Unkonventionell.Wild. We machine, weld and assemble - from simple to highly complex parts. Our wide product range offers you many advantages: they reduce the number of suppliers, thus saving expense in purchasing and optimize the quality and quantity of your purchased parts. Consider HMT as "internal division" of your company - through open communication, flexibility and adapted processes, we can create together a successful long-term partnership for the future. In addition, you benefit from our network, consisting of competent partners in the areas of surfaces, heat and other treatment techniques. It's the mix! We are your partner that responds quickly and flexibly to your current production needs and at the same time not lose the vision. We are actively trying to make your life a little easier, through adherence to agreements and by personal, ongoing consultation and cooperation. We support you ... ... already in the development phase to the production of prototypes and their production engineering optimization. ... throughout the product life cycle with series parts - from a few to tens of thousands of pieces per year. ... continually and demand-oriented with spare parts. We supply ... ... to order (Build to Order): The requested batch size to the desired delivery date. We pack and label the various components true to your specifications and compile them into matching commissions. ... suppliers controlled (Vendor Managed Inventory): We take responsibility for the assets of your purchased parts. Through continuous communication and exchange of inventory and your production plans we will optimize your inventory and purchasing costs and respond quickly to fluctuations in demand. So you can quickly and act flexibly in a dynamic, fast-paced market.

Founded

1980

Employees

10 - 20

Certifications

Kremsmünster

Austria - 4550

Founded

1976

Employees

200 - 500

Certifications

Höchstädt a.d. Donau

Germany - 89420

About us Kreutz & Mock is a medium-sized company and the leading manufacturers of wire bending parts of all types. With over 3000 different articles we can offer our customers a wide and diverse range of different wire products. The necessary machines for the production are developed and built in-house by our own engineering department which gives us the possibility to always be flexible according to our customer's needs. You can find further details about us and our philosophy on our website. Products We manufacture wire bending parts in all sorts of variations and models. We supply many industries with our products like the automotive industry, construction industry, agriculture, blinds manufacturers and many more. We also have numerous technical bent parts in our repertoire. We are happy to try to achieve your specific needs and requirements, because quality, punctuality and being in step with actual practice are our basic principles to deliver high quality as well as best functionality products. It does not matter whether they are single quantities, small quantities or a large series. We are flexible and deliver quality at fair conditions. We offer + Qualitycertficate DIN ISO 9001:2008 + in-house specified tool construction + in-house machinery construction + quick production of samples + technical and experienced know how + skilled telephone service + large production spectrum Materials Every material processed in our factory has a dedicated inspection certificate that will be provided with your delivery on request. We manufacture bent wire components for you in all variants and materials. Here a selection of the materials used: + Stainless steel wire 1.4301, 1.4310, 1.4362, 1.4401, 1.4404, 1.4571 in different tensile strengths + Spring steel wire 0.9 mm to 6.0 mm. Qualities A, B, C, D + Steel wire C9D bare or copper-plated. C9D soft galvanised in 1.0 mm to 8.0 mm + Crapal wire + Becrosi valve spring wire + Silver and Palladium wire

Founded

1934

Employees

20 - 50

Certifications

Neuendorf

Germany - 97788

We are a company that has been the right partner for 14 years now when it comes to prototypes, tools and devices for the mobile sector. General contract manufacturing in the areas of HSC machining, mold making and model making complete our offering.

Founded

Employees

10 - 20

Certifications

Sarntal

Italy - 39058

Founded

2015

Employees

20 - 50

Certifications

Oravska Polhora

Slovakia - 02947

Dear Ladies and Gentlemen, in this way we would like our service companies introducing we produce single pieces or small series, series, sub-assemblies, gauges, fixtures Tools, special machine parts for the Varied fields of application according to your Requirements, specifications, drawings. We can at reference customers from eg mechanical engineering, special engineering, medical, aircraft, automotive industry, tooling, etc. References. Our range of machines includes most modern technology currently available in these areas CNC milling, CNC turning, CNC surface grinding, CNC wire EDM, CNC sinker EDM CNC-Erodierbohren/Präzisionsbohrungen, CNC Ultra Sonic is offering. Thanks to this modern manufacturing equipment and years of experience and a team of employees profounded we are to be able almost all requirements in manufacturing technology needs. For more information about our machine park can be found on our website CNC milling, CNC turning, CNC surface grinding, CNC wire EDM, CNC sinker EDM CNC-Erodierbohren/Präzisionsbohrungen, CNC Ultrasonic www.KaPe-erodiertechnik.de

Founded

98

Employees

10 - 20

Certifications

Ostbevern

Germany - 48346

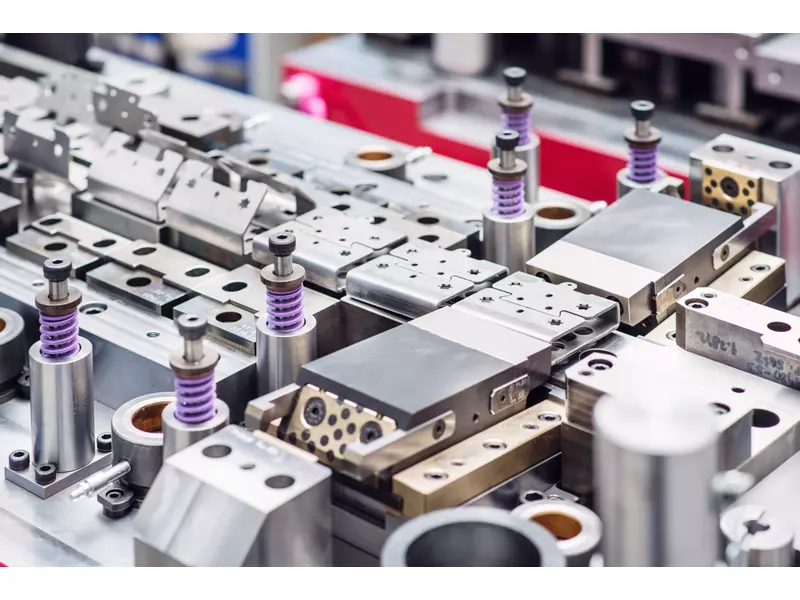

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

We enable you to focus on the essentials. The production of your parts and assemblies you provide to us, the Roeder GmbH & Co. KG is your competent partner for precision.

Founded

1999

Employees

10 - 20

Certifications

Biebergemünd

Germany - 63599

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

We are a medium-sized company based in Ganderkesee and have been producing sophisticated sheet metal and formed parts for our customers for over 65 years. Our customer base includes the automotive, mechanical engineering, electrical, marine and aircraft industries, where we are listed as an A-supplier and have already received several awards as a 0-ppm supplier. Our company is fundamentally different from other companies that can produce either only large or only small series at low cost. We are proficient in both technologies. Since we are convinced that only holistic quality and sustainability can lead to success today and in the future, we have a certified integrated management system in accordance with the requirements of IATF 16949, DIN EN ISO 9001 and DIN EN ISO 14001 established. (ext. TÜV Cert link). Our homepage is intended to give you a brief overview of our diverse production options. We would be delighted to work for you too. Give us a chance to do that.

Founded

1948

Employees

20 - 50

Certifications

Ganderkesee

Germany - 27777

The company Fetec Engelhardt GmbH is a modern enterprise specializing in CNC milling and turning as well as the construction of complete functional units. For the 2D and 3D Complete machining of simple to extremely complex workpieces made of steel, stainless steel, aluminum, plastic, etc. we are the right partner for you. Even sophisticated operations such as the production of free-form surfaces, supported by a CAD-CAM programming system belong to our services. Business The company FETEC Engelhardt GmbH was established on 1 Founded in May 1997 in Ruhla / Thuringia as a civil law and on 1 July 2005 umformiert into a GmbH. Starting point of the company producing basic turning and milling parts, the one manufactured in order for suppliers to the automotive industry. With the move in January 2001 in a new building, the production of parts, prototypes, small batches in contract manufacturing as well as complete assemblies and devices has been made possible.The expansion of contract manufacturing required on 1 July 2006 another move to a larger and also its own production facility. The workforce of FETEC Engelhardt GmbH consists of seven employees and three apprentices. Managing directors are Gerald and Ursula Engelhardt. Products Because of our diverse experience in the field of metal machining, we are able to offer comprehensive services. These range from performing individual work steps bishin for assembly of complete functional units. Turn 1 Turning the conventional way ----- BRAND NEW ------- Lathe with bar feeder 3m to 32mm diameter x / y machining with driven tools * Between centers 1000mm x D 220mm * In feed D 300mm * From the rod D 47mm 2 CNC turning with counter-spindle, Y-axis and bar feeder * Maximum diameter D 100mm (45mmStange) * Maximum turning length D500mm Mill 1Milling in a conventional manner * X-, Y, - Z-direction 300 mm x 220 mm x 300 mm 2 CNC milling Maximum travel: * DMU 60T monoblock (five axes) / X 500 mm, 400 mm, Y-, Z-400mm * Hurco VMX 42t (3-axis) / X 1060mm Devices Production of complete functional units * Devices * Tools * Assembly workstations * Special Machines * Prototypes * Items * Small series * And much more

Founded

1997

Employees

10 - 20

Certifications

Ruhla

Germany - 99842

SINCE 2009 .... The company was founded in 2009 by Mrs. Bettina Landgraf-Kaiser, storage capacity today is about 3000 m² in three halls. As a leading warehouse distributors constantly about 100 cars and well-preserved machines of best brands offered. State of the art warehouses with crane capacity up to 10 tons and forklift capacities up to 7 and highly trained staff are the benefits for potential customers to find the "perfect machine". Complete "all-inclusive" packages (eg transport, introduction, installation Complete training) are developed and implemented according to your. MEMBER OF: Since 2009 FDM - Germany Since 2009 EAMTM - Brussels (International) SPECIALITY: Cutting metal-working machines Our specialty is the trade used machines from metal cutting. Whether conventional or CNC - controlled, we each offer the right machine for you.In CNC - area we act almost exclusively with the control type Fanuc & Heidenhain. Here we can give you the best - provide service, whether coverage with qualified staff, service staff or software solutions. OTHER: Furthermore, even spare parts - remakes produced directly in the house with us. Through years of experience of our employees in the cutting process on Fanuc & Heidenhain controls, we can therefore offer cost effective replacement parts alternatives you.

Founded

2009

Employees

5 - 10

Certifications

Bruchsal-Büchenau

Germany - 76646

BFT is a company born in 2008 from the passion of two brothers for the mechanical sector. Specifically, the company deals with milling for the following sectors of application: - special machines (operating) - aeronautics - medical The company is young and has a modern and cutting-edge machine park that allows it to develop even very complex and elaborate components.

Founded

2008

Employees

5 - 10

Certifications

Villotta di Chions

Italy - 33083

Innovative plastic products since 1989 The BÖHL-plastic GmbH & Co. KG specializes in the production certified technical precision injection molded thermoplastics. We cooperate with raw material manufacturers, but also with colleges and universities. Because the plastic processing is a challenging topic. Individual solutions are our strength. Our activities span the injection molding production for the lighting and automotive supplier industry. We are also working for the industries fittings, electrical and electronics, medical, furniture, steel and textiles. The headquarters of our plastic processing company located in southern Westphalia. Here we present for you since 1989 plastic parts from all common thermoplastics ago. We are supported by our own mold.

Founded

1989

Employees

20 - 50

Certifications

Bad Berleburg-Aue

Germany - 57319

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge