Find suppliers for hardening and tempering

Discover specialized suppliers for hardening and tempering on Techpilot. Our platform connects buyers with suppliers who use advanced technologies to optimize the properties of materials. Use the e-sourcing process to find the best suppliers.

270 suppliers for Hardening and tempering

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

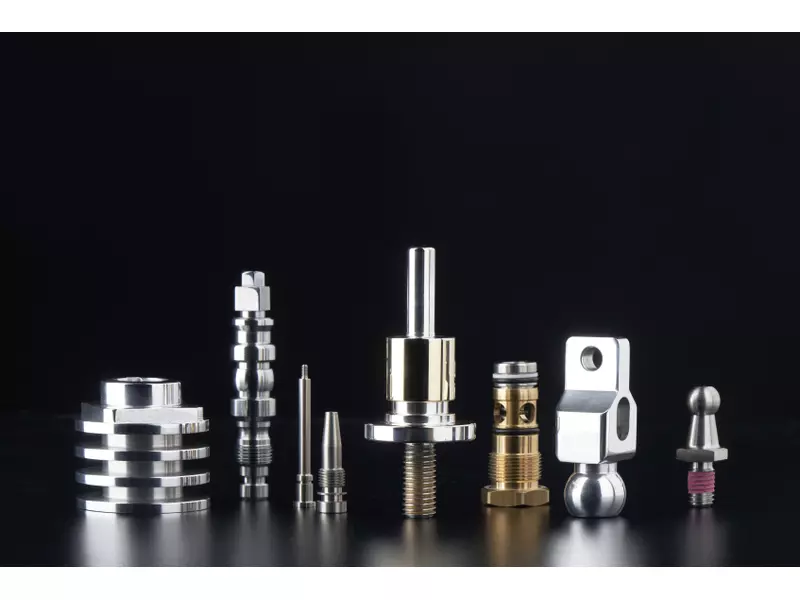

Manufacturer of series turned parts from all cut materials according to your specifications. In addition to being a reliable supplier, our major passion is the development of optimum solutions.

Founded

1971

Employees

50 - 100

Certifications

Gunningen

Germany - 78594

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

The company Rauscher has been active for different industries since 1984th The realization of specific customer requirements We achieve this through our modern and diverse machinery. Fully automated loading and unloading systems, we ensure a high Productivity in the production of turned parts. Do you have technical questions or want more detailed information? Then call us on the number 089/793 20 41, or send an email to: info@cnc-dreherei.com We advise you individually and in detail in your affairs. Translation by Google Translate

Founded

1984

Employees

5 - 10

Certifications

Putzbrunn

Germany - 85640

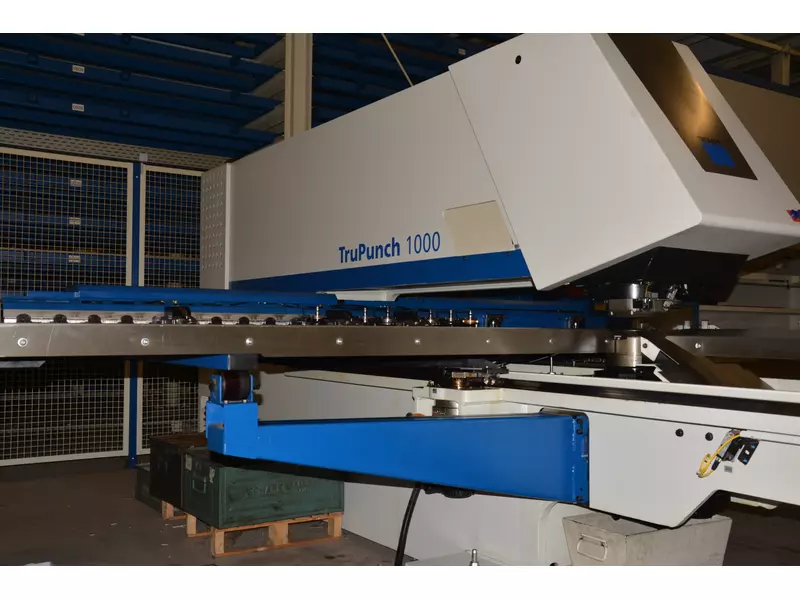

Since its inception in 1999 we have specialized in the manufacture of parts and series in the area of turning and milling, and are active throughout Europe. Regular investment in new technologies and manufacturing capabilities ensure optimal quality and customer satisfaction. Good Quality begins with a high-quality production equipment, efficient processes and a clear structure. Continuous development is the foundation of our success. We employ 35 employees in administration, construction and manufacturing. Join our 4 trainees for precision mechanics and in administration. The cooperation with TME is open, direct and uncomplicated. Our clients include companies in the areas of: Engineering, tooling, laser technology, and aerospace and automotive industries. Service overview Production / manufacture of components We manufacture parts, spare parts and small series to mass production according to your drawings or a pattern. Our machining capabilities include CNC-controlled milling, drilling, turning, wire EDM, surface grinding and conventional crafts and sheet metal processing. We can use our processing centers, parts machining, up to the size: L = about 2100, W= about 1000 B =, H = about 600 and up to a weight of 6500 lbs. Construction Design of tools, fixtures and equipment. 3D modeling for prototyping. Support for design tasks and advice on cost-effective and production-oriented manufacturing of your parts during development. CAD / CAM Acquisition and processing of all popular file formats such as : STEP, SAT, IGES, DWG and DXF programming with our CAM system. Welding / Heat treatment The welding of steel and heat treatment (hardening, tempering and annealing) are also of parts of the scope of our processing. Surface treatment Surface treatments, we can perform at our partner companies. Assembly Assembly of parts, components, tools and equipment. Reports On request, we create initial sample inspection reports and test protocols. Delivery We deliver your products on time with shipping or parcel service. We are a professional partner, trust TME!

Founded

1999

Employees

20 - 50

Certifications

Simmern

Germany - 55469

Torneria OML is specialized in high precision CNC machining. Since 1982 we have been specialized in the processing of any type of metal. Thanks to the use of the latest generation and highly technological machinery, we are able to guarantee the highest quality and precision, always offering an excellent quality / price ratio. Our qualified and constantly updated staff is able to quickly manage any type of order, from small and medium-sized production to high-precision machining. Thanks to the adoption of modern CNC technologies, we have considerably reduced production times, greatly increasing the reliability of the productions themselves. To always guarantee quality products, we have introduced systematic checks according to UNI and ISO 9001: 2015 and ISO 14001: 2015 regulations. Our company is part of the ATI set up for participation in the project “Venetian mechanical manufacturers on behalf of third parties present themselves in Europe”, which will be implemented using the POR Veneto region funding, part of the ERDF. Thanks to the use of the latest generation and highly technological machinery, we are able to guarantee the highest quality and precision, always offering an excellent quality / price ratio. Our qualified and constantly updated staff is able to quickly manage any type of order, from small and medium-sized production to high-precision machining. We are specialized in the creation of components for the sectors: Valves, Gas Components, Pneumatic Components, Automotive, Hydraulics, Hydraulic, Naval, Nuclear, Oil.

Founded

1982

Employees

20 - 50

Certifications

Castelgomberto

Italy - 36070

Founded

1976

Employees

200 - 500

Certifications

Höchstädt a.d. Donau

Germany - 89420

Manufacture of precision machined parts and milling parts from all machinable materials. CNC turning (up to D 90 mm rod) CNC turning (up to 250 mm in the feed) CNC long turning CNC multi-spindle turning (32 axes) CNC Machining Centers (5-Axis) Batch sizes up to 1000 pieces .... Piece including all subsequent operations up to the assembly In the field of machining there are many different ways of working. One is the CNC machining. Through this method, the milled parts get even complicated 3D contours. The CNC machining is done with machines with up to 8 axes. CNC turned parts can be made of different materials. For machining titanium, copper, brass, plastic, aluminum, stainless steel and other materials are suitable. Rotating parts in general can assume unusual shapes. In particular, the CNC milled parts often see pretty spectacular. Through its 3D contours CNC turned parts have a special effect.The machining is extremely versatile. Machining technology is used in various fields. Lathe parts, especially CNC lathe parts, are very expensive to manufacture. To produce a CNC lathe part, one special machines and more time than the normal CNC turned parts needed. The machining and especially the CNC machining requires a good education in the field. The partially very complex turned parts and just the CNC lathe parts require a tremendous expertise. A single CNC lathe part caused enormous amount of time. For these special turned parts, a particularly accurate work is absolutely necessary. For the purposes of machining are all chip forming materials. Depending on the material, the cutting is performed with different speeds. Are the turned parts made of wood, the cutting is done with high cutting speed and without cooling lubricants.Turned parts made of plastics, however, are processed at medium cutting speed. When machining water or alcohol are used for cooling. A special product from the metal cutting machines is the rotating part. Such automatic turned parts can be made from almost all machinable materials. Just like the CNC long turning parts of the screw-cutting without technical knowledge can not be produced. All machined parts require special machinery for the production. Rotating parts are to be finished by hand hardly. Are the turned parts made of wood or plastic, the machining is possibly still done manually, but with harder materials the use of expensive machining is necessary. To establish automatic turned parts, can not be dispensed with the machines. Automatic turned parts are usually ordered in enormous quantities and from extremely strong materials. Also for CNC turned parts is similar. This machining is simply too specific. CNC turned parts requiring extreme precision. Turned parts of this type are mainly used in machine and plant engineering. These industries would not do without CNC turned parts, turned parts, and the entire range of machining technology. Milling Services, CNC turned parts, turned parts, and just such special products as a CNC lathe part are absolute precision products. As simple as the concept sounds cutting, this process but it is not. Cutting sounds like simple separation that hide behind it but also things like complex CNC turned parts or automatic turned parts, no one thinks at first. Without these highly intricate parts, especially without the screw-cutting work would be impossible in some areas.

Founded

1938

Employees

50 - 100

Certifications

Wehingen

Germany - 78564

Modern technology + highly qualified personnel We are a powerful and flexible partner for the production of turning, milling and Cleans parts in series production. We manufacture to 2,800 m² technically sophisticated products with approximately 60 highly modern CNC machine tools from all Zerspanungsbereichen. Quality assurance system First-class quality has been in the production of AGA Machining GmbH priority. The work processes in our company based on the value-adding processes. These are fused together by the staff of manufacture within the meaning of the operator inspection and quality assurance. Quality as the foundation Quality is the basis of all activities at the AGA machining Gera GmbH. Every employee has to make a significant contribution to quality. The quality policy is the basis for work of every employee at AGA. Quality in national competition To prove the competitiveness of AGA obtaining the quality certificate 16949 stated goal of the company is TS. NULL-defect quality NULL-defect quality in all processes, products and services is essential to secure the future. To the total satisfaction of customers is our ultimate goal. This is achieved by error-free products and services, punctuality and by competent and friendly cooperation with our clients' staff. Continuous improvement means that every employee fully aware of the quality of his individual work as well as the active contribution to the continuous improvement of the quality of AGA processes - products and services. Quality by thinking and acting To achieve the quality objectives, the skills of all employees for customer and quality oriented thinking and action must be constantly developed and trained. Quality through Leadership The managers are an example for your employees. They must formulate clear, achievable objectives and support the employees in the achievement of these goals.The managers are responsible for the fulfillment of these goals. From design to finished product Through years of experience as a supplier to the automotive industry, we offer our customers the complete production of their products. We are partners with the pros and development and give you competent with technical know how, new manufacturing processes and over 100 qualified employees to the side. The creation of individual concepts in the field of machining is one of our strengths. We are your partner - already in the development phase.

Founded

1957

Employees

100 - 200

Certifications

Saalfeld/Saale

Germany - D-07318

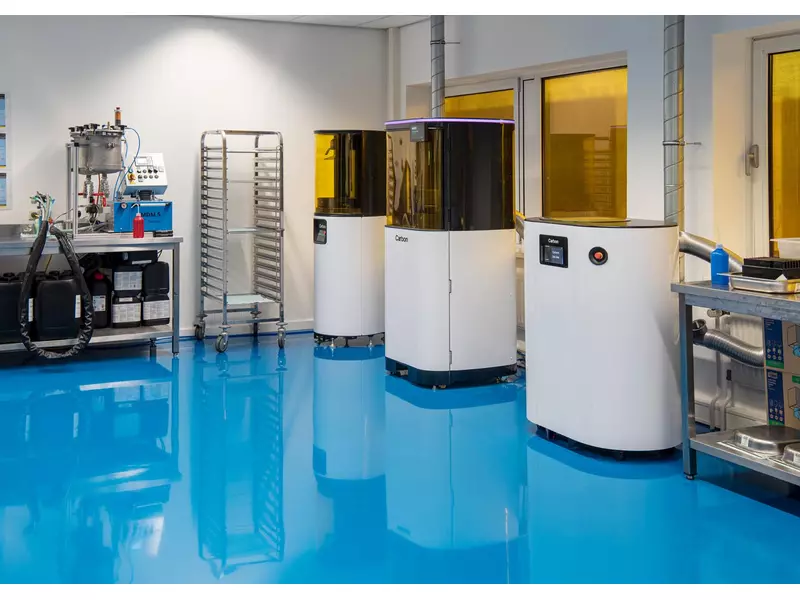

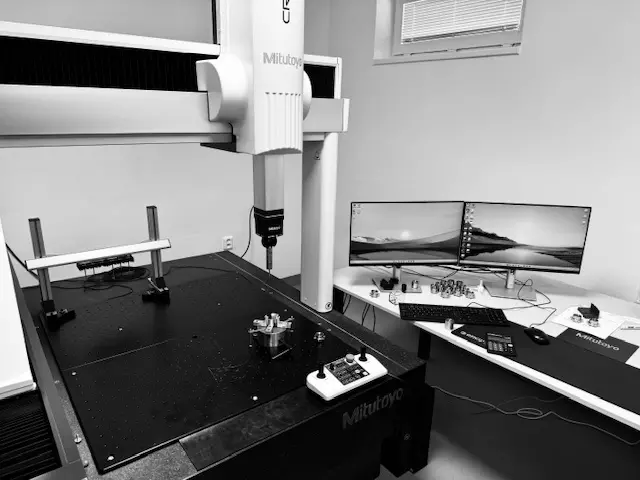

Our mission is to provide first-class services in the field of CNC machining. Thanks to our passion for technological progress and continuous improvement of production processes, we are able to meet even the most demanding requirements of our customers. Our customers demand not only high quality and precision, but also flexibility and the ability to quickly respond to changes in production requirements. We are proud to be able to offer comprehensive services from technology design through production to final quality control. Our customers particularly appreciate our professionalism, technological equipment and ability to meet even the strictest deadlines. We have a production capacity of 400 hours per week, which enables us to efficiently respond to the demands of our clients. Our 960 m² production facilities are equipped with the latest machines and technologies that ensure high precision and product quality. Our customers include : Siemens s.r.o., Flowserve s.r.o. John Crane Škoda Transportation a.s. DPOV a.s. Excalibur army spol. s.r.o. Company Technology : Metalworking - CNC turning , CNC milling , CNC measuring , conventional turning and milling. Cutting work on CNC plotter. 3D printing. Production of hydraulic hoses - industrial hoses, air hoses, rubber and flooring + accessories. MIG/MAG and TIG welding. Locksmith works. We also provide : - Heat treatment of metals (hardening, annealing..) - Casting (cast iron, steel, aluminium) - Forgings, forgings... - Surface treatment (comaxite, zinc, etc..) - Grinding Translated with www.DeepL.com/Translator (free version)

Founded

2021

Employees

10 - 20

Certifications

Šternberk

Czech Republic - 78501

Please allow me to introduce our company. We are a Slovak company whose major production program is orientated to manufacturing of special and precise parts for machines, different kind of fixtures, stamping tools, dies/progressive tools and transfer tools. We are a member of Rejlek Plastics Group in Vienna, Austria. We offer you capacities and experience in design and production. Our production is for the customers who are different tools and machine producers, special machine builders working in the automotive industry, electrotechnical and furniture industry and in automatization of industrial manufacturing. If you are interested in cooperation with our company, do not hesitate to call us. Yours sincerelly Viena International Slovakia

Founded

1951

Employees

100 - 200

Certifications

Martin

Slovakia - 03601

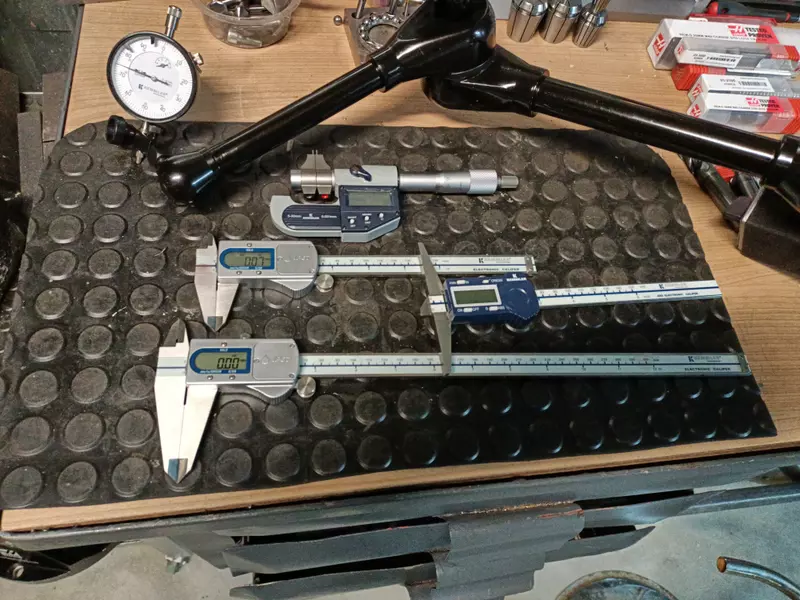

Since 2006, the company Bergbauer has established itself as a flexible and competent supplier of engineering and electronics industry in the field of metal cutting. With modern machining centers and tools to the latest technology, we can meet the different requirements. Our expertise lies in milling and turning of the item production to series production. The range of services covers the entire range of cutting tools to be processed materials, from plastics to aluminum, all kinds of non-ferrous metals and steels. Our young and flexible team of qualified staff is made up of technicians, skilled workers and trainees in the fields of mechanical engineering and machining Through continuous quality control, modern measuring devices and controlled manufacturing processes from receiving to shipping, it is possible always deliver us high and consistent quality.

Founded

1994

Employees

20 - 50

Certifications

Arnbruck

Germany - 93471

metal cutting technology, Steel, stainless-, brass turning, milling, grinding, inductive hardening, assembling

Founded

1969

Employees

50 - 100

Certifications

Winden

Germany - 79297

The company EDS-Maschinenbau GmbH was founded in 1989 as a contract manufacturer founded. At about 30 lathes and milling machines of different equipment produziern 35 employees and series parts.

Founded

1989

Employees

20 - 50

Certifications

Linnich

Germany - 52441

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

SINCE 2009 .... The company was founded in 2009 by Mrs. Bettina Landgraf-Kaiser, storage capacity today is about 3000 m² in three halls. As a leading warehouse distributors constantly about 100 cars and well-preserved machines of best brands offered. State of the art warehouses with crane capacity up to 10 tons and forklift capacities up to 7 and highly trained staff are the benefits for potential customers to find the "perfect machine". Complete "all-inclusive" packages (eg transport, introduction, installation Complete training) are developed and implemented according to your. MEMBER OF: Since 2009 FDM - Germany Since 2009 EAMTM - Brussels (International) SPECIALITY: Cutting metal-working machines Our specialty is the trade used machines from metal cutting. Whether conventional or CNC - controlled, we each offer the right machine for you.In CNC - area we act almost exclusively with the control type Fanuc & Heidenhain. Here we can give you the best - provide service, whether coverage with qualified staff, service staff or software solutions. OTHER: Furthermore, even spare parts - remakes produced directly in the house with us. Through years of experience of our employees in the cutting process on Fanuc & Heidenhain controls, we can therefore offer cost effective replacement parts alternatives you.

Founded

2009

Employees

5 - 10

Certifications

Bruchsal-Büchenau

Germany - 76646

Company with over 60 years of history in hot forging. It currently has 5+1 forging lines. The production departments are mainly these: 1 - steel warehouse 2 - cutting department 3 - DIES construction and assembly tooling 4 - hot forging steel 5 - heat treatment 6 - warehouse and shipping Other important departments : - Quality department - Technical Office - Work shop - Maintenance department.

Founded

1960

Employees

100 - 200

Certifications

SUMIRAGO

Italy - 21040

Rope clamps for chair lifts and cable cars, T-bar lifts Components for cable car construction, drive technology Camshafts, rocker arms, finger followers Shift forks Clutch baskets Precision parts for mechanical engineering Steel and aluminum snap hooks Belt buckles Drop forged parts machined Peening machine

Founded

1953

Employees

50 - 100

Certifications

Fulpmes

Austria - 6166

When working in higher levels we are RELIABLE yours. Tiger Lift is a subsidiary of the company Paksan in Turkey. Our parent company is 32 years active in the Turkish market for metal processing and is represented in more than 50 countries. Tiger Lift is a further development of the Turkish mother and is active in both down- and upstream active activities for metalworking and for crane and lift design. We offer extensive services around the material to metal as well as in the processing of. We also use our expertise in materials processing as well as in mechanical and automotive engineering to our customers reduce anew with tailored solutions always ahead. We are of the opinion that German craftsmanship is combined bring additional value with our international experience to our customers. We do not only follow the latest developments in our fields, we also develop self-innovation. Especially in mechanical and automotive engineering company Paksan has its research and development work massive boost to lay already the breeding ground for the work of tomorrow. Also in the metalworking sector, we are constantly keen to improve and expand our expertise. We are in constant contact with renowned research institutes in Turkey. This high demand is supported by the large number of certificates that have gotten our products. We strive every day with our successful staff who is always trying to improve and our products, yet offer you better services. When working in higher levels we are RELIABLE yours.

Founded

2013

Employees

50 - 100

Certifications

Wannweil

Germany - 72827

Hi , here we give you the reasons to work with us : Experience ; we are an small team of 11 working together since 2014 , we started provided reparations services for industrial machines ,as Romanian machines are old :) and spare parts impossible to find in 2015 we have started milling and turning to make the necessary parts . In house designed , manufactured and installed the parts for our customers :) . in 2021 we started milling parts for welding robots in auto industry as a subcontractor . We have build parts for robots to Audi , WV , Renault , PSA , Volvo and in 2023 for the shiny new Tesla plant in Berlin . Quality of manufacturing : -our milling machines are 2023 new :Haas Umc 750 and DMG FP3 , - we use Renishaw laser for 3D measuring the parts we produce - based on our experience we understand the applications of parts produced and we can adapt the manufacturing process for the best quality of parts . We monthly can mill in 5 axis up to 800 hours , and 400 turning CNC

Founded

2014

Employees

10 - 20

Certifications

Satu Nou De Jos

Romania - 437167

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge