Gravity die casting: find suitable suppliers in real time

Discover specialized suppliers for gravity die casting on Techpilot. Our platform connects buyers with suppliers who use advanced casting technologies to manufacture high-quality cast parts. Use the e-sourcing process to find the best suppliers.

270 suppliers for Gravity die casting

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

From our own (100% WFOE) production plant in China, we provide in-house manufacturing of injection molds and injection molded products. This is the only way how we can secure the quality and protect your Intellectual Property, so you can rest assured that your product is in safe hands. QDP has more than 25 years experience in injection molding and product development.

Founded

2007

Employees

50 - 100

Certifications

EX Duiven

Netherlands - 6921

Our core competencies are: Tools - Hard Metal Processing - Sheet metal rounds - Punching / pressing (tool Falling) - Punching-bending (Bihler machine) - Stamping - Injection molding, extruding - injection molding - Encapsulation of inserts - To water - Die-casting - Ingot - Machine molding (sand casting) Translation by Google Translate

Founded

2003

Employees

5 - 10

Certifications

Offenburg

Germany - 77652

With our experience in various casting techniques and finishing processes of various casting, we have been active in the market for more than 40 years. We support and relieve our customers and offer the possibility to deliver a complete product, from processing to after-treatment. Our mission We focus on designing, manufacturing and delivering a total package of products. You can call on us for small and large work, but you can also use a certain processing or finishing process for your products. We are happy to be your adviser and partner for all your castings, whether it is a single piece of product or a larger series of products. We cast, melt, rotate milling, assemble and construct your product exactly as you wish. We place high demands on our quality. With us, a product does not leave the warehouse until it meets all the requirements regarding the mechanical properties and conditions. That way you can be sure that you will receive the highest quality at a competitive price.

Founded

2018

Employees

50 - 100

Certifications

Doetinchem

Netherlands - 7002CA

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

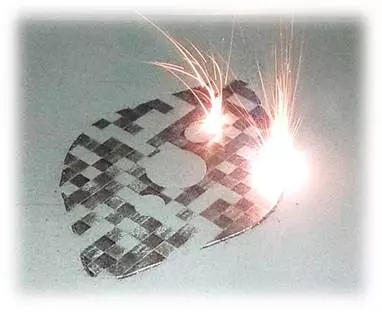

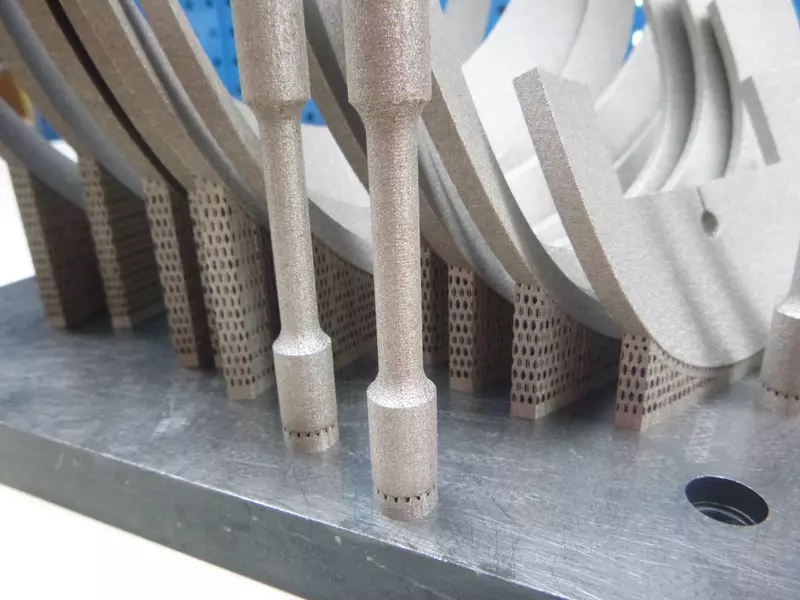

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

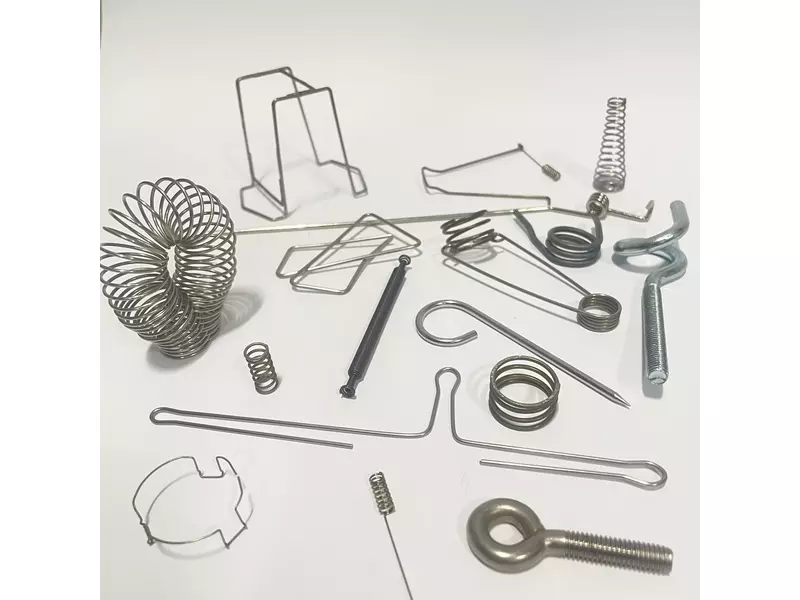

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

When working in higher levels we are RELIABLE yours. Tiger Lift is a subsidiary of the company Paksan in Turkey. Our parent company is 32 years active in the Turkish market for metal processing and is represented in more than 50 countries. Tiger Lift is a further development of the Turkish mother and is active in both down- and upstream active activities for metalworking and for crane and lift design. We offer extensive services around the material to metal as well as in the processing of. We also use our expertise in materials processing as well as in mechanical and automotive engineering to our customers reduce anew with tailored solutions always ahead. We are of the opinion that German craftsmanship is combined bring additional value with our international experience to our customers. We do not only follow the latest developments in our fields, we also develop self-innovation. Especially in mechanical and automotive engineering company Paksan has its research and development work massive boost to lay already the breeding ground for the work of tomorrow. Also in the metalworking sector, we are constantly keen to improve and expand our expertise. We are in constant contact with renowned research institutes in Turkey. This high demand is supported by the large number of certificates that have gotten our products. We strive every day with our successful staff who is always trying to improve and our products, yet offer you better services. When working in higher levels we are RELIABLE yours.

Founded

2013

Employees

50 - 100

Certifications

Wannweil

Germany - 72827

After many years of experience in drive technology and gear construction, Net-Components GmbH was founded in 2003 by Dipl.-Ing. Tarkan Peker. It is a DIN EN ISO 9001:2008 certified company. With our knowledge of the international market and with the goal-oriented way of working, we always strive for market-driven and customer-oriented solutions. The execution of complex tasks in series production, medium and small series production, as well as prototyping is carried out on modern machining centers, which guarantee a consistently high quality and flexibly realize customer requirements. We are able to make short-term as well as long-term investments depending on the order situation and thus secure the production with regard to quality, deadlines and prices. One of the company's principles is to manufacture our products economically using safe and environmentally friendly processes and to meet high quality standards. Our striving for constant improvement and cost-effective production leads to the competitiveness of our customers. We offer: - Turned parts - Milled parts - Forged parts - Complete assemblies Small or large series

Founded

2003

Employees

50 - 100

Certifications

Wustermark

Turkey - 14641

Since its founding in 1994, we deal with the handling and processing of metal parts according to drawings and specifications of our customers. We offer: - CNC - Turned parts - CNC - Milling - Weldments - Heavy mechanical engineering - Castings - Component Manufacturing - Punching and laser parts All surface treatments and heat treatments we can offer a complete package for you with our partners Our group of companies employs approximately 150 employees in the areas of CNC machining and welding constructions. "FOR YOUR BEST PERFORMANCE" We are an extension of your purchase and take responsibility for your performance

Founded

1994

Employees

50 - 100

Certifications

Oberneukirchen

Austria - 4181

Techpilot GmbH - DEMO

We are Europe's largest platform for the manufacturing industry.Since 2000, we have been connecting matching suppliers, buyers and manufacturers and enabling you to determine the right price of drawing parts. Every year, over 16,000 registered buyers inquire about more than 30,000 different parts on our platform with an average order value of 35,000 EUR. Registered suppliers can take advantage of strong online visibility, media reach and are given a lucrative sales channel.We serve the entire market for mechanical components and is the European market leader with 280 supported manufacturing technologies.

Founded

2000

Employees

20 - 50

Certifications

München

Germany - 81379

Founded

2001

Employees

20 - 50

Certifications

Dornhan

Germany - 72175

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

Hans Breuckmann founded our company in July 1966. In his one-man operation, he manufactured permanent mould casting parts from brass and silicon tombac in self-built furnaces. He gathered extensive practical experience while working as operations manager in a leading medium-sized enterprise. We are now in our second generation under the leadership of Volker Breuckmann and work with 80 employees to achieve joint success. The traditional permanent mould casting process has been supplemented by pressure die casting technology for heavy metals. Our range is completed by in-house mould construction and toolmaking, CNC machining technology and HSC milling technology. We are able to cover a complete work cycle with all required production steps, from designing a cast to mechanical processing. This provides us with direct access to all departments, which guarantees high quality and flexibility. The die is already cast for the future of our traditional company. Following his apprenticeship, Michael Breuckmann will join the company and follow in the footsteps of his grandfather and father, thus bringing the company into its third generation.

Founded

1966

Employees

50 - 100

Certifications

Heiligenhaus

Germany - 42579

YOUR GENERAL CONTRACTOR FOR FORMING and MOLDING! FORGING, HOT PRESSES KALTFLIESSPRESSSEN, FREE FORM FORGING IN STEEL, STAINLESS, ALUMINUM, BUNTMETALL, TITAN, FLANGE, RING, TRIMS, Longitudinally PIPES, FEINGUSS, SAND CASTING, DIE CASTING MACHINING PARTS OF FORM PART, OR FROM THE FULL PROFILE

Founded

1961

Employees

5 - 10

Certifications

Liestal

Switzerland - 4410

The medium-sized enterprises THIERBACH from Lower Hall near Heilbronn supplies Companies from all industries as tailored solutions for the Parts subject. TURNING AND MILLING PARTS THIERBACH processed according to your specifications, all machinable materials, including steel, stainless steel, brass, aluminum and bronze and precious metals and special materials for the aerospace industry. SINTERFACE PARTS For the production of sintered parts THIERBACH used exclusively powder with demonstrated high quality. Depending on requirements, the base material of various alloying elements are added. Formed In the area of formed THIERBACH offers various production options such as cold and hot extrusion. In addition, a mechanical, metal-cutting rework is possible. PUNCHING AND BENDING PARTS In the field of stamping and bending parts offers THIERBACH solutions of metallic and non-metallic materials that are manufactured on CNC machines.In addition, welding can be performed. LASER COMPONENTS In the area of laser parts are available from THIERBACH steel, stainless steel or aluminum products with extremely high precision contours in different thicknesses. CASTINGS In THIERBACH you get castings in all major manufacturing processes: aluminum die-casting, aluminum sand casting, zinc die casting, copper sand castings or precision castings. DEEP DRAWN PARTS THIERBACH provides you with high quality deep drawn parts made of stainless steel, aluminum, brass, bronze, iron, chromium or copper, either as a single function template or as a large series. ASSEMBLIES Not just when you need a single part, but even with demanding assemblies, you can count on THIERBACH: in partnership, economic and logistical point of view. CERTIFIED QUALITY An important part of THIERBACH quality philosophy is the maximum quality assurance in the production of your parts and assemblies. FACTS: QUALTÄTSSICHERUNG - Certification according to DIN EN ISO 9001:2008 - Erstmusterprüfberichtenach VDA - PPAP documentation - IMDS entries - Uniformity measurements - Surface measurements - Length measurements - Measuring equipment management - Sampling inspection according to AQL 1 - SPC tests Possibilities of surface and heat treatments Even when it comes ächen to the finishing of surfaces, THIERBACH provides organizational and economic advantages: Through partnerships with reputable companies you get: - Modern production techniques - Everything from prototype to mass production - Different machining options and THIERBACH all the possible rework and surfaces.In this way long and expensive transport routes and the total cost per piece If omitted significantly reduced. THIERBACH offers: Galvanizing / / Copper Passivation / / hard chrome plating Burnishing / / Gilding Dacromet / / Geomet coating Cadmium / / Nickel Chromate / / anodizing Phosphating / / pickling / / Silver Case hardening / / Inductive Glow / / start / / Slot Embossing / / Bending / / rubbing Lapping / / honing / / punching Engraving / / brushes Polishing / / electropolishing Grinding / / trowalizing Sand and glass bead blasting Flexible Logistics THIERBACH is not content to create the correct part, but is only satisfied when you is this the right time and at the right place. Thus, for example, already taken in the packaging that it contains all the elements for a smooth production: Logo, number, barcode.

Founded

1999

Employees

20 - 50

Certifications

Künzelsau

Germany - 74653

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

CASTING and FORGING PARTS BY CUSTOMER Together with our partner companies ISG industry service and Geiger Berger Industries, we offer you the opportunity to access from a wide range of different foundries, forging and machining company from Germany, Spain, Hungary and China. We take care of you this vendor selection, request, technical clarification, quality assurance, packaging, shipping and timely delivery of your products according to your drawings and specifications. Through our three locations in Germany, we are always in their vicinity: CFT Hanseatic Guss GmbH, 28195 Bremen ISG industry service Geiger e.Kfm., 73491 Neuler Berger Industries K., 50668 Cologne You have a question or want to get to know us? Please contact one of the below mentioned contact, we'll take care of everything else.

Founded

2004

Employees

10 - 20

Certifications

Bremen

Germany - 28197

Klava has been a full-service engineering and production company for aluminium and stainless steel casting products since 1946. Specialised from development to delivery of complete aluminium- and stainless steel castings, Klava aims to offer expertise and optimum total solutions to its customers, who require high quality standards and complex applications.

Founded

1946

Employees

10 - 20

Certifications

Rotterdam

Netherlands - 3045 PD

Delivery of castings and forgings including processing in Asia. The Asian partners have the appropriate approvals. ISO 9001: 2008 is granted. Approvals under the Pressure Equipment Directive (PED / AD 2000) or ship classification approval LRS, GL, DNV, BV available. Certificates available on request. Partner agencies on site to monitor the production as an indispensable part of our quality philosophy. Material: cast iron, ductile iron, cast steel, cast stainless steel, duplex Casting processes: investment casting, sand casting Form process: Hand molds and machinery forms Models: wood or metal

Founded

2010

Employees

< 5

Certifications

Hofheim am Taunus

Germany - 65719

We are an industrial and commercial agency with direct suppliers and production facilities in Poland, Czech Republic, China, Italy, Taiwan, India, Turkey and Germany. We design and produce together with our partners to our customers in the following areas: Welded structures such as caddies, storage racks, long-product pallets. Steel construction, welding in general. Surfaces such as rays, galvanizing, painting, powders. Sheet metal processing all materials: CNC punching, nibbling, edges, laser welding, cutting Fully automated bending center, powder coating, Deep drawing, laser cutting, punching from coil, components, Services according to customer requirements Turned parts, milled parts made of all materials Castings and their processing Plastic injection molded parts up to 2,500 grams weighing, + Toolmaking Extrusion plastic profiles Aluminum profiles and their processing Cable assemblies, wire harnesses, control boxes and control cabinets completely Agricultural Engineering Bent wire parts Diecast Bend and process tubes

Founded

1986

Employees

5 - 10

Certifications

Hörstel - Bevergern

Germany - 48477

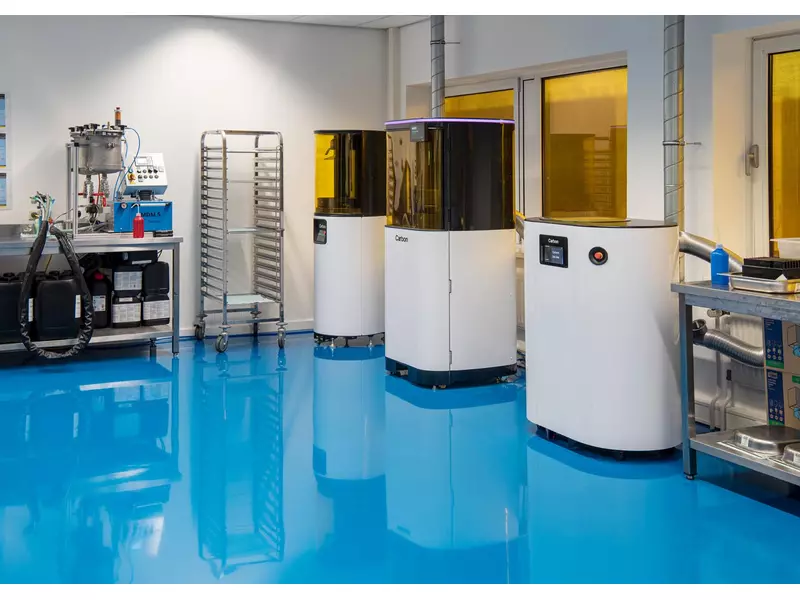

We specialize in Additive Manufacturing - particularly DMLS and precision CNC processes. From design conceptualization to AM, modeling, prototyping, serial production, and post-processing, we offer comprehensive Engineering and Manufacturing solutions tailored to drive your success.

Founded

Employees

5 - 10

Certifications

Valencia

Spain - 46013

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge