Fused deposition modelling: realize better purchase prices

Discover specialized suppliers for fused deposition modeling on Techpilot. Our platform enables buyers to find the best suppliers for this technology. Use our comprehensive supplier database to gain complete market transparency and optimize your procurement processes.

283 suppliers for Fused deposition modelling

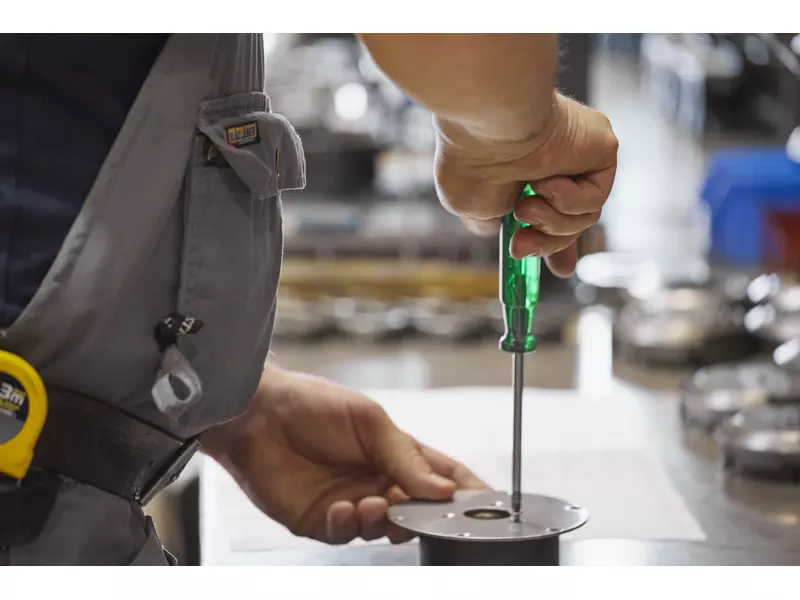

Since 2005 we develop with our partner companies, new approaches and innovative solutions for the production of technical parts and assemblies. Our slogan "New Thinking! New action! New ways! ", We carry a competent and reliable contribution to your company's success. We advise our customers both during the product development process as well as the optimization of existing products in terms of the structural design, as well as on the use of suitable production methods and materials. We specialize in rotary swaging, spin forming, cold forging, machining (cutting all kinds), sintering, MIM, hot forging, stamping, deep drawing, sheet metal forming of all kinds, die-cast zinc, cast aluminum, cast iron, fasteners, ductile iron, cast iron and lots more! We enable potential costs through the re-design of your purchasing parts with the help of TRIZ methods, value analysis and Attributive sourcing.

Founded

2005

Employees

10 - 20

Certifications

Rahden

Germany - 32369

Individuality and innovation - two tags that characterize the modern world of work. In our family the development of individual and holistic solutions for our customers for over eighty years program. With this philosophy, our company has successfully maintained on a challenging market. What has changed in that time, the technical possibilities. Thanks to modern means of production, the processing of sheet metal are virtually no limits today. A highly motivated team of around thirty-five employees would be to develop tailor-made solutions for our customers. A permanent training of employees and an innovative spirit development offer our customers the guarantee of a professional advice, reliability and quality. Outward sign of our high quality standards, the ISO 9001:2008 certification, which we have since 1996. Create and develop unusual, this is our daily challenge. Customer focus and experience are qualities which we have maintained for four generations in our company and want to keep up in the future.

Founded

1930

Employees

20 - 50

Certifications

Wil

Switzerland - 9500

Founded

1976

Employees

200 - 500

Certifications

Höchstädt a.d. Donau

Germany - 89420

TMV Vago is a company located close to Milano, specialized in precision mechanical machining. Born as a mechanical turning shop, over the time it has developed a set of technologies and skills that now collaborate in the mass production of mechanical components for various sectors: Turning, milling, laser cutting and welding. Machining from solid of multiple metals, some plastic materials, and sheet metal and three-dimensional laser cutting is carried out. Additionl services such ad mechanical assembly, laser marking, finishing are provided.

Founded

1991

Employees

5 - 10

Certifications

Gerenzano (VA)

Italy - 21040

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

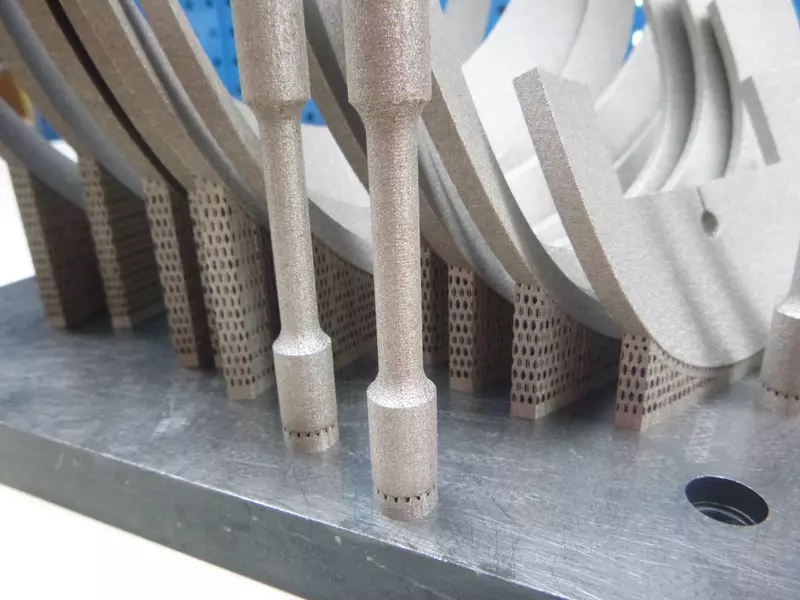

You would like to make metallic components additive? Are you interested in the possibilities of this technology? With the additive manufacturing of 3D-printing metal (SLM, Laser-cusing®, DMLS etc.) we offer you a production technology that is no longer used only in prototype production. This process offers completely new possibilities where conventional processes such as laser cutting, turning or milling reach their limits. This is a process that is used exclusively for the production of metal. As with 3D printing, the components are built up by layer-by-layer build-up and fusion of metal powder; the component has almost identical mechanical properties to the original material. You need support in implementing your automation project? Then you are exactly right with us! We realize complete manufacturing cells according to your idea. From the feasibility study on the construction and assembly to commissioning and on-site support, we are the right partner for your project. In particular, we cover the following areas of responsibility: - Project Management - Programming - 3D printing metal (additive manufacturing) - Security management - 3D scanning - Milling technology - Construction - Assembly - Hose packages - Service - Training Our 3D metal printing services at a glance: - construction work (cooling ducts, component optimization, etc.) - Checking the cooling channel design (flow simulation, thermal images, flow analyzes) - coatings - Plastic prototypes - Component measurement - Creation of plastic models - 3D scanning / reverse engineering - fine machining (milling, grinding, eroding etc.) - Surface treatment (anodizing, electropolishing, etc.) - hardening - welding

Founded

Employees

20 - 50

Certifications

Berlin

Germany - 10365

Innovative plastic products since 1989 The BÖHL-plastic GmbH & Co. KG specializes in the production certified technical precision injection molded thermoplastics. We cooperate with raw material manufacturers, but also with colleges and universities. Because the plastic processing is a challenging topic. Individual solutions are our strength. Our activities span the injection molding production for the lighting and automotive supplier industry. We are also working for the industries fittings, electrical and electronics, medical, furniture, steel and textiles. The headquarters of our plastic processing company located in southern Westphalia. Here we present for you since 1989 plastic parts from all common thermoplastics ago. We are supported by our own mold.

Founded

1989

Employees

20 - 50

Certifications

Bad Berleburg-Aue

Germany - 57319

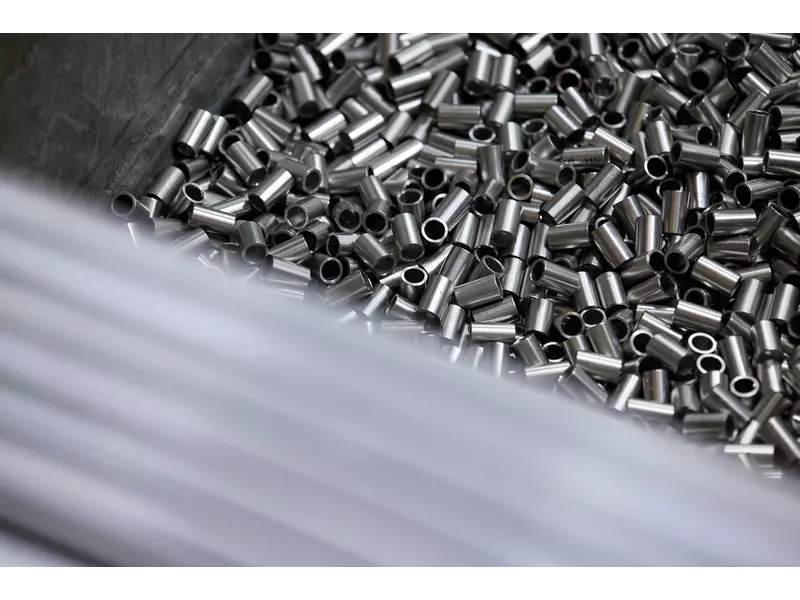

We are a small family company, which is engaged in metal bar processing. In the market we are present since 1990. We excel in quality service, high-speed production and exceptional adaptability to customer requests. We are dealing with producing axially symmetric products on conventional lathe machines and manufacture of products using CNC Swiss-type dual spindle lathes with driven tools for a wide variety of machining possibilities.

Founded

1990

Employees

< 5

Certifications

Begunje na Gorenjskem

Slovenia - 4275

FMT-Fertigungstechnik was founded on January 1st, 2020 by Felix Schweers. Many years of experience in various manufacturing processes, both in production and in a managerial position, mean that there are hardly any limits to finding solutions in this area. Thanks to our good network of companies from various industries, we can offer a large number of manufacturing processes and ensure the required quality. In product development, we can draw on a wealth of experience through the implementation and introduction of our own patents - from the idea to the design, to the prototype and finally to the finished product. Advantages for them -Low program costs thanks to our own CAM algorithms -Low set-up costs due to a high degree of digitization -Fast production of individual parts -Shipping internationally -24/7 available

Founded

2020

Employees

5 - 10

Certifications

Emertsham / Tacherting

Germany - 83342

Precision meets innovation. We are your partner for high-precision CNC-manufactured individual parts and specialized special parts for aerospace, and all demanding industries. We have the latest technology and produce according to your data, drawings, samples or ideas. Team and solidarity define work that is fun and develops the full potential of commitment, creativity and enthusiasm.

Founded

2024

Employees

10 - 20

Certifications

Varel

Germany - 26316

Founded

2001

Employees

20 - 50

Certifications

Dornhan

Germany - 72175

Injection We squirt for you all on behalf of small batches to larger blanket orders. Moldings with insert (eg metal) are possible. Upon request, we also take over the complete material management for your production order, and store the injection molding tools for you. You only call from, we do the rest for you. Mould With a choice of partner companies in Germany, Europe and Asia, we are able to create you an offer for your individual molding tool you define the number of cycles, number of cavities, as 1k / 2k tool etc. mounting service If you already have a fully developed product and are still looking for a suitable partner for the assembly of sub-groups or complex assemblies, we are pleased to offer our services. Our strength lies in a very precise mounting. Here we are particularly specialized in the soldering and bonding, accurate mounting crafted and reliable final inspection.

Founded

2013

Employees

20 - 50

Certifications

Meschede-Berge

Germany - 59872

With decades of experience and a proven track record, we are experts in designing and manufacturing – completely in-house – one off-machines and equipment, batches, advanced technical engineered solutions, including unique parts, robot cells and production lines. Production and assembly are carried out in our ISO9001/ISO14001 certified 2000 square meter site in Hungary, running on 60% renewable energy, with a team of over 50 professional colleagues. It also contains a separate machining department, space for assembling activities and a dedicated showroom. Our current logistics department allows us to ship and/or transport our products and solutions all over Europe, with a strong international team giving us the capabilities to communicative effectively with our customers in most European languages. With a particular expertise in the automotive, dairy, food and consumer good market, we have dozens of reference projects at your disposable.

Founded

1991

Employees

50 - 100

Certifications

Szekszárd

Hungary - 7100

Founded

1947

Employees

20 - 50

Certifications

Meschede

Germany - 59872

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

In 1982, Peter Sedlak, the CNC machining technology with an employee and three machines in Schwäbisch Hall. Were produced turned parts in small and medium-sized batches. Over the next few years, additional machines were added. The number of employees rose steadily. An increased demand for pre-finished parts made the first purchase of a conventional milling machine and a CNC machining center later inevitable. So it was always close in the rented hall and the desire to own a larger hall and getting stronger. In December 1991, finally, the company moved to Untermünkheim-Enslingen so that in January 1992, production could be included in the new hall. The economic downturn slowed in subsequent years, the growth of the company. But it soon went up again. Until 2000, all machines were replaced with new, more modern. In 2000, the certification according to DIN EN ISO 9002 was carried out. As of January 2002, the company operates under a new name. Peter Sedlak and his longtime collaborator and master Friedrich Schiele founded the Hohenlohe precision parts GmbH. Today, 12 employees produce pre-finished parts and assemblies for many satisfied customers from different industries. Various grinding work, as well as heat and surface treatments we have them implemented by competent and reliable partners. The reward for good quality and very little complaints are our satisfied customers.

Founded

1982

Employees

10 - 20

Certifications

Untermünkheim-Enslingen

Germany - 74547

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

The Pittrich GmbH CNC Turning & Milling created by machining Production of products made of metals and plastics on behalf of the customer. We produce individual parts, prototypes and medium-sized series. Based on our experience, looking back on a hitherto over 20 year old Company history, are among our clients leading companies from the areas:

Founded

Employees

10 - 20

Certifications

Lengenfeld

Germany - 86932

3D printing service for small series, functional parts and prototypes made of plastic.

Founded

2018

Employees

5 - 10

Certifications

Pfaffenhofen

Germany - 89284

As a Swiss company in the field of precision CNC milling and turning, we offer turned and milled parts of the highest quality, always on time and at competitive prices. You will never look for other CNC service providers again!

Founded

2022

Employees

5 - 10

Certifications

Fiesch

Switzerland - 3984

Plastic is our passion. Design our strength. In line with our guiding principle "Innovation in Plastics", we have been developing clever plastic solutions for the individual needs of our customers for decades. The high-quality plastic applications are produced exclusively by experts in our factory in Switzerland. 100% Swiss quality and genuine craftsmanship. No production line work. Reliability and timely delivery are very important to us. Cellwar is an owner-managed company. Benedikt Zenhäusern, Chairman of the Executive Board and Christian Poffet, Member of the Executive Board work day by day with more than 30 highly qualified and motivated employees on new ideas and solutions in processing technology. In order to get qualified junior staff, we directly train our own apprentices.

Founded

1906

Employees

20 - 50

Certifications

Gwatt bei Thun

Switzerland - 3645

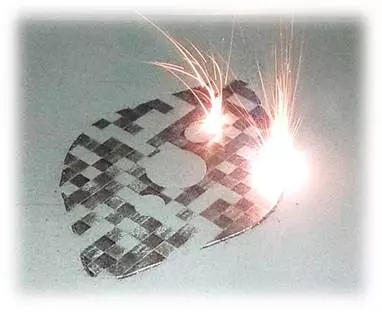

Since the 1960s, the Simaform company has mastered many manufacturing processes including 4 laser technologies: high-precision cutting, welding, engraving and marking, and metal 3D printing. But also wire erosion cutting (EDM), micro-milling, press shaping, heat treatment (quenching / tempering), deburring by tumbling, sanding and polishing. In addition, the Simaform design office supports and advises you at every stage of your project. Simaform is an expert in the manufacture of complex high-precision parts in fine sheet metal for all industry sectors as well as in 3D printing using metal powder. Simaform guarantees products perfectly suited to your needs with optimum quality and value to satisfy all domestic and International customers.

Founded

1960

Employees

20 - 50

Certifications

Eselborn

Luxembourg - 9779

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge