Cleaning: benefit from a efficient e-sourcing process

Discover specialized suppliers for cleaning on Techpilot. Our platform connects buyers with suppliers who offer various cleaning methods to clean and deburr your components. Use the e-sourcing process to find the best suppliers.

334 suppliers for Cleaning

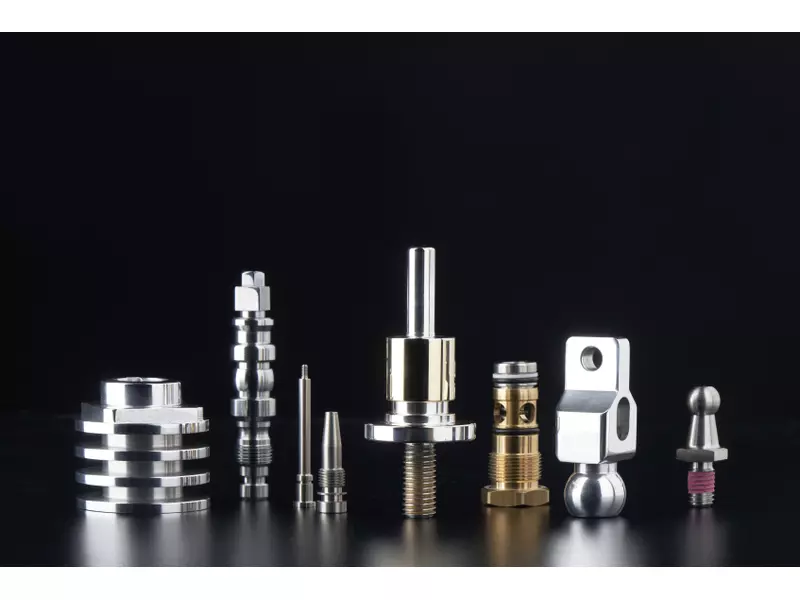

Manufacturer of series turned parts from all cut materials according to your specifications. In addition to being a reliable supplier, our major passion is the development of optimum solutions.

Founded

1971

Employees

50 - 100

Certifications

Gunningen

Germany - 78594

We provide machining services of unit parts, prototypes and short-run production. Problem-solving and provision of suitable machining solutions are what we do best. Our customers trust us because we are flexible with their enquiries and requirements, we deliver on-time and offer short- delivery times. This is what makes us stand out from the rest. The precision parts that we produced are known for its top quality, due to the raw materials used. Our experienced and passionate personnel carry a high sense of responsibility towards our customers and their product. We continue our expansion and growth, especially in technological developments. Our precision components are manufactured according to customer drawings, specifications and international standards. Design and production by reverse engineering method is also provided as a service. And finally, we offer competitive pricing, guaranteed!

Founded

1986

Employees

10 - 20

Certifications

Thessaloniki

Greece - 57022

Torneria OML is specialized in high precision CNC machining. Since 1982 we have been specialized in the processing of any type of metal. Thanks to the use of the latest generation and highly technological machinery, we are able to guarantee the highest quality and precision, always offering an excellent quality / price ratio. Our qualified and constantly updated staff is able to quickly manage any type of order, from small and medium-sized production to high-precision machining. Thanks to the adoption of modern CNC technologies, we have considerably reduced production times, greatly increasing the reliability of the productions themselves. To always guarantee quality products, we have introduced systematic checks according to UNI and ISO 9001: 2015 and ISO 14001: 2015 regulations. Our company is part of the ATI set up for participation in the project “Venetian mechanical manufacturers on behalf of third parties present themselves in Europe”, which will be implemented using the POR Veneto region funding, part of the ERDF. Thanks to the use of the latest generation and highly technological machinery, we are able to guarantee the highest quality and precision, always offering an excellent quality / price ratio. Our qualified and constantly updated staff is able to quickly manage any type of order, from small and medium-sized production to high-precision machining. We are specialized in the creation of components for the sectors: Valves, Gas Components, Pneumatic Components, Automotive, Hydraulics, Hydraulic, Naval, Nuclear, Oil.

Founded

1982

Employees

20 - 50

Certifications

Castelgomberto

Italy - 36070

KALİBRE MAKİNA TAAHHÜT TİC.LTD.ŞTİ. Köseköy San.Sit.M Blok No: 248 ZIP: 41250 Kartepe / KOCAELİ / TURKEY Tel: +90262 373 52 52 kalibre.mak@hotmail.com

Founded

2010

Employees

10 - 20

Certifications

Bornova-İzmir

Turkey - 35040

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Metalex is a metal working company from Croatia, which is continuation of family company Gumex Eko, founded in 1990. Our production site is located 50 kilometers from the capital – Zagreb, and 5 kilometers away from the highway. We have 1270m2 of indoor production facility space, and professional staff who can respond to any of your request. Our main activity is producing metal construction, laser cutting, bending and other metal processing. Our laser has dimension of the table 4000x2000mm and our bigger press brake is 4300mm long. We also have our own powder coating line with curing oven of 7 meter long. We are working in whole Croatian market, but we also export in Slovenia, Austria and Germany. Mostly of our products are powder coated, but we are also producing items which are electro galvanized, hot dip galvanized and made of stainless steel or aluminium. Laser Concept is a brand name for our products. Our production range is metal sheet production, CNC laser cutting, CNC metal sheet bending, MIG and TIG welding, tube cutting, tube bending, punching of holes and profiles, notching, and POWDER COATING. Continuously look for ways to improve our quality, process efficiency, training, working conditions, equipment, and technology. Long lasting relationships with our customers and vendors is a fundamental goal at Metalex. Metalex d.o.o. Nikola Devčić, managing director

Founded

2013

Employees

10 - 20

Certifications

Dubrava

Croatia - 10342

Your partner for fine sheet metal work - competent, innovative and flexible We are a family owned company in the field of sheet metal processing. As a system supplier, we specialize in the custom case production and the Production of sheet metal parts, assemblies and mechanical systems specializes. We manufacture the most modern equipment parts in the technologies stamping, punching lasers, laser (Trumpf), bending (trump), stud welding (Soyer) and Bolzeneinpressen (PEM, Haeger), milling (DMG), riveting, spot welding and welding. We have all the options to implement high-precision and highly complex designs. The own 3D design processes all common file formats. We design, of course, optimized for production in-house. We offer not only the powder coating on all major galvanic surfaces and screen printing. In our assembly we assemble electronic components to building complete electronic devices including commissioning, packaging and shipping. United with our qualified staff we offer you high quality products from prototypes to series production. B & S is a powerful partner from the idea to series production. We have the know-how, the capacity and the associated technology to deliver from simple stamping, laser part to the complex case or cabinet, all from one source.

Founded

2004

Employees

100 - 200

Certifications

Grafenau

Germany - 94481

Saint Jean Industries Stuttgart GmbH is specialized in the production of sophisticated light metal components. Our objective developing and implementing the best technical and economic solution for our customers. Executed by a highly motivated team, advanced manufacturing facilities, and a well-developed quality assurance according to ISO 9001:2015 and IATF 16949:2016.

Founded

1992

Employees

100 - 200

Certifications

Ilsfeld-Auenstein

Germany - 74360

We are a medium-sized company in the field of metal processing. Our core competencies include the production of series parts and assemblies for industry and plant and mechanical engineering, in particular the food and beverage industry. For over 75 years, Lungmetall OHG has stood for efficiency, flexibility and competence in steel, stainless steel and aluminum. Whether individual or series production, with our modern machine park tailored to the requirements of our customers, we manufacture for you flexibly, inexpensively and quickly. We are lean enough to flexibly implement your ideas and wishes, but also large enough to provide you with the capacity you need, even for large series. Thanks to our high level of vertical integration, we appear on the market as a system supplier, as we are not dependent on other trades. This manifests itself in short delivery times and a high quality standard. With our currently 60 employees and our in-house design office, we offer you an extensive service portfolio and reliable processing of your orders! We would be happy to win you as a valued customer and assure you of a partnership and team-oriented cooperation.

Founded

1924

Employees

50 - 100

Certifications

Kottenheim

Germany - 56736

LEIKO SA, founded in 1962, is an innovative SME that manufactures your individual parts and small series with a lot of power and passion for perfection. The fascination lies in the diversity of our work and the quest for the highest quality — down to the smallest detail. If you're looking for a complete solution for your design, you've come to the right place. We specialize in the production of complex precise components, instruments, assemblies as well as in general tool and device manufacturing. In addition to extensive technical experience, you benefit from the absolutely discreet handling of the manufacturing principles and information provided to us. Thanks to our highly qualified and flexible employees, we are also able to fulfill express orders on time. We are proud to offer excellent customer service, convinced of the importance of a successful business relationship in our specialized industrial segment.

Founded

1962

Employees

5 - 10

Certifications

Bettlach

Switzerland - 2544

Founded

1949

Employees

200 - 500

Certifications

Tittmoning

Germany - 84529

The company EDS-Maschinenbau GmbH was founded in 1989 as a contract manufacturer founded. At about 30 lathes and milling machines of different equipment produziern 35 employees and series parts.

Founded

1989

Employees

20 - 50

Certifications

Linnich

Germany - 52441

Sheet metal processing, surface processing and Zerpanung everything from one source. Sheet metal fabrication - CNC laser cutting / CNC punching - Edges and rollers - CNC stud welding Welding steel / stainless steel / aluminum - Separate production halls for Stainless Steel (Food & Pharma) - TIG / MIG / MAG - Laserwelding with 6-axis Roboter - Sheet metal supply parts to complex housing Surface treatment - Steel / Aluminium * Our own powder coating * Zinc plating / anodizing / barrel finishing (with partner companies) - Stainless Steel * Glass bead blasting * Grinding / Brush * High gloss polishing Machining - Turning * CNC turning up to 12 driven tools * NC turning - Milling * CNC milling with up to 5 axes. Special precision even at Langen components (up to 2.6 meters) * NC milling Assembly - Pre and final assembly - side assembly - Enduser and oversee packing Construction on behalf of customers - Over 20 CAD workstations Translation by Google Translate

Founded

1982

Employees

100 - 200

Certifications

Everswinkel

Germany - 48351

We are a company dedicated to ugarisches sheet metal processing and exciting machining by machining centers for small and medium series .. The focus of our work lies in the production of complex assemblies including assembly such as FTS, Heber and packaging machines. Our machinery, we continuously expand and modernize one of the most modern in Hungary. From single part production through installation to commissioning of the modules and machines, we can offer the full range of services you need. Give us a try. We put an offer below that will convince you.

Founded

1993

Employees

50 - 100

Certifications

Kiskörös

Hungary - 6200

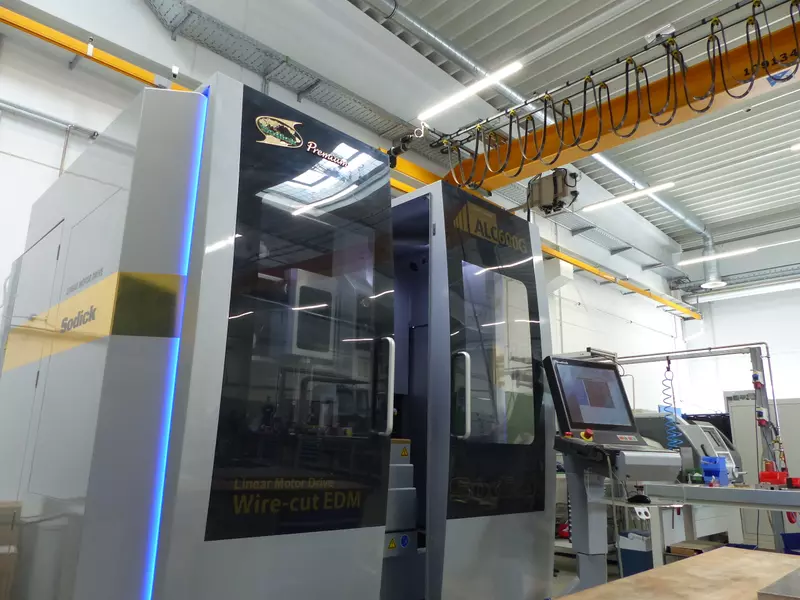

SINCE 2009 .... The company was founded in 2009 by Mrs. Bettina Landgraf-Kaiser, storage capacity today is about 3000 m² in three halls. As a leading warehouse distributors constantly about 100 cars and well-preserved machines of best brands offered. State of the art warehouses with crane capacity up to 10 tons and forklift capacities up to 7 and highly trained staff are the benefits for potential customers to find the "perfect machine". Complete "all-inclusive" packages (eg transport, introduction, installation Complete training) are developed and implemented according to your. MEMBER OF: Since 2009 FDM - Germany Since 2009 EAMTM - Brussels (International) SPECIALITY: Cutting metal-working machines Our specialty is the trade used machines from metal cutting. Whether conventional or CNC - controlled, we each offer the right machine for you.In CNC - area we act almost exclusively with the control type Fanuc & Heidenhain. Here we can give you the best - provide service, whether coverage with qualified staff, service staff or software solutions. OTHER: Furthermore, even spare parts - remakes produced directly in the house with us. Through years of experience of our employees in the cutting process on Fanuc & Heidenhain controls, we can therefore offer cost effective replacement parts alternatives you.

Founded

2009

Employees

5 - 10

Certifications

Bruchsal-Büchenau

Germany - 76646

We manufacture various plastic components individually according to your wishes and requirements, as well as support you with our know-how in the planning and implementation of your project. With our various processing methods, we have the possibility to carry out the entire component processing. Alternatively, we will be glad to assist you in subsequent work such as contour adjustments or deburring of existing components.

Founded

2017

Employees

10 - 20

Certifications

Murr

Germany - 71711

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

High-quality products – from the concept to the finished part. EVN Blechverarbeitung manufactures individual parts and series production from aluminum, stainless steel, and steel for the mechanical engineering and automotive industries. Our machinery includes high-tech laser and bending machines, such as the Trumpf Fiber, which operate with the highest precision. With 24 kW of power, we can cut sheet metal up to 60 mm thick.

Founded

2000

Employees

10 - 20

Certifications

Peißenberg

Germany - 82380

MAKROSAN was founded as a family company with the production experience of more than 30 years and is mainly focused in turning & milling, sheet-metal cutting, laser cutting, sheet bending, pipe and profile bending, welding and assembly operations for the automotive, furniture, mechanical engineering, construction, agriculture and supplier industries. We manufacture according to your drawing specifications many varied parts: from aluminum to titanium. In the metal sector, we know almost no limits. We started with CNC laser cutting. Encouraged by the growing demands of our customers, we have added more technologies to our production spectrum over time; CNC bending, hand welding and robot welding, assembly assembly and CNC profile and tube bending. We can also offer CNC tube laser, CNC machining / milling / turning. We also have other business partnerships that we have been working together for years in the metal sector as well as the stamping, pressing parts and fasteners and tooling. We also have cold and hot formed parts made. Our company is located in Bursa, in the heart of the Turkish industry. Our company is certified by PCA to ISO 9001. MAKROSAN PROMOTION FILM: https://www.youtube.com/watch?v=Wn_3hNaqo5I As a competent supplier of sheet metal and metalworking and other areas, we work nationwide with well-known companies. We also export to several companies throughout Europe. We are interested in a long-term, strategic cooperation with your company. Best regards from Bursa! Murat RAHİMOĞLU Managing Sales Manager / Managing Director MAKROSAN METAL - Flexible Sheet & Metal Processing Mobile: +90 542 360 45 12 Mail: mr@makrosanmetal.com.tr MAKROSAN METAL San. & Tic. Ltd. Şti. Kayapa Sanayi Bölgesi, Orkide Cad. No: 9 16315 Bursa / TURKEY

Founded

2012

Employees

20 - 50

Certifications

BURSA

Turkey - 16315

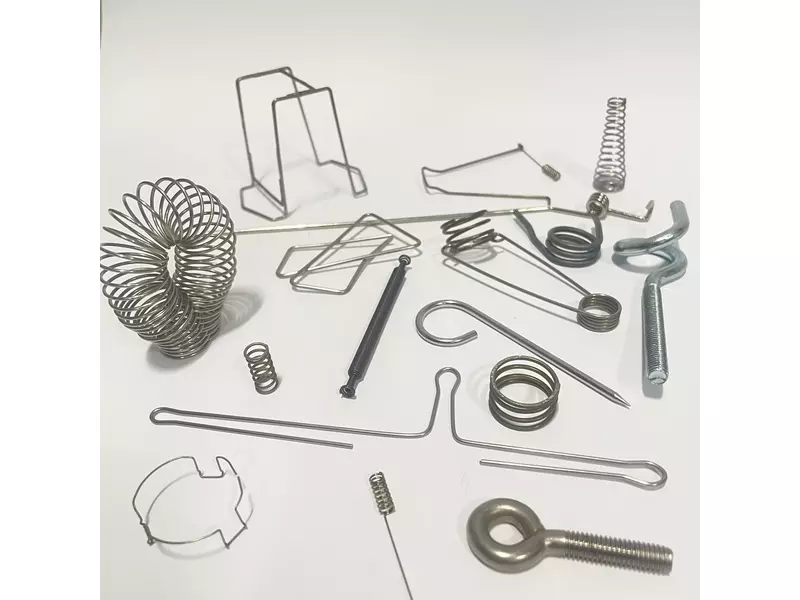

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

Founded

2018

Employees

20 - 50

Certifications

Eitensheim

Germany - 85117

As a system supplier for electromechanical assemblies, we manufacture plastic and metal components using hybrid technology. This means that we concentrate on the production technologies of plastic injection moulding and punching and bending of metal components. The advantage for you is that you can obtain ready-assembled assemblies of the most diverse production processes from one source. By moving Friedrich Joerg GmbH in 2016 to newly built production and office premises, we were able to create a capacitive buffer. Thanks to a high degree of automation, we can offer you particularly competitive prices. We manufacture manually in small series up to large series fully automated and pre-assemble all components for you. In short, we adapt flexibly to your requirements. We provide support as early as the product development stage in order to take into account quality, cost and tool-specific aspects in the early phase. We manufacture the necessary tools or devices in our own tool shop. This also allows us to increase our flexibility, for example in case of short-term changes. Furthermore, we also offer finishing processes such as: printing on plastic parts (cliché/pad printing), hot foil stamping for a particularly noble appearance of the products, machining and ultrasonic welding. It goes without saying that we are certified according to ISO 9001:2015 and deliver a very high and consistent quality. We would be pleased if you contact us. categories: Electromechanical assemblies; Foil hot stamping; Customised plastic mouldings; Plastic optical fibres; Optical fibre components; Optical fibre systems; Optical fibre technology; Optical fibre transmission systems; Pre-assembly Assembly of small parts for industry; Assembly of plastic components; Assembly of mechanical components; Stamp-bending parts made of stainless steel, non-ferrous metal, steel; Stamp-bending tools; Connectors; Connectors for surface mounting; Complete plug connections; Pad printing; Thermoplastic precision mouldings; Thermoplastic overmoulding with plastic; ultrasonic welding of plastics; overmoulding tools for insert parts; 3-D MID components; connecting terminals for power cables low voltage & high voltage; component assembly; die casting; mould making; housings for the electrical industry; terminals for electrical cables; plastic injection moulded parts; plastic injection moulded parts with metal insert; electrotechnical plastic parts; technical plastic parts; plastic processing; multi-component injection-moulded parts; plastic-injected metal parts; product development; prototype construction; terminal blocks; technical injection-moulded parts; thermoplastic elastomer (TPE) moulded parts; jig and fixture construction; toolmaking; two-component injection-moulded parts; Imprint: https://www.friedrich-joerg.com/kontakt/impressum/ Privacy policy: https://www.friedrich-joerg.com/kontakt/datenschutzerklaerung/

Founded

1920

Employees

50 - 100

Certifications

Marktrodach

Germany - 96364

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge