Pad printing for precise prints

Find specialized suppliers for pad printing on Techpilot. Our platform offers access to suppliers who use this printing technique to achieve precise and high-quality prints. Use the e-sourcing process to find the best suppliers and optimize your procurement costs.

153 suppliers for Pad printing

Founded

1933

Employees

20 - 50

Certifications

Forchheim

Germany - 91301

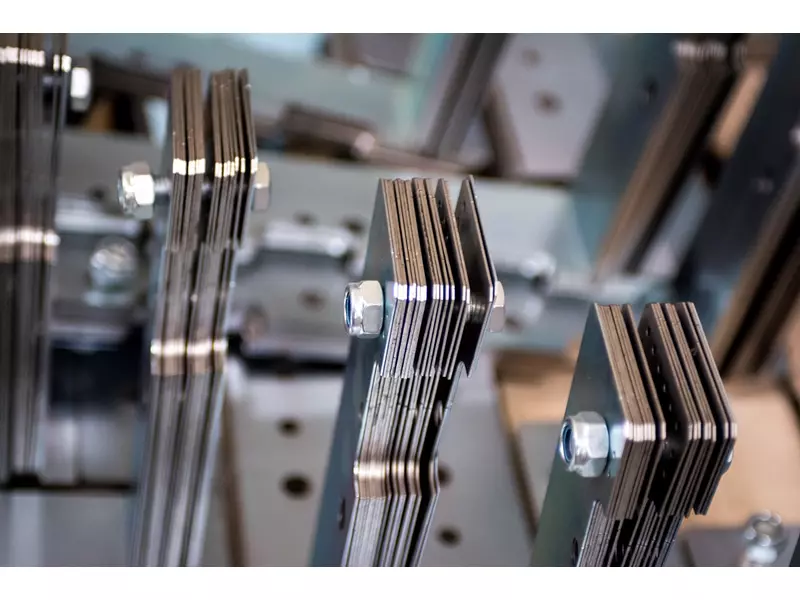

Your partner for fine sheet metal work - competent, innovative and flexible We are a family owned company in the field of sheet metal processing. As a system supplier, we specialize in the custom case production and the Production of sheet metal parts, assemblies and mechanical systems specializes. We manufacture the most modern equipment parts in the technologies stamping, punching lasers, laser (Trumpf), bending (trump), stud welding (Soyer) and Bolzeneinpressen (PEM, Haeger), milling (DMG), riveting, spot welding and welding. We have all the options to implement high-precision and highly complex designs. The own 3D design processes all common file formats. We design, of course, optimized for production in-house. We offer not only the powder coating on all major galvanic surfaces and screen printing. In our assembly we assemble electronic components to building complete electronic devices including commissioning, packaging and shipping. United with our qualified staff we offer you high quality products from prototypes to series production. B & S is a powerful partner from the idea to series production. We have the know-how, the capacity and the associated technology to deliver from simple stamping, laser part to the complex case or cabinet, all from one source.

Founded

2004

Employees

100 - 200

Certifications

Grafenau

Germany - 94481

We manufacture various plastic components individually according to your wishes and requirements, as well as support you with our know-how in the planning and implementation of your project. With our various processing methods, we have the possibility to carry out the entire component processing. Alternatively, we will be glad to assist you in subsequent work such as contour adjustments or deburring of existing components.

Founded

2017

Employees

10 - 20

Certifications

Murr

Germany - 71711

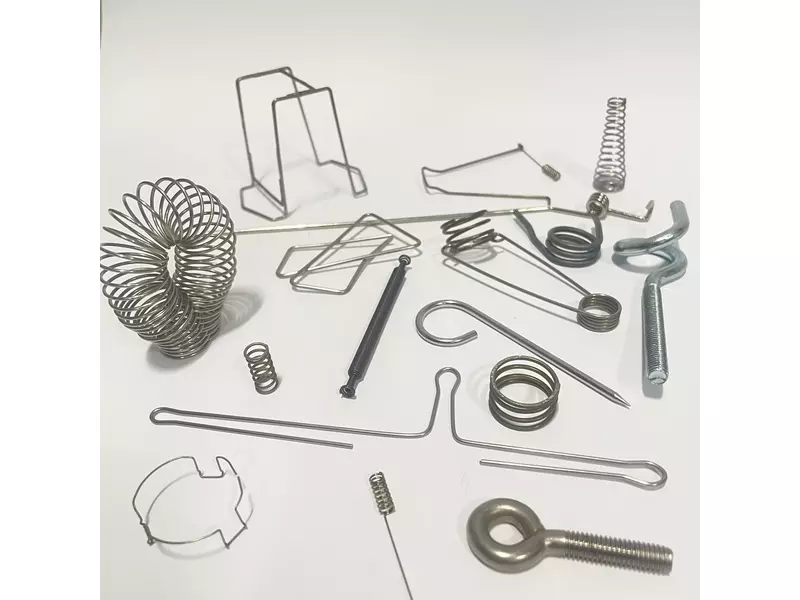

Welcome to the world of precision parts We are pleased that we can imagine in this way with you a powerful supplier of CNC turned parts, CNC milling parts, bending parts, the complete CNC sheet metal and especially the mechanical assembly. In the area of our assembly often diverse precision parts, such as aluminum machined parts, plastic machining parts, wire parts, laser cutting of stainless steel and metal stampings used to complete some complex mechanical + electro-mechanical assemblies. This in turn requires an extensive technology park ahead of puts us in a position to open up a very broad range of cutting and non-cutting metal and plastic processing, such as the manufacture of precision aluminum milling parts, brass turned parts, turned parts and laser blanks. This will open up with just a central partner considerable parts and technology spectrum in the field of precision parts. Although we sometimes are merely a supplier of CNC machined parts, CNC turning parts or bending parts, our tasks go beyond the mere delivery of structural parts by far. We are often a development partner for stamping parts, the CNC sheet metal and aluminum milled parts and also possess expertise in materials and technology experience. As a result, we are rather a QUALITY and COST OPTIMIZER. Customer satisfaction is our ultimate goal. Therefore, we are a value-added partner that ensures this requirement through comprehensive services, innovative technologies and reliable communication. This in turn leads to positive effects in the areas of cost reduction, security of supply and increase productivity. We are happy to provide you with reference products such as aluminum milled parts, brass turned parts, plastic machining parts and turned parts from our prior production and develop according to your requirements, for example, complex precision turning parts, stamping bending parts, wire parts or CNC turned parts.

Founded

1995

Employees

20 - 50

Certifications

Hildesheim

Germany - 31139

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

VJB PARTNER s r.o. is interested in the production of plastic and metal components for electrotechnical industry, telecommunications, building industry and other related industries. Most of our production is exported to the EU. Available technology: injection moulding, stamping, bending, powder coating, production and maintenance of injection moulds and tools. Thanks to reconstruction of our production areas, we also offer assembly work. In the preparation of new production we focus on the right quality settings, so that we meet customer expectations. Our efficiency, flexibility and short delivery terms are the base for functional business relationship.

Founded

1995

Employees

50 - 100

Certifications

Jáchymov

Czech Republic - 36251

As a system supplier for electromechanical assemblies, we manufacture plastic and metal components using hybrid technology. This means that we concentrate on the production technologies of plastic injection moulding and punching and bending of metal components. The advantage for you is that you can obtain ready-assembled assemblies of the most diverse production processes from one source. By moving Friedrich Joerg GmbH in 2016 to newly built production and office premises, we were able to create a capacitive buffer. Thanks to a high degree of automation, we can offer you particularly competitive prices. We manufacture manually in small series up to large series fully automated and pre-assemble all components for you. In short, we adapt flexibly to your requirements. We provide support as early as the product development stage in order to take into account quality, cost and tool-specific aspects in the early phase. We manufacture the necessary tools or devices in our own tool shop. This also allows us to increase our flexibility, for example in case of short-term changes. Furthermore, we also offer finishing processes such as: printing on plastic parts (cliché/pad printing), hot foil stamping for a particularly noble appearance of the products, machining and ultrasonic welding. It goes without saying that we are certified according to ISO 9001:2015 and deliver a very high and consistent quality. We would be pleased if you contact us. categories: Electromechanical assemblies; Foil hot stamping; Customised plastic mouldings; Plastic optical fibres; Optical fibre components; Optical fibre systems; Optical fibre technology; Optical fibre transmission systems; Pre-assembly Assembly of small parts for industry; Assembly of plastic components; Assembly of mechanical components; Stamp-bending parts made of stainless steel, non-ferrous metal, steel; Stamp-bending tools; Connectors; Connectors for surface mounting; Complete plug connections; Pad printing; Thermoplastic precision mouldings; Thermoplastic overmoulding with plastic; ultrasonic welding of plastics; overmoulding tools for insert parts; 3-D MID components; connecting terminals for power cables low voltage & high voltage; component assembly; die casting; mould making; housings for the electrical industry; terminals for electrical cables; plastic injection moulded parts; plastic injection moulded parts with metal insert; electrotechnical plastic parts; technical plastic parts; plastic processing; multi-component injection-moulded parts; plastic-injected metal parts; product development; prototype construction; terminal blocks; technical injection-moulded parts; thermoplastic elastomer (TPE) moulded parts; jig and fixture construction; toolmaking; two-component injection-moulded parts; Imprint: https://www.friedrich-joerg.com/kontakt/impressum/ Privacy policy: https://www.friedrich-joerg.com/kontakt/datenschutzerklaerung/

Founded

1920

Employees

50 - 100

Certifications

Marktrodach

Germany - 96364

We work in contract manufacturing, manufacture products according to customer's drawing, made of steel, stainless steel, aluminum, etc. We have our own design department and offer a complete service, including surface treatment and shipping. We love challenges! Our priority is our satisfied customers.

Founded

2012

Employees

50 - 100

Certifications

Aldeia de Paio Pires

Portugal - 2840-050

Our company is a 68-year-old company and with its expert team and qualified product selection, we offer our customers and the companies that choose us the opportunity to work together by prioritizing quality. Our company video https://youtu.be/iOXV0C5f_v8?si=kLx2VGLXe1QAvMev

Founded

1957

Employees

200 - 500

Certifications

Gaziantep

Turkey - 27100

VPL d.o.o. comprises knowledge, innovativity, experience and technology in plastic injection moulding, plastic aqua-lacquering, vacuum evaporation and metallisation for almost 60 years. With the emphasis on innovativity and development our clients are offered an integrated solution – carrying out a desired project from a conceptual draft or idea to realisation and final product. Due to the production specifics our knowledge, experience, flexibility and work input are of the utmost importance, as they lead to high-quality products. Production circle is completed with meticulous control of final products; very high criteria is used throughout the whole production process.

Founded

1965

Employees

20 - 50

Certifications

Ljubljana

Slovenia - 1000

The firm Joh Treschnak was founded in 1978. She pursued from the beginning a two-pronged strategy based on metal products according to customers' drawings on the one hand and thermoplastic injection molded parts on the other. In line with the growing demands in the metal-processing area of our machinery has been steadily expanded. The Ter Steege Groep 2003 took over its long-standing Liferanten and supports the company in their current business fields in full. By moving to the new factory buildings at the site Zollhausstraße 5 in 2004, the company also equips spatially for future requirements For more info you like to see at our presentation.

Founded

1978

Employees

20 - 50

Certifications

Iserlohn

Germany - 58640

Surfaces with system The Matthias Wetzel Industriebeschriftungen GmbH stands for the treatment, processing and labeling of surfaces. She has mastered technologies such as laser marking, engraving and mechanical parts, screen and pad printing, powder coating and painting as well as precision finishing, drag finishing and processing. Both the printing of round surfaces especially of optical components and surfaces of tools, trim panels, front panels, labels, watches trays, implants, scales, mechanical parts and complete assemblies can be coated and grafted. We are certified according to DIN EN ISO 9001, DIN EN ISO 14001 and OHSAS 18001 for laser-etched labels we are CSA approved supplier for the North American market.

Founded

1999

Employees

20 - 50

Certifications

Jena

Germany - 07747

The medium-sized enterprises THIERBACH from Lower Hall near Heilbronn supplies Companies from all industries as tailored solutions for the Parts subject. TURNING AND MILLING PARTS THIERBACH processed according to your specifications, all machinable materials, including steel, stainless steel, brass, aluminum and bronze and precious metals and special materials for the aerospace industry. SINTERFACE PARTS For the production of sintered parts THIERBACH used exclusively powder with demonstrated high quality. Depending on requirements, the base material of various alloying elements are added. Formed In the area of formed THIERBACH offers various production options such as cold and hot extrusion. In addition, a mechanical, metal-cutting rework is possible. PUNCHING AND BENDING PARTS In the field of stamping and bending parts offers THIERBACH solutions of metallic and non-metallic materials that are manufactured on CNC machines.In addition, welding can be performed. LASER COMPONENTS In the area of laser parts are available from THIERBACH steel, stainless steel or aluminum products with extremely high precision contours in different thicknesses. CASTINGS In THIERBACH you get castings in all major manufacturing processes: aluminum die-casting, aluminum sand casting, zinc die casting, copper sand castings or precision castings. DEEP DRAWN PARTS THIERBACH provides you with high quality deep drawn parts made of stainless steel, aluminum, brass, bronze, iron, chromium or copper, either as a single function template or as a large series. ASSEMBLIES Not just when you need a single part, but even with demanding assemblies, you can count on THIERBACH: in partnership, economic and logistical point of view. CERTIFIED QUALITY An important part of THIERBACH quality philosophy is the maximum quality assurance in the production of your parts and assemblies. FACTS: QUALTÄTSSICHERUNG - Certification according to DIN EN ISO 9001:2008 - Erstmusterprüfberichtenach VDA - PPAP documentation - IMDS entries - Uniformity measurements - Surface measurements - Length measurements - Measuring equipment management - Sampling inspection according to AQL 1 - SPC tests Possibilities of surface and heat treatments Even when it comes ächen to the finishing of surfaces, THIERBACH provides organizational and economic advantages: Through partnerships with reputable companies you get: - Modern production techniques - Everything from prototype to mass production - Different machining options and THIERBACH all the possible rework and surfaces.In this way long and expensive transport routes and the total cost per piece If omitted significantly reduced. THIERBACH offers: Galvanizing / / Copper Passivation / / hard chrome plating Burnishing / / Gilding Dacromet / / Geomet coating Cadmium / / Nickel Chromate / / anodizing Phosphating / / pickling / / Silver Case hardening / / Inductive Glow / / start / / Slot Embossing / / Bending / / rubbing Lapping / / honing / / punching Engraving / / brushes Polishing / / electropolishing Grinding / / trowalizing Sand and glass bead blasting Flexible Logistics THIERBACH is not content to create the correct part, but is only satisfied when you is this the right time and at the right place. Thus, for example, already taken in the packaging that it contains all the elements for a smooth production: Logo, number, barcode.

Founded

1999

Employees

20 - 50

Certifications

Künzelsau

Germany - 74653

Brewhouse develops and manufactures complex, close-tolerance stamping and bending parts for their own assemblies. Fixed partners in close proximity produce these parts SUDHAUS tools. Are used: Ribbons, wire and sections of steel, brass, bronze and chrome-nickel steel. The SUDHAUS tool and equipment meets all Requirements for the efficient production of various tools and equipment. High quality plastic and versatile manufacturing techniques provide the user with countless alternatives. In product development and design of the imagination are almost no limits. SUDHAUS has acquired a special know-how of the painting, the highest demands erfüllt.Teile the so-called Tag-/Nacht-Design not only found in the vehicle industries. The use of modern technology enables individual labeling of parts.

Founded

1844

Employees

100 - 200

Certifications

Iserlohn

Germany - 58644

Every company works best when all employees are happy to do their job every day and with a great deal of commitment. Just like ours: A well-rehearsed, down-to-earth team, an uncompromising approach to quality and the right mix of experience and youth. We supply ready-to-install components, including the required surfaces and heat treatments, including Empb, CoC, CMM measurement protocols.

Founded

2011

Employees

10 - 20

Certifications

St. Marein im Mürztal

Austria - 8641

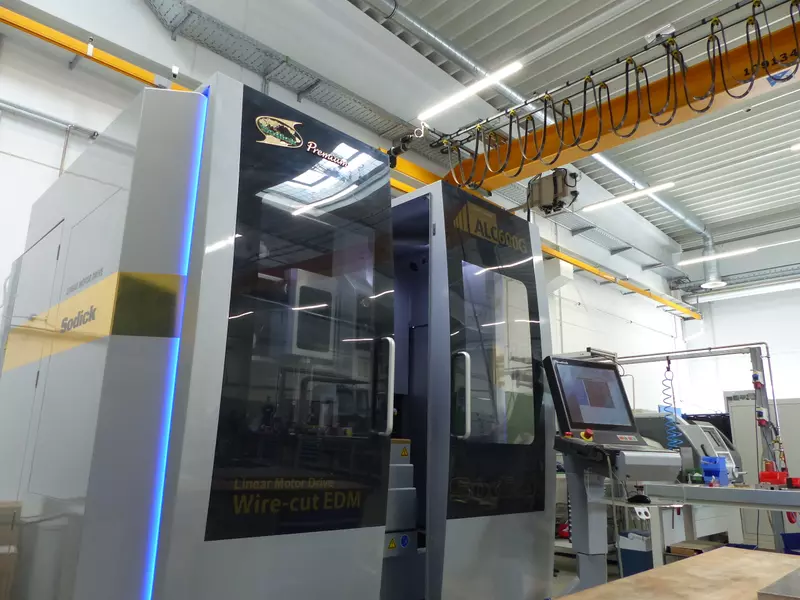

Our customers are offered everything they need within our group of companies, all in one basket: from development and project management via the production of tools for plastic and metal fabrication, through to manufacturing the parts. In this way we closely co-operate with our customers in developing functional structural plastic and metal components on the basis of the design, thereby achieving an optimum combination between plan, design, manufacture, and cost structure. The integrated possibilities have enabled us substantially to shorten the project run up to the point of series production. The systems Pro-engineer and Catia, available to our staff, permit the creation of structural components and tools, "in one casting" as it were. Injection Moulds Our staff in the individual manufacturing areas have state-of-the-art technologies and most up-to-date machines (such as 12-wire and 15-wire cavity sinking EDM machines) at their disposal. In producing moulds with a guaranteed number of shots, especially for the automobile industry and consumer electronics, our dictum is precision and quality. This holds true for injection moulds, diecasting, duroplastic, two-component, rotating, transfer and insert/outsert moulds, just as much as it does for two-colour moulds, combinations of hard and soft plastics, automatic wire leads, in-mould decoration, and precision gear wheels. Rapid tooling with the aid of our EOS metal sintering machine M250 Extended makes it possible to produce mould inserts for injection moulds and prototype tools within a very short time. Eighty moulding machines in Vienna and Hungary, with a clamping force of between 25 and 1,100 tons, offer all the possibilities of manufacturing moulded, thermosetting and duroplast, gas-injection moulded, two-component moulded, insert and outsert moulded, as well as in-mould decoration parts. Our machines are equipped with automatic robot systems, and automatic packaging lines complement the production line. Vienna: 3-shift operation / technical products and precision parts with a mould clamping force of up to 500 tons, Hungary: 4-shift operation / technical products and design parts with a mould clamping force of up to 1,100 tons. Your plastic parts are coated in three fully automated painting lines on a water-soluble basis (single-component or two-component coating). Your metal parts are electrostatically painted, from the smallest parts up to housing coatings for consumer electronics.

Founded

1966

Employees

100 - 200

Certifications

Wien

Austria - 1230

Would you like to know which suppliers are ideally suited to your requirements?

Register now and submit your request.

Founded in 1985 Certified according to TS 16949:02 Audit according to DIN EN ISO 14001:2005 Technical advice for the development of cost-effective and tool fair injection moulded parts Project management, for each of your products you will have a competent person to turn to in our company Construction of process-safe injection moulding and punching tools on the premises Samples as per PPAP Level 1 to 5 and VDA 6.1 Establishing of initial samples test certificates according to VDA script vol. 2, fig. 3 Own toolmaking in case optimizing is required on your injection moulding tools Favourable auxiliary tools, good pre-series tools, process-safe serial tools and high-quality punching tools Takeover of existing tools is possible 35 Precision injection moulding machines with a locking pressure from 15t to 250t Precision injection moulded parts from 0,01g to 400g Two-component injection moulding Precision plastic parts with insert parts from Germany and Czech Republic Round-injecting of artificial leather High-quality articles with Tampon-Print lettering Cost-effective assembly of modular parts Last but not least, 90 employees who will be reliably working for you

Founded

1985

Employees

100 - 200

Certifications

Flachslanden

Germany - 91604

CASTING and FORGING PARTS BY CUSTOMER Together with our partner companies ISG industry service and Geiger Berger Industries, we offer you the opportunity to access from a wide range of different foundries, forging and machining company from Germany, Spain, Hungary and China. We take care of you this vendor selection, request, technical clarification, quality assurance, packaging, shipping and timely delivery of your products according to your drawings and specifications. Through our three locations in Germany, we are always in their vicinity: CFT Hanseatic Guss GmbH, 28195 Bremen ISG industry service Geiger e.Kfm., 73491 Neuler Berger Industries K., 50668 Cologne You have a question or want to get to know us? Please contact one of the below mentioned contact, we'll take care of everything else.

Founded

2004

Employees

10 - 20

Certifications

Bremen

Germany - 28197

We are an industrial and commercial agency with direct suppliers and production facilities in Poland, Czech Republic, China, Italy, Taiwan, India, Turkey and Germany. We design and produce together with our partners to our customers in the following areas: Welded structures such as caddies, storage racks, long-product pallets. Steel construction, welding in general. Surfaces such as rays, galvanizing, painting, powders. Sheet metal processing all materials: CNC punching, nibbling, edges, laser welding, cutting Fully automated bending center, powder coating, Deep drawing, laser cutting, punching from coil, components, Services according to customer requirements Turned parts, milled parts made of all materials Castings and their processing Plastic injection molded parts up to 2,500 grams weighing, + Toolmaking Extrusion plastic profiles Aluminum profiles and their processing Cable assemblies, wire harnesses, control boxes and control cabinets completely Agricultural Engineering Bent wire parts Diecast Bend and process tubes

Founded

1986

Employees

5 - 10

Certifications

Hörstel - Bevergern

Germany - 48477

Turning technology From single part production to mass production. 12 lathes and automatic lathes. In the diameter range from 6 - 40 mm and a length up to 130 mm. We work to the highest quality standard with the latest test methods. From individual part production to mass production with automation, we label every part, whether aluminum or steel Max. Labeling area 120x120x150 mm Get your personal offer now

Founded

1999

Employees

10 - 20

Certifications

Schloss Holte Stukenbrock

Germany - 33758

We are your supplier for high-quality injection molding tools, plastic and metal components, from development to production. We develop and manufacture individual vehicles for you exactly according to your requirements. We offer you certified special protection vehicles and solutions that protect lives. Companies from the automotive sector, industry, medical technology and other sectors rely on our expertise. Our special vehicle construction meets every wish and requirement. Emergency personnel, NGOs and high-ranking personalities rely on our certified special protection solutions. With over 1,000 employees at seven locations across Europe and powerful machinery, we are ready for any task — and are sure to offer you the best solution.

Founded

Employees

500 - 1000

Certifications

Georgsmarienhütte

Germany - 49124

Find the ideal supplier in just 1 minute

Communicate directly with buyers

Unique market price comparison to realize the best prices

Existing processes, systems and suppliers can be easily integrated.

Buyers use the platform completely free of charge