Gröbmer GmbH

Contacts

Christian Rainer

Commercial management

Phone:

E-Mail:

Katrin Gasteiger

Commercial management

Phone:

E-Mail:

Michael Gröbmer

Owner, company manager, member of the board

Phone:

E-Mail:

Stefan Gröbmer

Production

Phone:

E-Mail:

Thomas Gröbmer

Production

Phone:

E-Mail:

Peter Gröbmer

Production

Phone:

E-Mail:

Competencies

Parts (37)

Technologies

Welding

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Inert gas shielded arc welding (MIG/MAG) | 1 - 2000 | 1 - 10000 | 1 - 10000 | 1 - 10000 | - | max. 5000 | - |

Inert gas shielded arc welding (TIG) | 1 - 500 | 1 - 10000 | 1 - 10000 | 1 - 5000 | - | max. 5000 | - |

Robot welding | 1 - 10000 | 1 - 1200 | 1 - 1200 | 1 - 1200 | - | max. 2000 | - |

Spot welding | 1 - 5000 | - | - | - | - | - | 0.5 - 3 |

Manual electrode welding | 1 - 1000 | 1 - 10000 | 1 - 10000 | 1 - 10000 | 1 - 5000 | max. 5000 | 1 - 50 |

Electron-beam welding | 1 - 2000 | 100 - 4000 | 20 - 2000 | 20 - 2000 | - | max. 2500 | - |

Stud welding | 1 - 10000 | - | - | - | - | - | - |

Company description

The ... Vielfätigkeit of mechanical engineering. For 35 years, our company has been working in the engineering industry. Always the goal in mind, independent and flexible manufacture our workpieces and to expand our product range, we manufacture to the highest quality standards and precision. With a modern and versatile machinery, we offer our customers experience and commitment in the development and production of their mission. Our handicraft business with about 20 employees specializing in the manufacture of parts, components and assemblies; manufacture both single and serial production are possible. We process a wide variety of metals and plastics - from 3D - CAD - design to the finished product. We design and manufacture - take your product ready for installation in reception, thus saving costs and time. As an experienced Hertseller of turned and milled parts in machinery and mold with a variety of materials, we guarantee quality, precision and flexibility. With CNC machines from renowned manufacturers in the field of machining, we produce from prototype to series production of technically demanding parts with consistent quality in 2D and 3D. Our modern CNC lathes are equipped with automatic bar feeder, driven tools, Y-axis and sub-spindle, so they allow the individual and series production of complex parts in a single pass. New in our machine park is a 5 - axis "Millturn" machining center with which we completely finished workpieces in one set-up, which leads to a significant reduction of the idle times and the precision significantly increases. With corresponding 5 - a pallet exchange system and a total of 90 tool places, we are well prepared for series production. - CNC Milling - 3-D mold - Vermessarbeiten and quality control

Machines (29)

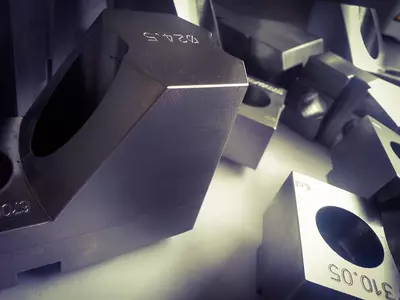

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Titanium and titanium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Cast metals

Cast steel

Cast iron

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Industries

Construction and architectural supplies

Machine tool manufacturing

Building, agricultural and forestry machinery manufacturing

Plant engineering and construction

Mechanical engineering

Automotive and vehicle construction

Drive and gear engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.