CNC Speedform AG

Contacts

Sascha Skarupke

Marketing and Sales

Phone:

E-Mail:

Competencies

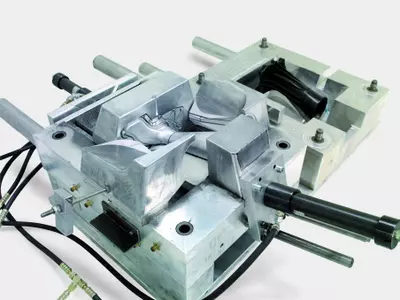

Parts (1)

Technologies

Injection Moulding, Extruding

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Injection moulding | - | - | - | - | - | - | - |

Injection-mould around inserts | - | - | - | - | - | - | - |

Multi component injection moulding | 1 - 1000 | 1 - 500 | 1 - 1000 | 1 - 1000 | - | max. 500 | - |

Company description

The CNC Speed Form AG is a service provider for prototype construction and water jet cutting. We finished workpieces in water jet process from almost all materials up to a thickness of 200mm. Furthermore, we provide prototypes in the following procedure ago: Laser sintering Vacuum casting Stereolihtographie Objet 3D Printing FDM The build of prototypes is our strength. From the gyroplane to model wind turbine we manufacture according to your data or to assist you in creating the data.

Machines (2)

Copmany images

Materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Tool steel

Spring steel

Cold extruding steel

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Carbide

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Precious metals

Silver

Platinum

Other precious metals

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Natural Fibre Composites (NFC)

Non-metal inorganic materials

Ceramics

Glass

Cast minerals

Graphite

Natural materials

Rock

Industries

Lighting industry

Mechanical engineering

Power generation and transmission industry

Medical technology

Paper and printing machinery industry

Military engineering

Plant engineering and construction

Building, agricultural and forestry machinery manufacturing

Mining and tunnel engineering

Boiler, container and tank construction

Aerospace and aviation industry

Automotive and vehicle construction

Electrical industry

Shipbuilding industry

Machine tool manufacturing

Special purpose machinery manufacturing

Railway and rail vehicles industry

Automation and control engineering

Apparatus engineering

Precision engineering, mechatronics and optics

Fittings engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.