Dillinger Fabrik gelochter Bleche GmbH

Contacts

Andreas Poss

Marketing and Sales

Phone:

E-Mail:

Competencies

Parts (9)

Technologies

Sheet Metal Processing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Laser cutting 2D | 1 - 5000 | 1 - 3000 | 1 - 1500 | - | - | max. 500 | 0.1 - 8 |

Punching / nibbling | 1 - 5000 | 1 - 3000 | 1 - 1500 | - | - | max. 500 | 0.1 - 8 |

Combined forming laser cutting / punching | 1 - 5000 | 1 - 3000 | 1 - 1500 | - | - | max. 500 | 0.1 - 8 |

Company description

Founded in 1895, Dillinger Fabrik gelochter Bleche GmbH has more than 100 years experience in the field of manufacturing and processing perforated plates. Together with its subsidiaries and affiliated companies, the Dillinger Fabrik group employs more than 380 people, 200 of whom work in the Dillingen location. Our perforated plate products are sold directly and by our foreign partners in more than 20 European and non-European countries. On this website, we would like to introduce ourselves as one of the leading European manufacturers of perforated plates, offering an exceptionally wide product range: from ultra-thin sheet to 30 mm thick perforated plates; from complex housings for electrical switchgear to medium-sized plant engineering; from perforated slotted casings to installation-ready rotary screens for large-scale mineral processing and sorting plants. The use of laser systems, the welding processes Metal Inert Gas Welding/Metal Active Gas Welding, Tungston Inert Gas Arc Welding, Plasma Jet Welding, and various processes of surface treatment enable us to meet almost any customer’s requirements in the field of perforated plates and further processing of perforated plate. In addition to manufacturing and processing, we provide advice to our customers right from the product development phase to jointly secure production and cost-optimised design of the outsourced parts. Our CAD department will be glad to supply appropriate drawings.

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Laser cutting 2D

Laser cutting, tube & section

Powder coating

1

1

1

Machines (3)

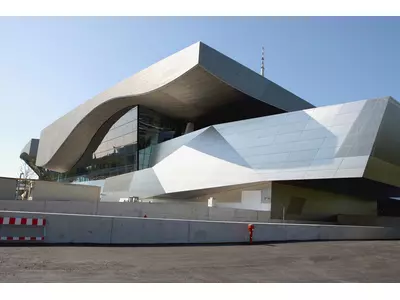

Copmany images

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Light metals

Aluminium and aluminium alloys

Titanium and titanium alloys

Industries

Mining and tunnel engineering

Electrical industry

Furniture industry

Railway and rail vehicles industry

Automotive and vehicle construction

Precision engineering, mechatronics and optics

Measurement and control technique, laboratory equipment

Shipbuilding industry

Paper and printing machinery industry

Machine tool manufacturing

Hydraulic and pneumatic industry

Military engineering

Mechanical engineering

Plant engineering and construction

Medical technology

Boiler, container and tank construction

Construction and architectural supplies

Building, agricultural and forestry machinery manufacturing

Apparatus engineering

Power generation and transmission industry

Special purpose machinery manufacturing

Packaging industry

Chemical industry

Air conditioning, refrigeration and ventilation industry

Aerospace and aviation industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.