Dreherei Horst Peter Häcki GmbH

Contacts

Sabine Häcki

Production

Phone:

E-Mail:

Competencies

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 10000 | 10 - 990 | - | - | 8 - 280 | - | - |

Automatic turning (bar) | 1 - 10000 | 10 - 990 | - | - | 8 - 280 | - | - |

Full-range turning (including milling) | 1 - 10000 | 10 - 990 | - | - | 8 - 280 | - | - |

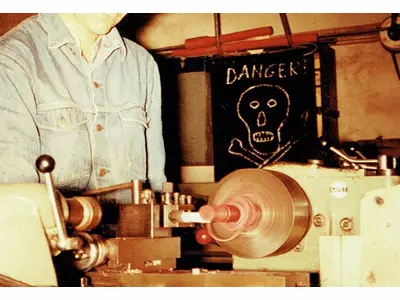

Company description

Our production program includes: Turning (CNC) approx. Ø30 to ø300, center distance max. 800mm Turning (conventional) approx. Ø30 to ø250, center distance max. 600mm Milling (CNC) table size 600x560x510mm Drilling (CNC and conventional) Sawing max. ø250 Assembly and other general machining work in stainless steel, steel, non-ferrous metals and plastic Special inserts (also regrinding) For further work that is required for complete production, e.g. B. hardening, grinding or eroding, we have been working with well-known partner companies for many years. Execution and quality correspond to our and your high requirements. An air-conditioned measuring room with TESA - 3D coordinate measuring machine is available.

Copmany images

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Light metals

Aluminium and aluminium alloys

Natural materials

Wood/timber

Industries

Automotive and vehicle construction

Paper and printing machinery industry

Building, agricultural and forestry machinery manufacturing

Mechanical engineering

Special purpose machinery manufacturing

Packaging industry

Machine tool manufacturing

Hydraulic and pneumatic industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.