Eberhard Automatizace s.r.o.

Contacts

Peter Klöpfel

Owner, company manager, member of the board

Phone:

E-Mail:

Martin Krontorad

Technical management

Phone:

E-Mail:

Competencies

Parts (9)

Technologies

Etching and Spark Erosion

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Spark erosion wire cutting | 1 - 500 | 5 - 350 | 5 - 250 | 1 - 250 | - | max. 50 | - |

Spark erosion countersinking | 1 - 200 | 10 - 350 | 10 - 250 | 5 - 300 | - | max. 50 | - |

Company description

The Eberhard Automatizace sro was founded in 2009 in Jihlava Czech Republic as a subsidiary of Eberhard AG Germany. Our core competencies lie in the realization of projects of automation technology, general engineering and toolmaking. Our services range from planning, design, parts production, assembly to Ausprobe and plant commissioning. Furthermore, we manufacture individual parts, small series and assemblies for our international customers mentioned in the drawing. Moreover, we maintain a good cooperation with competent partner companies in the region, which will allow us to offer our customers a very wide range of services. A flawless and professional-quality order execution, as is for our company as well as a fast, economical and flexible account of customer requests. Quality starts with the job costing and processing.Our technically competent and motivated employees to take responsibility for quality in the manufacturing process. Desires our customers yet a 100% testing, and their documentation, we create these as well. We offer the following manufacturing services: mill * CNC milling, 3-axis milling, 5-axis milling, conventional milling Erode * Wire EDM with wire diameters from 0.05mm and finishes from Ra 0,10μm * EDM with surfaces from 0.5 micron Ra * Start hole drilling from ø 0,1mm grind * Round, flat and profile grinding surface treatment * Sand and glass bead blasting, vibratory grinding / vibratory grinding, polishing * Anodizing, hard anodizing, plating, galvanizing, hard chrome plating, bronzing, painting, etc. * All hardening processes - such as hardening, carburizing, nitriding, etc. Assembly * Assembly to customer order * Installation and Ausprobe of punching and bending tools * Pre / final assembly of machines and modules to customer quality assurance * We guarantee the quality of our work you by competent and motivated employees.A certification according to DIN EN ISO 9001: 2008 we are aiming for in 2015, but already guarantee highest quality and punctuality. On request, we carry out a 100% inspection of parts. Translation by Google Translate

Machines (6)

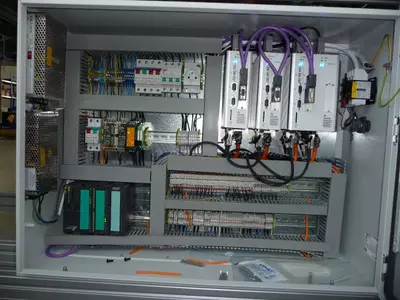

Copmany images

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Steel

Structural steel

Case hardening/tempering steel

Free-cutting/mild steel

Tool steel

Light metals

Aluminium and aluminium alloys

Advanced Materials

Carbide

Industries

Special purpose machinery manufacturing

Mechanical engineering

Automation and control engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.