ELTING Geräte- und Apparatebau GmbH & Co.KG

Contacts

Guido Elting

Owner, company manager, member of the board

Phone:

E-Mail:

Stefan Pasieka

Marketing and Sales

Phone:

E-Mail:

Guido Döring

Marketing and Sales

Phone:

E-Mail:

Daniel Zehetmeier

Purchasing / Material management

Phone:

E-Mail:

Competencies

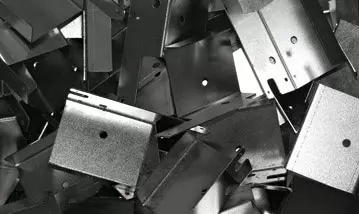

Parts (13)

Technologies

Sheet Metal Forming (Stamping, Deep-drawing)

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / pressing (Out-of-tool) | 100 - 99999 | 1 - 600 | 1 - 600 | - | - | - | - |

Plate rolling / bending | 1 - 999 | - | 1 - 3000 | - | - | - | 0.5 - 15 |

Company description

Service providers from conviction. For the past 75 years. Since the foundation of our family business as a repair operation in 1936 in Bocholt, we have evolved into a powerful metalworking specialists. A development that is now promoted in the third generation by Guido Elting. We are proud to manufacture for handicraft and industrial companies in the European market. As a service provider we offer our customers a wide range of services that range from assistance with design work on the production of semi-finished products, complete components, assemblies, through to installation support. The customer is the center of our efforts. In order to implement his wishes are now next 50 qualified and highly motivated staff ready more than 8000sqm production area and a modern machine park. Flat management hierarchies, team-oriented, ability to work independently in optimized processes guarantees the implementation of customer requirements in the desired quality. Quality, quantity, qualification From quality many speak. Our staff they live. We place great emphasis on the quality of our products. Close communication with our customers from design to delivery provides the basis for high quality products and satisfied customers. Well-qualified, independently working employees are using the latest manufacturing technologies and processes to produce these products. A complete quality assurance in the workflow, even with the most modern methods of measurement, is achieving and maintaining the quality standards, not least in quantity and deadlines safely. They call us the challenge. We provide you with the solution. When it comes to the correct processing of various materials, our team is always on the cutting edge of things. We are to be processed in a position to steel, stainless steel, aluminum or non-ferrous metals for you. We always advise you giving detailed and take into account costs, processing, application and the expected stress.Talk to us - we look forward to meeting you! We put good ideas to good. From handcrafted to high-tech. Our focus is the CNC sheet metal processing. The spectrum of our services from cutting to the transformation extends down to the welding assembly or final assembly. We work with the latest high-speed laser systems and CNC-Stanz/Nibbel-Automaten and robotic welding cells with which we guarantee the highest productivity. At the same time, however, we still have traditional craft skills that we use precisely and goal-oriented. According to your wishes. Our strengths include manufacturing small and medium series. Thanks to our high level of automation, we can submit interesting conditions you right here. With the help of our modern warehouse logistics realisierenwir also like to retrieve, or Kanban solutions. Of course we also may organize incurred outsourced processing, for example for various surface treatments to packaging and shipping. With consistent service orientation, we have developed a reliable partner in sheet metal processing. Visions into reality. With innovations from our house. Laser tube processing Innovation and investment joy traditionally among our strengths. So we have invested heavily in technologies eingesetztund for a diverse pipe laser processing early laser cutting technology. Today, we are specialists for large pipe and profile laser cut parts and materials of any kind With our powerful 3-D tube laser system we ...

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Laser cutting, tube & section

1

Machines (10)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Plastics/synthetic materials

Thermoplastics

Thermosets

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Spring steel

Industries

Automation and control engineering

Drive and gear engineering

Apparatus engineering

Power generation and transmission industry

Plant engineering and construction

Air conditioning, refrigeration and ventilation industry

Boiler, container and tank construction

Furniture industry

Paper and printing machinery industry

Shipbuilding industry

Telecommunication industry

Lighting industry

Construction and architectural supplies

Mining and tunnel engineering

Automotive and vehicle construction

Electrical industry

Medical technology

Building, agricultural and forestry machinery manufacturing

Special purpose machinery manufacturing

Packaging industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.