Felker Drehtechnik<br>Langdrehtechnik GmbH

Contacts

Gerhard Felker

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (1)

Technologies

Assembly

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Mechanical assembly | - | - | - | - | - | max. 1 | - |

Company description

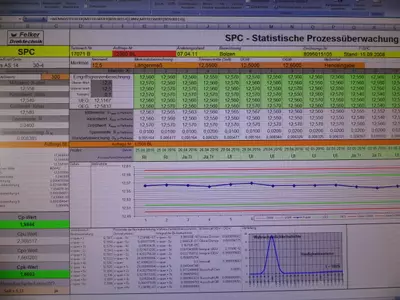

Portrait of the company Felker Drehtechnik The company Felker rotation technique was founded by Mr. Gerhard Felker and his wife Verica Felker as a pure contract manufacturing companies in D-89610 Oberdischingen in December 2004. The range consists mainly in the manufacture of automatic lathe parts (valve seats, valve pistons, valves, anchors, piston, pin, spring plate, lathe parts, micro turned parts, micro-turning), made of steel such as 9S Mn Pb 28K, 16 Mn Cr5 C 45, 42 Cr Mo4 Stainless steel to 1.4301, 1.4305, 1.4105 (X6Cr Mo S17), cast iron, aluminum (Al Mg Si) and brass (to Zn 39 Pb) on 9 Tornos AS 14 six-spindle automatic lathes up to Ø 14 and an additional plastic on a Star lathes up to Ø 16 in Central series and large series from a lot size of 20,000 or 5,000 units at long lathe. Besides this installation work, Nachdreharbeiten and Deburring and Aussuch or testing work of rotary parts of all kinds are carried out. Our strength lies in the flexibility of the company.An absolutely smooth cooperation among the employees as well as with senior management and the customer ensures virtually zero defect deliveries. We endeavor to expand and consolidate its above-average quality, our previous successful and trusting relationship with our customers. Our goal is to provide systematic improvement in quality and on time delivery to satisfy the customer and implement its requirements given us 100% error-free and at a reasonable cost. We are certified according to DIN EN ISO 9001:2000 and reject ourselves to the standard DIN ISO TS 16949. Be able to work more efficiently in addition to three of these aircraft were purchased, which have been found in our new premises good place. The new building has a production area with warehouse and office of approximately 1000 m², as well as buildings for more than one employee / inside of about 170 m².

Machines (16)

Copmany images

Materials

Non-metal inorganic materials

Ceramics

Glass

Concrete

Cast minerals

Graphite

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Sintered materials

Metal powder for formed parts

Metal powder for hard metal

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Carbide

Silicium

Precious metals

Silver

Gold

Platinum

Other precious metals

Plastics/synthetic materials

Thermoplastics

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Natural materials

Wood/timber

Rock

Industries

Precision engineering, mechatronics and optics

Building, agricultural and forestry machinery manufacturing

Automotive and vehicle construction

Drive and gear engineering

Electrical industry

Plant engineering and construction

Special purpose machinery manufacturing

Automation and control engineering

Apparatus engineering

Fittings engineering

Hydraulic and pneumatic industry

Mechanical engineering

Measurement and control technique, laboratory equipment

Office machinery and supplies

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.