Flüss Werkzeugbau & Erodiertechnik

Contacts

Lars Flüss

Owner, company manager, member of the board

Phone:

E-Mail:

Christian Flüss

Technical management

Phone:

E-Mail:

Competencies

Technologies

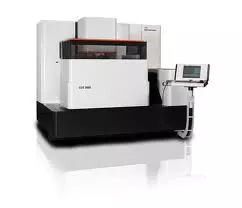

Etching and Spark Erosion

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Spark erosion wire cutting | 1 - 50 | 10 - 500 | 10 - 700 | 1 - 250 | - | max. 250 | - |

Spark erosion countersinking | 1 - 30 | 10 - 300 | 10 - 200 | 10 - 300 | - | max. 150 | - |

Company description

The company Flüss tooling was founded on 01/05/1908 by Heinrich Flüss. At this time we dealt with the production of electrical switches, star delta switches and cable lugs, which were made from sheets about tools. Among other things, the company founder Heinrich Flüss developed roller skates and the company HUDORA that were made then about tools of the company Flüss. Another task was the production of deformed covers for irons, as well as the manufacture of mechanical parts for wringers. For the sign industry we made high-quality metal signs (Horch, NSU, VW) to the deep embossing process. In 1958, his son Paul Flüss the company he leads today in the third generation with his son Christian Flüss. Flüss tooling manufactures cutting and punching tools for the production of plastic panels for the automotive, appliance and electrical industries. Next we finished cutting and punching tools for the paper and plastics industry for the manufacture of suchB. Parking ticket labels, price marking labels, magnetic tickets, billets of all types and package carriers for the pharmaceutical industry (eg OP needles) as well as chip and plastic cards according to ISO. We manufacture on CNC machines and conventional machine. In eroding for over 30 years, we rely on Agie machines. Our CNC machines are always up to date technical Stand.Im CAD / CAM area, we work with NX8 and creo Modeling (formerly ME10/ME30, CoCreate) Erodierprogramme be created mecanic about the software. In the milling area, we work with Heidenhain (415 and he 530i control)

Machines (4)

Materials

Light metals

Aluminium and aluminium alloys

Sintered materials

Metal powder for formed parts

Metal powder for hard metal

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Plastics/synthetic materials

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Industries

Automotive and vehicle construction

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.