Geiger GmbH

Contacts

Markus Stenglein

Phone:

E-Mail:

Beate Lauer

Phone:

E-Mail:

Dieter Neller

Marketing and Sales

Phone:

E-Mail:

Christoph Fleischmann

Phone:

E-Mail:

Johannes Gebelein

Phone:

E-Mail:

Competencies

Parts (12)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 9999999 | 10 - 300 | - | - | 5 - 150 | - | - |

Automatic turning (bar) | 1 - 999999 | 10 - 300 | - | - | 5 - 150 | - | - |

Swiss turning | 1 - 999999 | 10 - 300 | - | - | 5 - 150 | - | - |

Full-range turning (including milling) | 1 - 999999 | 10 - 300 | - | - | 5 - 150 | - | - |

Hard turning | 1 - 999999 | 10 - 300 | - | - | 5 - 150 | - | - |

Company description

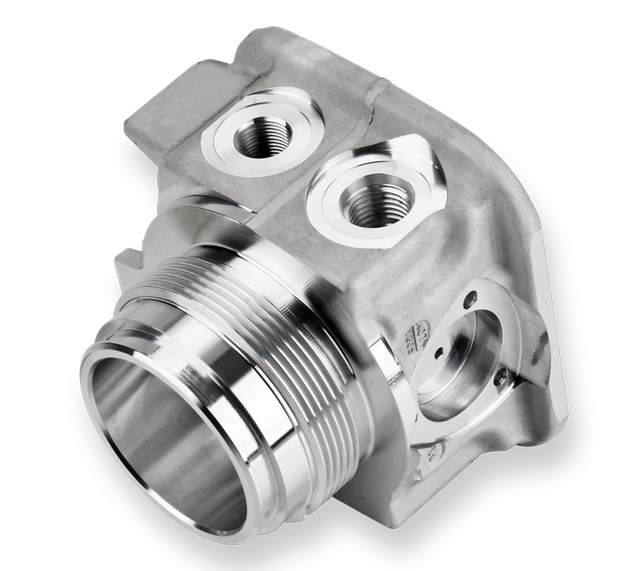

More than 60 years of experience in the production of highly complex and demanding turned and milled parts, including all other accompanying work processes, have made us a recognized partner and preferred supplier of the most important companies in the metalworking industry

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Centreless grinding

Inert gas shielded arc welding (MIG/MAG)

Inert gas shielded arc welding (TIG)

Drop forging

Milling

Turning

Drilling / threading / tapping

1

1

1

1

1

1

1

Machines (7)

Copmany images

Materials

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Cast metals

Cast steel

Cast iron

Sintered materials

Metal powder for formed parts

Metal powder for hard metal

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Industries

Shipbuilding industry

Precision engineering, mechatronics and optics

Aerospace and aviation industry

Plant engineering and construction

Construction and architectural supplies

Hydraulic and pneumatic industry

Military engineering

Furniture industry

Drive and gear engineering

Mining and tunnel engineering

Electrical industry

Power generation and transmission industry

Household appliance industry

Medical technology

Special purpose machinery manufacturing

Telecommunication industry

Apparatus engineering

Automotive and vehicle construction

Building, agricultural and forestry machinery manufacturing

Railway and rail vehicles industry

Air conditioning, refrigeration and ventilation industry

Machine tool manufacturing

Automation and control engineering

Lighting industry

Office machinery and supplies

Information technology (hardware)

Boiler, container and tank construction

Clean room technology

Paper and printing machinery industry

Mechanical engineering

Fittings engineering

Chemical industry

Measurement and control technique, laboratory equipment

Packaging industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.