Gerdt CNC-Technik GmbH

Contacts

Sven Gerdt

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

Parts (2)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Full-range turning (including milling) | 1 - 100000 | 1 - 400 | - | - | 1 - 200 | - | - |

Company description

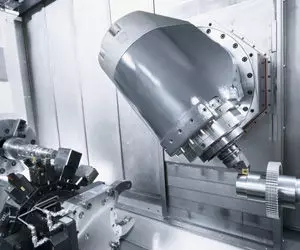

Gerdt CNC-Tchnique GmbH is operating for 20 years as a supplier for milling parts and mill-turn parts in the metal cutting industry. Here we are focused on processing all metallic, non-metallic and difficult to machine materials like titanium. Many years of cooperation with leading companies of the medical technique, have created valuable experiences in 5 axis maching of optically highly complex components like various plier handles, housings and endoscopy components, electrodes, monitors and jaw parts. This will also benefit our customers in the automotive interior industry for which we manufacture high quality gear selectors, using the latest HSC machining. The high productivity and efficiency advantages offered by HSC machining is currently not only in case of aluminum processing becoming increasingly popular. Thanks to modern drive technology, HSC milling is today also realized in dificult to machine materials like titanium. The production of medium and large batch sizes is accomplished through fully automated machining centers, using bar loaders and palletizing systems. With up to 11 CNC controlled axes and speeds > 20.000 1 / min it is also possible to machine 5-axis simultaneous as well as HSC cutting. Beeing innovative is important to us. A reliable supplier of milling parts is growing with the increasing demands of their customers. To stay competitive and to exploit potentials, we regularly invest in the latest technology. So we have been working for more then 10 years in todays famous combined milling and turning strategy. Modern machinery is not enough. Equally important are advances in CAD / CAM, new technology cycles, machining strategies, tool selection and workpiece clamping. For CAM programming we work with different Software for 5-axis milling, mill-turn machining, 3D milling and HSC machining. A fast generation of 3D models is essential, as profiled clampings, enclosures, who are needed for further processings, and special designs are internally designed and manufactured. Whether prototypes, pilot runs or medium series, whether as a delivery plan or fixed deadline call, we deliver on schedule and always in the estimated quality that our customers expect from us. As a provider of CNC machined parts, we offer our customers also all additional related operations such as coatings and hardening processes. The good cooperation with regionally based partner companies creates synergies which will benefit our customers – Everything you will get from us, is from one source.

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Full-range turning (including milling)

Turning

1

1

Machines (5)

Copmany images

Materials

Cast metals

Cast steel

Cast iron

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Plastics/synthetic materials

Thermoplastics

Acrylic (PMMA)

High performance plastic

Thermosets

Elastomers

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Natural Fibre Composites (NFC)

Natural materials

Wood/timber

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Industries

Automotive and vehicle construction

Apparatus engineering

Machine tool manufacturing

Special purpose machinery manufacturing

Power generation and transmission industry

Air conditioning, refrigeration and ventilation industry

Clean room technology

Telecommunication industry

Office machinery and supplies

Hydraulic and pneumatic industry

Mechanical engineering

Railway and rail vehicles industry

Automation and control engineering

Construction and architectural supplies

Military engineering

Paper and printing machinery industry

Furniture industry

Measurement and control technique, laboratory equipment

Information technology (hardware)

Chemical industry

Building, agricultural and forestry machinery manufacturing

Fittings engineering

Drive and gear engineering

Aerospace and aviation industry

Electrical industry

Mining and tunnel engineering

Lighting industry

Packaging industry

Shipbuilding industry

Boiler, container and tank construction

Household appliance industry

Precision engineering, mechatronics and optics

Plant engineering and construction

Medical technology

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.