H. P. Kaysser GmbH + Co. KG

Contacts

Frank Niedermaier

Marketing and Sales

Phone:

E-Mail:

Michael Sanzenbacher

Marketing and Sales

Phone:

E-Mail:

Andreas Bahler

Marketing and Sales

Phone:

E-Mail:

Competencies

Parts (33)

Technologies

Welding

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Inert gas shielded arc welding (MIG/MAG) | 50 - 1000 | 800 - 8000 | 200 - 2000 | 200 - 2000 | 200 - 2000 | max. 3000 | 2 - 100 |

Inert gas shielded arc welding (TIG) | 50 - 1000 | 250 - 2500 | 125 - 1250 | 150 - 1500 | 125 - 1250 | max. 200 | 2 - 6 |

Laser-beam welding | 50 - 50000 | 1 - 2500 | 10 - 1250 | 1 - 600 | 2 - 600 | max. 100 | - |

Robot welding | 100 - 5000 | 800 - 8000 | 200 - 2000 | 200 - 2000 | - | max. 3000 | - |

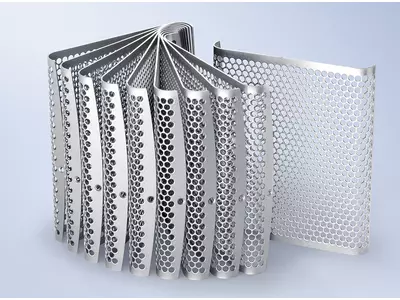

Company description

For more than 60 years H.P. Kaysser GmbH + Co. KG has been belonging to the internationally accepted best sheet metal processors on the market. As a customer-oriented, family run medium-sized enterprise we produce with more than 300 dedicated employees at our locations in Nellmersbach (near Stuttgart, Germany) and Bistrita, Romania. Our strengths: An incredible versatility and an unique density of technology offer – paired with experience and technical knowledge of our well-trained employees. Our LernFabrik is evidence for consistent training and education schemes for our staff. 12 workcells guarantee the entire machining under one roof. Integrated system solutions complete the manifold programme with big advantages for our customers. It basically applies: Together with our customers we look ahead. Our customers benefit from the consolidated knowledge we established for years. We utilize our synergies and thereby extend your lead in market together. In collaboration our 3-F-formular applies: far – flexible- fair Our ambition: - best partnership - a long lasting, successful collaboration with all of our regular customers - discretion and exclusivity agreements if desired - mutual esteem and ethical behaviour Our motivation is the satisfaction of our customers.

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Wire bending

Galvanizing

1

1

Machines (14)

Copmany images

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Sintered materials

Metal powder for formed parts

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Tool steel

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Cast metals

Cast steel

Cast iron

Industries

Electrical industry

Furniture industry

Measurement and control technique, laboratory equipment

Drive and gear engineering

Medical technology

Special purpose machinery manufacturing

Mechanical engineering

Lighting industry

Packaging industry

Air conditioning, refrigeration and ventilation industry

Automotive and vehicle construction

Machine tool manufacturing

Paper and printing machinery industry

Building, agricultural and forestry machinery manufacturing

Power generation and transmission industry

Precision engineering, mechatronics and optics

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.