Heinz Knöpfle GmbH

Contacts

Dipl.-Kff. Susanne Knöpfle

Owner, company manager, member of the board

Phone:

E-Mail:

Competencies

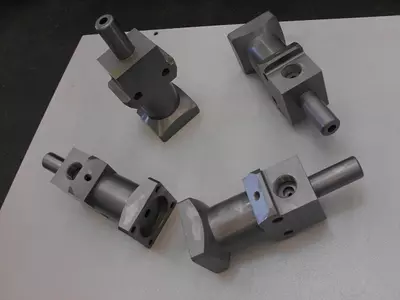

Parts (15)

Technologies

Turning

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Turning | 1 - 100000 | 1 - 1900 | - | - | 1 - 650 | - | - |

Automatic turning (bar) | 1 - 100000 | 5 - 500 | - | - | 5 - 65 | - | - |

Swiss turning | 1 - 100000 | 5 - 1900 | - | - | 5 - 650 | - | - |

Full-range turning (including milling) | 1 - 100000 | 5 - 2000 | - | - | 5 - 650 | - | - |

Hard turning | 1 - 100000 | 5 - 1900 | - | - | 5 - 650 | - | - |

Broaching | 1 - 100000 | 1 - 425 | - | - | 10 - 230 | - | - |

Centering / end facing | 1 - 100000 | 5 - 1900 | - | - | 5 - 650 | - | - |

Shaft machining | 1 - 100000 | 5 - 2000 | - | - | 5 - 650 | max. 1200 | - |

Company description

Dear Ladies & Gentlemen, as a family from the metal-working industry, we want to introduce you to our wide range. The versatility of possible solutions is one of our strengths and allows flexible solutions to complex challenges. So we have only the necessary know-how through various practices, such as CNC turning, CNC milling, wire EDM, etc. We combine the latest technology with years of experience and guarantee you reliability and quality. The company Heinz Knöpfle GmbH was founded in 1979 by Mr. Heinz Knöpfle as a company for special machines. The company is located in Schwabmunchen / Schwabegg, about 30km south-west of Augsburg. We supply our products mainly to a solid customer base with great success, we would like to introduce our company. Proof of quality: Through the coordinate measuring machine Crysta Apex S544 Mitutoyo, we can now also supply with measuring protocol the manufactured parts. CNC Turning: With our CNC lathes we can to edit 65mm rotary parts of the rod automatically and completely. The machines are equipped with a 12 - equipped trade revolver and with driven tools. A counter-spindle and Y-axis enables short cycle times and make some cases further machining on a milling machine unnecessary. We manufacture precise and sophisticated turned parts as individual parts, small or large production runs with short delivery times and consistently high quality. CNC Milling: Years of experience, modern production techniques and machining centers, highly qualified and motivated employees are the basis of our performance. This allows us to present the desired results our customers quickly and inexpensively. Working in oscillation mode allows us to equalize loading times and increase output. Saws: The basis for a safe and good machining is not only a good material quality, but also a good blank. With our cutting precise cuts are realized with short cutting times. We saw our own production as well as in wages for other companies. We offer to Sägezuschnitte from € 0.03 per cut. The range of materials ranging from mild steel on non-ferrous metals to stainless steel. Our state of the stocks enable us short delivery times for their Sägezuschnitte. Welding: In order to offer production from one source, we have a welding robot available.Through this, a constant quality is ensured. Device & toolmaking: With our well-stocked machinery and many years of experience in tooling, we are able to create bending, punching and stamping tools. Our fixtures and special machines find their use in various industries. Depending on customer requirements, we offer ready-made parts or just the tool. The further refinement of the products we take over for you. The parts production in the field punching, bending and stamping can be held up 150to in-house. Try us, we look forward to your orders! Sincerely, Heinz Knöpfle Susanne Knöpfle Andreas Knöpfle Christian Knöpfle Management Management Management Manage...

Machines (29)

Copmany images

Materials

Non-metal inorganic materials

Ceramics

Cast minerals

Graphite

Plastics/synthetic materials

Thermoplastics

High performance plastic

Thermosets

Elastomers

Silocone (LSR)

Natural and vulcanised rubber

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Sintered materials

Metal powder for formed parts

Metal powder for hard metal

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Magnesium and magnesium alloys

Titanium and titanium alloys

Precious metals

Silver

Gold

Platinum

Other precious metals

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Industries

Packaging industry

Medical technology

Hydraulic and pneumatic industry

Paper and printing machinery industry

Furniture industry

Aerospace and aviation industry

Automation and control engineering

Mining and tunnel engineering

Drive and gear engineering

Precision engineering, mechatronics and optics

Fittings engineering

Plant engineering and construction

Shipbuilding industry

Power generation and transmission industry

Office machinery and supplies

Building, agricultural and forestry machinery manufacturing

Apparatus engineering

Chemical industry

Machine tool manufacturing

Automotive and vehicle construction

Mechanical engineering

Military engineering

Measurement and control technique, laboratory equipment

Air conditioning, refrigeration and ventilation industry

Information technology (hardware)

Railway and rail vehicles industry

Electrical industry

Boiler, container and tank construction

Telecommunication industry

Lighting industry

Household appliance industry

Clean room technology

Special purpose machinery manufacturing

Construction and architectural supplies

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.