HMT Rüffel GmbH

Contacts

Frank Rüffel

Technical management

Phone:

E-Mail:

Edgar Kine

Technical management

Phone:

E-Mail:

Competencies

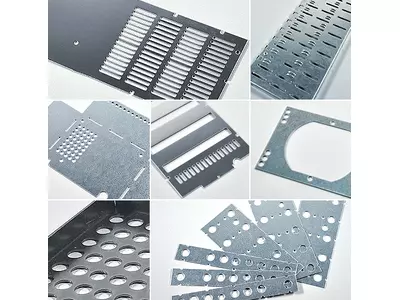

Parts (8)

Technologies

Sheet Metal Processing

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Laser cutting 2D | 1 - 50000 | 1 - 2500 | 1 - 1250 | - | - | - | 0.5 - 4 |

Bending / folding | 1 - 1000 | 5 - 1250 | - | - | - | - | 0.2 - 2 |

Punching / nibbling | 1 - 50000 | 1 - 2500 | 1 - 1250 | - | - | - | 0.5 - 3 |

Combined forming laser cutting / punching | 1 - 50000 | 1 - 2500 | 1 - 1250 | - | - | - | 0.5 - 4 |

Company description

Stamping, punching nibbling, punching and laser processing or pure laser processing, folding, bending, bolt presses and bolt welding. In sheet metal forming, we offer everything under one roof. Powder coating, industrial / wet painting and screen printing are also available. In the Device installation or assembly components as well as finished units are assembled and packaged for shipment on request. The HMT rebuke GmbH is a middle company based in Halsbach the Vorderhunsrück, exactly located between the picturesque Middle Rhine Valley (Lorelei rock) and the terrace Mosel. Founded 20 years ago by Patrick reprimand (Financial Officer) and Frank reprimand (technical management). The company is comprised of three main divisions: Sheet metal processing, surface treatment and assembly, which individually accept contract manufacturing or manufacture complete equipment in the composite. The Blechverbeitung offers modern facilities, stamping, punching lasers, laser (Trumpf), bending (trump), stud welding (Soyer) and bolt press-fit (Haeger), rivets and spot welding, all possibilities hochpräzieser implement even the most complex constructions. The eigenene 3D design processes all common file formats. We design, of course, optimized for production in-house. From prototypes to large series on the fully automated punch-laser combination system we are qualified orders able to edit. Through the Surface Engineering Department we offer not only powder coatings and wet painting to also screen printing work. Our assembly department handles the mounting of most electronic components to building complete electronic devices including commissioning, packaging and shipping. We have sufficient storage space, which can take advantage of our customers flexible.

Machines (7)

Copmany images

Materials

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Steel

Structural steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Cold extruding steel

Light metals

Aluminium and aluminium alloys

Natural materials

Wood/timber

Plastics/synthetic materials

Acrylic (PMMA)

Wood-Plastic-Composites (WPC)

Industries

Hydraulic and pneumatic industry

Power generation and transmission industry

Plant engineering and construction

Mechanical engineering

Telecommunication industry

Air conditioning, refrigeration and ventilation industry

Fittings engineering

Electrical industry

Precision engineering, mechatronics and optics

Lighting industry

Machine tool manufacturing

Information technology (hardware)

Medical technology

Automation and control engineering

Measurement and control technique, laboratory equipment

Paper and printing machinery industry

Special purpose machinery manufacturing

Packaging industry

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.