Huissel GmbH

Contacts

Peter Busalt

Owner, company manager, member of the board

Phone:

E-Mail:

Jörg Weidenthaler

Purchasing / Material management

Phone:

E-Mail:

Susanne Riedt

Purchasing / Material management

Phone:

E-Mail:

Gerald Schug

Owner, company manager, member of the board

Phone:

E-Mail:

Marc Schulze

Marketing and Sales

Phone:

E-Mail:

Competencies

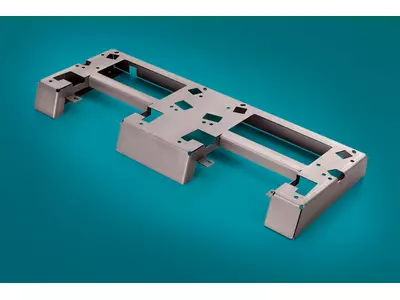

Parts (2)

Technologies

Cutting dies / deep drawing dies

| Technologies | Lotsize | Length | Width | Height | Diameter | Weight | Material thickness |

|---|---|---|---|---|---|---|---|

Punching / Cutting tools | - | 50 - 2200 | 50 - 1200 | 50 - 1000 | - | max. 5000 | - |

Follow-on composite tools | - | 50 - 2200 | 50 - 1200 | 50 - 1000 | - | max. 5000 | - |

Deep-drawing dies | - | 50 - 2200 | 50 - 1200 | 50 - 1000 | - | max. 5000 | - |

Trimming | - | 50 - 2200 | 50 - 1200 | 50 - 1000 | - | max. 5000 | - |

Die replacement / wearing part manufacturing | - | - | - | - | - | - | - |

Company description

The tooling was founded in 1906 and currently employs 60 people. Focuses on the areas of tool and equipment, as well as contract manufacturing in the field of machining and EDM. Our customer base spans virtually all areas of automotive, capital and consumer goods industry and includes many names that are at the forefront of the world market. Construction We design our tools in 3D mainly on Catia V5 from IBM. In addition, eligible for 2D and 5-axis machining Tebis and Cadda V4 used. The data is done with dial name or e-mail in the IGES formats 2 - and 3D, VDAFS, CATIA, DXF or DWG. Toolmaking * Follow-on composite tools * Cutting and punching tools * Bending Tools * Stamping and pressing tools * Foil cutting tools * Foil deep drawing tools We design and manufacture according to supplied designs presented or patterns, tools up to a size of 1200x4000 mm and a weight of max.25,000 kg. State of the art production facilities make it possible to edit the design in 3D CNC-controlled production to initial sample inspection reports on 3D measuring machines, virtually any data and drawing documents. Years of experience and a largely self-trained staff allows us to implement safe production of complex tasks in the situation. Precise milling and wire EDM in air conditioned rooms give us the opportunity to manufacture cutting tools with an average gap of less than 10 microns. In series production, we rely on machining centers manufactured by Heller with a pallet changer. With speeds up to 16,000 min-1 and rapid traverses up to 90m/min and aluminum parts are to be machined economically Jigs and fixtures * Welding equipment * Benders * Drilling, milling and turning device * Testers * Handling Systems Another mainstay is the manufacture of devices for the mechanical manufacturing, welding machining and measurement and testing tasks. Certified welders ensure a stable basic structure, annealing furnaces for stress-free post-processing, and milling machines up to 5 axis for precise stop points in space. Modern 3-D coordinate measuring machines also help in free-form surface area to verify the accuracy measure to record and document. Contract Manufacturing CNC milling CNC turning CNC Surface Grinding CNC Wire EDM CNC sinker EDM Conv machining Welding Heat treatment Measuring and testing

RFQs

RFQ Overview Technologies

Technologies and number of posted RFQs

Centreless grinding

Spark erosion countersinking

Coordinate jig grinding

Milling

Stamping and bending machine (Bihler)

Turning

Automatic turning (bar)

1

1

1

1

1

1

1

Machines (18)

Copmany images

Materials

Advanced Materials

Nickel alloy (Inconel, Monel, Hastelloy)

Carbide

Plastics/synthetic materials

Thermoplastics

Thermosets

Elastomers

Glass fibre-reinforced plastic

Carbon fibre-reinforced plastic

Particle reinforced composite materials

Wood-Plastic-Composites (WPC)

Steel

Structural steel

Case hardening/tempering steel

Stainless steel (rust-proof V2A)

Stainless steel (rust-proof V4A)

Free-cutting/mild steel

Tool steel

Spring steel

Cold extruding steel

Cast metals

Cast steel

Cast iron

Light metals

Aluminium and aluminium alloys

Titanium and titanium alloys

Heavy metals

Copper-zinc alloys (brass)

Copper and copper alloys

Zinc and zinc alloys

Solder

Industries

Medical technology

Mining and tunnel engineering

Hydraulic and pneumatic industry

Paper and printing machinery industry

Power generation and transmission industry

Precision engineering, mechatronics and optics

Measurement and control technique, laboratory equipment

Special purpose machinery manufacturing

Machine tool manufacturing

Building, agricultural and forestry machinery manufacturing

Automation and control engineering

Packaging industry

Aerospace and aviation industry

Railway and rail vehicles industry

Chemical industry

Automotive and vehicle construction

Drive and gear engineering

Construction and architectural supplies

Military engineering

Electrical industry

Air conditioning, refrigeration and ventilation industry

Shipbuilding industry

Plant engineering and construction

Boiler, container and tank construction

Mechanical engineering

Are you a supplier?

Find perfectly matching requests.

Are you a buyer?

Submit your request.